A kind of sulfonation method of naphthalene

A sulfonation, one-time technology, applied in the direction of sulfonic acid preparation, organic chemistry, etc., can solve the problems of lower production efficiency, can not truly reflect the content or purity of sulfonated material, large error, etc., achieve good application effect, shorten the production time of sulfonate The effect of saving time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of Cr-SO by Sol-Gel Method 4 / ZrO 2 The process is as follows:

[0016] 18mL Zr(OCH 2 CH 2 CH 3 ) 4 Dissolve in 60mL of 15% (w / w) aluminum isopropoxide solution, add 30mL of isopropanol and 4mL of water, add nitric acid (65%, w / w, 0.6mL) as catalyst, and keep stirring (25°C) for 30min, The obtained zirconium hydroxide sol was aged at 40°C for 24 hours to complete the polycondensation reaction, and the resulting gel was slowly dried at 150°C to obtain a highly hydrated amorphous gel. Grinding to 200 mesh, soaking in (sulfuric acid / potassium dichromate=2mol / 1mol) / L potassium dichromate sulfuric acid solution (70°C) for 24h, drying at 500-550°C for 3h, the specific surface area can be obtained Up to 228m 2 / g Cr-SO 4 / ZrO 2 Solid super acid.

Embodiment 2

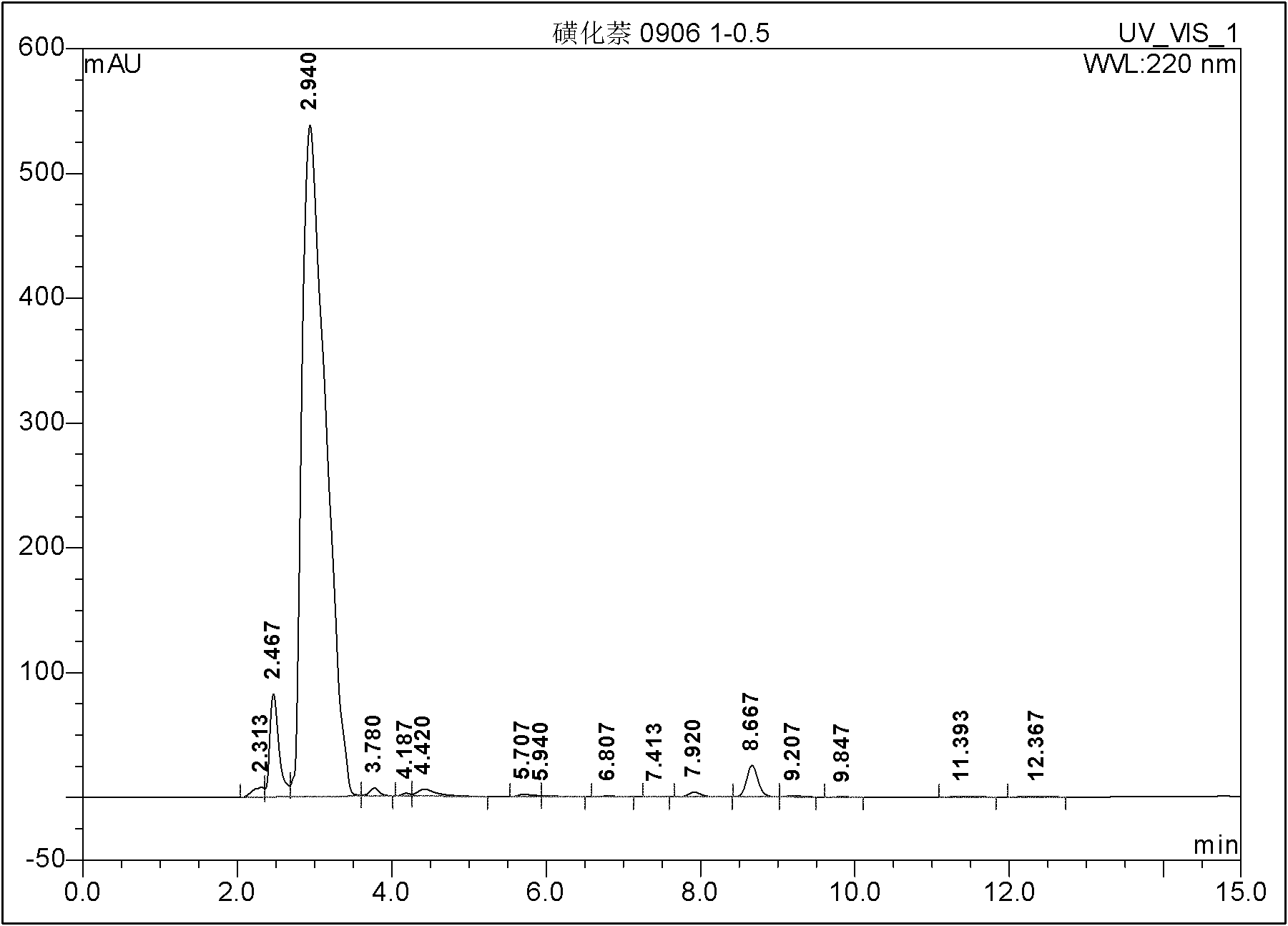

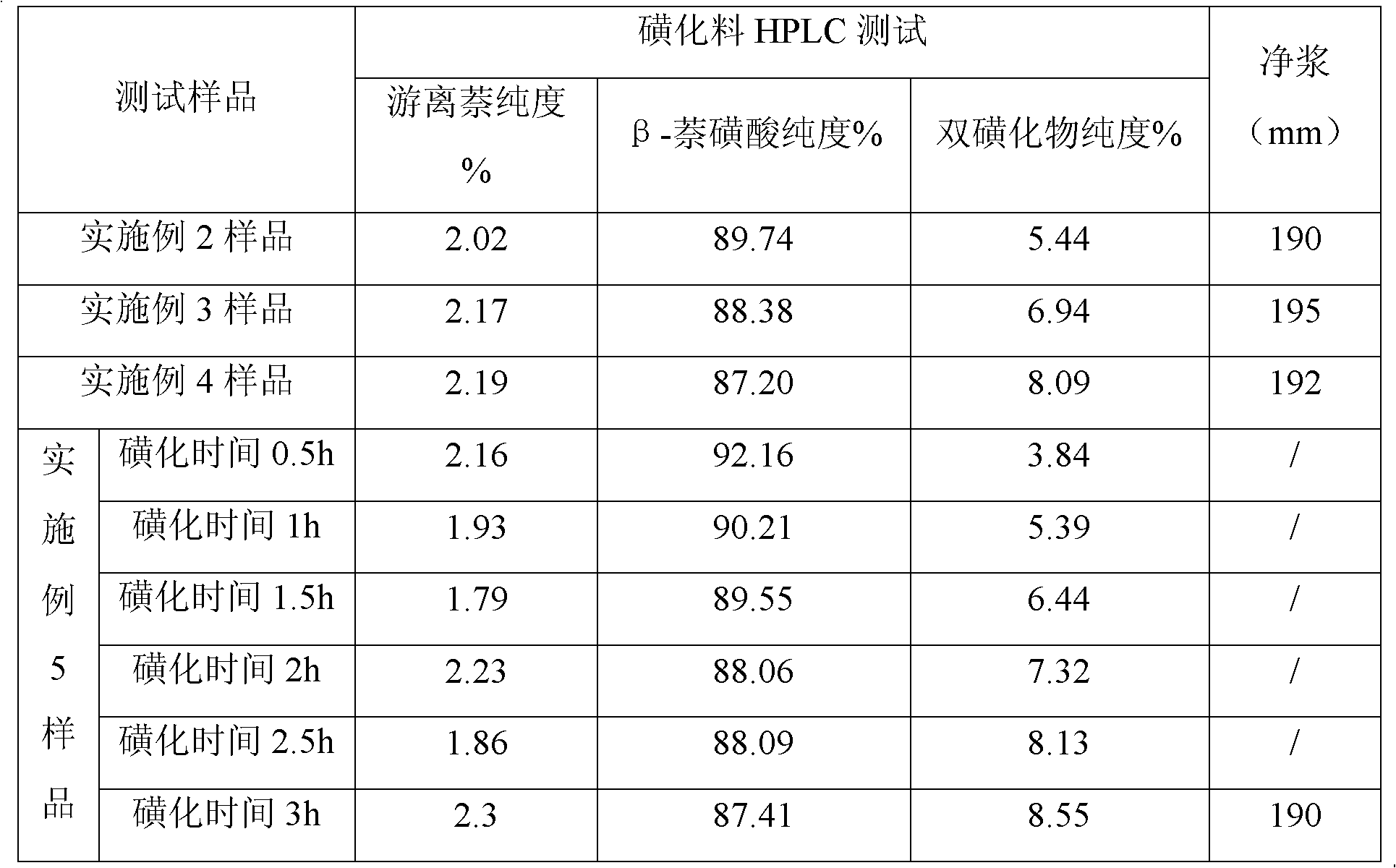

[0018] Weigh 2400kg of industrial naphthalene with a content of 96%, 2700kg of 98% concentrated sulfuric acid, and make Cr-SO 4 / ZrO 2 0.3kg of solid super acid, 50kg of anhydrous sodium sulfate; put industrial naphthalene into the sulfonation reactor, raise the temperature to 140°C, add concentrated sulfuric acid, raise the temperature to 169°C, react for 0.5 hours, cool down to 120°C, and take samples for HPLC detection Naphthalene content, purity of β-naphthalenesulfonic acid and purity of double sulfonates (results see figure 1 ), and then transferred to the condensation kettle.

[0019] At 120°C, pass 155°C high-temperature steam into the condensation kettle for hydrolysis and recovery of naphthalene homologues; stop feeding steam after 45 minutes, add 300kg of water, adjust the temperature to 100°C, and then add 1420kg of formaldehyde After condensing for 5 hours, transfer the material to a neutralization tank, add 30-32% NaOH aqueous solution, adjust the pH value to 7...

Embodiment 3

[0021] Weigh 2400kg of industrial naphthalene with a content of 97.5%, 2750kg of 98% concentrated sulfuric acid, and make Cr-SO 4 / ZrO 2 0.35kg of solid super acid, 60kg of anhydrous sodium sulfate; put industrial naphthalene into the sulfonation reactor, raise the temperature to 140°C, add concentrated sulfuric acid, raise the temperature to 166°C, react for 1 hour, cool down to 120°C, and take samples for HPLC detection The content of naphthalene, the purity of β-naphthalenesulfonic acid and the purity of double sulfonates are then transferred to the condensation reactor.

[0022] At 120°C, pass 155°C high-temperature steam into the condensation kettle for hydrolysis and recovery of naphthalene homologues; stop feeding steam after 45 minutes, add 300kg of water, adjust the temperature to 100°C, and then add in proportion After condensing 1450kg of formaldehyde for 5 hours, transfer the material to the neutralization tank, add 30-32% NaOH aqueous solution, adjust the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com