Thrust bearing and suspension for vehicle

A technology of thrust bearings and suspensions, which is applied in the direction of suspensions, ball bearings, elastic suspensions, etc., and can solve the problems of thrust bearing life and harmful effects of penetrating suspensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

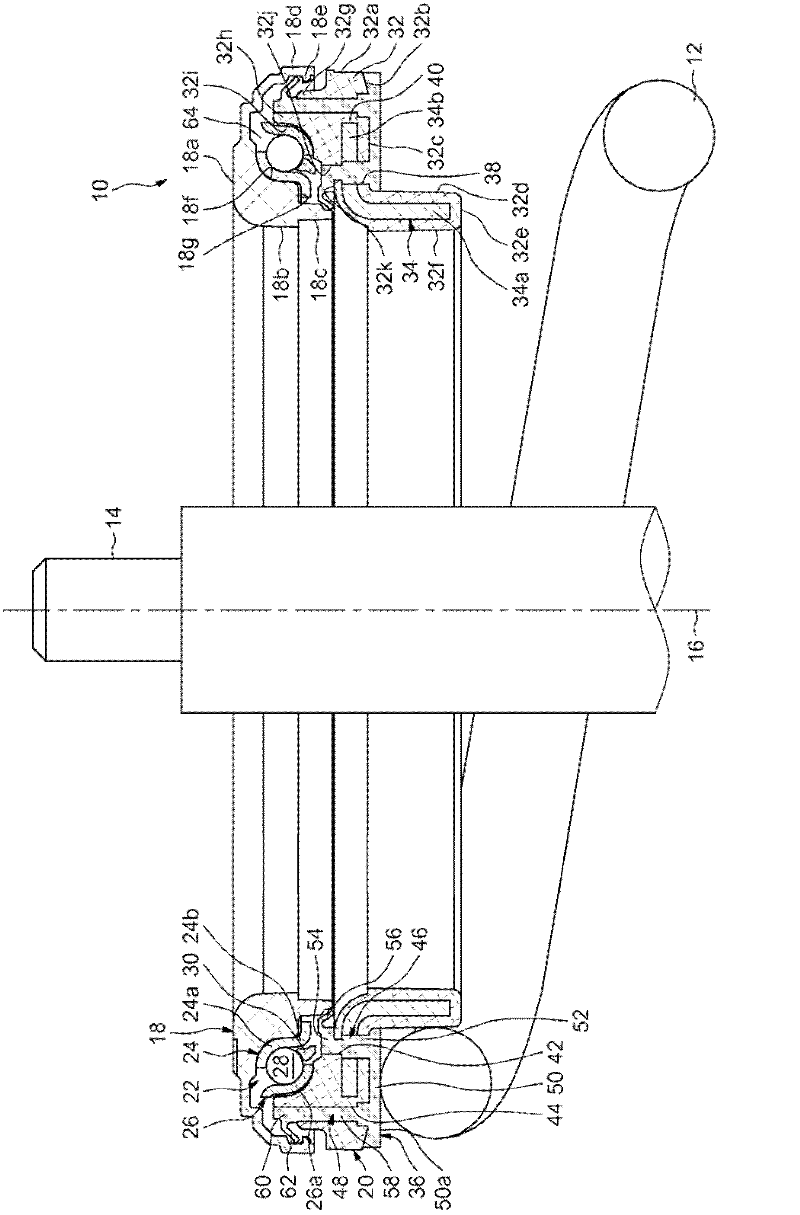

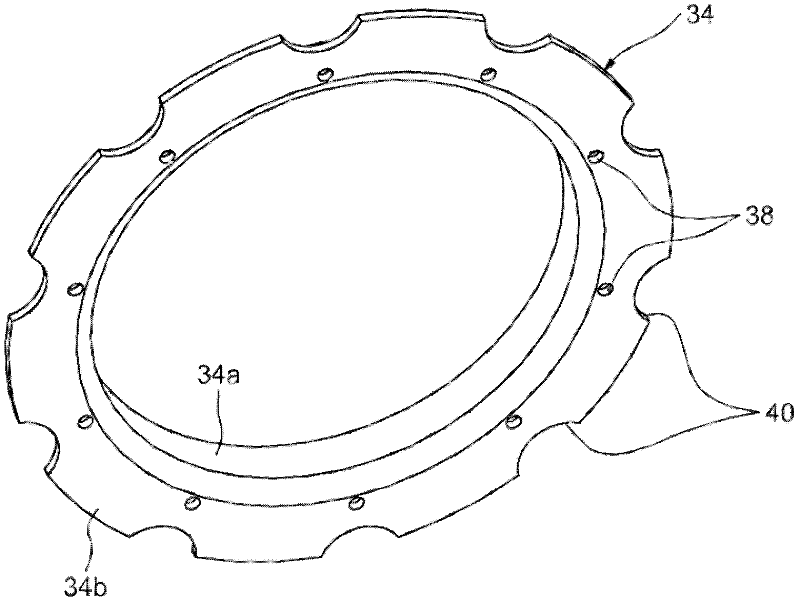

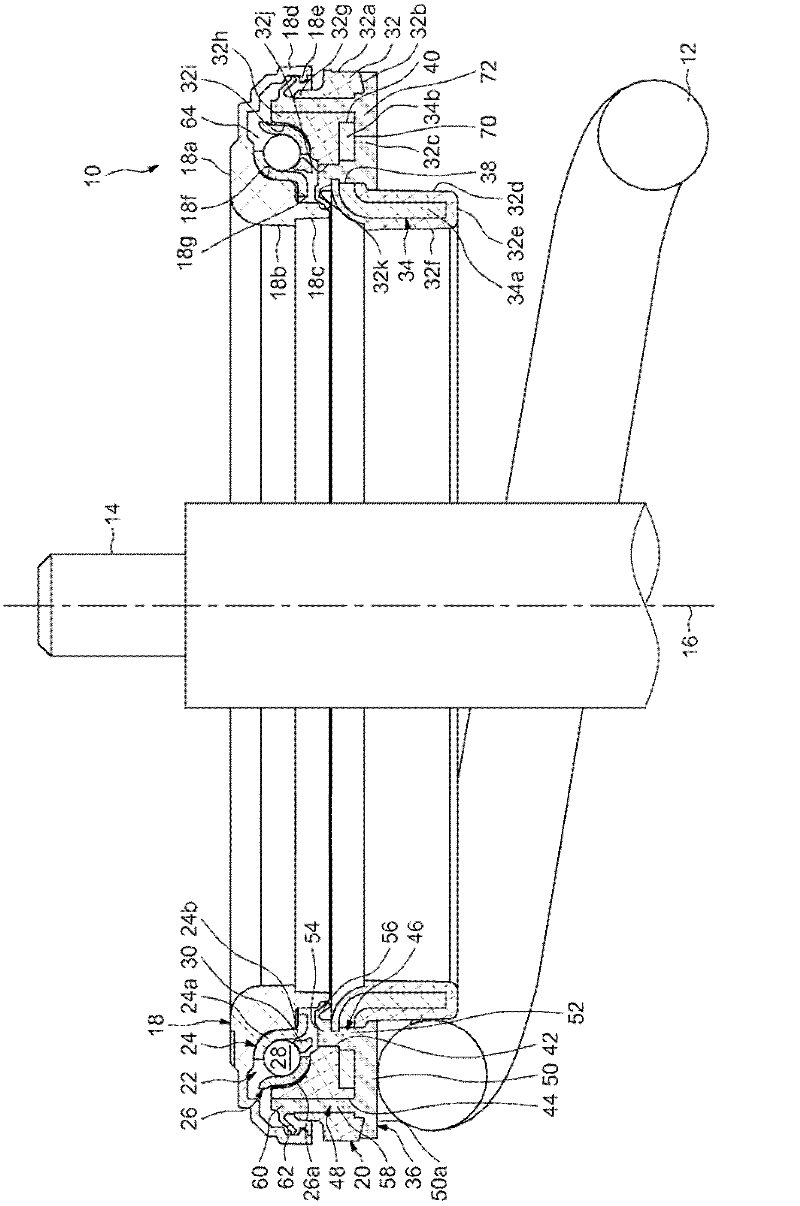

[0027] figure 1 There is shown a suspension thrust bearing arrangement generally indicated by 10 which is designed to be mounted between a chassis element of a motor vehicle and a helical suspension spring 12 . The device 10 is arranged around a shock absorber rod 14 having an axis 16 assumed to be vertical, said rod being axially elongated in the form of a cylinder of revolution. A suspension spring 12 is mounted around a shock absorber rod 14 .

[0028] The device 10 having the axis 16 comprises: an upper bearing cap 18 designed to come into contact against a filter-aid elastic mass interposed between said device and the chassis of the vehicle; a lower support forming a bearing mechanism for the spring 12 covers 20 ; and rolling bearings 22 arranged axially between said covers and forming axial thrust bearings.

[0029] The bearing cover 18 can consist of a one-piece part made of plastic, for example polyamide PA 6.6, optionally reinforced with glass fibres. The bearing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com