Surface mount device (SMD) type solid laser, and adjusting device, and manufacturing method for SMD type solid laser

A technology of solid-state lasers and manufacturing methods, which is applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of time-consuming and labor-intensive adjustments, reduce errors and inconvenience, reduce matching procedures, and change manual adjustment methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

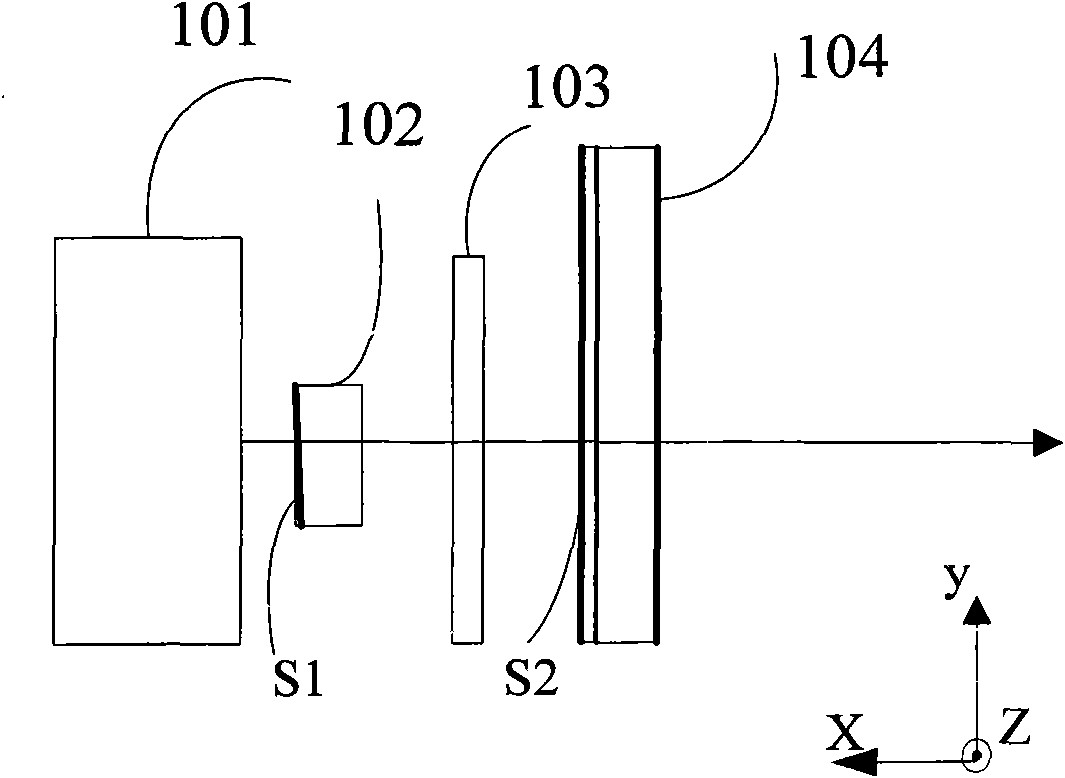

[0033] figure 1 It is a schematic diagram of the component position structure of the patch type solid-state laser described in the present invention.

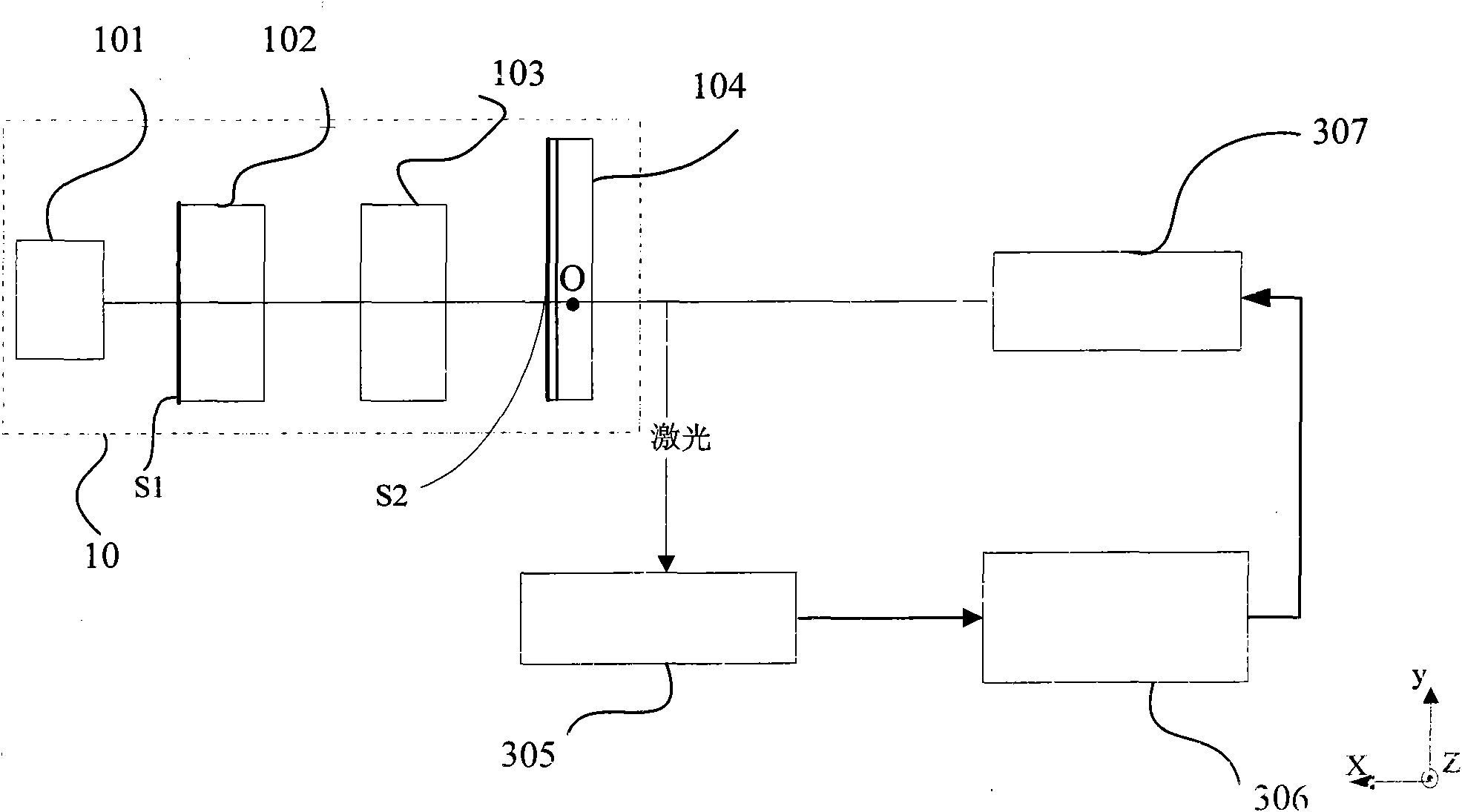

[0034] Such as figure 1 As shown, the patch type solid-state laser 10 disclosed in the present invention includes an LD pump light source 101 and a resonant cavity, and the resonant cavity is composed of a laser crystal 102 parallel to each other, a frequency doubling crystal 103 and a planar output mirror 104, Wherein, the incident surface S1 of the laser crystal 102 and the incident surface S2 of the planar output mirror 104 form a flat cavity. LD pumping light source 101, laser crystal 102, frequency doubling crystal 103 and planar output mirror 104 are all fixed on the laser substrate with corresponding grooves.

[0035] Wherein, the LD pumping light source 101 is used to provide pumping light.

[0036] The la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com