Low-E hollow glass

A low-e, glass technology, applied in the field of glass processing, can solve the problems of poor light transmittance and transparency, and achieve the effect of improved optical performance, comfortable light environment, and better appearance

Inactive Publication Date: 2012-05-23

俞志稳

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Due to its excellent thermal properties and good optical properties, Low-E glass is used more and more widely. Most of the existing Low-E glass is sprayed directly onto the surface of hot glass with liquid metal or metal powder. Cooling, a layer of metal film is formed on the glass surface, and in order to increase the wear resistance of the glass, it is often necessary to increase the thickness of the metal film, resulting in poor light transmittance and transparency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

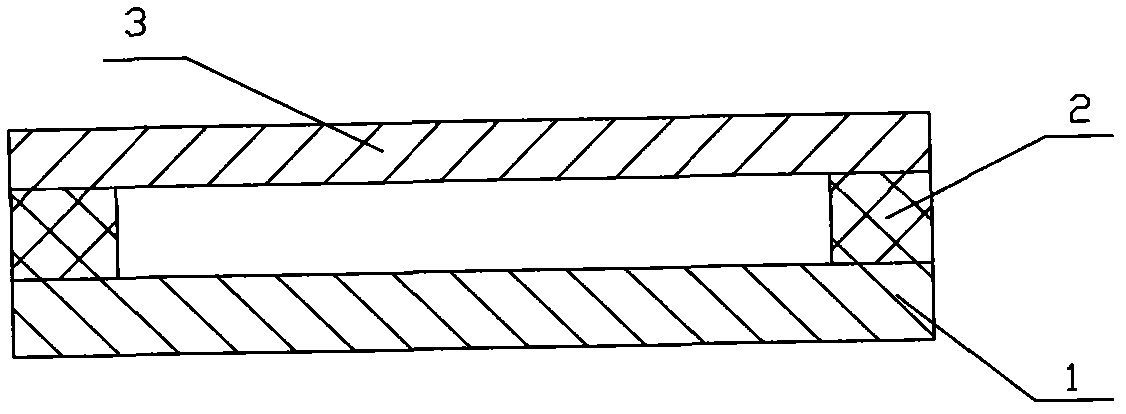

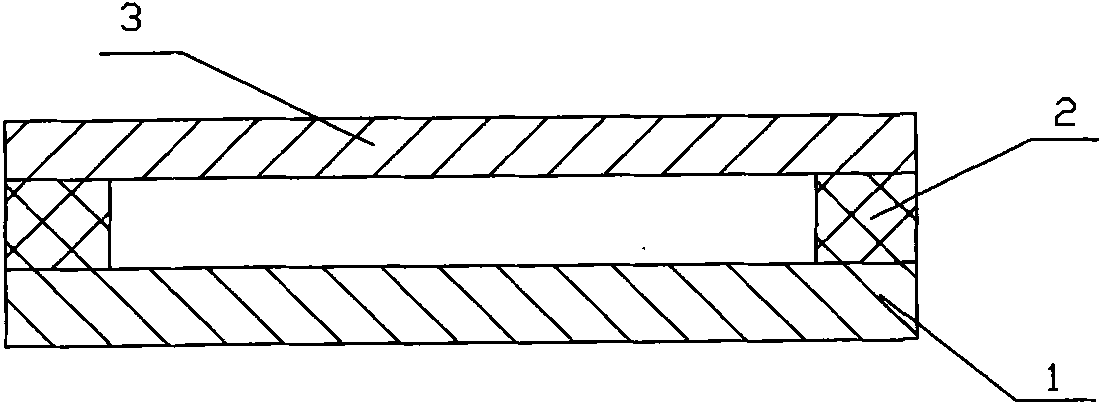

[0008] A Low-E hollow glass, comprising a negative sheet Low-E glass 1. An aluminum frame made of aluminum strips 2 is provided on the Low-E glass 1, and float glass 3 is also provided on the aluminum frame , The aluminum frame and Low-E glass 1 and float glass 3 are bonded and fixed by polysulfide glue.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to Low-E hollow glass which comprises negative Low-E glass. An aluminium frame which is formed in a mode that an aluminium rod is folded is arranged on the Low-E glass. Float glass is arranged on the aluminium frame. The aluminium frame is fixedly adhered to the Low-E glass and the float glass through polysulfide glue. The Low-E hollow has high transmittance of over 80 percent for visible light in sunlight, but has low reflectance, so compared with the optical property of conventional coated glass, the optical property of the Low-E hollow glass is greatly improved. Seen from the outdoors, the Low-E hollow glass has more transparent and clear appearance, so that not only is excellent lighting of a building ensured, but also the phenomenon of light pollution caused by light reflection of a conventional large-area glass curtain wall and a conventional hollow glass door or window is avoided, and a softer and more comfortable light environment is created. The Low-E hollow glass is radiation-proof, has heat preservation and heat insulation performance and is energy-saving and environmental-friendly.

Description

Technical field [0001] The invention relates to the technical field of glass processing, in particular to a Low-E hollow glass. Background technique [0002] Due to its excellent thermal performance and good optical performance, Low-E glass is more and more widely used. Most of the existing Low-E glass is sprayed directly on the surface of the hot glass with liquid metal or metal powder. Cooling, a metal film is formed on the surface of the glass. In order to increase the wear resistance of the glass, it is often necessary to increase the thickness of the metal film, resulting in poor light transmittance and transparency. Summary of the invention [0003] In order to solve the above problems, the present invention provides a Low-E hollow glass with anti-radiation, thermal insulation, energy saving and environmental protection. [0004] The technical solution of the present invention is to include a negative film Low-E glass, the Low-E glass is provided with an aluminum frame made o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C27/10C03C27/08

Inventor 俞志稳

Owner 俞志稳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com