Surface mount device (SMD) solid laser and manufacturing method thereof

A solid-state laser, patch technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of unsatisfactory laser quality, difficulty in mass production, time-consuming and labor-intensive adjustment process, and save manual adjustment. process, to achieve large-scale production, and the effect of easy production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

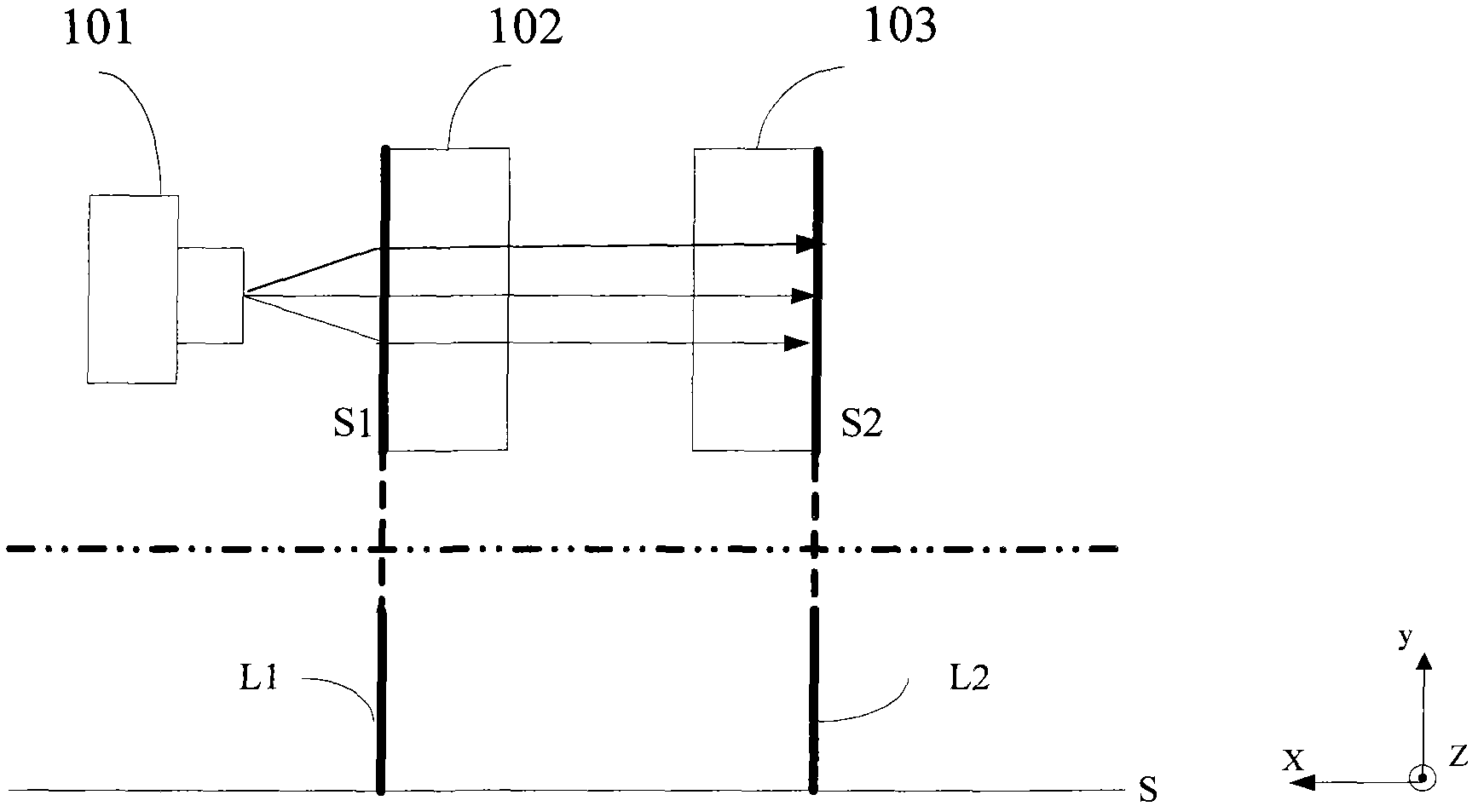

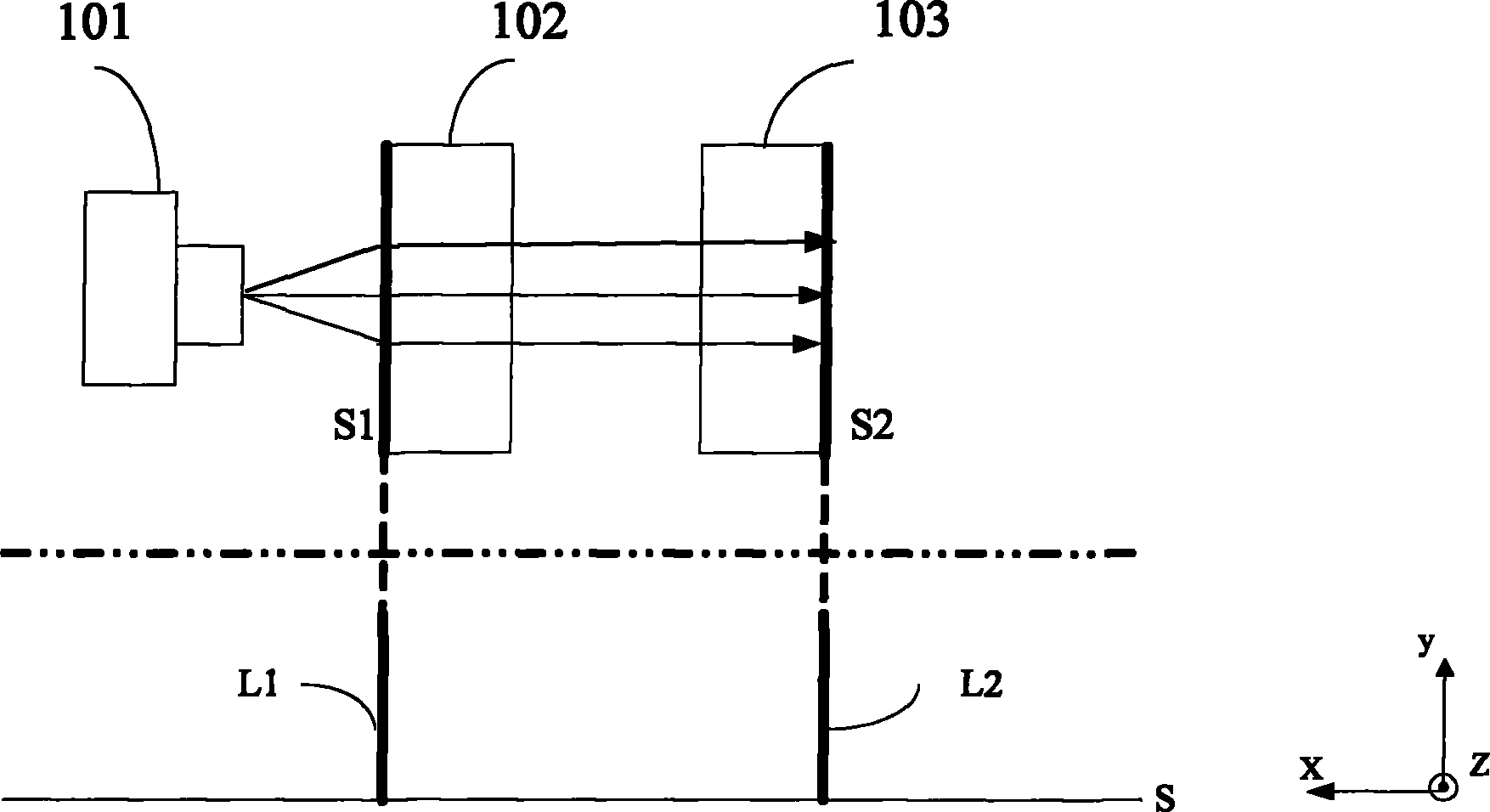

[0026] figure 1 It is a structural schematic diagram of the patch type solid-state laser described in the present invention.

[0027] like figure 1 As shown, the patch-type solid-state laser includes an LD pumping light source 101 and a resonant cavity, and the LD pumping light source 101 is a fiber shaped and compressed LD pumping light source for providing pumping light. The resonant cavity includes a laser crystal 102 and a frequency doubling crystal 103 parallel to each other. The laser crystal 102 is used as a working material of the laser to convert the pumping light provided by the LD pumping light source 101 into fundamental frequency light. In the present embodiment, laser crystal 102 selects Nd:YVO 4 (Nd-doped yttrium vanadate) crystal. The frequency doubling crystal 103 is used to convert the fundamental frequency light emitted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com