LED (light emitting diode) lamp tube structure

A technology of LED tube and LED lamp, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of high energy consumption, short life, long-term environmental and human body harm, etc., and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

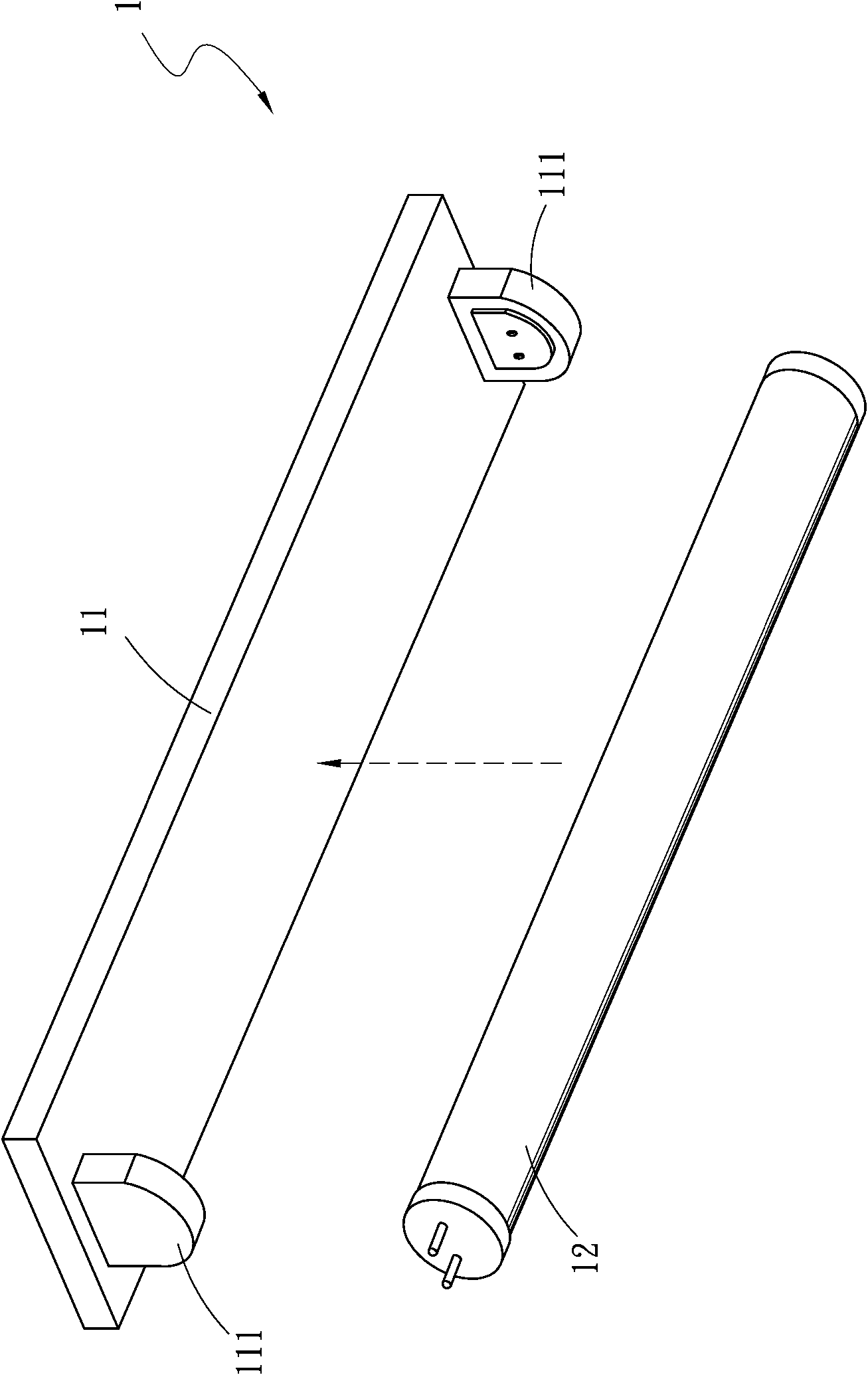

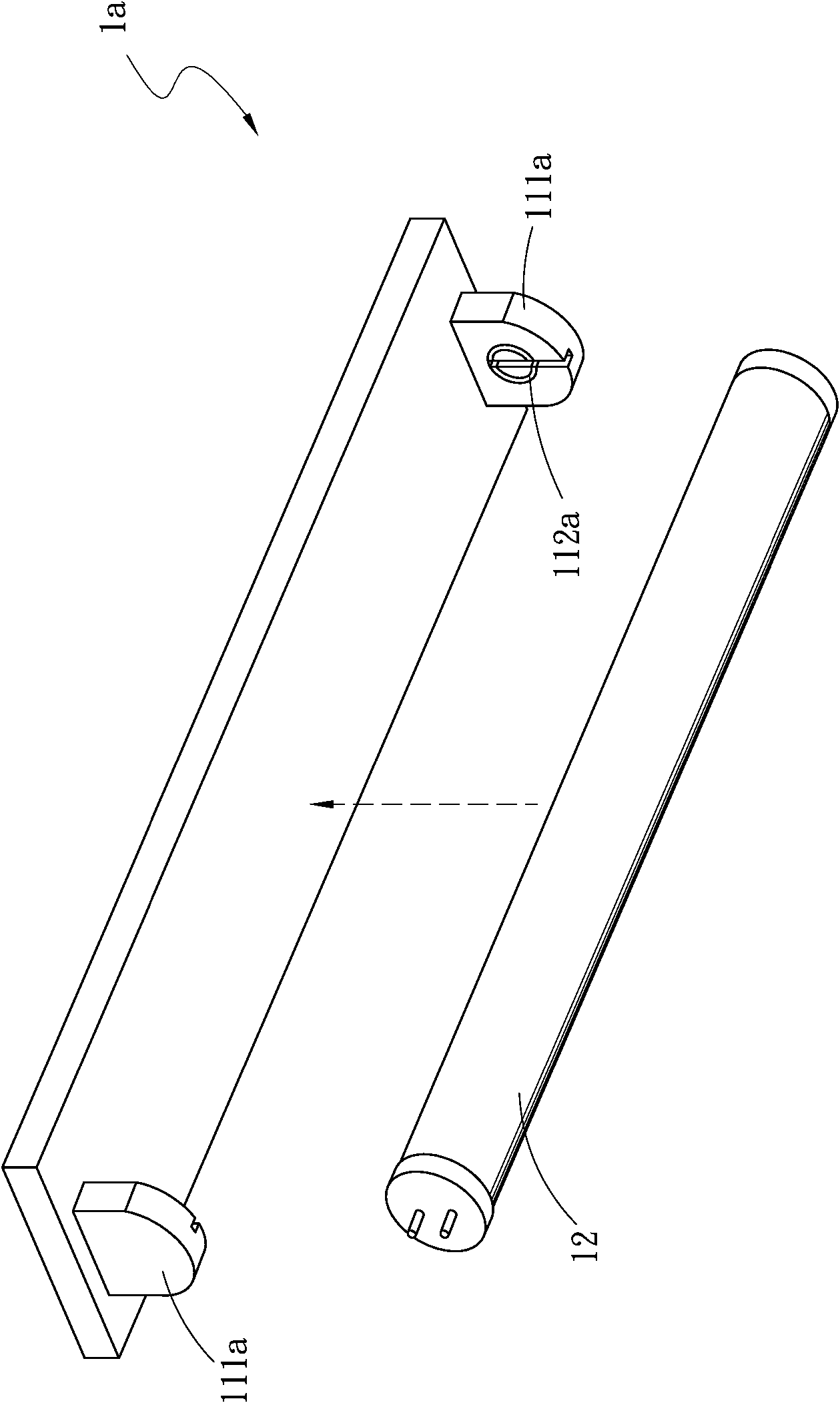

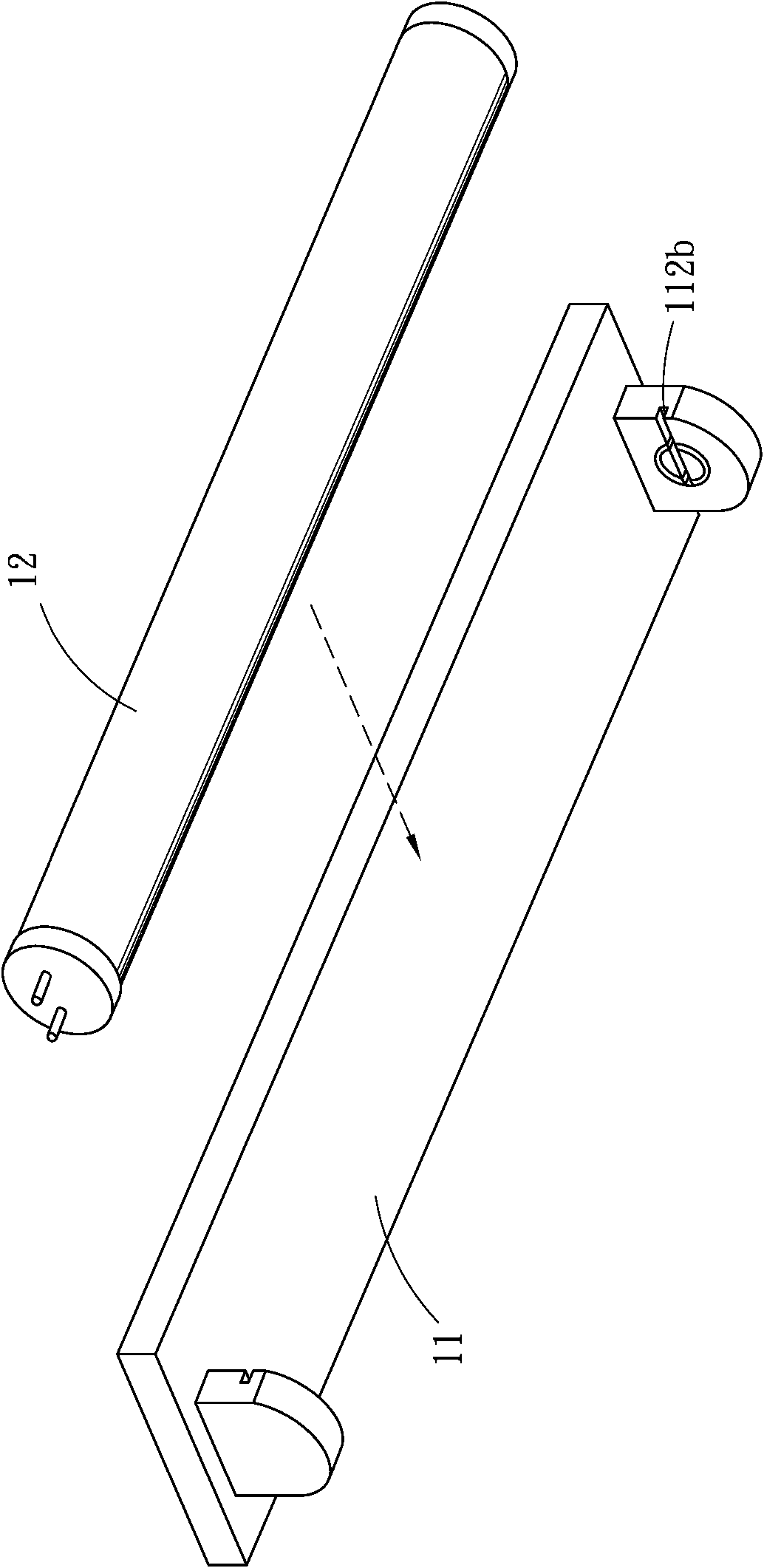

[0035] see Figure 4 to Figure 7 As shown, the present invention provides an LED lamp tube structure, including a lamp tube 2, two fittings 3 and two end caps 4, wherein:

[0036] A lamp tube 2, the lamp tube 2 includes a heat sink 21, an LED lamp group 22 and a light-transmitting member 23, the heat sink 21 is a semicircular hollow column, which can be copper or aluminum, etc. The material with good thermal conductivity and heat dissipation has fitting grooves 211 respectively provided on the plane end and the two sides parallel to the axial direction, and a fastening hole 212 is respectively provided at the two ends of the heat sink 21, and the fastening hole There is a through groove 213 between 212 and the end edge; the LED lamp group 22 includes at least one circuit board 221 and a plurality of LED lamps 222, and the circuit board 221 is a long board, which can be firmly clamped on the heat dissipation Between the fitting grooves 211 of the parts 21, the circuit board 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com