Energy ray-curable epoxy resin composition having excellent curing properties in deep portions

A technology of energy ray curing and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive type, hydrocarbon copolymer adhesive, etc., can solve the problem of poor deep curing of epoxy resin, and improve deep curing , the effect of high fixed precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1~2

[0041] Based on the proportions recorded in Table 1, dissolve the photoacid generator PI2074 in 4-butyrolactone, add it to EPICLON 850 and CEL3000, stir until transparent, and prepare the energy ray-curable epoxy resin combination of Comparative Example 1 thing.

[0042] Based on the compounding ratio shown in Table 1, GS350T or GS310T was added to the epoxy resin composition of Comparative Example 1 and stirred until uniform, thereby preparing the energy ray-curable epoxy resin composition of Example 1 or Comparative Example 2.

[0043] The deep curability of the epoxy resin compositions of Example 1 and Comparative Examples 1 and 2 was measured. Deep cure is determined as follows: In the clarinet tube of the hole, the energy ray-curable epoxy resin compositions of Example 1 and Comparative Example 1 and 2 were filled with a height of 5 mm, and the UV irradiation machine made by Hamamatsu Photonics was used from the top at 500 mW / cm 2 (365nm) irradiation for 10 seconds, ta...

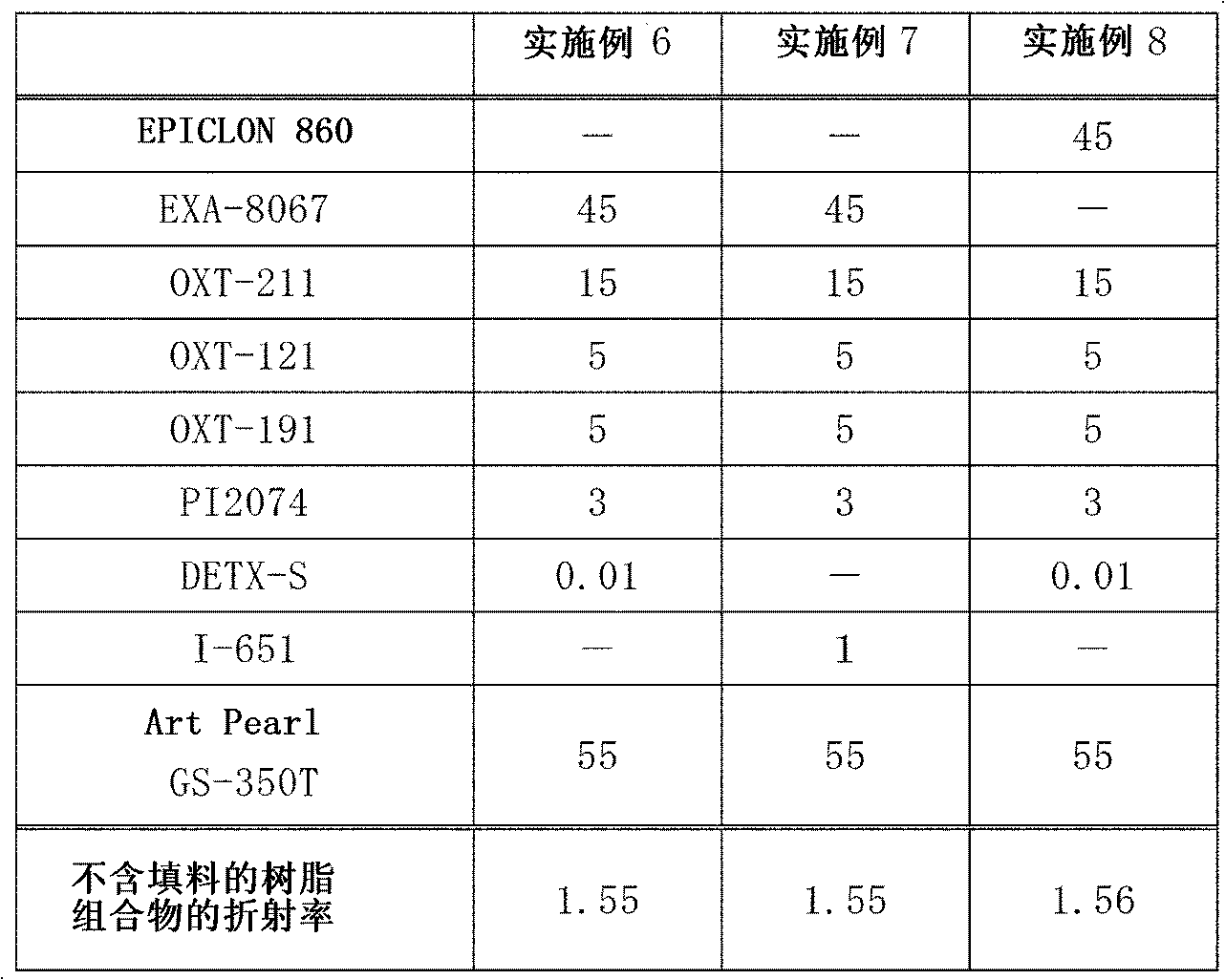

Embodiment 2 and comparative example 3

[0054] Based on the compounding ratio described in Table 2, the epoxy resin compositions of Example 2, Comparative Examples 3 and 4 were prepared. The deep curability of each epoxy resin composition was measured. The results are shown in Table 2.

[0055] [Table 2]

[0056] Product Number

Example 2

Comparative example 3

Comparative example 4

EPICL0N 860

45

45

45

OXT-211

15

15

15

OXT-121

5

5

5

OXT-191

5

5

5

PI2074

3

3

3

DETX-S

0.01

0.01

0.01

CPI-210S

Art Pearl GS-350T (refractive index 1.55)

45

TALC P-2 (refractive index 1.58)

20

45

Refractive index of resin composition without filler

1.55

155

1.55

Deep curability 500mW / cm 2 ×10s

2.7mm

1.9mm

1.4mm

[0057] EPICLON 860: Bisphenol A type epoxy resin (manufac...

Embodiment 3 and comparative example 5

[0067] Based on the formulations described in Table 3, the epoxy resin compositions of Example 3 and Comparative Example 5 were prepared. The deep curability of each epoxy resin composition was measured. The results are shown in Table 3.

[0068] [table 3]

[0069] Example 3

Comparative Example 5

YX8034

45

45

OXT-211

30

30

OXT-191

5

5

CPI-210S

2

2

Art Pearl GS-310T (refractive index 1.51)

32.5

Art Pearl GS-350T (refractive index 1.55)

325

Refractive index of resin composition without filler

1.51

1.51

Deep hardening 500mW / cm 2 ×10s

3.3mm

1.7mm

[0070] YX8034: hydrogenated bisphenol A type epoxy resin: jER company (Japan Epoxy Resins)

[0071] OXT-211: 3-ethyl-3-(phenoxymethyl)oxetane (manufactured by Toagosei Co., Ltd.)

[0072] OXT-191: Oxetanyl silicate (manufactured by Toagosei Co., Ltd.)

[0073] CPI-210S: S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com