Method for producing glass film, method for treating glass film and glass film laminate

一种制造方法、处理方法的技术,应用在玻璃/矿渣层状产品、薄料处理、化学仪器和方法等方向,能够解决难以进行定位、处理困难、错位等问题,达到密合性好、操作性好的效果

Active Publication Date: 2012-05-23

NIPPON ELECTRIC GLASS CO LTD

View PDF6 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when filming glass substrates used in these electronic devices, since glass is a brittle material, breakage occurs due to slight stress changes, and it is very difficult to handle the above-mentioned various processes related to the manufacture of electronic devices. The problem

In addition, glass films with a thickness of 200 μm or less are excellent in flexibility, so there are also problems such as difficulty in positioning during processing, and misalignment during patterning.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0071] Hereinafter, although the manufacturing method of the glass film of this invention is demonstrated in detail based on an Example, this invention is not limited to these Examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Login to View More

Abstract

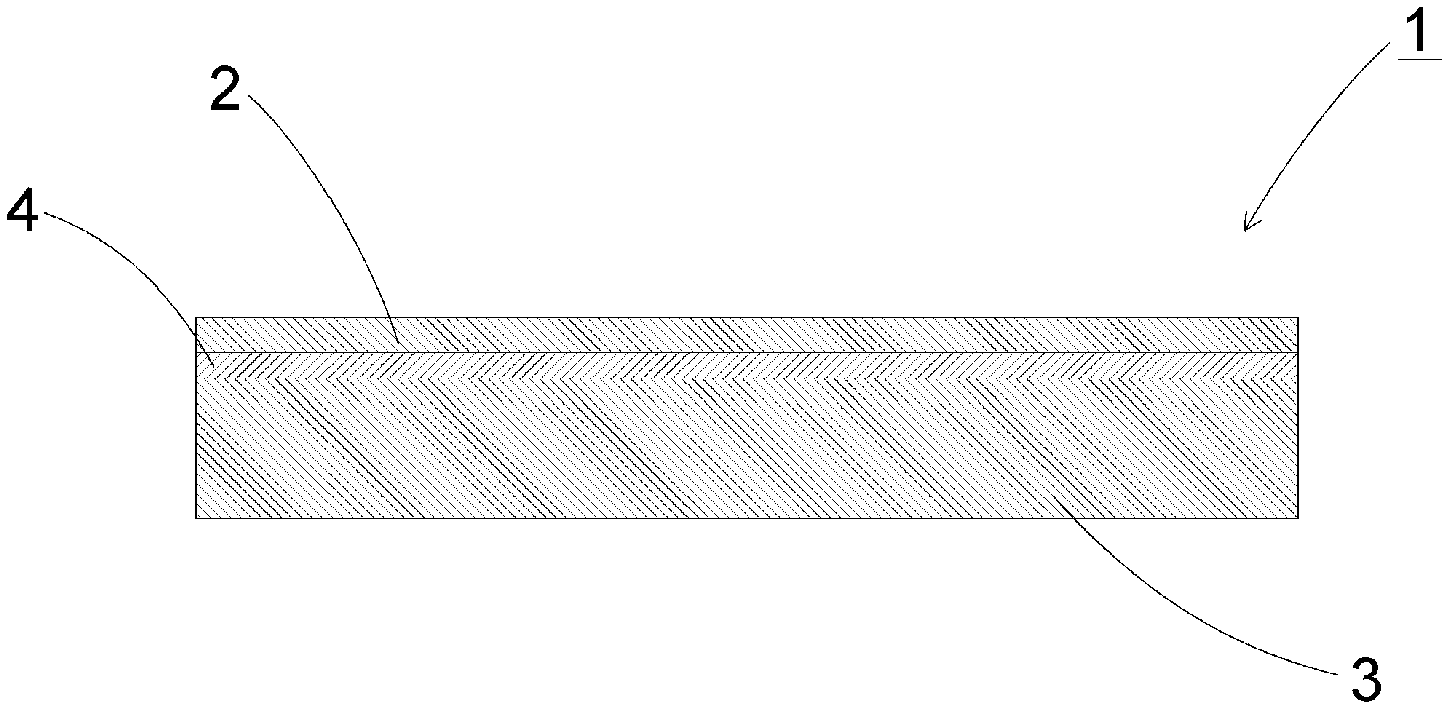

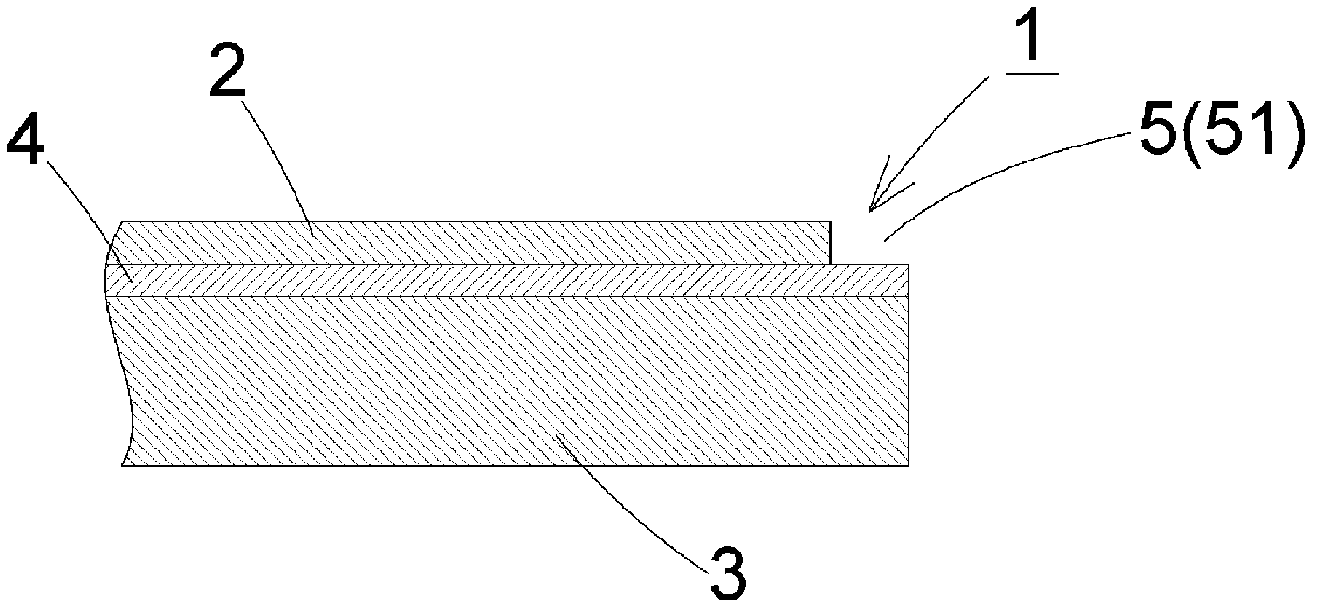

A method of producing a glass film comprises a first step of forming an inorganic thin film on a surface of a supporting glass so that a surface of the inorganic thin film after being formed has a surface roughness Ra of 2.0 nm or less after film formation, a second step of forming a glass film laminate by laminating a glass film having a surface roughness Ra of 2.0 nm or less on the surface of the inorganic thin film in a state of being in contact with each other, a third step of carrying out treatment involving heating with respect to the glass film laminate, and a fourth step of peeling off the glass film from the supporting glass after the treatment involving heating.

Description

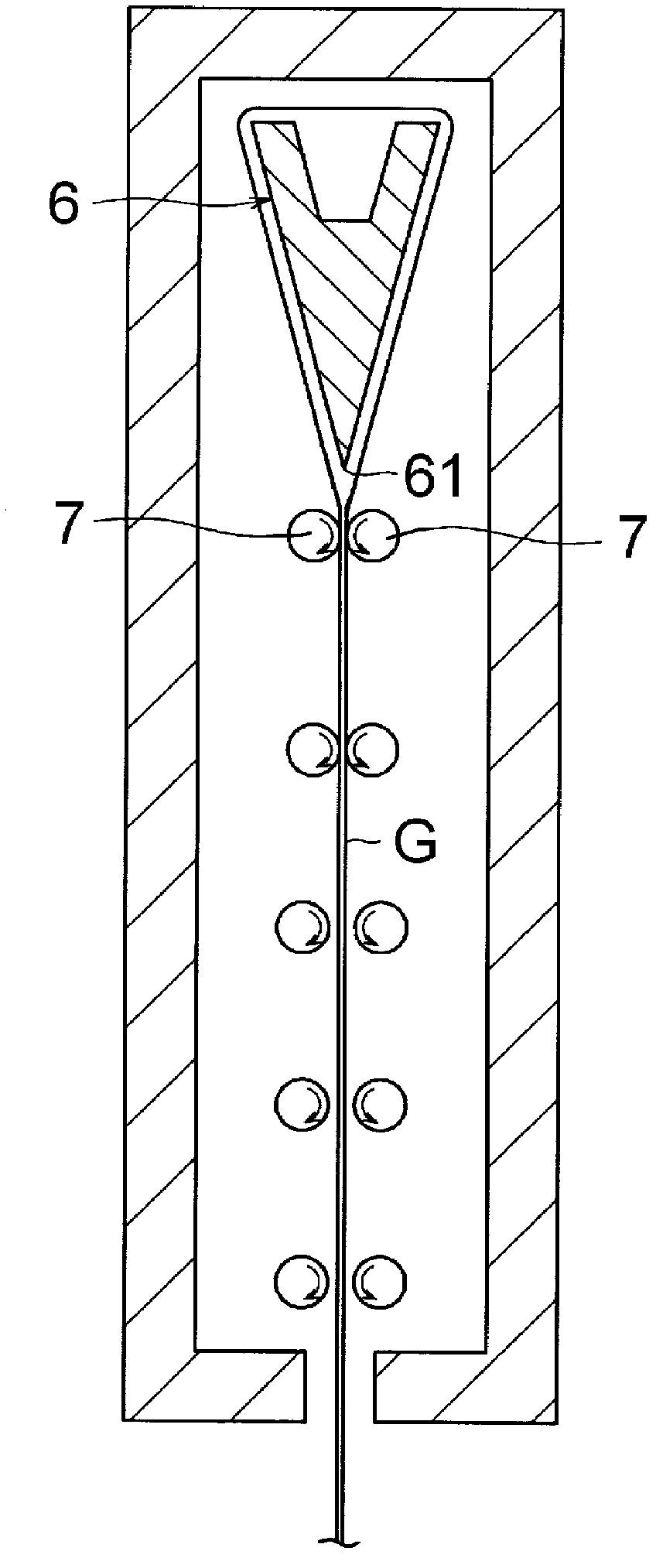

technical field [0001] The present invention relates to flat panel displays such as liquid crystal displays and organic EL displays, glass substrates for devices such as solar cells, lithium-ion batteries, digital signboards, touch panels, and electronic paper, and protective glasses for devices such as organic EL lighting and pharmaceutical packaging. A method for producing a glass film to be used, and a glass film laminate supported by a supporting glass. Background technique [0002] From the viewpoint of space saving, in recent years, flat panel displays such as liquid crystal displays, plasma displays, organic EL displays, and field emission displays have been popularized instead of conventionally popular CRT displays. In these flat panel displays, further thinning is required. Especially in an organic EL display, it is required to be able to use not only a flat surface but also a curved surface while being easy to carry by folding or winding. In addition, it is not l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B40/033B32B17/06G02F1/1333G09F9/00G09F9/30H01L51/50H05B33/02

CPCH01L51/52C03C2217/77C03C17/3411B32B17/06B32B7/06Y10T428/24942Y10T428/26Y10T428/266H05B33/02H10K50/80B32B37/06B32B38/10B32B2457/20

Inventor 笘本雅博高谷辰弥泷本博司折口长敏

Owner NIPPON ELECTRIC GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com