Patents

Literature

42results about How to "Reduce logistics time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

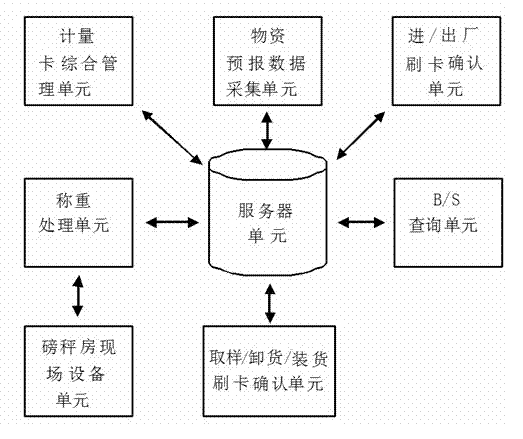

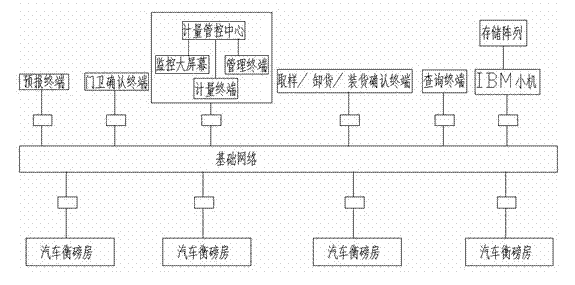

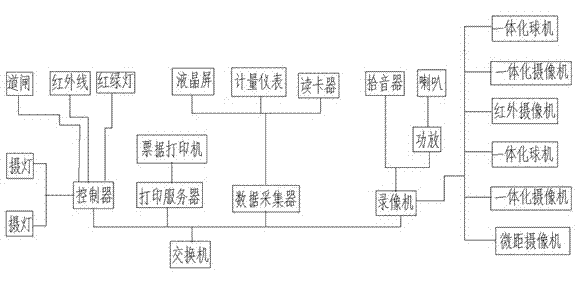

Automobile card reading measurement control system and use method

InactiveCN102496094AReduce the quantity requiredReduce the number of requirements and reduce labor costsCo-operative working arrangementsLogisticsManagement unitControl system

An automobile card reading measurement control system relates to automobile material unmanned remote centralized weighing measurement and process management, and consists of a measuring card comprehensive management unit, a material forecasting data acquisition unit, an in-factory / ex-factory card reading confirmation unit, a scale room field equipment unit, a weighing processing unit, a sampling / unloading / loading card reading confirmation unit, a B / S inquiry unit and a server unit, wherein the scale room field equipment unit is connected with the weighing processing unit; the measuring card comprehensive management unit, the material forecasting data acquisition unit, the in-factory / ex-factory card reading confirmation unit, the weighing processing unit, the sampling / unloading / loading card reading confirmation unit and the B / S inquiry unit are respectively connected with the server in a data transmission manner. By adopting the automobile card reading measurement control system, all measuring personnel are centralized in a hall, dynamic dispatching of man power and various equipment resources can be realized, the required measuring personnel quantity is greatly reduced, and the manpower cost is lowered.

Owner:WUKUN STEEL

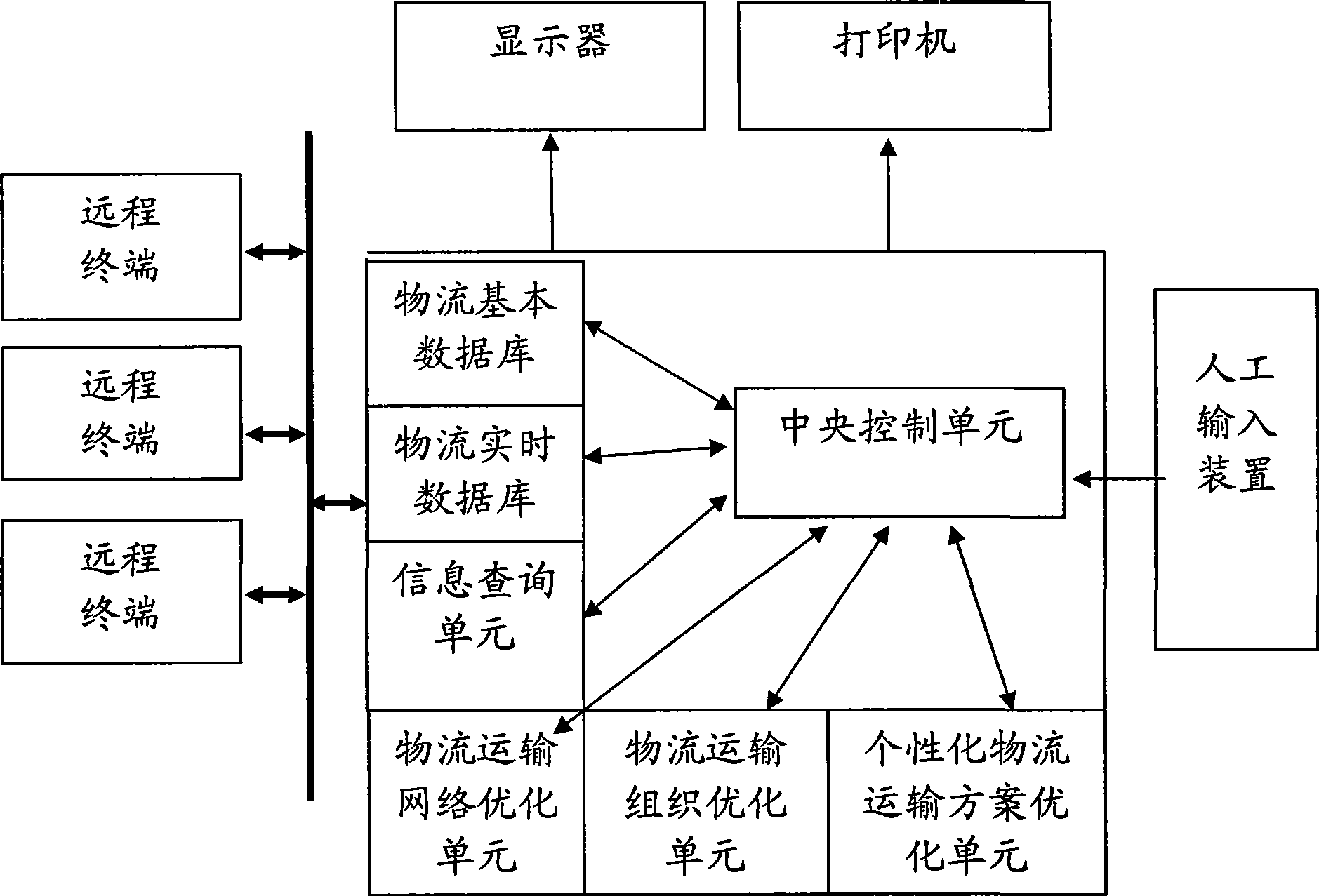

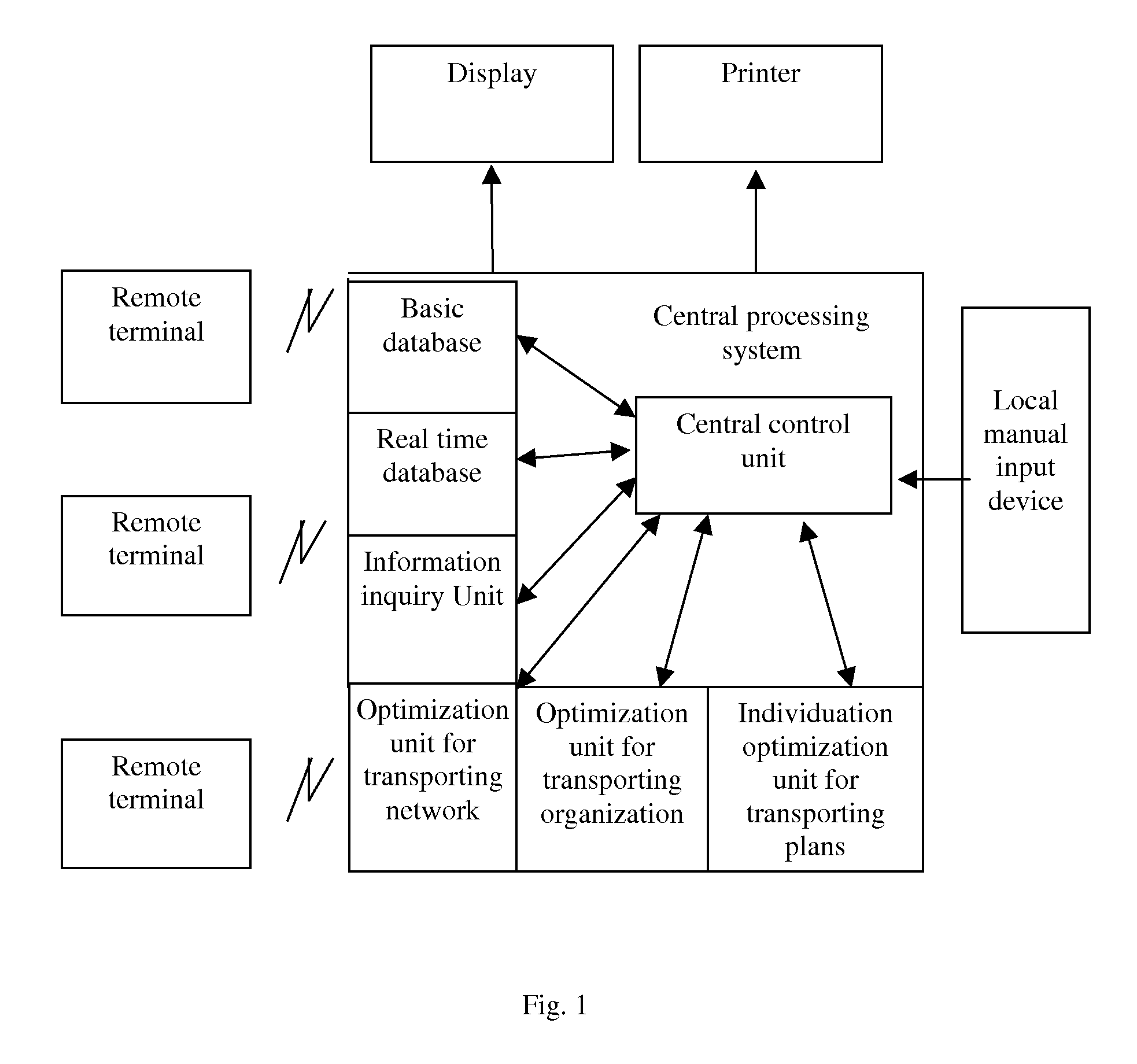

Physical distribution optimizing management system

InactiveCN101441731AImprove operational efficiencySimple designLogisticsPersonalizationLogistics management

The invention relates to a logistics optimization management system, which is provided with a logistics basic database and a real-time database, and comprises an information query unit, a logistics transportation network optimization unit, a logistics transportation organization optimization unit and an individualized logistics transportation proposal optimization unit, wherein the information query unit is used for reading data in the logistics basic database and the real-time database according to manually input query information; and the logistics transportation network optimization unit, the logistics transportation organization optimization unit and the individualized logistics transportation proposal optimization unit read the data of the logistics basic database and the real-time database according to input instructions and logistics information respectively, execute optimization operation according to preset programs, and generate corresponding optimization proposals. The system has the advantages that the system is favorable for improving logistics efficiency and reducing logistics time as well as logistics cost, and can be used for various logistics enterprises or other large-scale enterprises.

Owner:BEIJING AOTENGXUNDA SCI & TECH

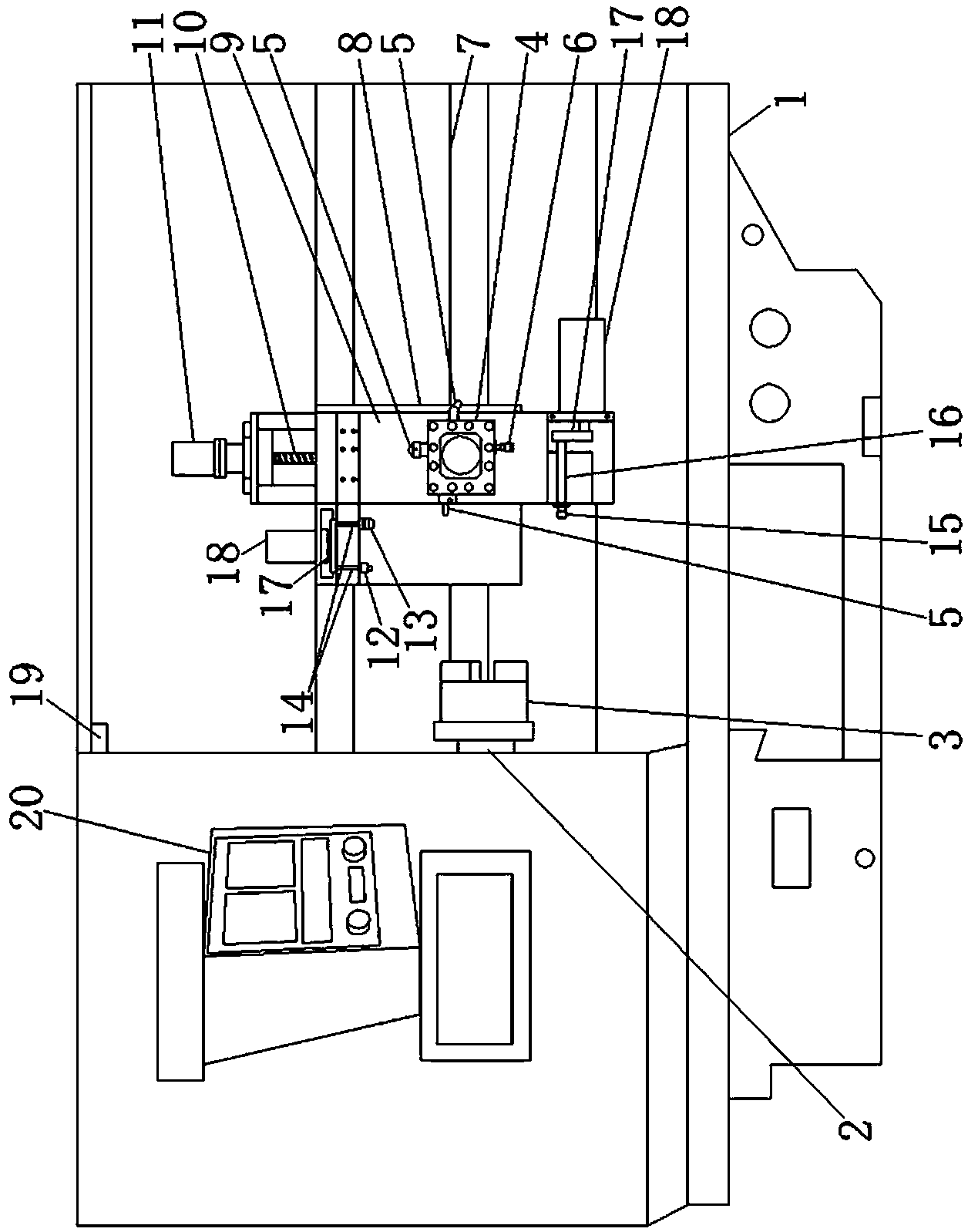

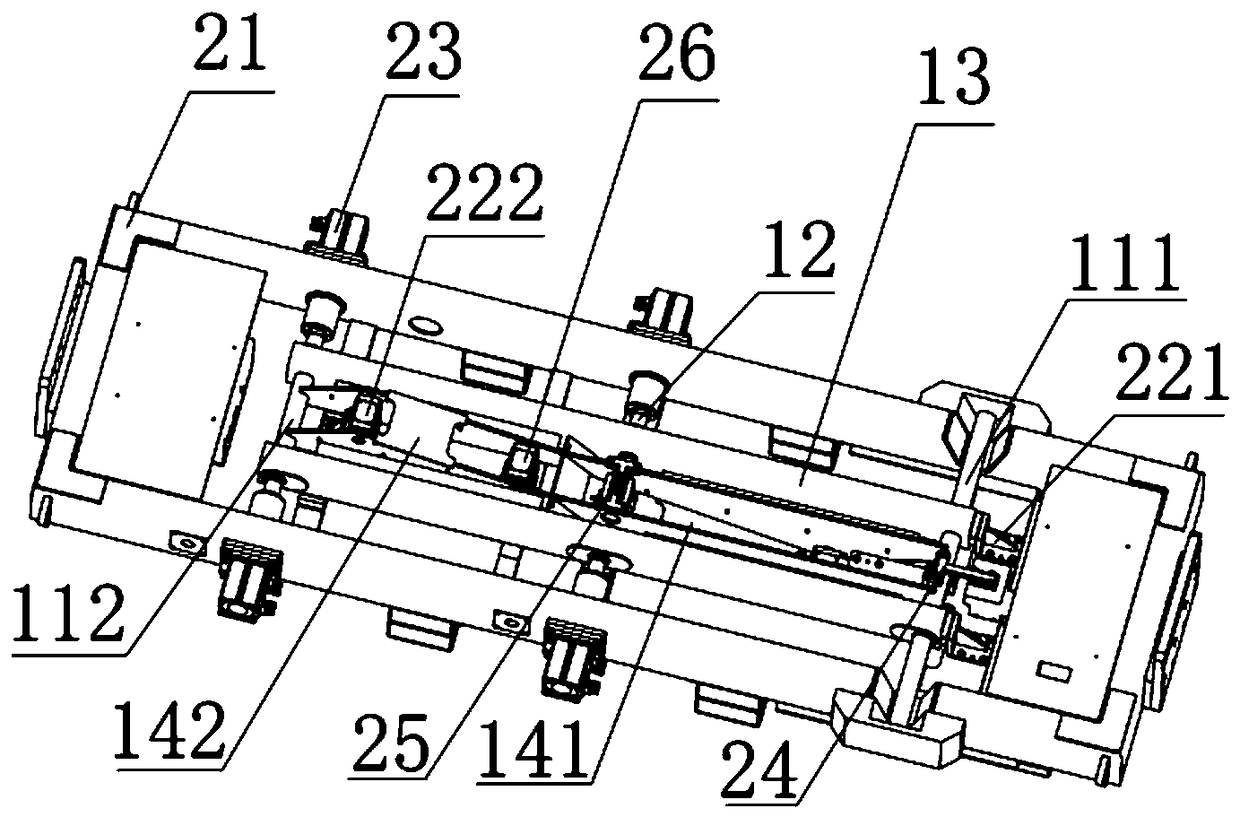

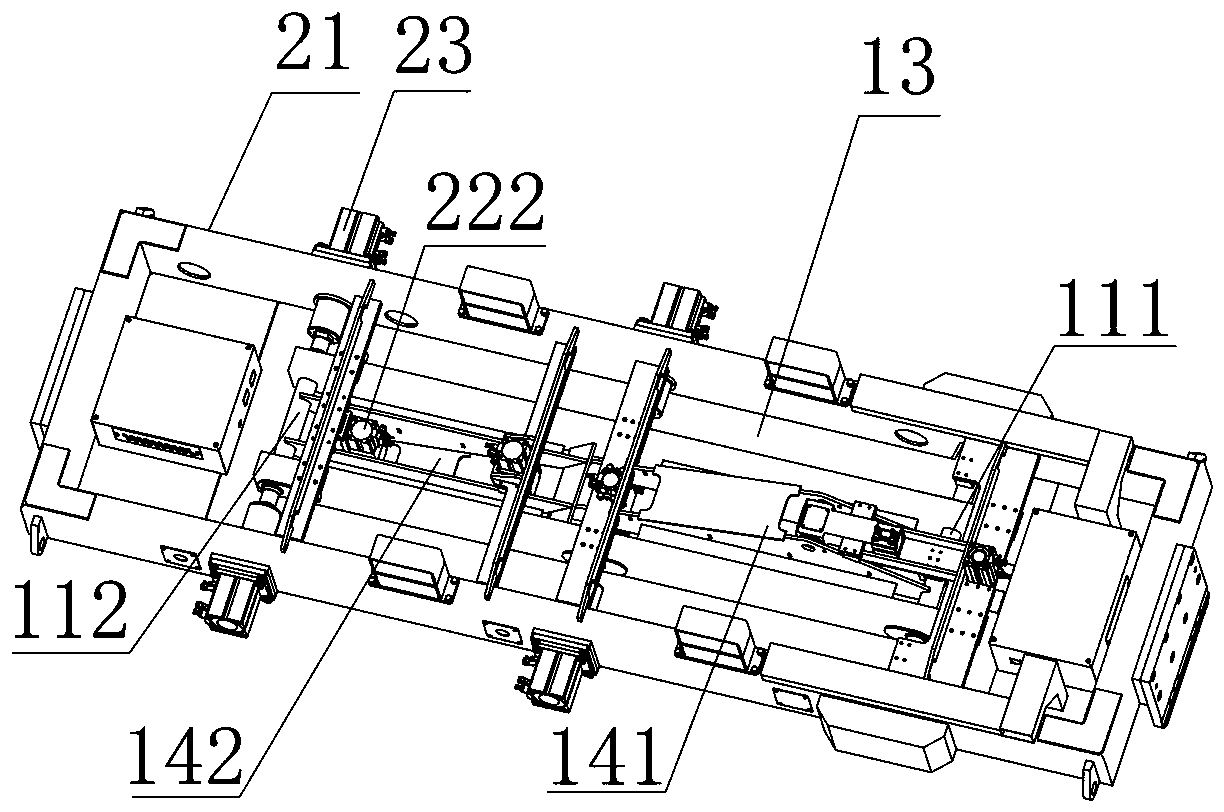

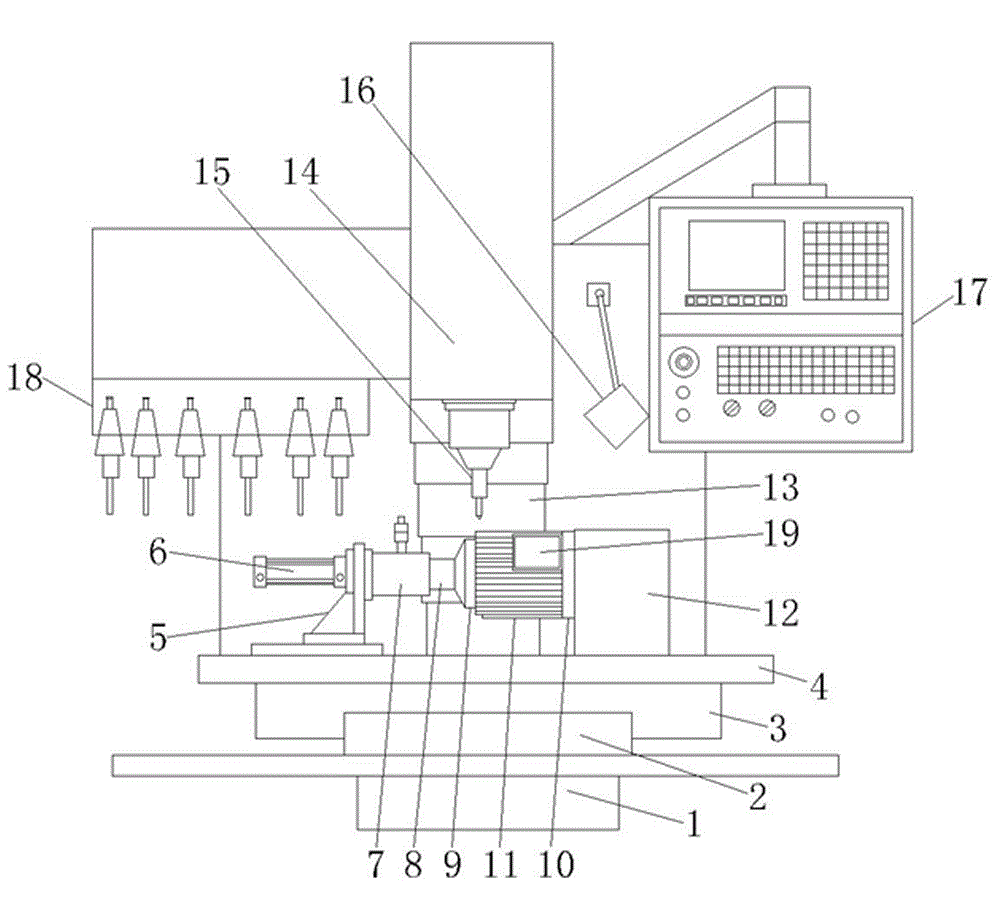

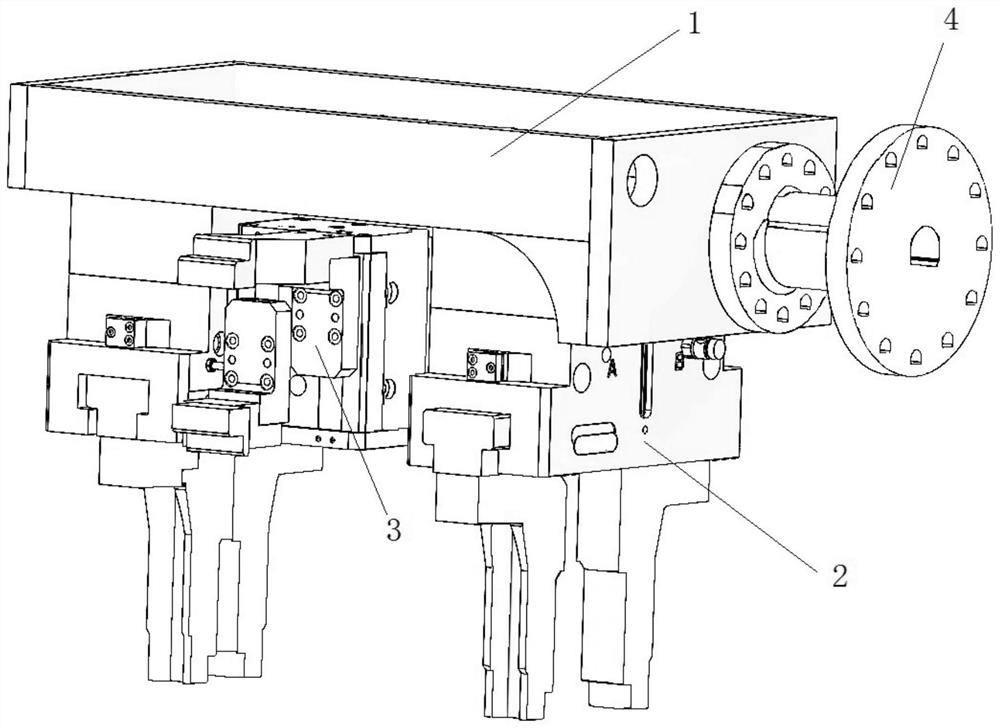

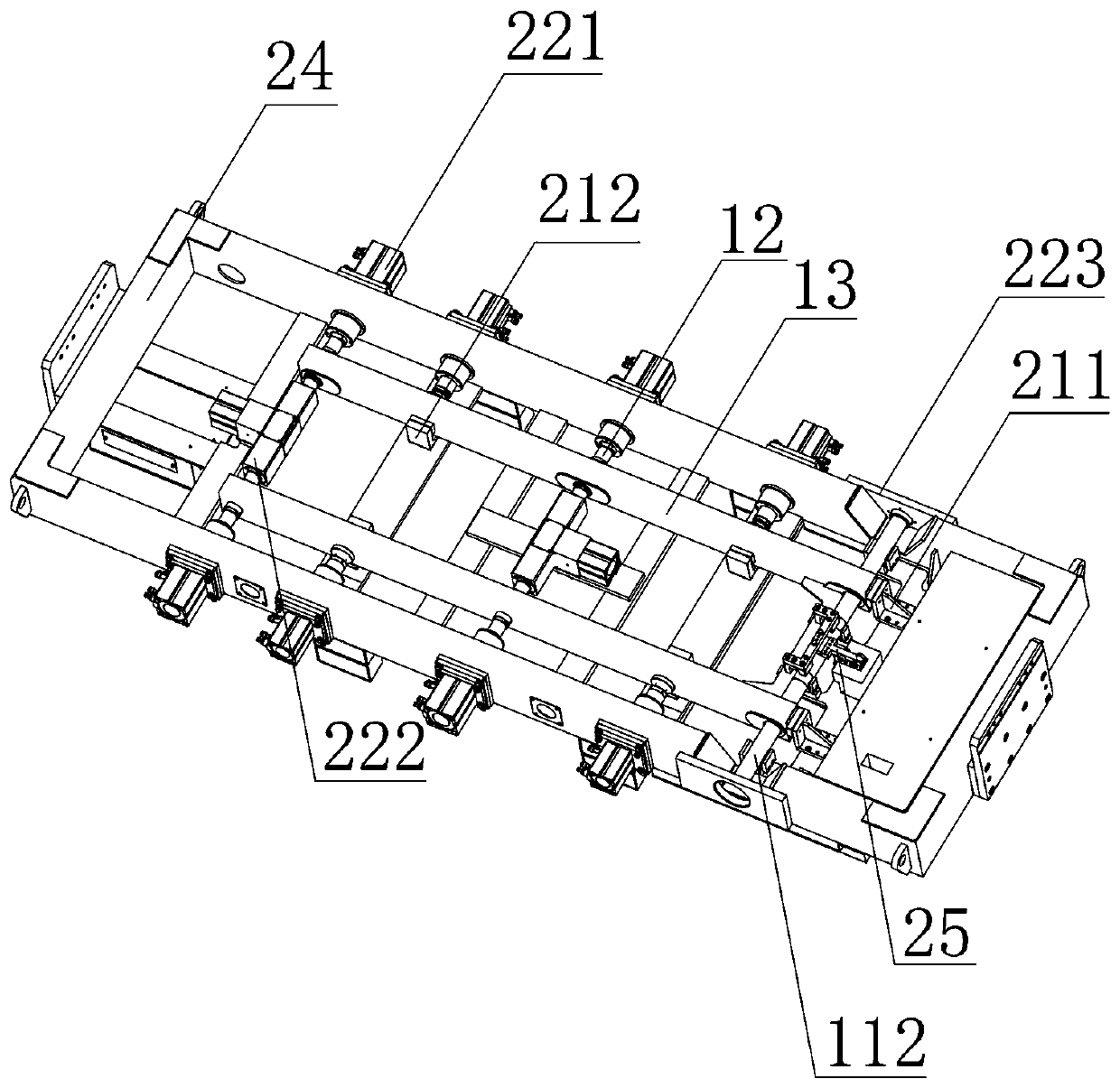

Five-axis triple-linkage turning/drilling/tapping integrated machine

ActiveCN104259860AIncrease productivityReduce logistics timeOther manufacturing equipments/toolsChucksSlide plateLinkage concept

The invention discloses a five-axis triple-linkage turning / drilling / tapping integrated machine. The five-axis triple-linkage turning / drilling / tapping integrated machine comprises a frame, an X-axis guide rail transversely arranged on the frame, a rotation driving device arranged on the left side of the X-axis guide rail, a workpiece clamp located on the right side of the rotation driving device and driven by the servo motor of the rotation driving device to rotate, an X-axis sliding plate arranged on the X-axis guide rail, moving left and right along the X-axis guide rail and located on the right side of the workpiece clamp, an X-axis driving servo motor, an X-axis lead screw mechanism arranged between the X-axis driving servo motor and the X-axis sliding plate, a Z-axis guide rail arranged on the upper end of the X-axis sliding plate, a Z-axis sliding plate arranged on the Z-axis guide rail and moving up and down along the Z-axis guide rail, a Z-axis driving servo motor, a Z-axis lead screw mechanism arranged between the Z-axis driving servo motor and the Z-axis sliding plate, and a four-positon turning mechanism arranged on the Z-axis sliding plate. The five-axis triple-linkage turning / drilling / tapping integrated machine is capable of automatically completing turning, drilling and tapping of the end cover of a motor housing.

Owner:SHANGHAI LONGDAY MACHINERY

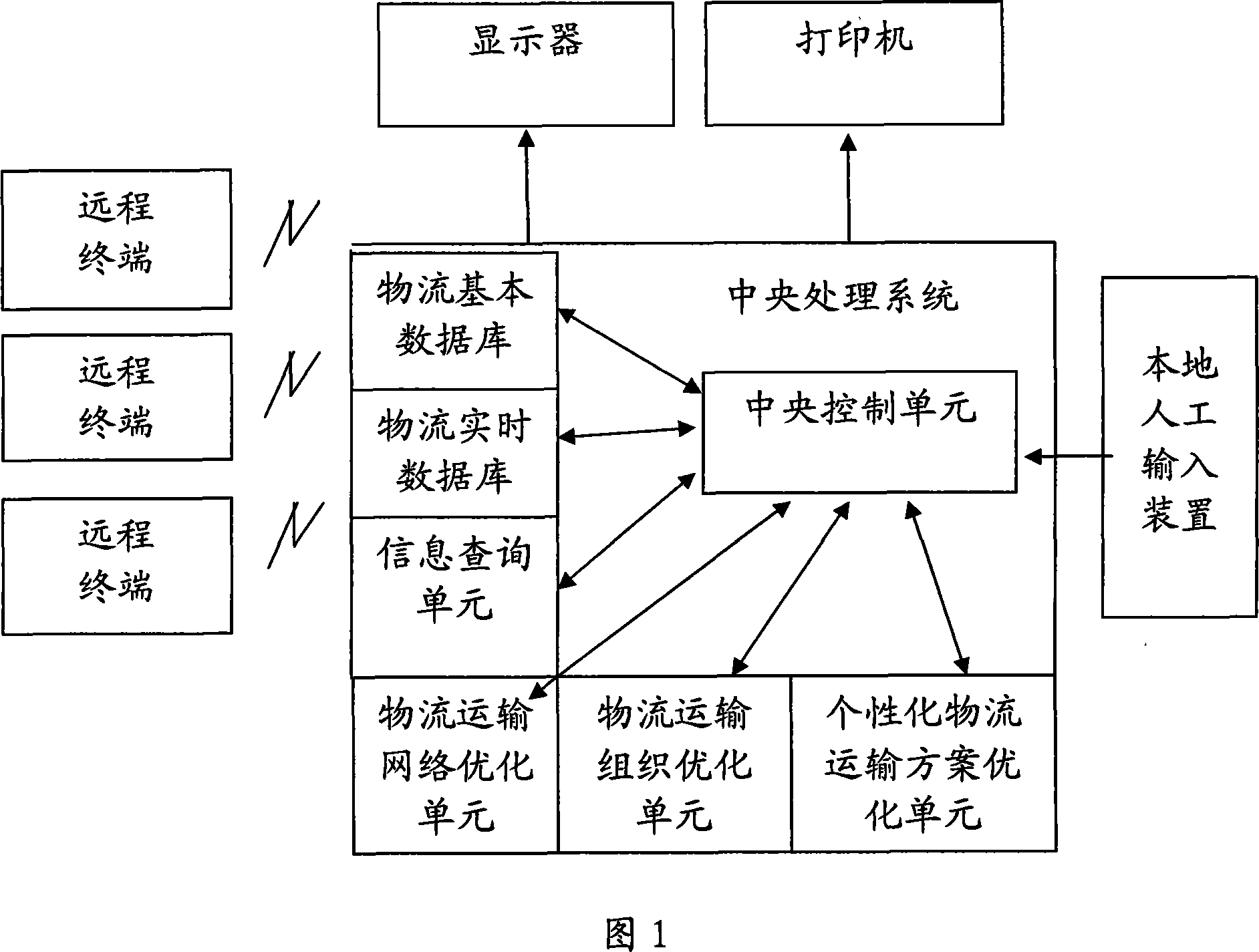

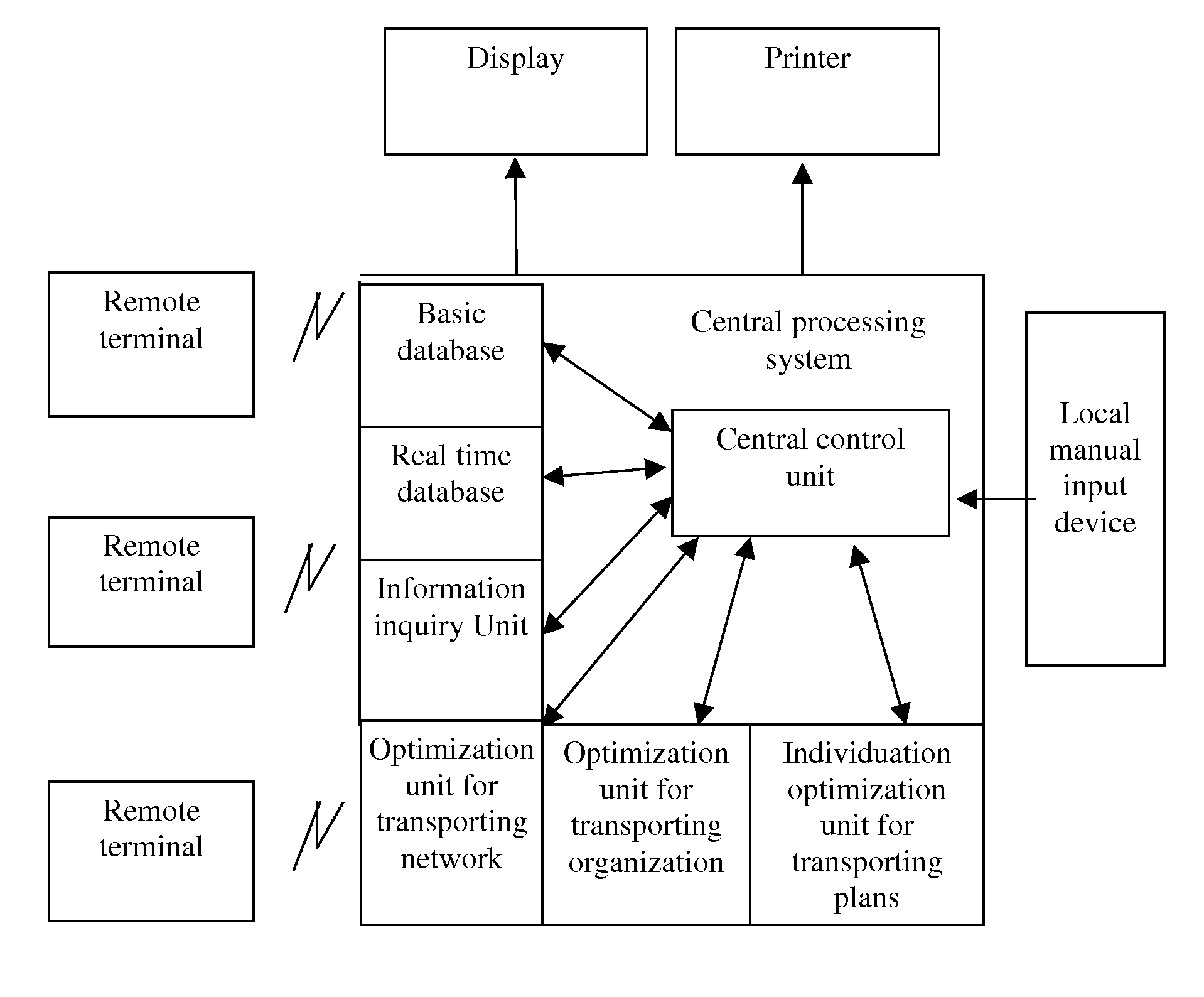

Remote physical distribution optimizing management and counseling system

InactiveCN101251908AImprove operational efficiencySimple designLogisticsSpecial data processing applicationsPersonalizationLogistics management

The invention relates to a remote logistics optimization management and consultation system, which mainly comprises a central processing system and a remote terminal made data exchange with the central processing system, wherein, the remote terminal is provided with a wireless transmitting and receiving module, the central processing system is provided with a supporting wireless transmitting and receiving module, a logistics basic database and a real-time database, and comprises an information query unit, a logistics transportation network optimization unit, a logistics transportation organization optimization unit and a personalized logistics transportation scheme optimization unit, and an optimization operation is made according to the preset program to generate a corresponding optimization scheme. The system contributes to improving the logistics efficiency, reducing the logistics time and decreasing the logistics cost, and can be used for various logistics enterprises or other large-scale enterprises.

Owner:BEIJING AOTENGXUNDA SCI & TECH

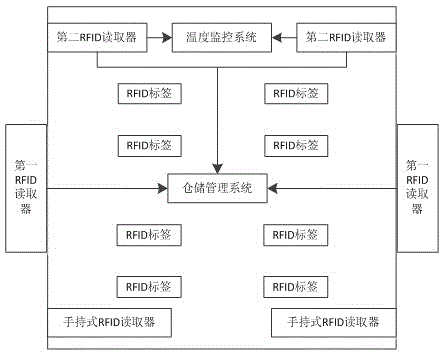

Internet-of-things based agricultural product cold chain logistics management system

InactiveCN105139171ALow costSimplify the work processSensing record carriersLogisticsCold chainLogistics management

The invention provides an internet-of-things based agricultural product cold chain logistics management system. The system comprises RFID labels arranged on agricultural product packages, first RFID readers arranged on entrance and exit of an agricultural product warehouse, second RFID readers arranged in the agricultural product warehouse as well as a temperature monitoring system and a warehouse management system arranged in the agricultural product warehouse; each RFID label stores a production place, a type, a processing date, a provider and a temperature point of an agricultural product; each second RFID reader reads the RFID label, transmits the temperature point to the temperature monitoring system and transmits remaining information to the warehouse management system; and each first RFID reader reads RFID label information, records in-warehouse and out-warehouse time and quantity of the agricultural product and uploads the in-warehouse and out-warehouse time and quantity of the agricultural product to the warehouse management system. According to the internet-of-things based agricultural product cold chain logistics management system, manual input links are reduced, the RFID labels can identify the in-warehouse and out-warehouse information of the agricultural product packages in batch, the efficiency can be obviously improved, and the labor is saved; and the temperature information of the agricultural product packages is collected at any time in a stock process, and when abnormality occurs, the system can give an alarm, thus reducing the cargo loss rate.

Owner:苏州田园优贡电子商务有限公司

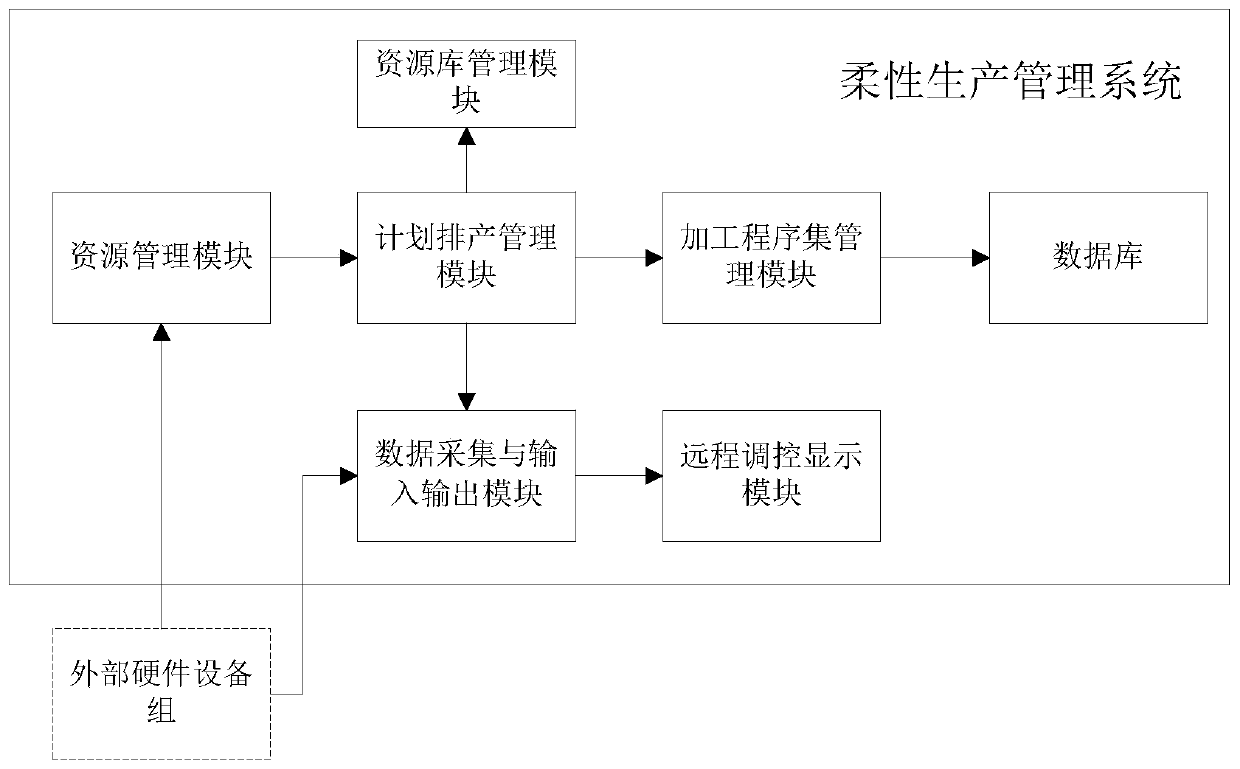

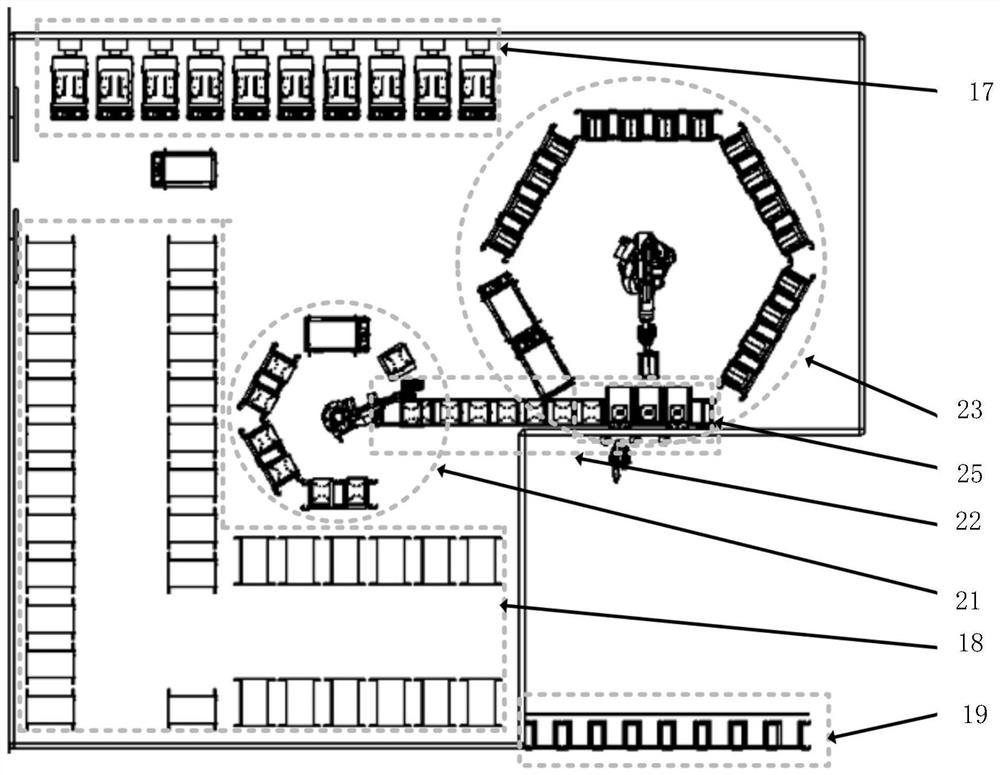

Flexible production management system

InactiveCN111538295AGuaranteed unobstructedIncrease incomeTotal factory controlProgramme total factory controlInformatizationData acquisition

The invention relates to a flexible production management system, which comprises a data acquisition and input / output module, a remote regulation and control display module, a resource management module, a plan production scheduling management module, a machining program set management module, a tool management module and a resource library management module. According to the invention, material identification, warehousing, production scheduling, logistics distribution, production polishing processing, cutter clamp replacing and the like are completed automatically, so that the production process is transparent and intelligent; and lean ideas are injected into intelligent hardware, an informatization system and embedded software, and the system and the hardware equipment group perform bidirectional interaction through a data acquisition device and a remote control device and perform self-organizing and self-adapting ordered production according to a demand plan.

Owner:DALIAN YUYANG IND INTELLIGENT

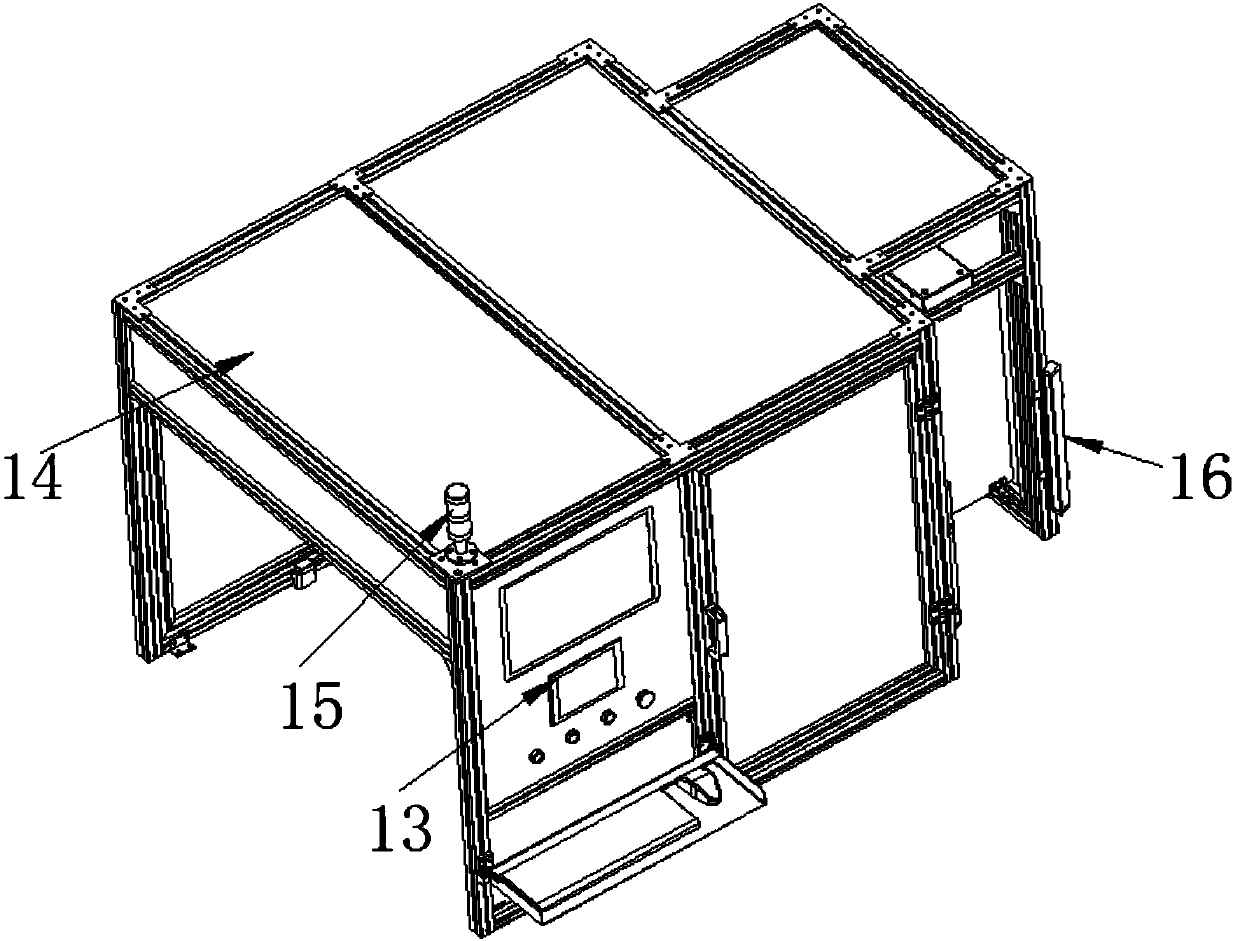

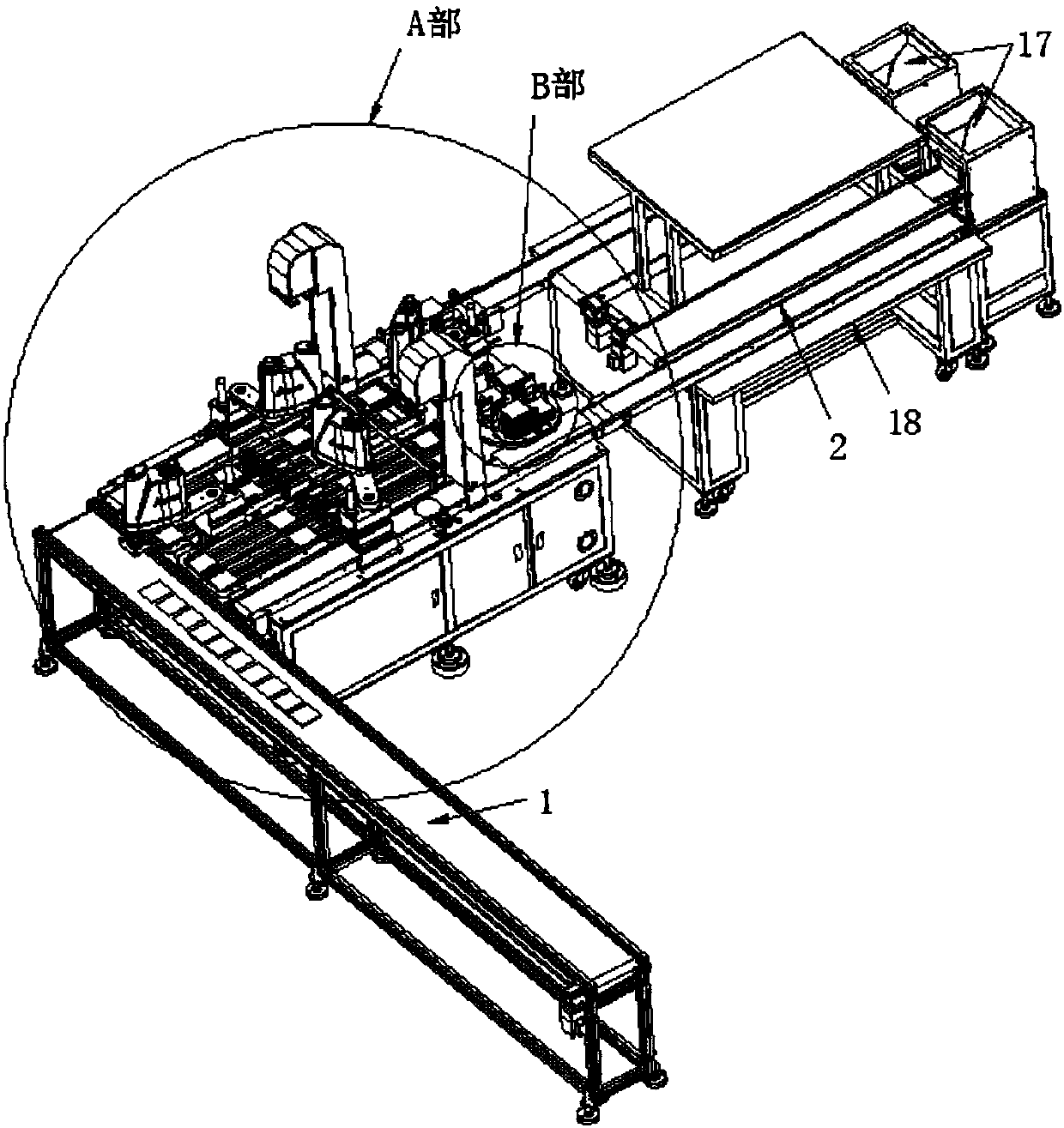

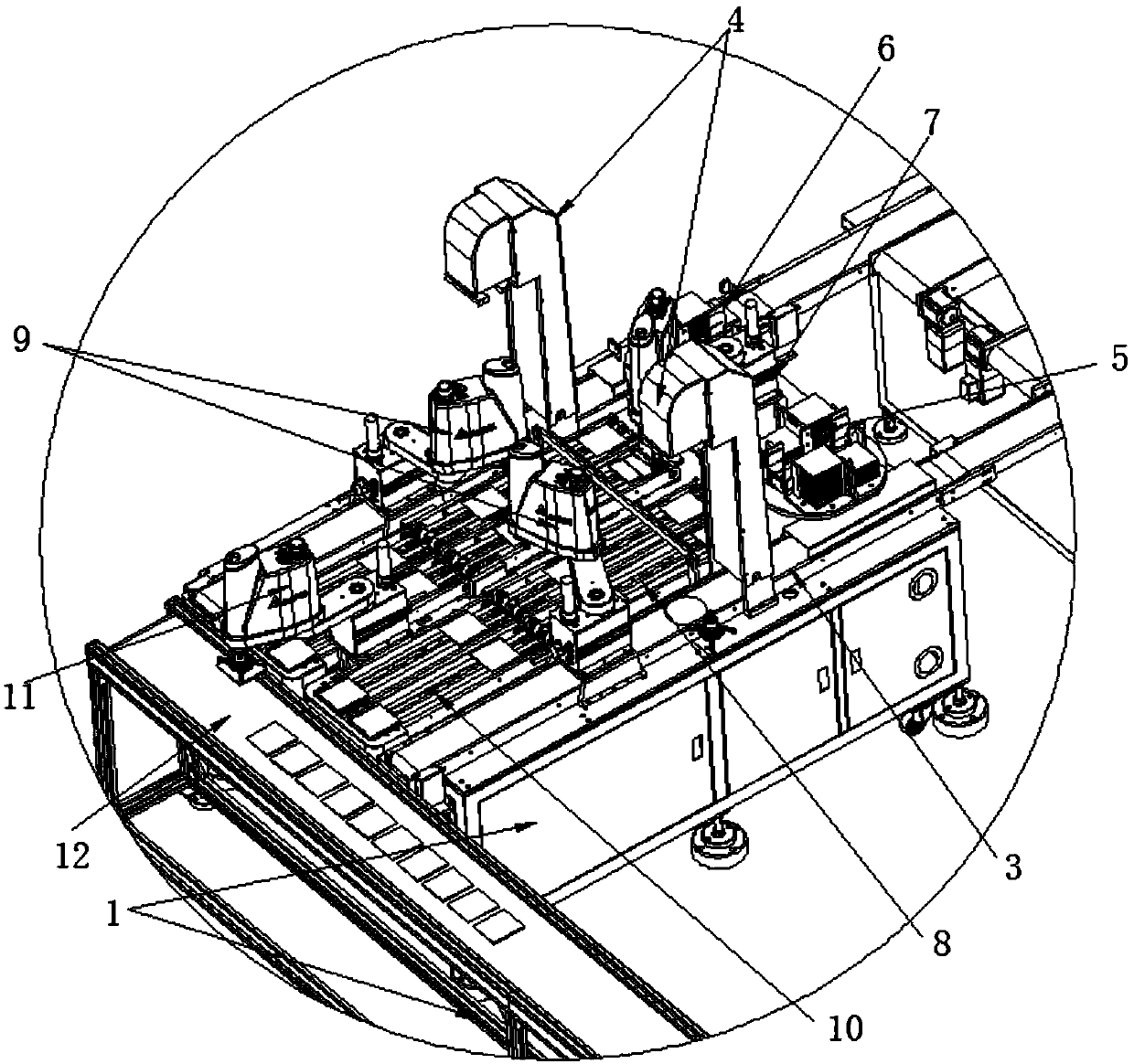

MIM full-automatic component placement equipment

PendingCN107891153AReduce labor inputImprove work efficiencyTotal factory controlProduction lineVisually guided

The invention provides MIM full-automatic component placement equipment and relates to the technical field of hardware processing and production equipment. A stander main body is of an ''L''-shaped structure, sorting-conveying belts are arranged on the front and rear sides of an inlet side of the stander main body, a vision guiding device is arranged on each sorting-conveying belt, and the bottomend of the vision guiding device is connected to the inlet side fixed at the stander main body; a ceramic plate loading mechanism I and a ceramic plate loading mechanism II are respectively arranged on upper production lines of the sorting-conveying belts on two sides of the stander main body and are fixed at a port of the inlet side of the stander main body; and feeding-conveying belts are connected to inlet ends of the two sorting-conveying belts. According to the MIM full-automatic component placement equipment, the drawbacks in the prior art can be overcome, the manual operation is not required, and multiple equipment can be operated by one operator, so that the labor input is greatly reduced, the working efficiency is improved, the working quality is guaranteed, the interprocess physical distribution time is greatly shortened, and the practicability is relatively strong.

Owner:DONGGUAN HUAJING POWDER METALLURGY

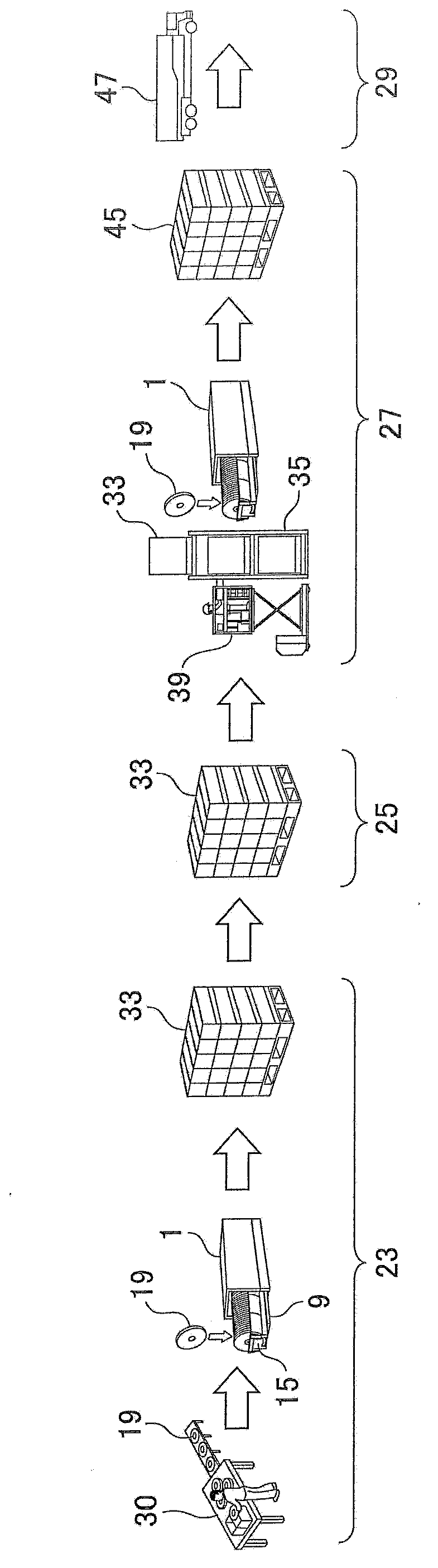

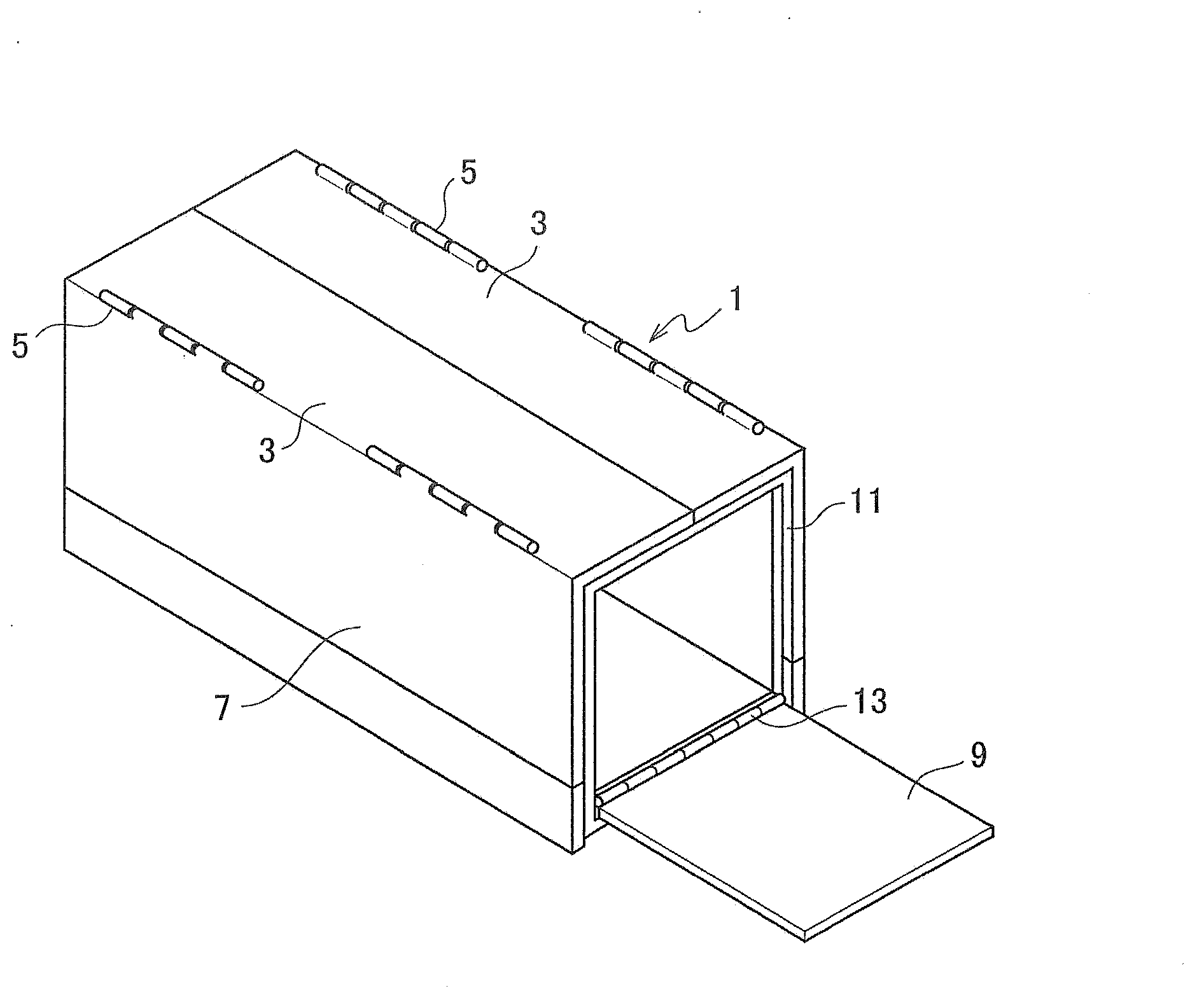

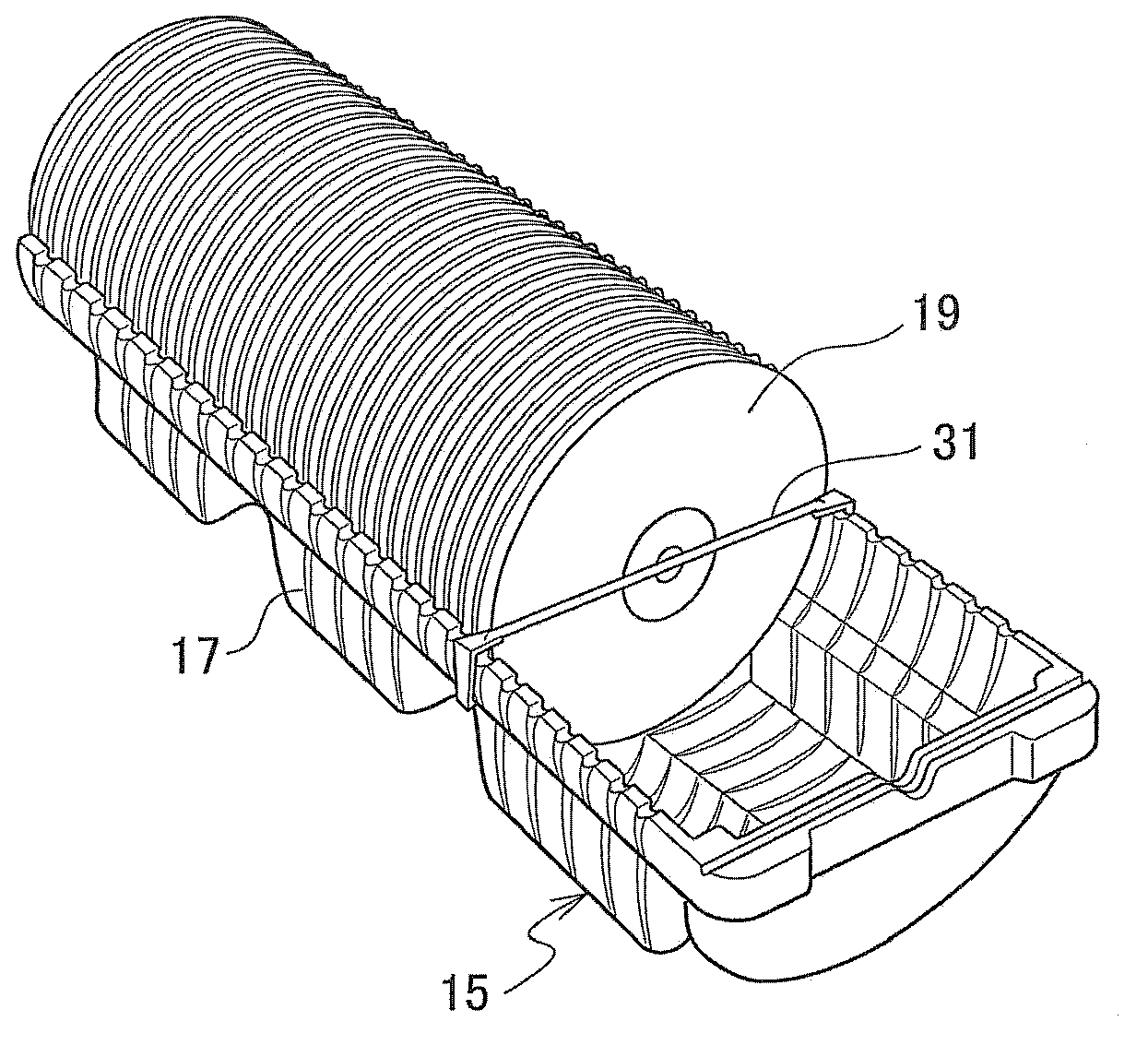

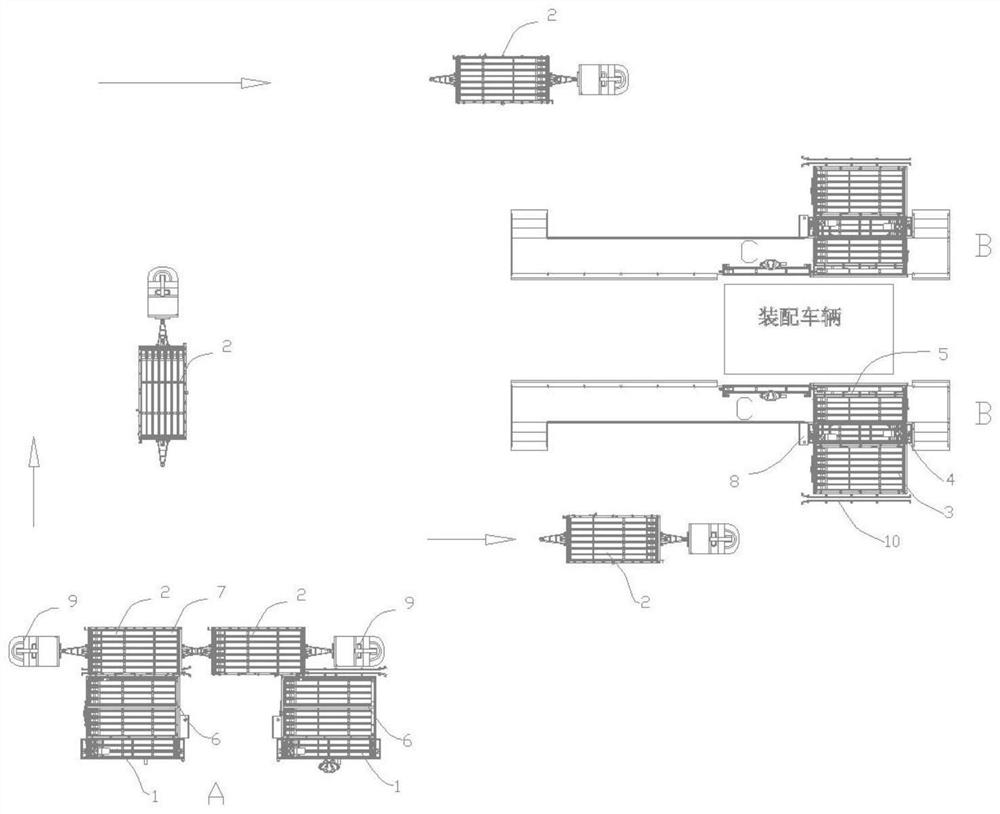

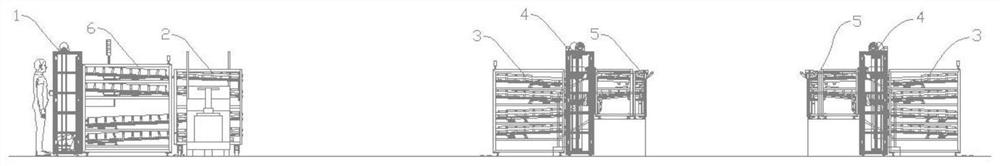

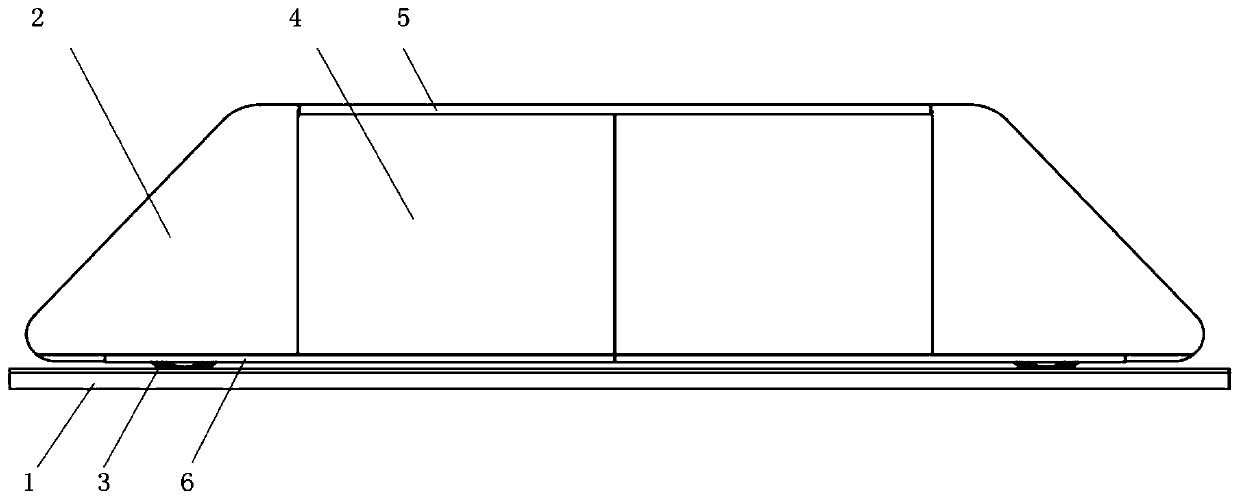

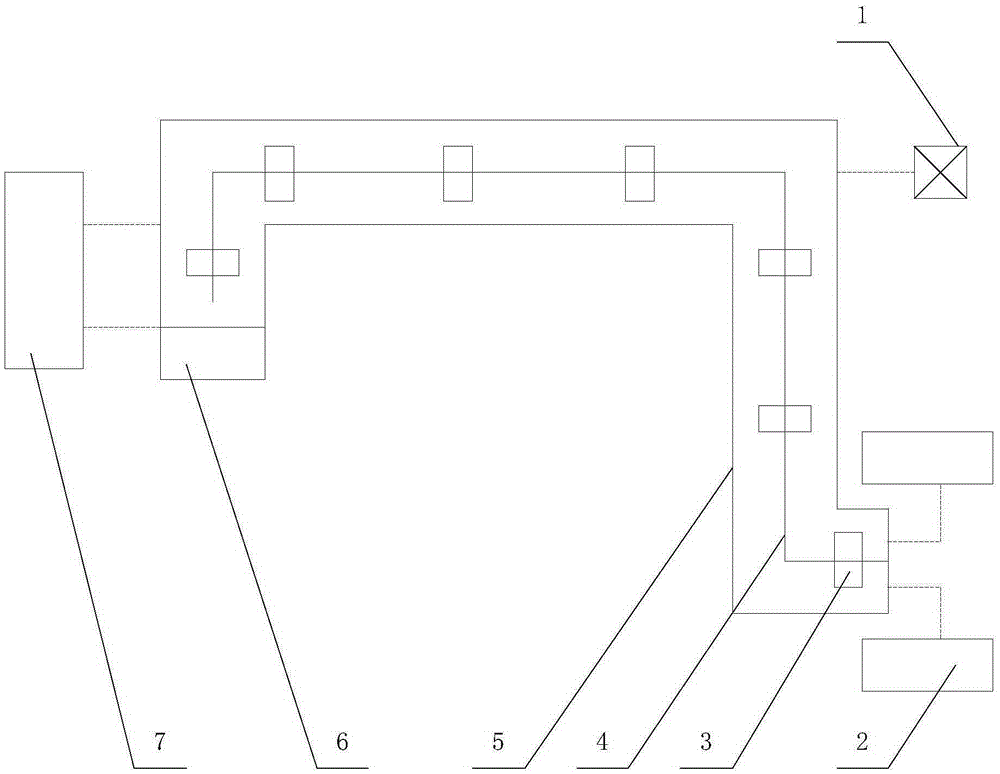

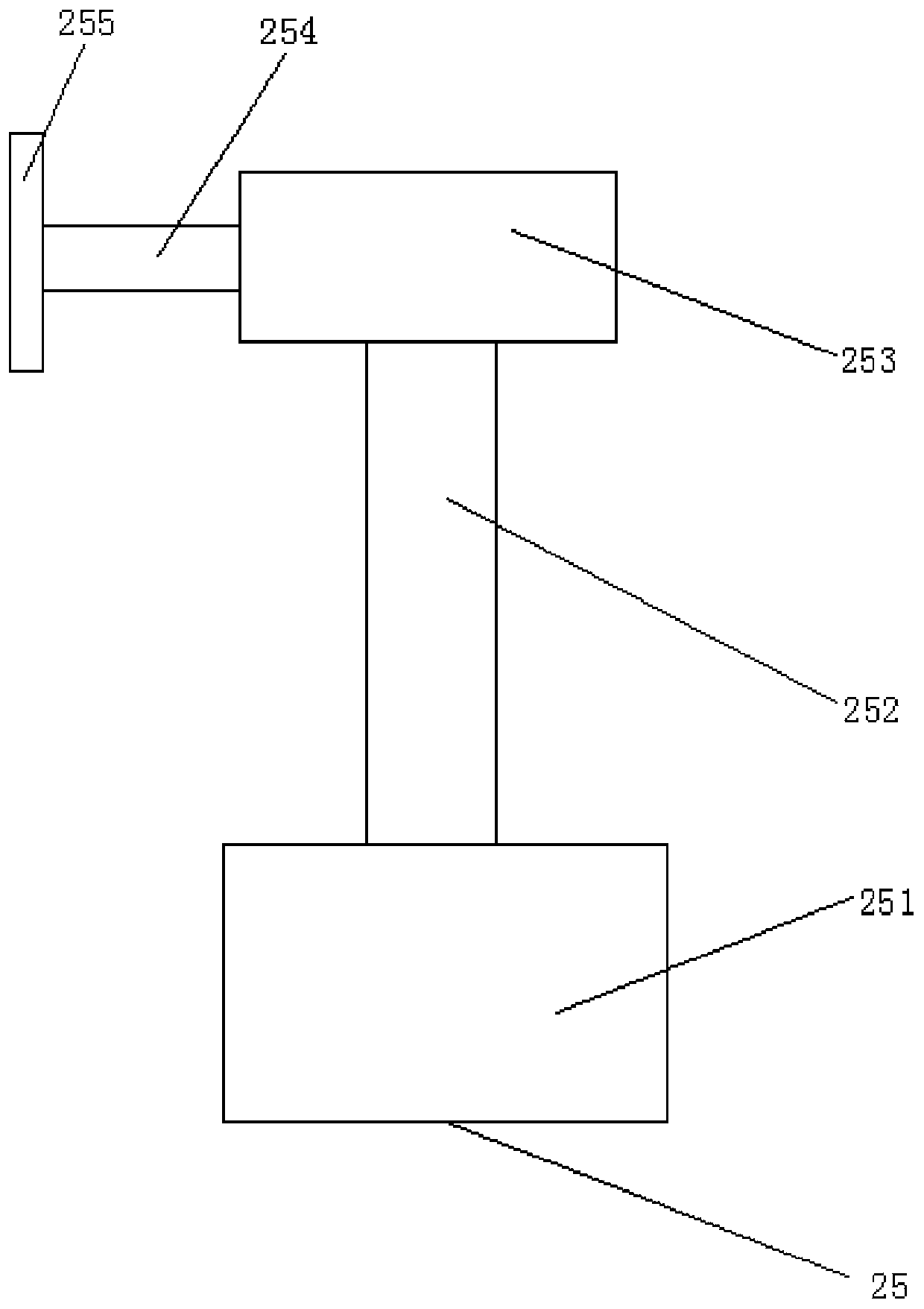

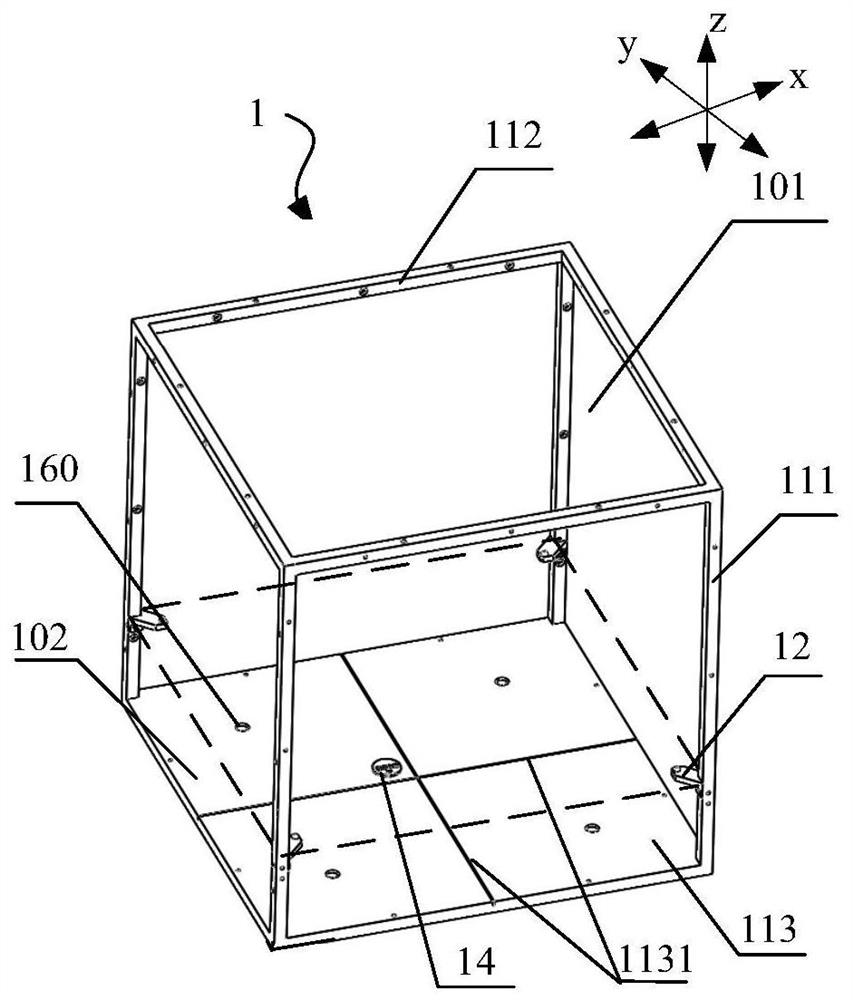

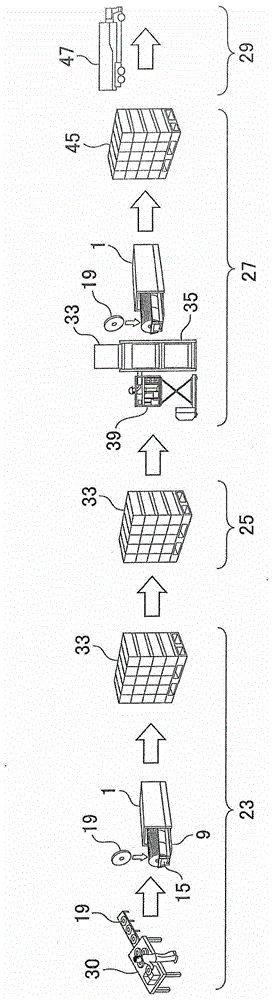

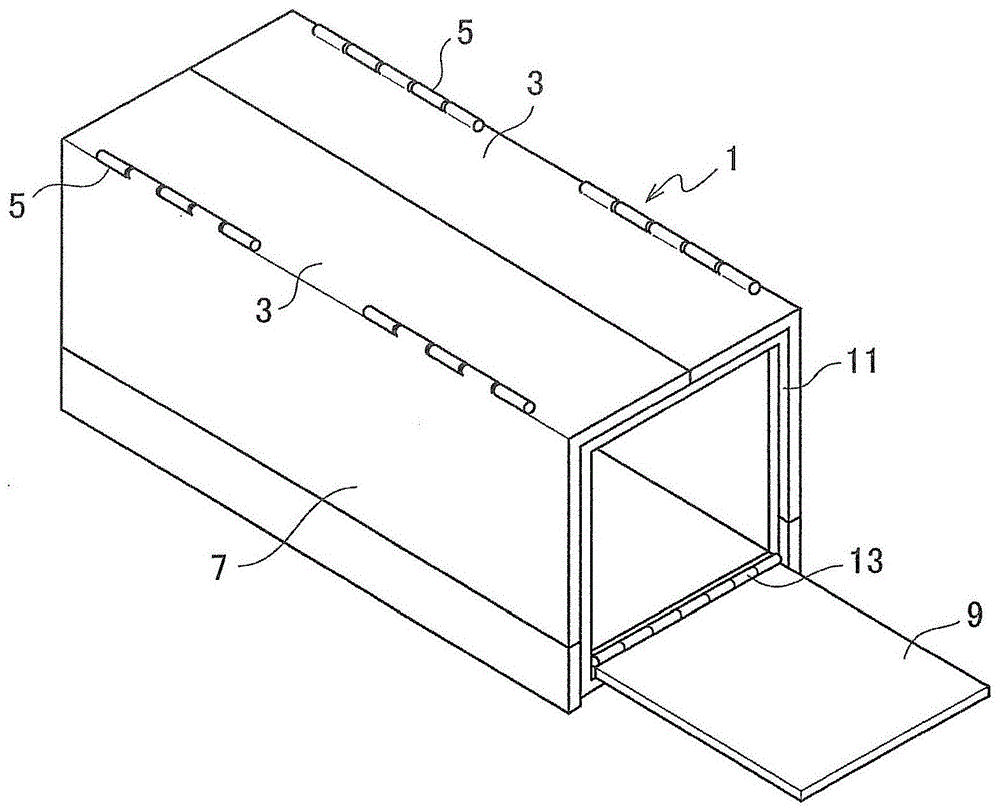

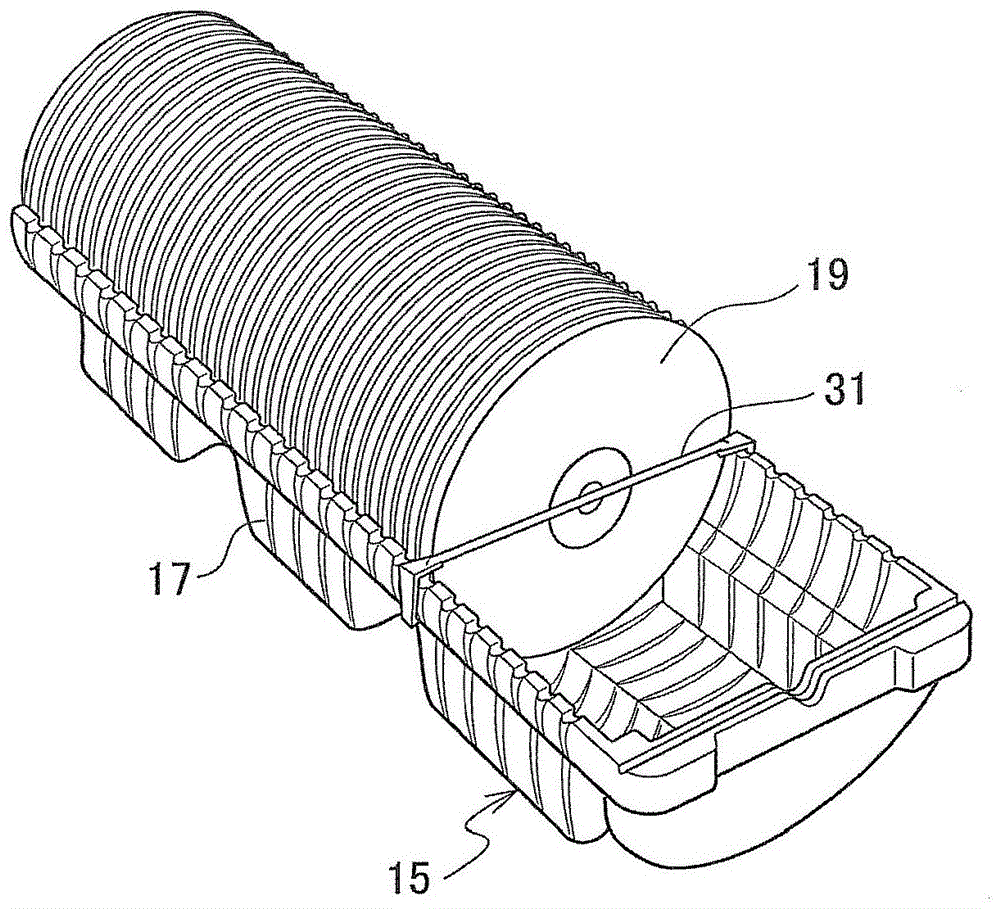

Logistic method of object

ActiveCN103359417AReduce the burden onReduce logistics timePackage recyclingContainers for annular articlesLogistics managementComputer science

The invention aims to mitigate the load of a worker in an object transporting, keeping and selecting process, and aims to reduce the logistic time. The logistic method of the object comprises the following steps: a first step (23) of containing the object (19) sent from the factor in a package; a second step (25) of gathering and keeping the packages; a third step (27) of forwarding the object pulled from the kept package to a package to be sent away according to the requests of a delivery party; a fourth step (29) of transporting the package to be sent through a transportation mechanism. The packages used in the steps employ same shape; the package comprises a special purpose carrier (15) containing many objects and a special purpose container (1) for containing the special purpose carrier; the special purpose container (1) is made of resin and in a rectangular box shape; at least one side of the short side faces of the special purpose container is provided with an open-close door allowing the special purpose carrier to enter or exit in a length direction of the special purpose container.

Owner:SANKYU INC +1

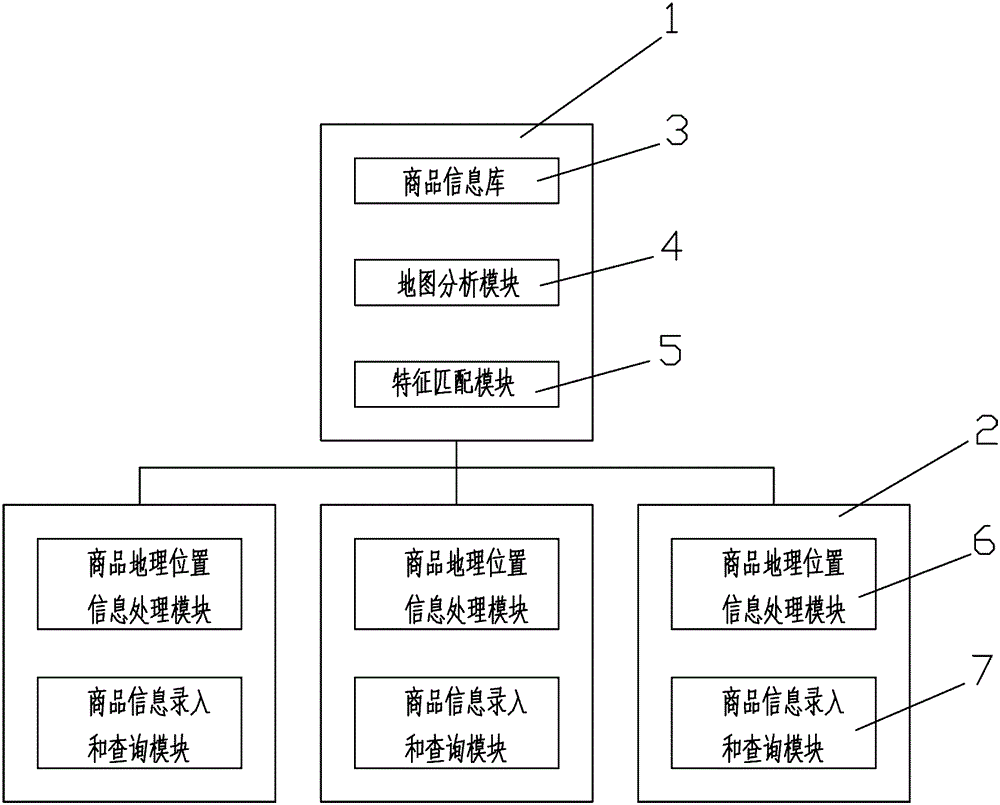

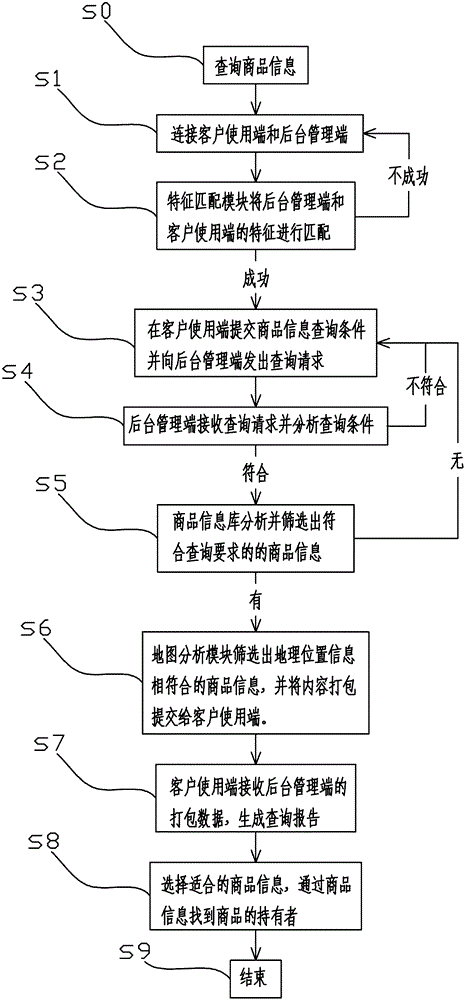

Commodity information sharing method

InactiveCN106530053AAchieve sharingReduce logistics costsBuying/selling/leasing transactionsInformation repositoryInformation processing

Disclosed in the invention is a commodity information sharing method. A background management terminal 1 and client usage terminals 2 are arranged and carry out communication by an internet network. The background management terminal 1 consists of a commodity information base 3, a map analysis module 4 and a feature matching module 5; and the client usage terminals 2 include commodity information inputting, recording and query modules 6 and commodity geographic position information processing modules 7. The background management terminal 1 and the distributed client usage terminals 2 are arranged; the commodity information base 3 is arranged at the background management terminal 1; the commodity information inputting, recording and query modules 6 arranged at the client usage terminals 2 are used for recording and inputting different commodity information into the commodity information base 3 together; the commodity information base 3 is used for realizing sharing of the collected commodity information; the commodity information inputting, recording and query modules 6 arranged at the client usage terminals 2 are used for inquiring the commodity information base 3 to inquire any piece of commodity information in the commodity information base 3. Therefore, commodity information sharing is realized.

Owner:肖欣城

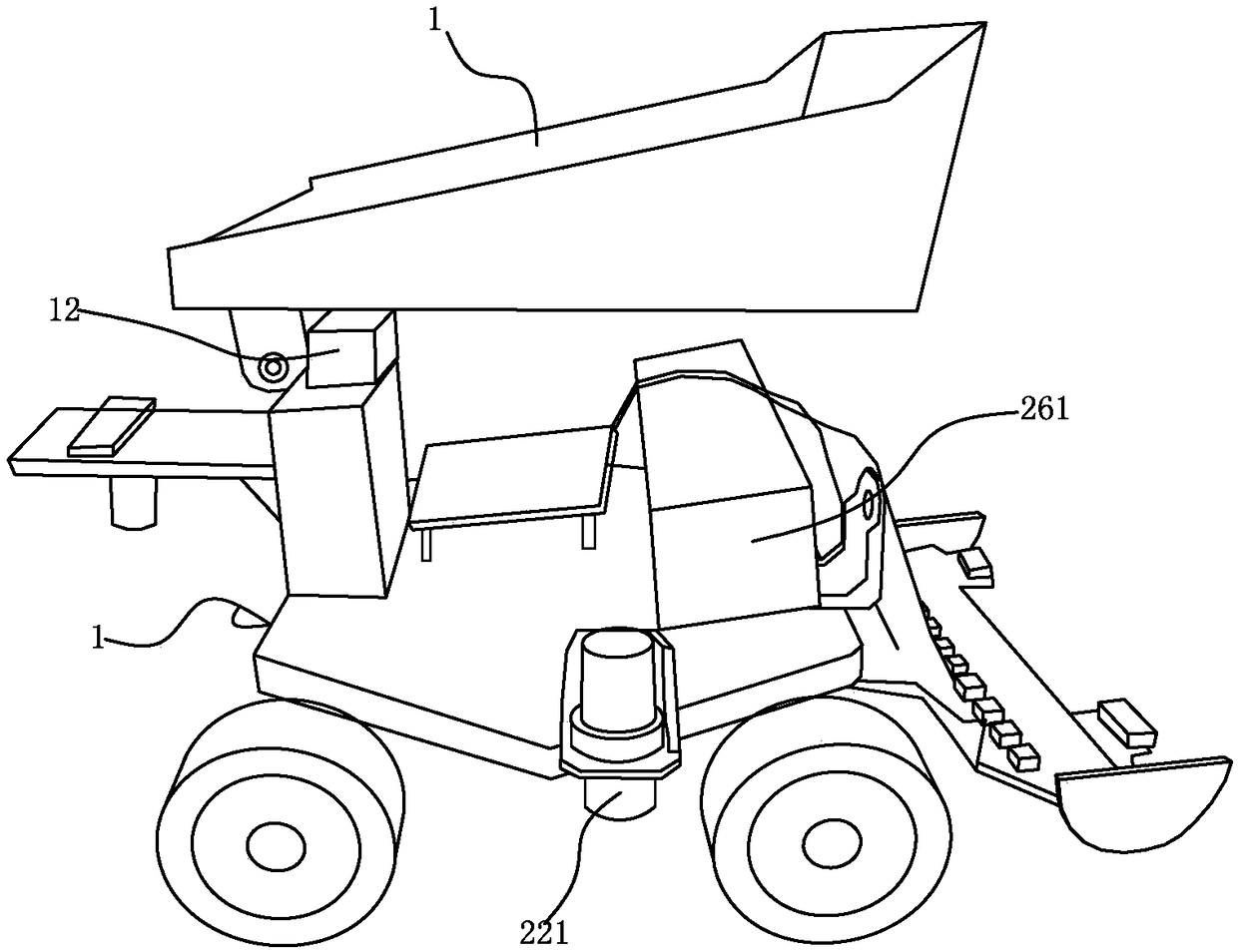

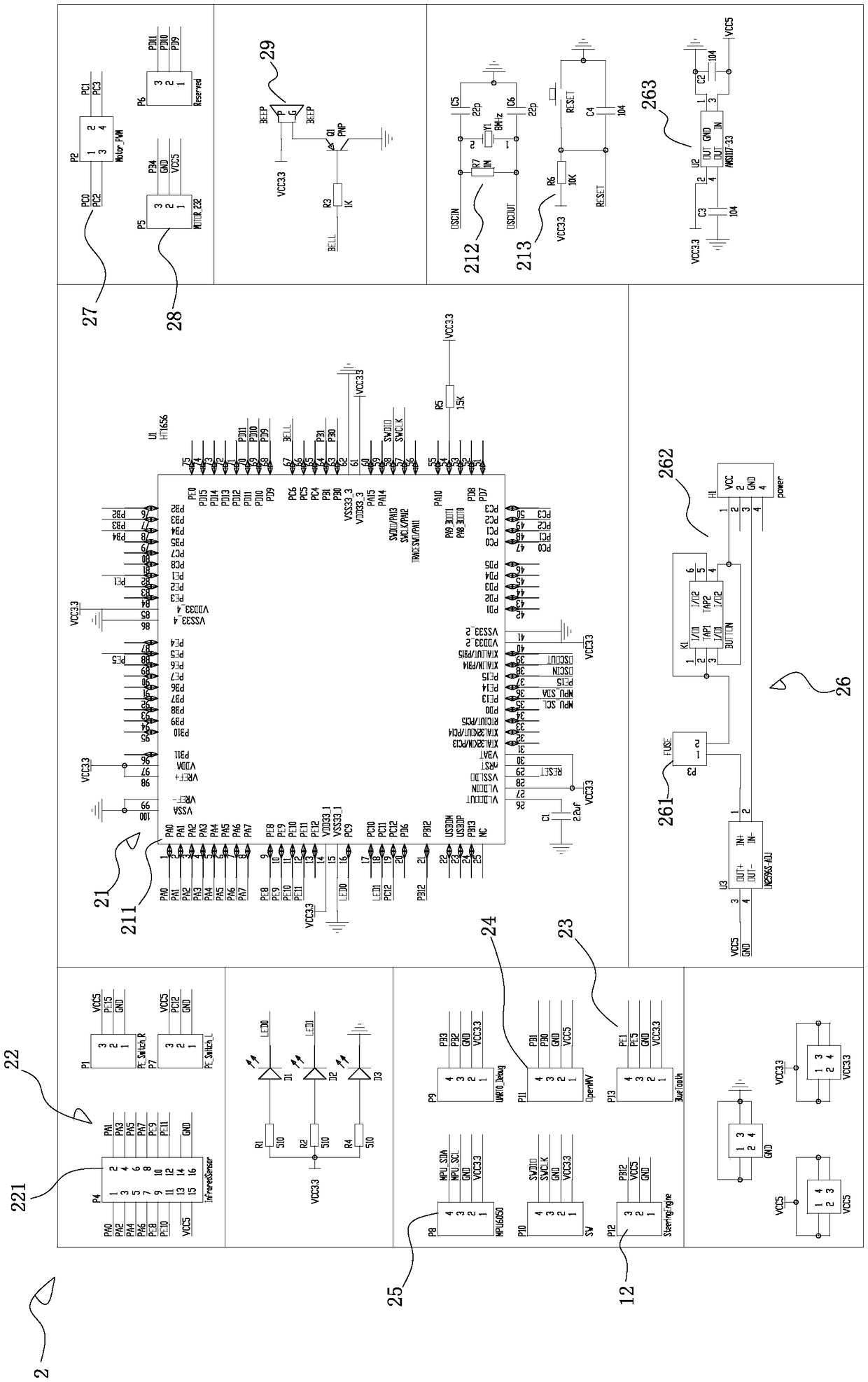

Scanning and tracing logistics trolley and logistics transportation method thereof

PendingCN109032152AIncrease sorting costIncrease shipping costsPosition/course control in two dimensionsVehiclesLogistics managementGyroscope

The present invention discloses a scanning and tracing logistics trolley and a logistics transportation method thereof. The scanning and tracing logistics trolley comprises a logistics trolley main body and an electronic control unit. The logistics trolley main body is provided with a loading hopper and a steering engine used for driving the loading hopper to tilt and dump goods. The electronic control unit comprises a main control circuit board, wherein the steering engine is electrically connected with the main control circuit board; a sensor module used for acquiring route(s) and route intersection information, wherein the sensor module is electrically connected with the main control circuit board; a wireless communication module used for forming electrical connection with a mobile terminal, wherein the mobile terminal sends preset route information to the main control circuit board via the wireless communication module; a camera module used for scanning to get destination information, wherein the camera module is electrically connected with the main control circuit board; a gyroscope module used for acquiring the the course angle of the logistics trolley, wherein the gyroscopemodule is electrically connected with the main control circuit board; a power supply module used for supplying power, wherein the power supply module is electrically connected with the main control circuit board; and a left motor and a right motor arranged at the lower end of the logistics trolley main body, wherein the left motor and the right motor are separately used for driving a left front wheel and a right front wheel to rotate.

Owner:DONGGUAN UNIV OF TECH

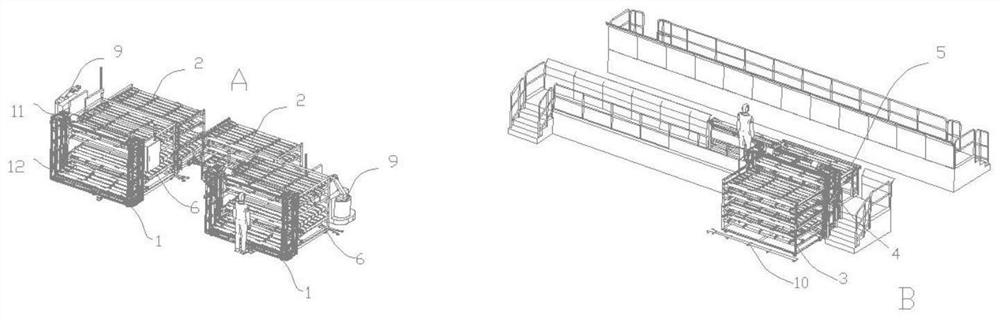

Automobile baggage holder and antenna base mixed sorting and automatic butt joint online and offline system

InactiveCN112009597AImprove the protective effectGuarantee quality requirementsVehiclesControl systemOnline and offline

The invention provides an automobile baggage holder and antenna base mixed sorting and automatic butt joint online and offline system which comprises a plurality of mixed sorting packaging boxes, a first lifting device, a material transfer trolley, a line edge butt joint storage device, a second lifting device, a transition material taking and recycling device and a control system, and the first lifting device is arranged in a sorting area; the material transfer trolley is used for transferring the mixed sorting packaging boxes from the sorting area to the material taking area; the line edge butt joint material storage device, the second lifting device and the transition material taking and recycling device are sequentially arranged in the material taking area in a butt joint mode. The transition material taking and recycling device is arranged at a material taking point, the second lifting device is arranged between the line edge butt joint material storage device and the transition material taking and recycling device, and the mixed sorting packaging boxes can be switched between the line edge butt joint material storage device and the transition material taking and recycling device along with ascending and descending of the second lifting device. All the devices in the sorting area and the material taking area can be automatically connected in a butt joint mode, the automation degree is high, and the distribution efficiency is high.

Owner:GAC FIAT CHRYSLER AUTOMOTIVE CO LTD

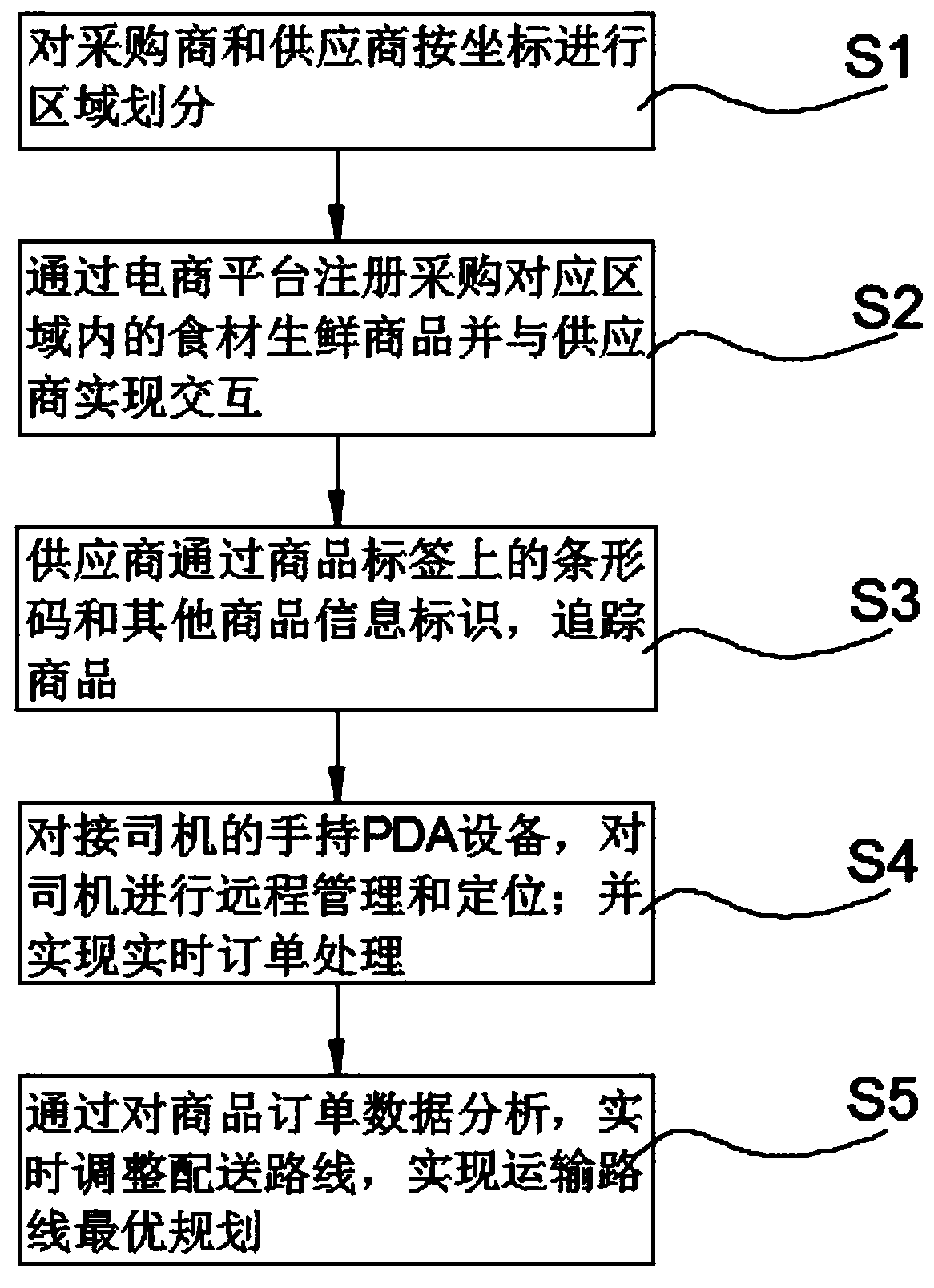

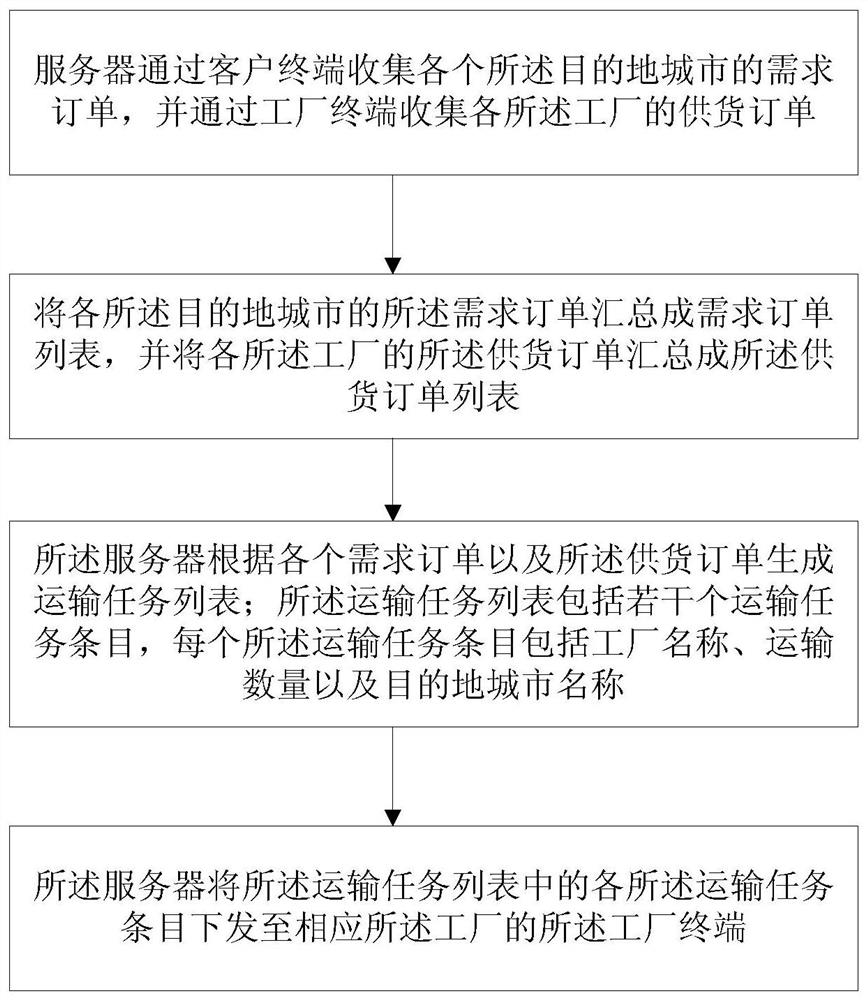

Intelligent warehouse logistics management method and system

PendingCN111461389AReduce logistics timeAvoid empty trucks without goodsForecastingLogisticsLogistics managementElectronic identification

The invention relates to the technical field of intelligent logistics, in particular to an intelligent warehouse logistics management method and system, and the method comprises that: the regional division of purchasers and suppliers is performed according to coordinates; food material fresh commodities in corresponding areas are registered and purchased through the e-commerce platform and realizing interaction with suppliers; a supplier identifies the commodity through a bar code on the commodity label and other commodity information; handheld PDA equipment of a driver is docked, and remote management and positioning are carried out on the driver; real-time order processing is realized; through commodity order data analysis, a distribution route is adjusted in real time, and optimal planning of a transportation route is realized; and unified management of commodity movement, electronic identification and commodity tracking are realized, and logistics time is shortened to create value.The transportation route is optimally planned, and empty vehicle cargo-free transportation, roundabout transportation, repeated transportation, backflow transportation, over-distance transportation and dispatched material recruitment are avoided. Comprehensive services are provided to users. The user request is responded at a high speed, and the expectation of food fresh products and services isimproved.

Owner:淘大集(武汉)供应链有限公司

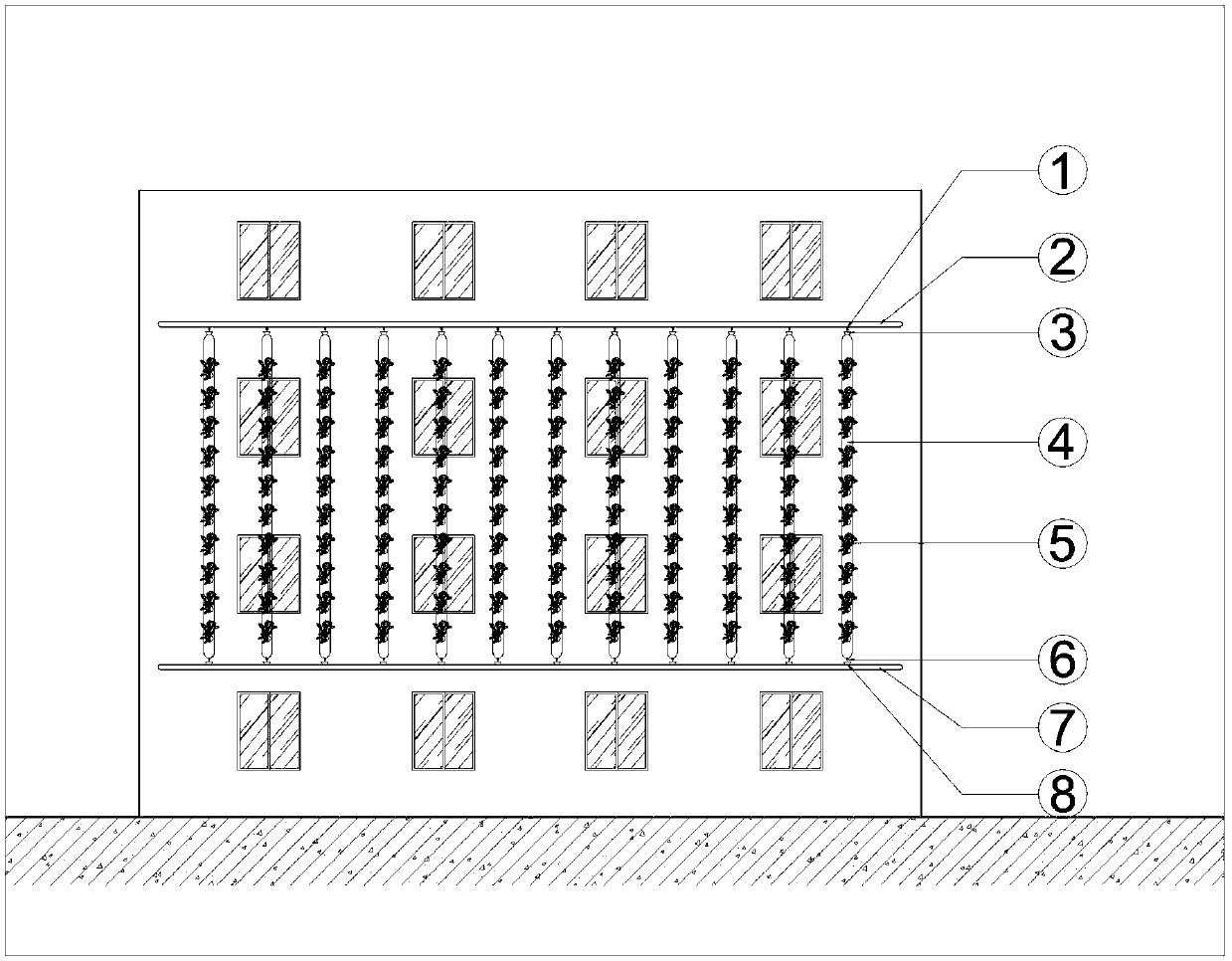

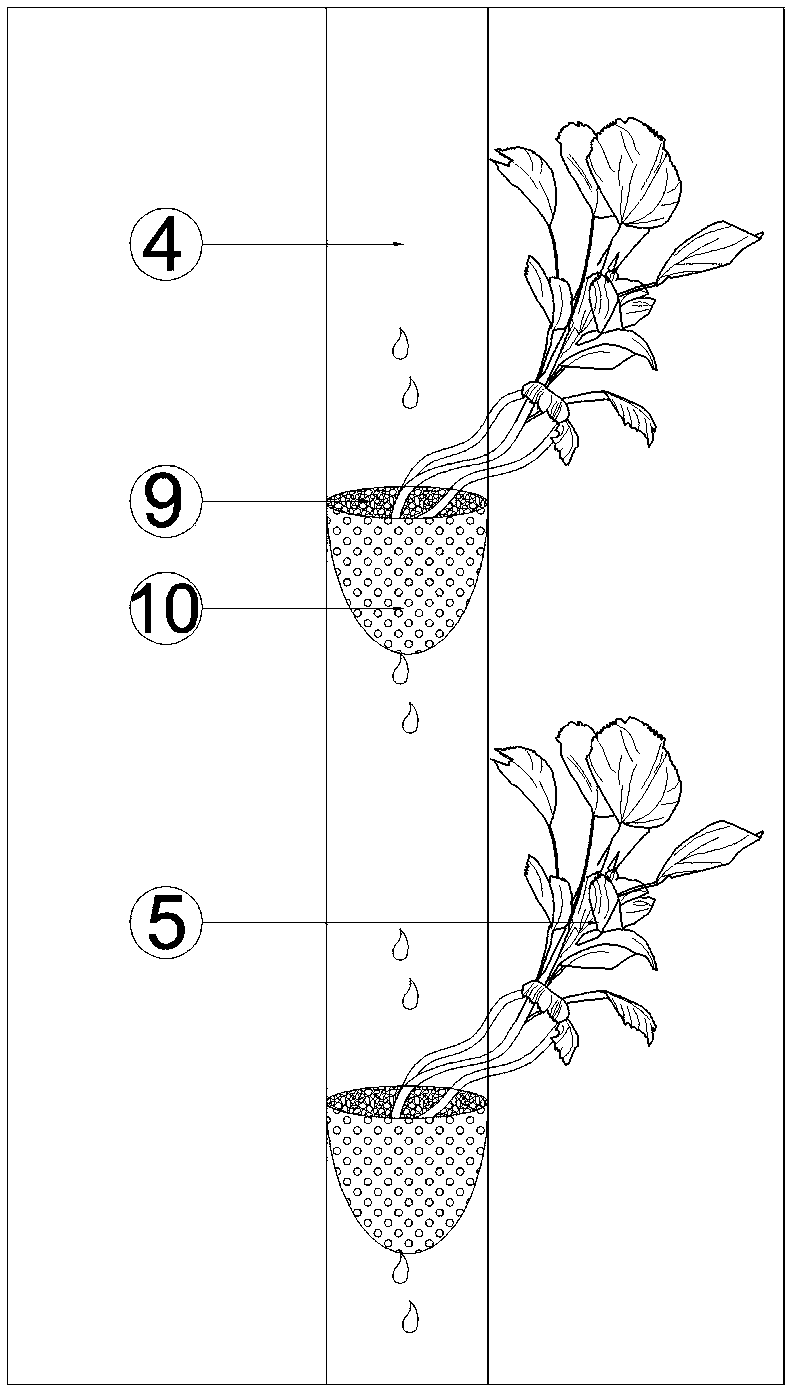

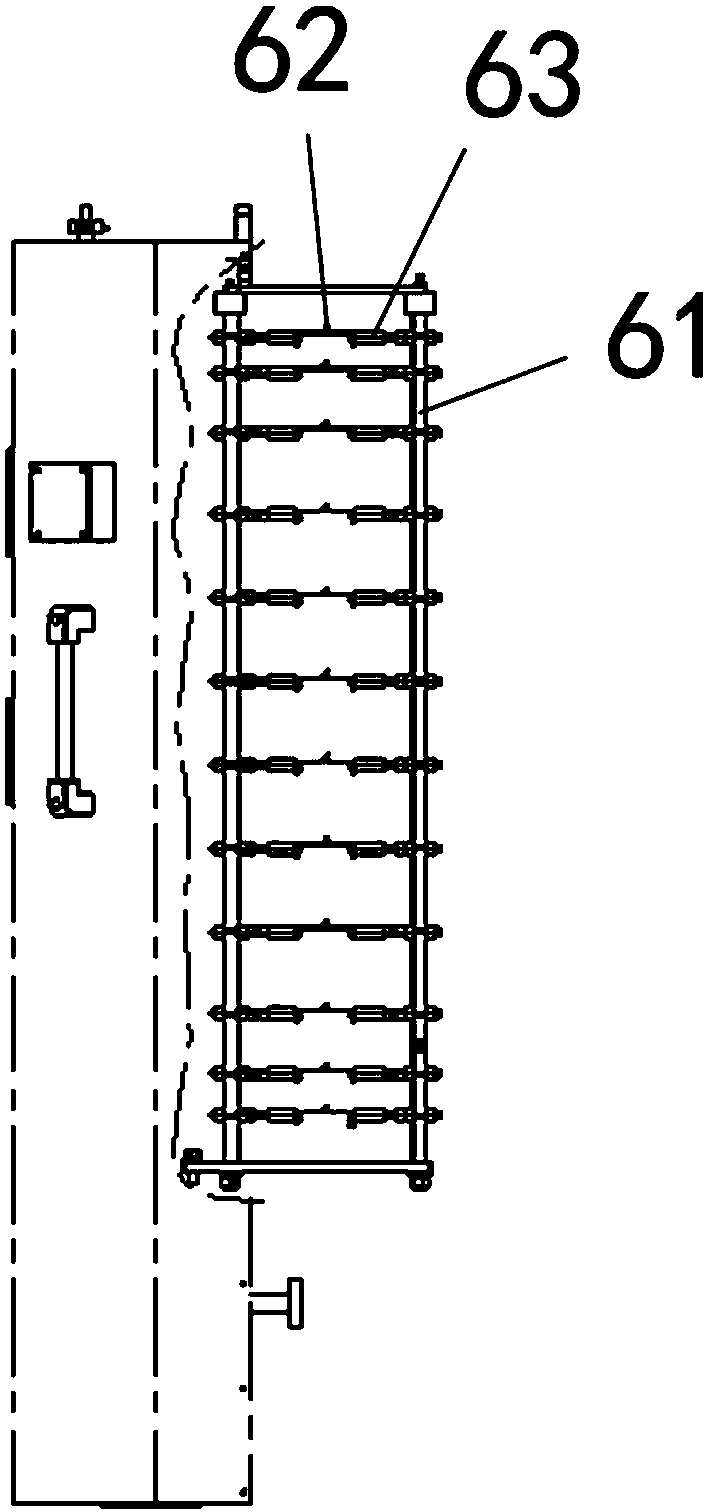

Vertical farm

InactiveCN110278863AMake full use of the spaceTake full advantage of the characteristicsClimate change adaptationAgriculture gas emission reductionSpray nozzleEconomic benefits

The invention provides a vertical farm. A vegetable stereoscopic culture mode is innovatively put forward through an existing building, the vertical space layout advantages and characteristics are brought into full play, the problem that cultivated land resources are lacked in the current world is solved, the urban heat island effect can be reduced, the inside and outside temperature of the building are adjusted, energy is saved, the urban air quality is improved, and economic benefits are improved. By means of the scheme, the vertical farm comprises a nutrient solution spraying nozzle, a nutrient solution supply pipeline, a supply hopper, a vertical planting pipeline, plants, a nutrient solution outlet, a nutrient solution recovery pipeline, a recovery hopper, a culture medium and a water-permeable substrate container. The vertical farm is characterized in that a nutrient solution passes through the nutrient solution spraying nozzle from the nutrient solution supply pipeline, enters the supply hopper, and flows through the vertical planting pipeline to be poured on the culture medium, and the redundant nutrient solution can flow to the recovery hopper from the nutrient solution outlet at the lower end to be collected in the nutrient solution recovery pipeline to be recovered. The nutrient solution evenly circulates and flows in the system, and the stability and health of the vertical farm are ensured.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

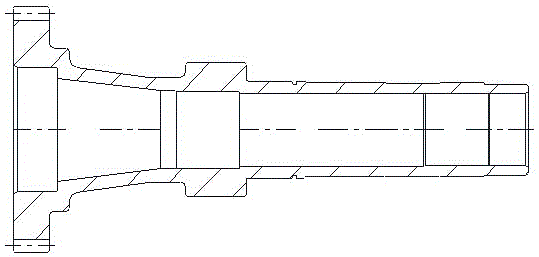

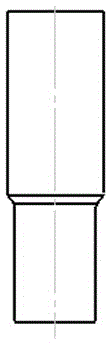

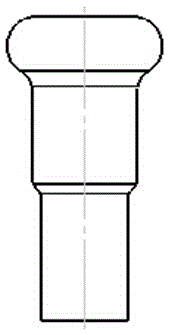

Manufacturing method for precisely-forged blank of outer input shaft II of automatic dual clutch transmission (DCT) of automobile

The invention provides a manufacturing method for a precisely-forged blank of an input shaft II of an automatic dual clutch transmission (DCT) of an automobile. Surface grinding, lubricant spraying and drying are conducted on a material section, cold diameter reduction treatment is conducted on the material section in a grinding tool, and the material section is heated to 1000 DEG C-1080 DEG C in a protective atmosphere; blank forming and heading are conducted on a press machine, and a hot manufactured blank piece is obtained; a concave guide groove with the depth being 5-8 mm is pre-forged; then hot extrusion is conducted, a deep hole with the aperture ratio being smaller than or equal to 4.5 is formed through extrusion, and the bottom thickness of the deep hole is greater than or equal to D / 2; isothermal annealing is conducted, shot blasting is conducted then, and phosphorization and saponification are conducted on the surface; a cold extrusion machine is used, and the final forged blank is obtained; and machining and distressing heat treatment are conducted. According to the method, the inner hole is formed through extrusion, the metal flow line is reserved, mechanical strength is improved by 25%, and the phenomenon that a bevel gear on the input shaft II is stressed and consequently the tube wall is broken can be prevented effectively; the material utilization rate is increased by 22%, and machining efficiency is improved substantially; the quality of manufactured products is stable, batch production efficiency is improved, and the requirement for domestic production of the automatic DCT is met.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

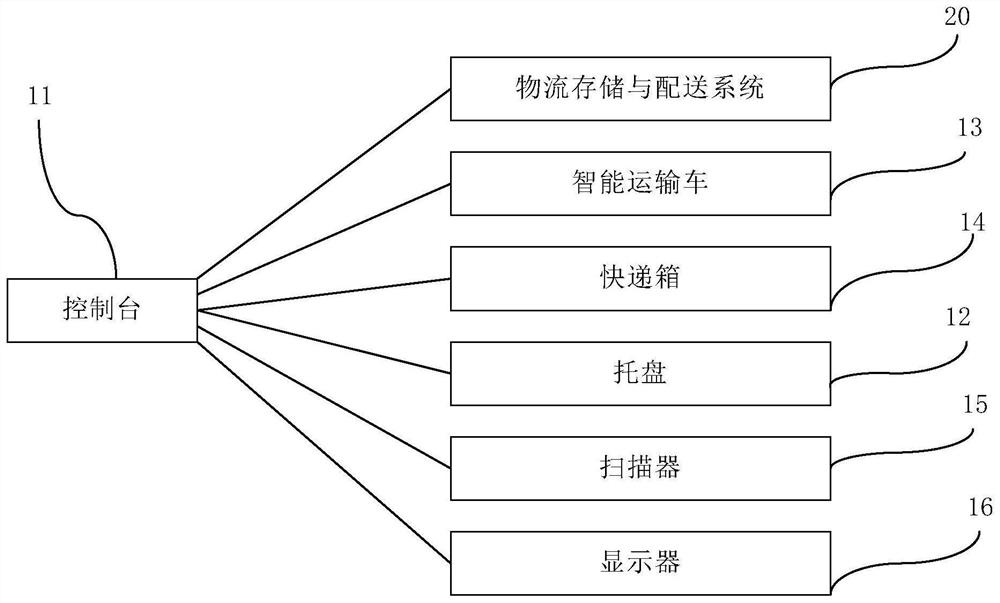

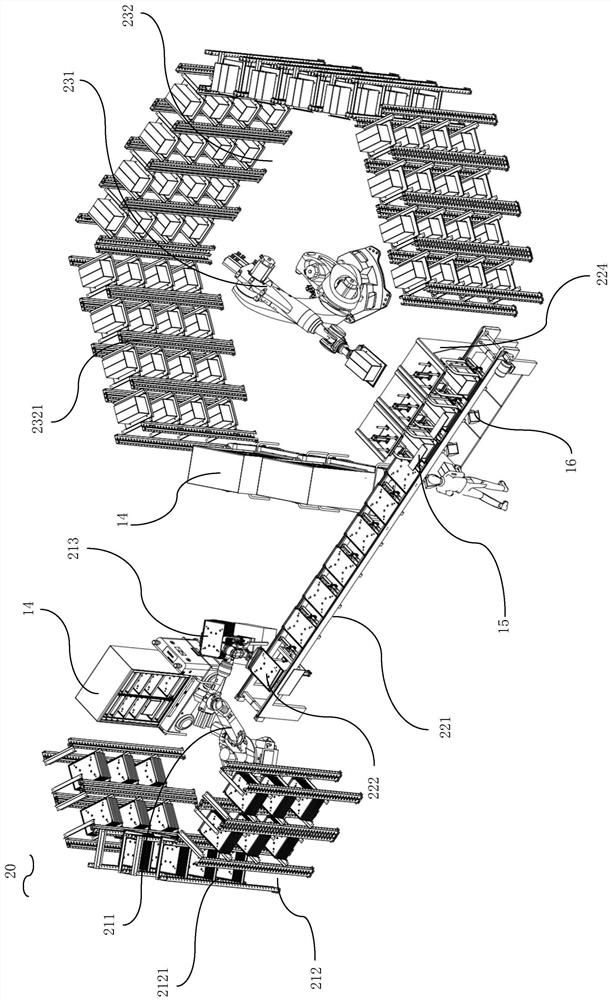

Logistics storage and distribution system, logistics tail end automatic post and method

ActiveCN112645025AImprove work efficiencyReduce logistics timeConveyor partsLogistics managementDistribution system

The invention relates to a logistics storage and distribution system, a logistics tail end automatic post and a method. The logistics storage and distribution system comprises a tray supply system, a tray conveying device and an express input and output system, wherein the tray supply system comprises a first mechanical arm, a first storage area and a tray supply platform for stacking empty trays; the first mechanical arm places a first storage area or a tray on the tray supply platform on the tray conveying device, the tray conveying device conveys the tray to the express input and output system which comprises a second mechanical arm and a second storage area; and the second mechanical arm stores the trays on the tray conveying device to the second storage area or places the trays in the second storage area on the tray conveying device. The logistics storage and distribution system and the logistics tail end automatic post can automatically store and distribute the expresses needing to be distributed and send out the expresses needing to be sent.

Owner:西湖大学(杭州)智能产业研究院有限公司

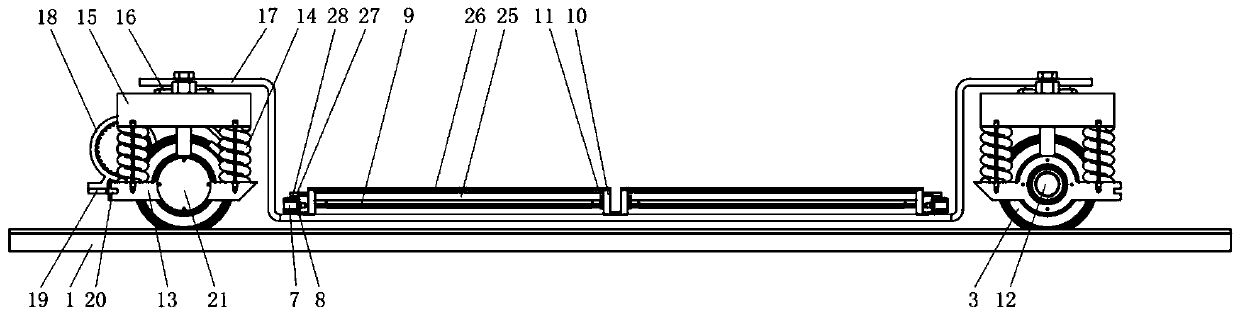

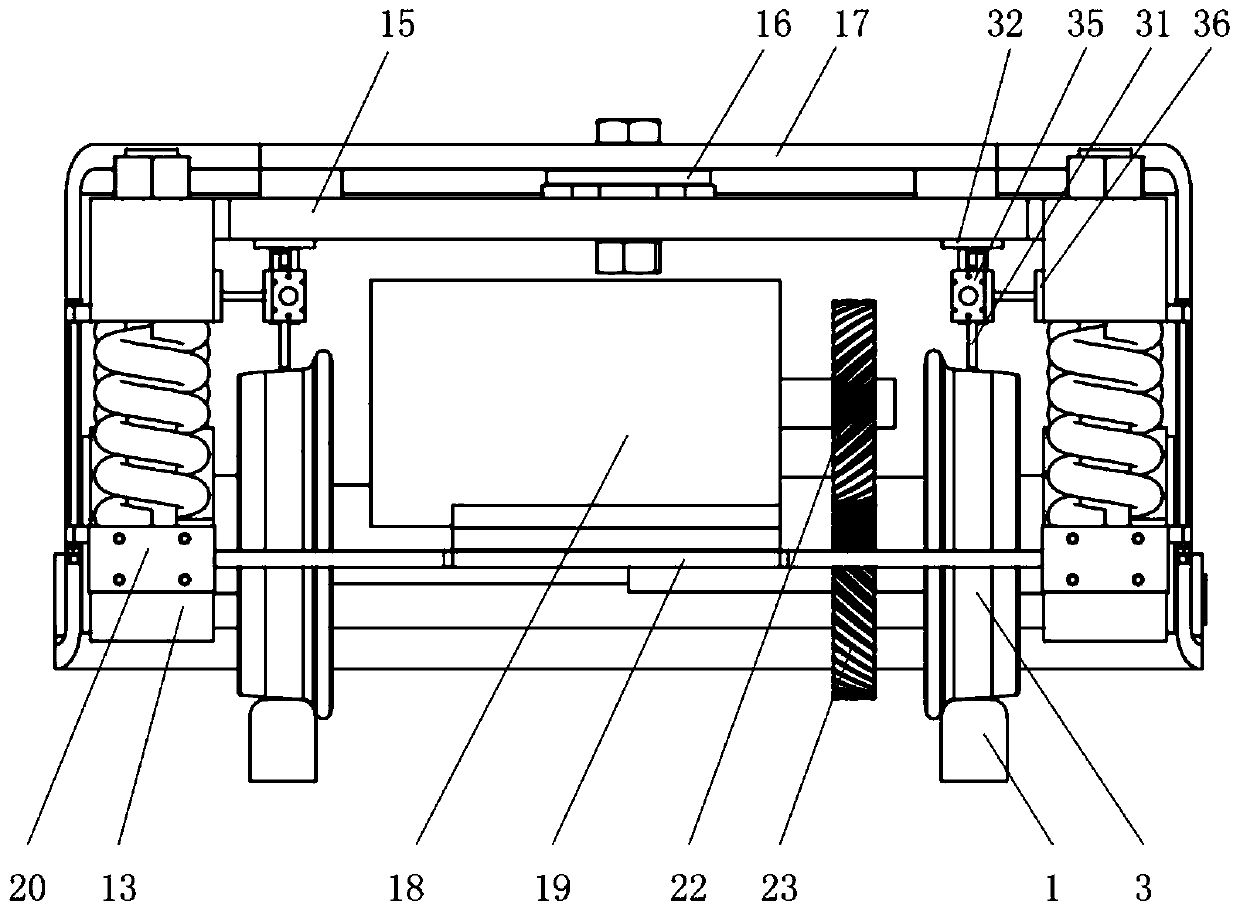

Underground logistics pipeline transportation tool

PendingCN111098869ASolve shipping problemsImprove logistics efficiencyElectric motor propulsion transmissionWagons/vansBogieLogistics management

The invention discloses an underground logistics pipeline transportation tool. The transportation tool is characterized in that four wheels are arranged at the bottom of the transportation tool, two wheels form a pair and are respectively clamped on two parallel rails, the transportation tool includes a shell, wheels, axles, a vehicle door, a door motor, a door motor base, lead screws, lead screwbases, sliding blocks, axles, axle boxes, damping springs, bogies, bogie connecting blocks, carriage bodies, driving motors, driving motor bases, connecting blocks, axle end covers, first gears, second gears, rollers, front baffles, rear baffles, moving blocks, cams, a front baffle motor, a front baffle motor base, brake shoes, brake shoe supporting bases, connecting rods, air cylinder connectingblocks, air cylinders and air cylinder bases. The transportation tool is advantaged in that the transportation tool can carry out logistics transportation of a special underground logistics track, solves a problem of cargo transportation from an urban distribution center to a distribution center, improves logistics efficiency, shortens logistics time and relieves urban ground traffic jam.

Owner:CHINA CONSTR UNDERGROUND SPACE

Remote managing and consulting system for logistics

InactiveUS20090172029A1Improve logistics efficiencyReduce logistics timeLogisticsSpecial data processing applicationsPersonalizationLogistics management

This invention relates to A remote managing and consulting system for logistics comprising a central processing system and one or more remote terminals which exchange data with the central processing system, wherein each of the remote terminals includes a wireless transmitting and receiving module, a optimization unit for logistics organization of the central processing system will generate optimization plans for transporting organization, an individuation optimization unit for logistics plans of the central processing system will generate optimization plans for individuation transporting. This invention is favorable to improve logistics efficiency, reduce logistics time and decrease logistics costs.

Owner:BEIJING AOTENGXUNDA SCI & TECH

Plastic product production line and product forming and coating conveying chain device thereof

InactiveCN105268576AReduce logistics timeReduce labor costsLiquid surface applicatorsSpraying apparatusProduction lineEngineering

The invention discloses a product forming and coating conveying chain device. The device comprises lifting tools for conveying workpieces, a conveying chain matched with the lifting tools, a conveying chain support supporting the conveying chain, a power device and a controller. One end of the conveying chain is located in a forming workpiece discharging region, and the other end of the conveying chain is located in a coating workpiece feeding region. The conveying chain is driven by the power device to transmit along the conveying chain support. The controller is used for controlling start and stop and speed regulation of the power device. By means of the product forming and coating conveying chain device, the lifting tools are arranged and matched with the conveying chain with one end located in the forming workpiece discharging region and the other end located in the coating workpiece feeding region, start and stop and speed regulation are conducted on the conveying chain under the effect of the controller, the workpieces are conveyed from the forming workpiece discharging region to the coating workpiece feeding region, logistic time of product coating is shortened, production cost is reduced, and production efficiency is improved. The invention further discloses a plastic product production line.

Owner:CHONGQING DAJIANG TONG YANG PLASTIC PROD

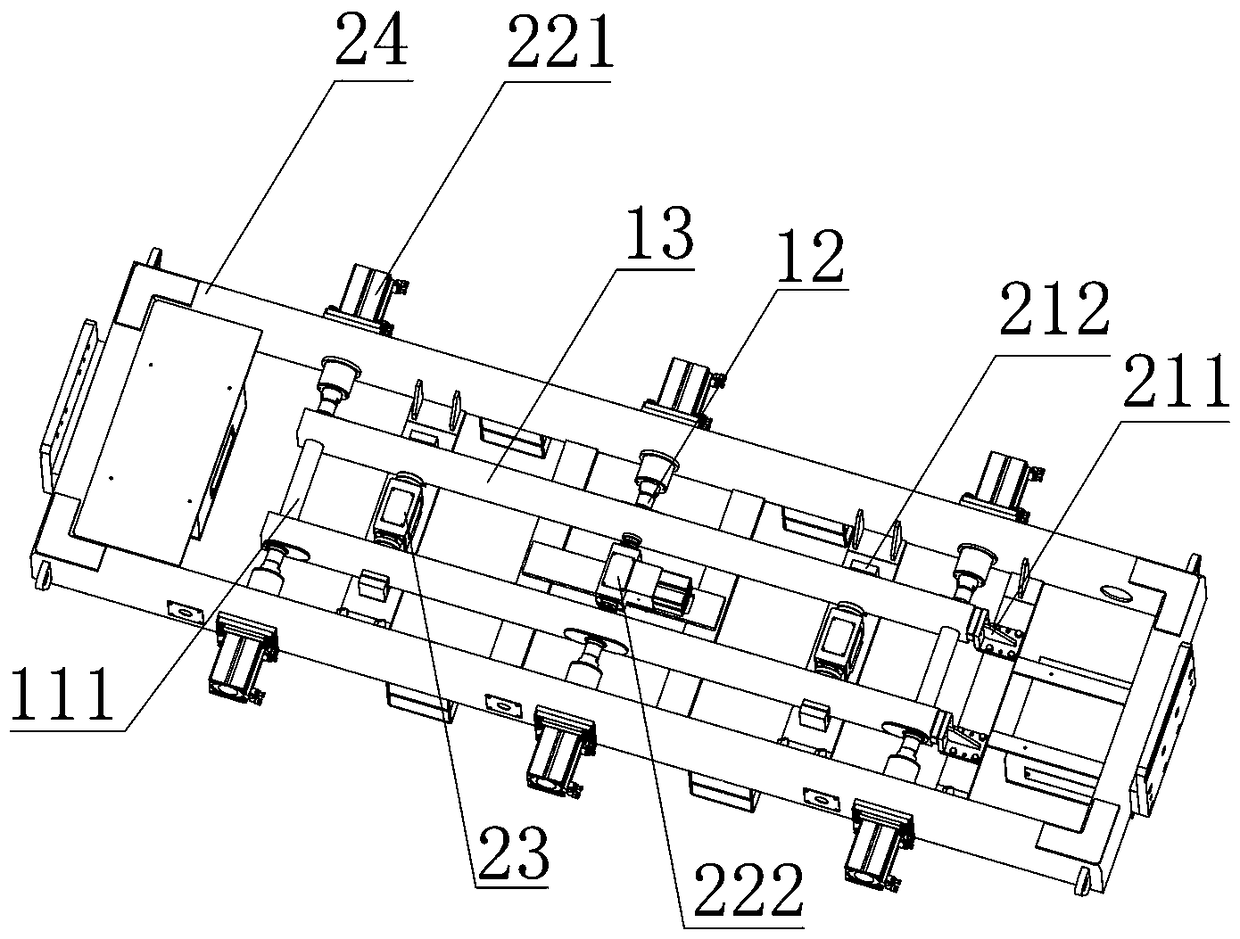

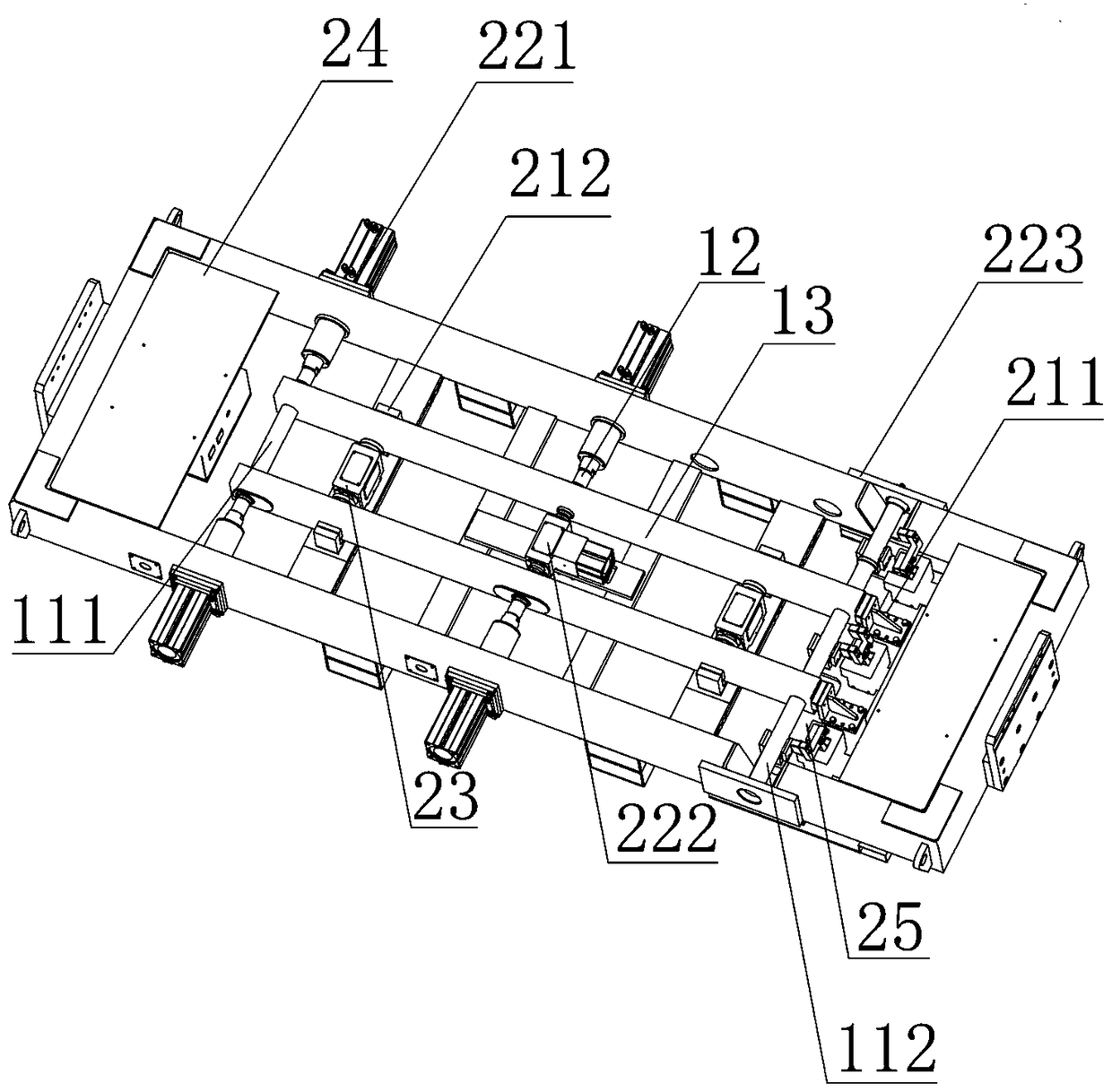

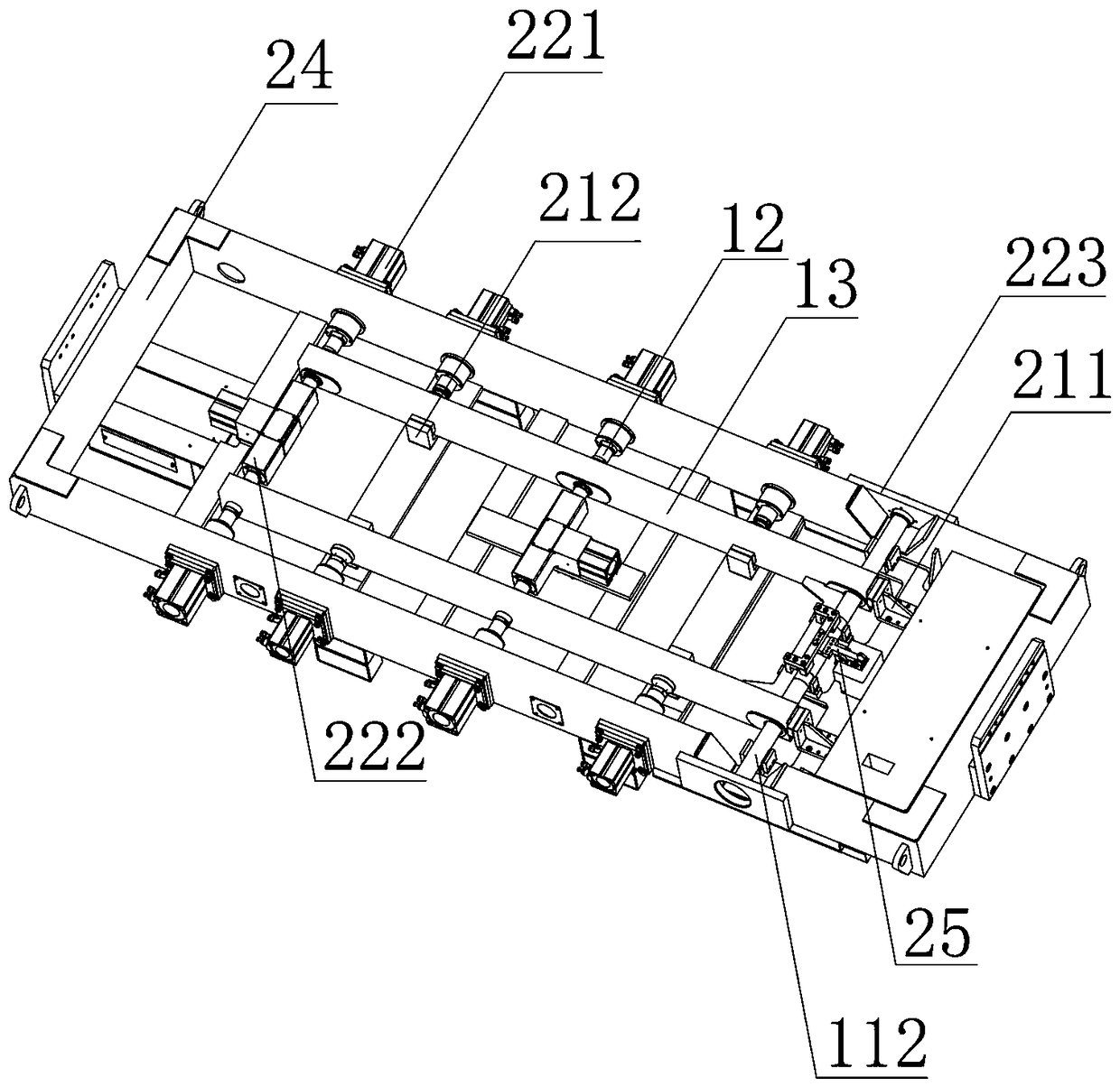

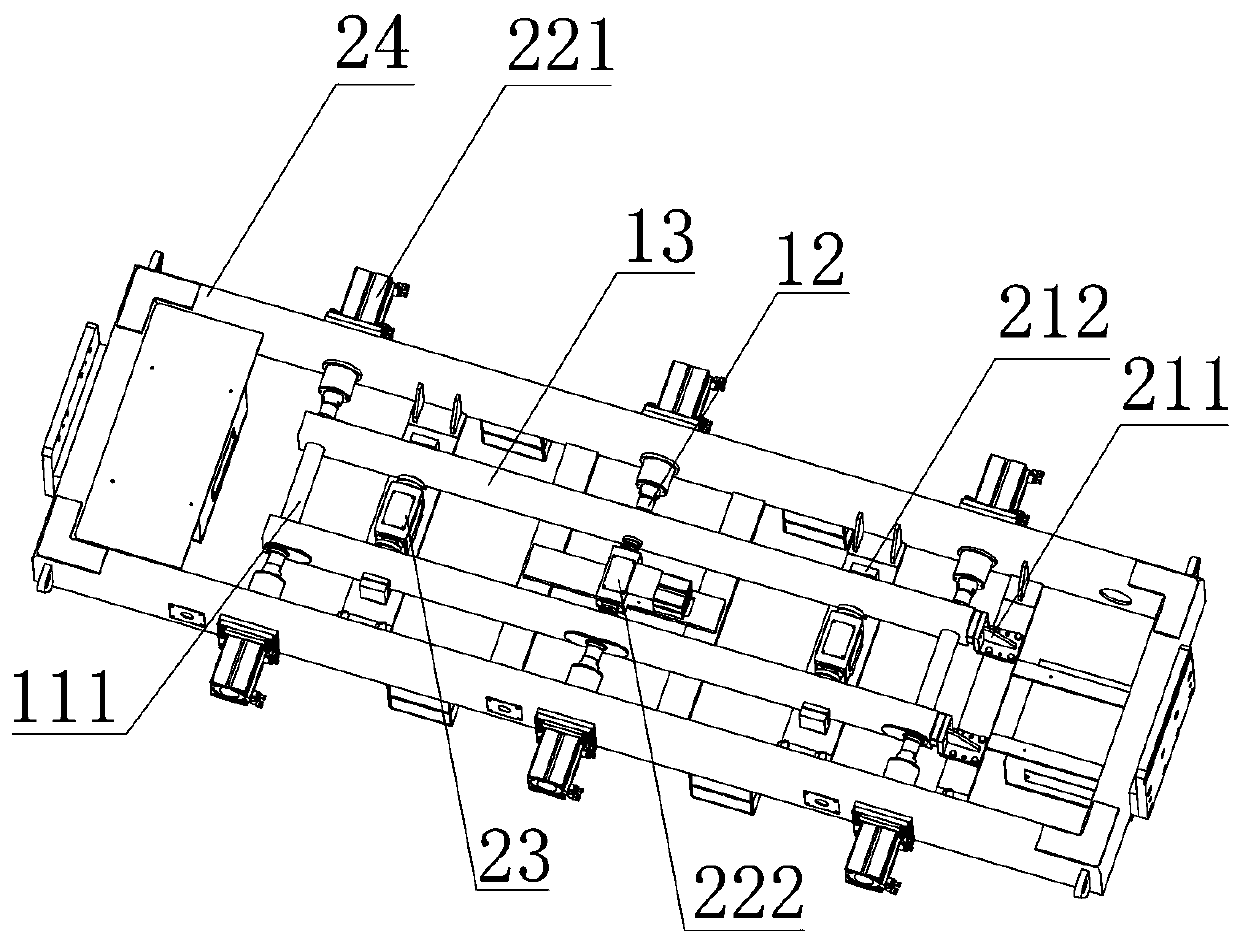

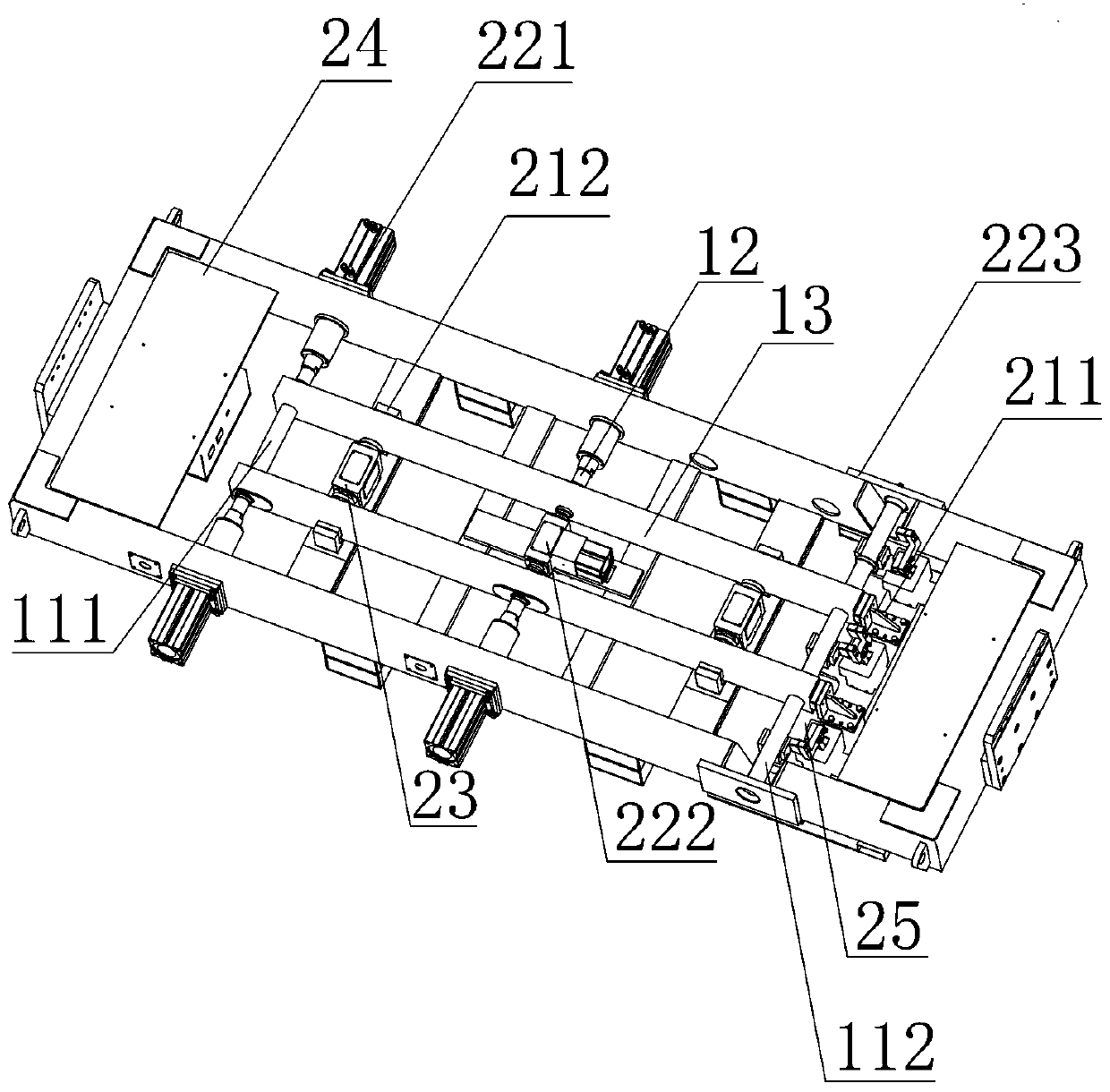

Assembly welding tool of inner and outer fork part

ActiveCN108161311ASmall footprintReduce logistics timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an assembly welding tool of an inner and outer fork part in the field of welding tools. The inner and outer fork part is formed by welding two fork rods, two long shaft sleevesand two short shaft sleeves. Connecting holes are formed in the head, the middle and the tail of each fork rod, and the two fork rods are arranged in parallel. One long shaft sleeve penetrates the connecting holes in the heads of the two fork rods. The other long shaft sleeve penetrates the connecting holes in the tails of the two fork rods. The two short shaft sleeves penetrate the connecting holes in the middles of the two fork rods correspondingly. The assembly welding tool comprises a workpiece mounting rack, a locating mechanism used for locating the fork rods, a jacking mechanism used for jacking the fork rods and a shaft sleeve fastening device used for fastening the long shaft sleeves and the short shaft sleeves, and the locating mechanism, the shaft sleeve fastening device and the jacking mechanism are all fixed to the workpiece mounting rack. All parts of an inner fork and an outer fork are assembled on the welding tool, the fixed point procedure is omitted, a both-way locating and jacking device is adopted, and the number of the locating mechanism and the jacking mechanism is reduced.

Owner:长沙天一智能科技股份有限公司

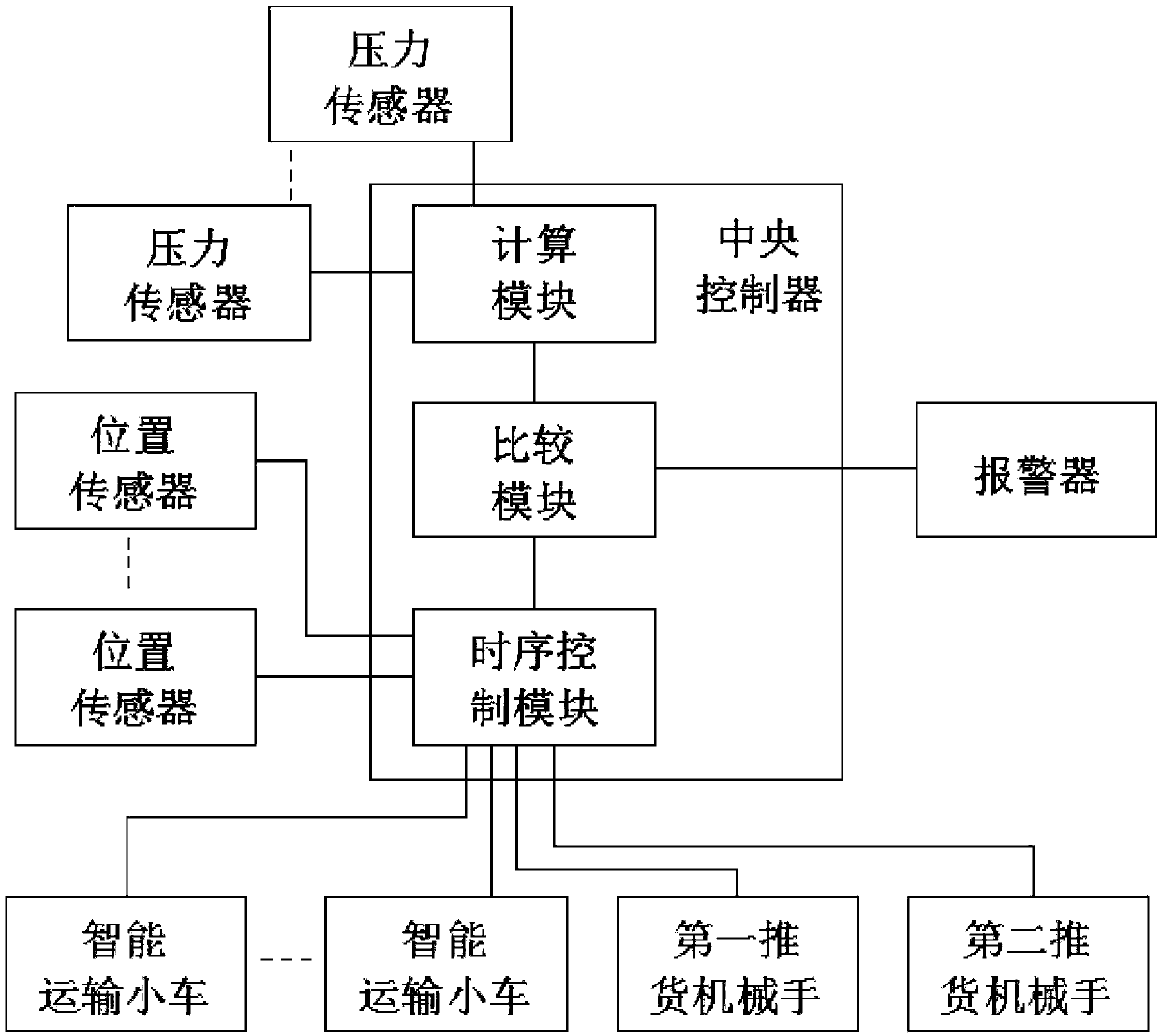

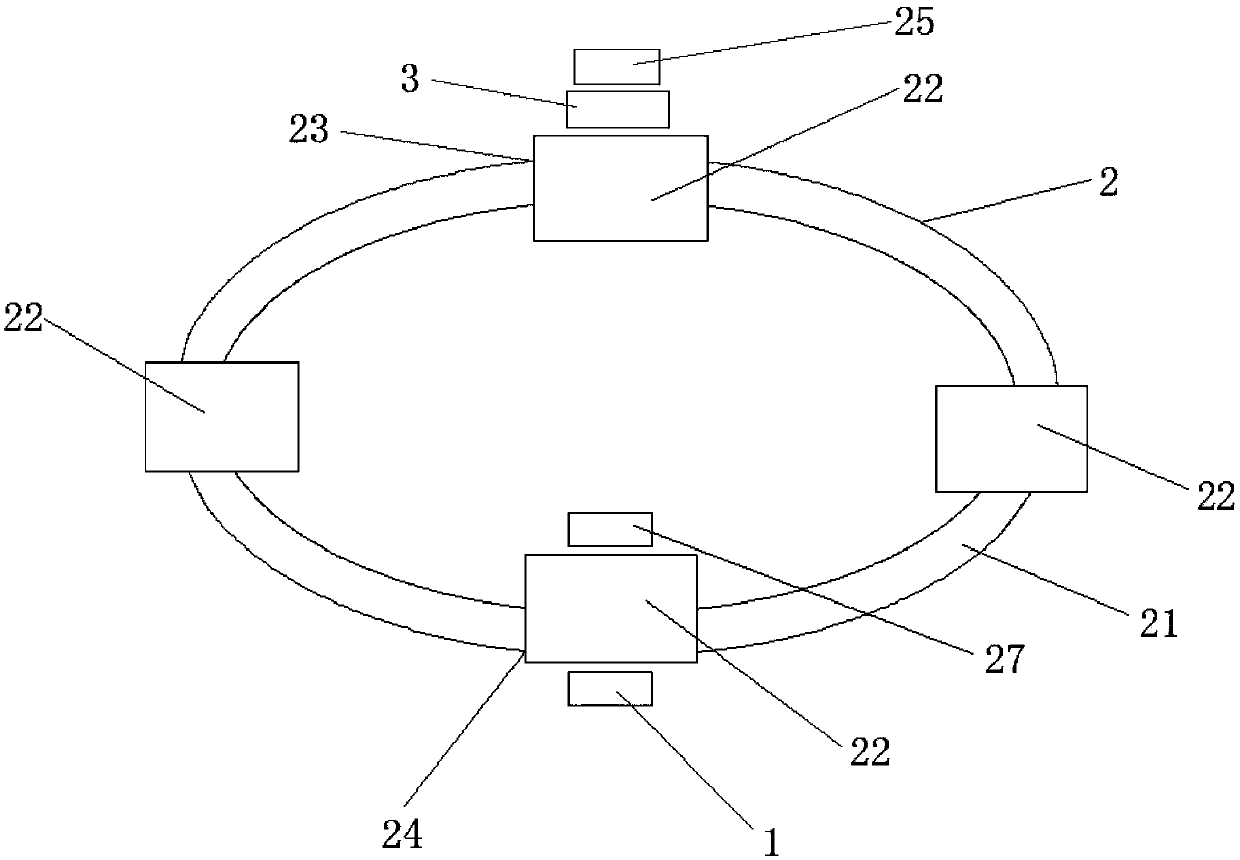

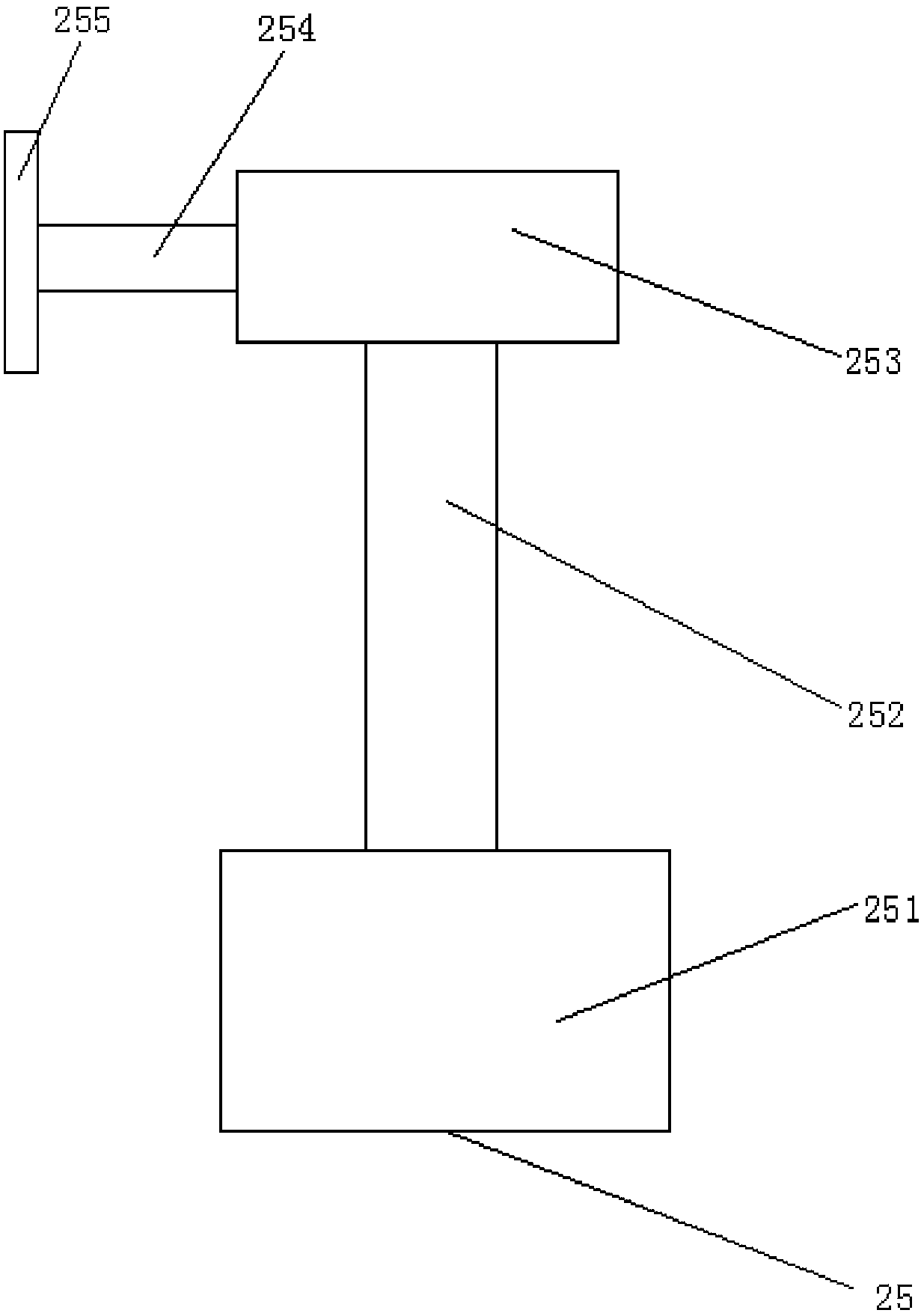

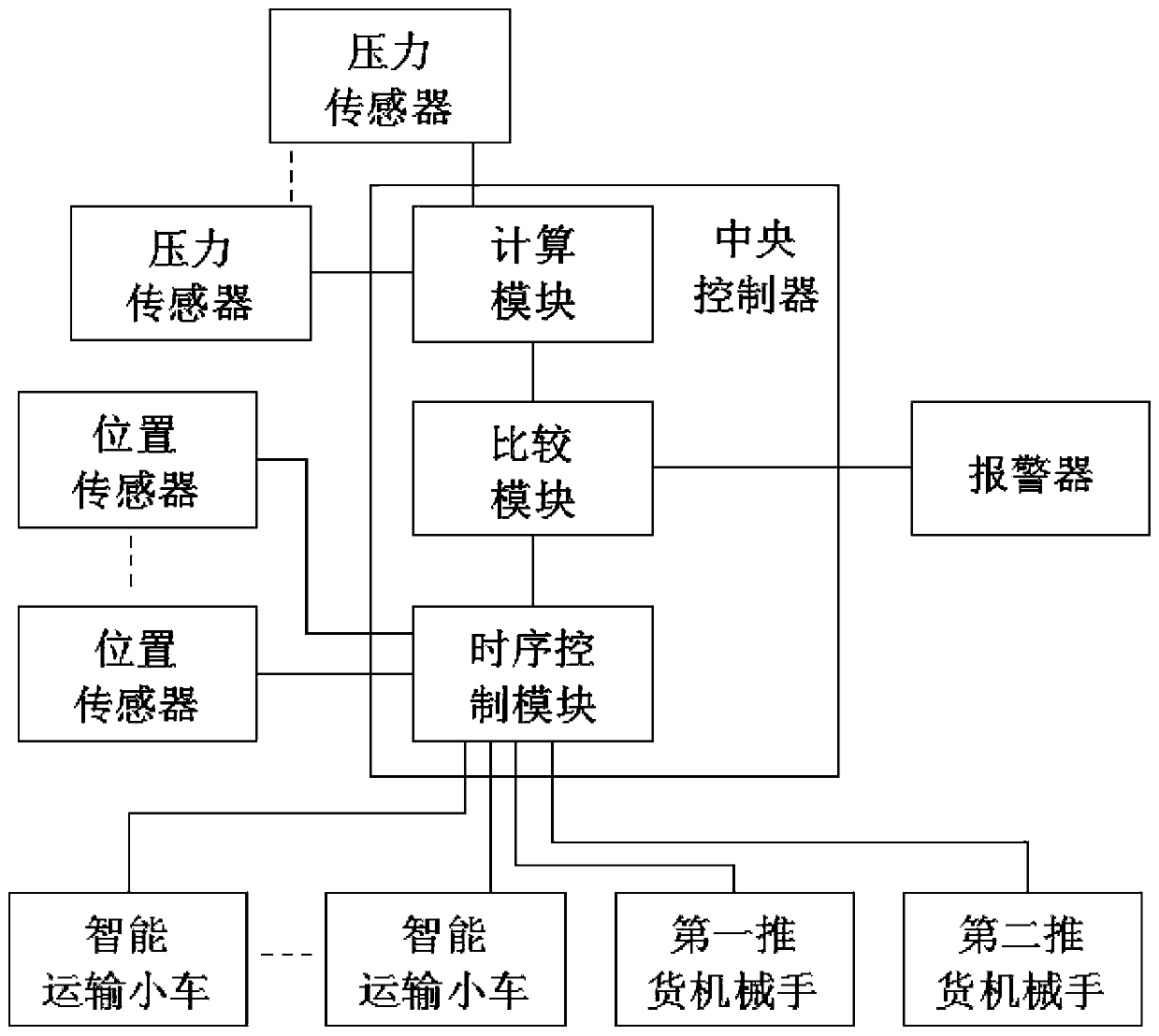

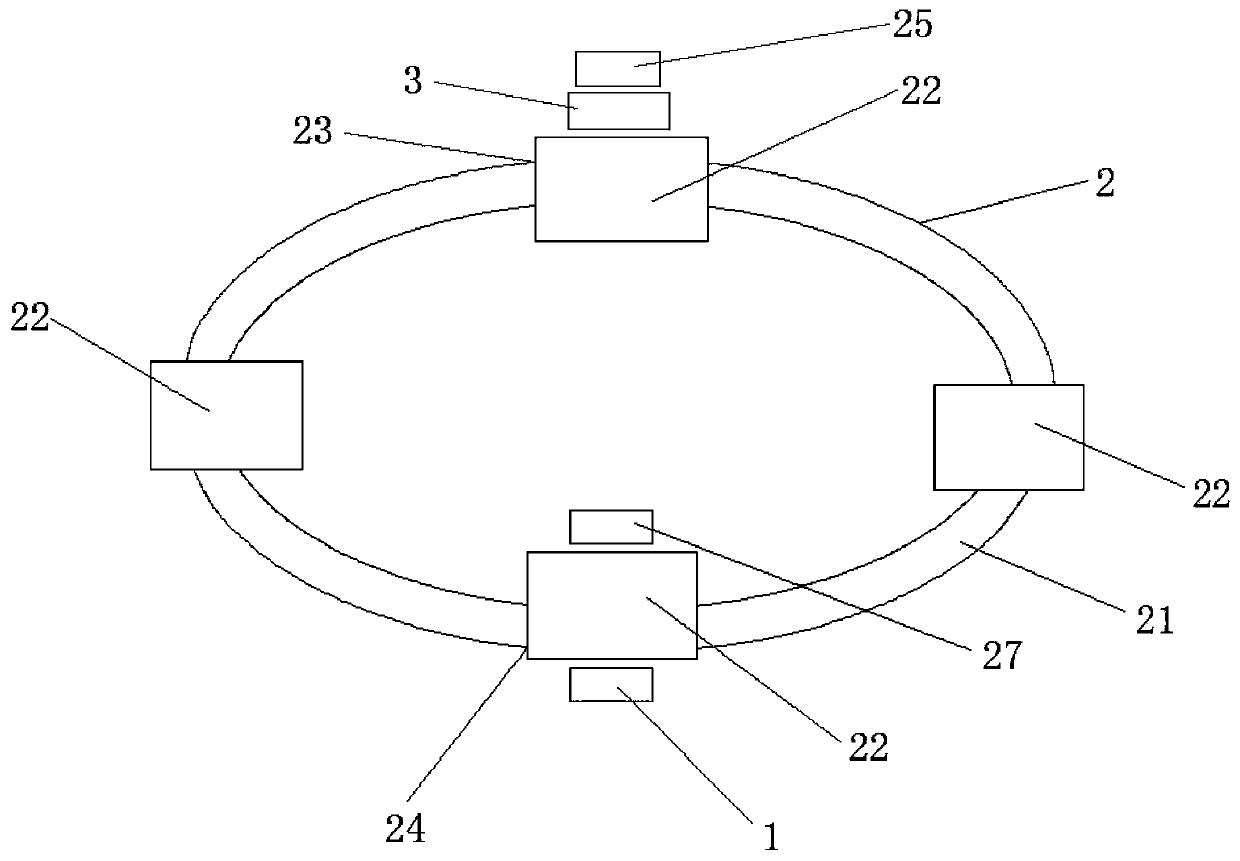

Annular trolley transportation device for logistics

ActiveCN108045871AReduce logistics timeImprove buffer capacityMechanical conveyorsManipulatorWhole systems

The invention relates to the technical field of logistic equipment, and particularly relates to an annular trolley transportation device for logistics. The annular trolley transportation device comprises an annular transportation rail and at least three intelligent transportation trolleys arranged on the annular transportation rail, wherein at least one cargo transportation start-point position and at least one cargo transportation endpoint position are arranged on the annular transportation rail; first cargo pushing mechanical arms are correspondingly arranged on the all cargo transportationstart-point positions; and second cargo pushing mechanical arms are correspondingly arranged on all automatic cargo lifting devices. According to the annular trolley transportation device for logistics disclosed by the invention, time for loading, transporting and unloading cargoes are effectively shared, so that a lot of logistic time is reduced; and meanwhile, because of the arrangement of a plurality of intelligent transportation trolleys, even if a certain specific intelligent transportation trolley has an error, the other intelligent transportation trolleys also can be used as back-up trolleys, so that a transportation operation of a whole system cannot be affected, and the buffer ability of the system is greatly improved.

Owner:绍兴市德帏纺织科技有限公司

Assembly welding tool of inner and outer fork assembly

ActiveCN108161310ASmall footprintReduce logistics timeWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringClamp connection

The invention discloses an assembly welding tool of an inner and outer fork assembly in the field of assembly tools. The inner and outer fork assembly comprises two fork rods, a lengthened long shaftsleeve, a common long shaft sleeve and two short shaft sleeves. Connecting holes are formed in the head, the middle and the tail of each fork rod, and the two fork rods are arranged in parallel. The lengthened long shaft sleeve penetrates the connecting holes in the heads of the two fork rods. The common long shaft sleeve penetrates the connecting holes in the tails of the two fork rods. The two short shaft sleeves penetrate the connecting holes in the middles of the two fork rods correspondingly. The tail of a short oil cylinder support is in clamped connection to the common long shaft sleeve, and a long oil cylinder support is in clamped connection to the lengthened long shaft sleeve. The long oil cylinder support and the short oil cylinder support are in central symmetry and are provided with fixed holes. The welding tool comprises a workpiece mounting rack, an inner and outer fork part locating mechanism, a fastening mechanism, an oil cylinder support locating mechanism, a jackingmechanism and a clamping mechanism, and the inner and outer fork part locating mechanism, the fastening mechanism, the oil cylinder support locating mechanism, the jacking mechanism and the clamping mechanism are all fixed to the workpiece mounting rack. All parts of the inner and outer fork assembly are assembled on the welding tool, and the fixed point procedure is omitted.

Owner:ZHUZHOU TIANYI AUTOWELDING SYST CO LTD

Five-shaft four-linkage drilling, milling and tapping machine

InactiveCN104139300AIncrease productivityReduce logistics timeOther manufacturing equipments/toolsMetal working apparatusLeft halfEngineering

The invention discloses a five-shaft four-linkage drilling, milling and tapping machine. The five-shaft four-linkage drilling, milling and tapping machine comprises a lath body base, a Y-axial-direction guide rail arranged at the upper end of the lathe body base, a Y-axial-direction sliding block arranged on the Y-axial-direction guide rail, an X-axial-direction guide rail arranged at the upper end of the Y-axial-direction sliding block, an X-axial-direction worktable arranged on the X-axial-direction guide rail, a clamping device arranged at the upper end of the left half part of the X-axial-direction worktable, a rotary device used for driving workpieces to rotate is arranged at the upper end of the right half part of the X-axial-direction worktable, a Z-axial-direction guide rail arranged on the lathe body base, a cutter driving device which is arranged on the Z-axial-direction guide rail and vertically moves along the Z-axial-direction guide rail, an Z-axis driving servo motor, a screw mechanism arranged between the Z-axis driving servo motor and the cutter driving device and a cutter which is arranged at the lower end of the cutter driving device and above the X-axial-direction worktable. Drilling, milling and tapping of the same type of motor accessories can be automatically finished on the same machine.

Owner:SHANGHAI LONGDAY MACHINERY

A circular trolley transport device for logistics

ActiveCN108045871BReduce logistics timeWill not affect the transport workMechanical conveyorsLogistics managementRobot hand

The invention relates to the technical field of logistic equipment, and particularly relates to an annular trolley transportation device for logistics. The annular trolley transportation device comprises an annular transportation rail and at least three intelligent transportation trolleys arranged on the annular transportation rail, wherein at least one cargo transportation start-point position and at least one cargo transportation endpoint position are arranged on the annular transportation rail; first cargo pushing mechanical arms are correspondingly arranged on the all cargo transportationstart-point positions; and second cargo pushing mechanical arms are correspondingly arranged on all automatic cargo lifting devices. According to the annular trolley transportation device for logistics disclosed by the invention, time for loading, transporting and unloading cargoes are effectively shared, so that a lot of logistic time is reduced; and meanwhile, because of the arrangement of a plurality of intelligent transportation trolleys, even if a certain specific intelligent transportation trolley has an error, the other intelligent transportation trolleys also can be used as back-up trolleys, so that a transportation operation of a whole system cannot be affected, and the buffer ability of the system is greatly improved.

Owner:绍兴市德帏纺织科技有限公司

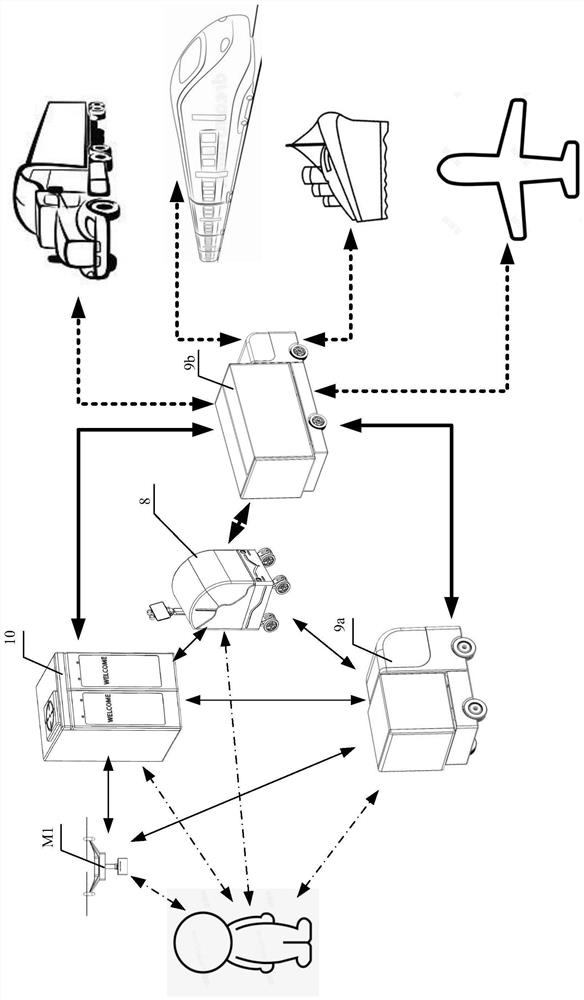

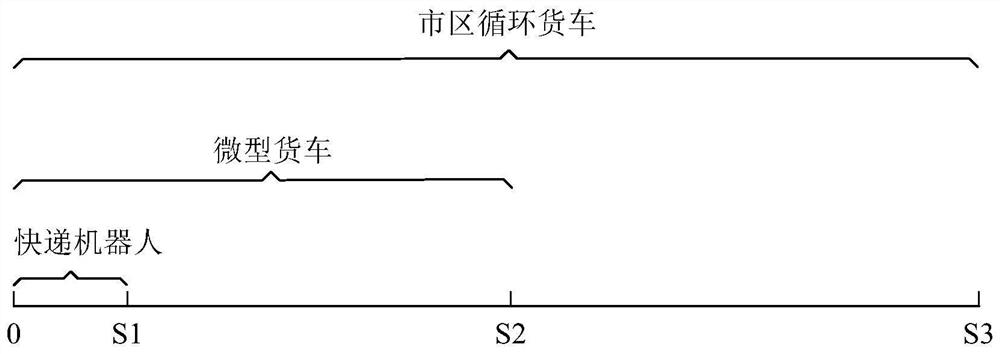

A logistics system and method for reducing sorting time

ActiveCN112061653BReduce logistics timeImprove logistics efficiencyLogisticsStorage devicesLogistics managementIndustrial engineering

The present invention relates to a logistics system and method for reducing sorting time, the system comprising a plurality of first freight units and a plurality of second freight units, wherein the first freight units are configured to communicate with the second freight units Goods; the first freight unit includes a goods sorting system configured to sort goods in the first freight unit during operation of the first freight unit. The freight device of the present invention uses the transportation time to complete the sorting of the goods, so the sorting of the goods does not occupy the logistics time. Compared with the existing logistics mode that requires multiple, multi-level fixed sorting times, the present invention effectively reduces the time of goods. The overall logistics time, thus can effectively improve the logistics efficiency.

Owner:久恒理树

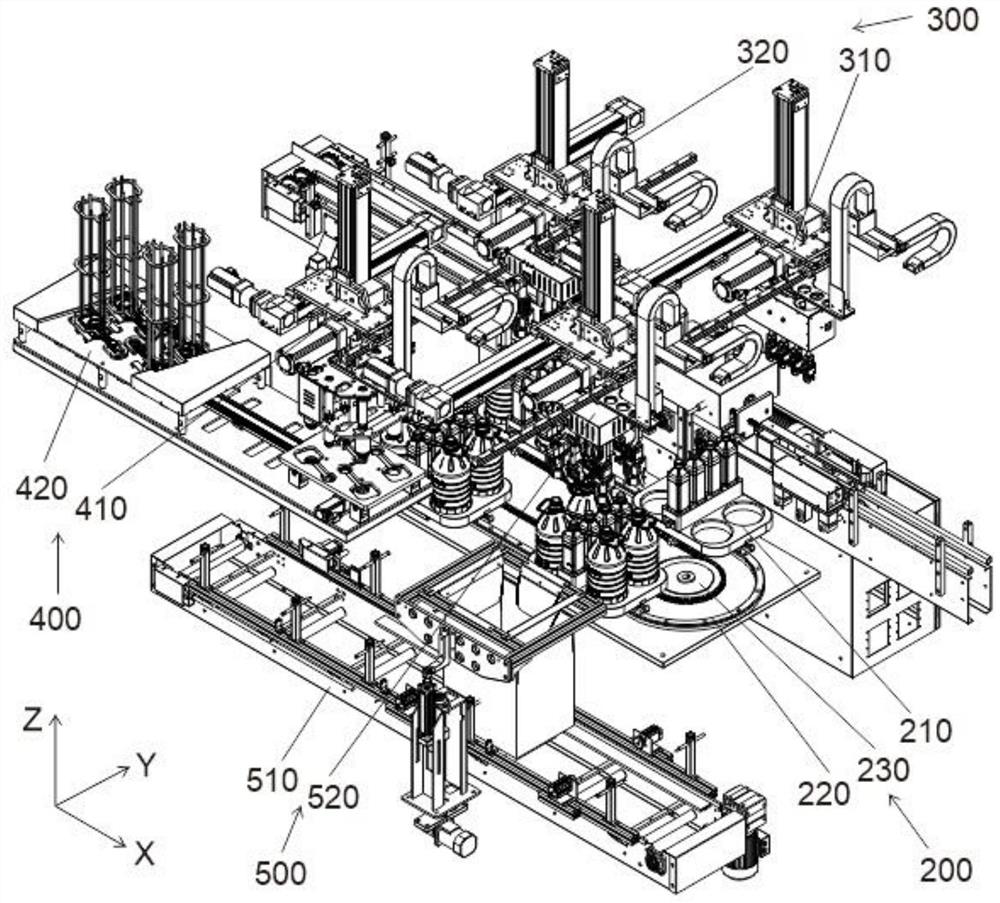

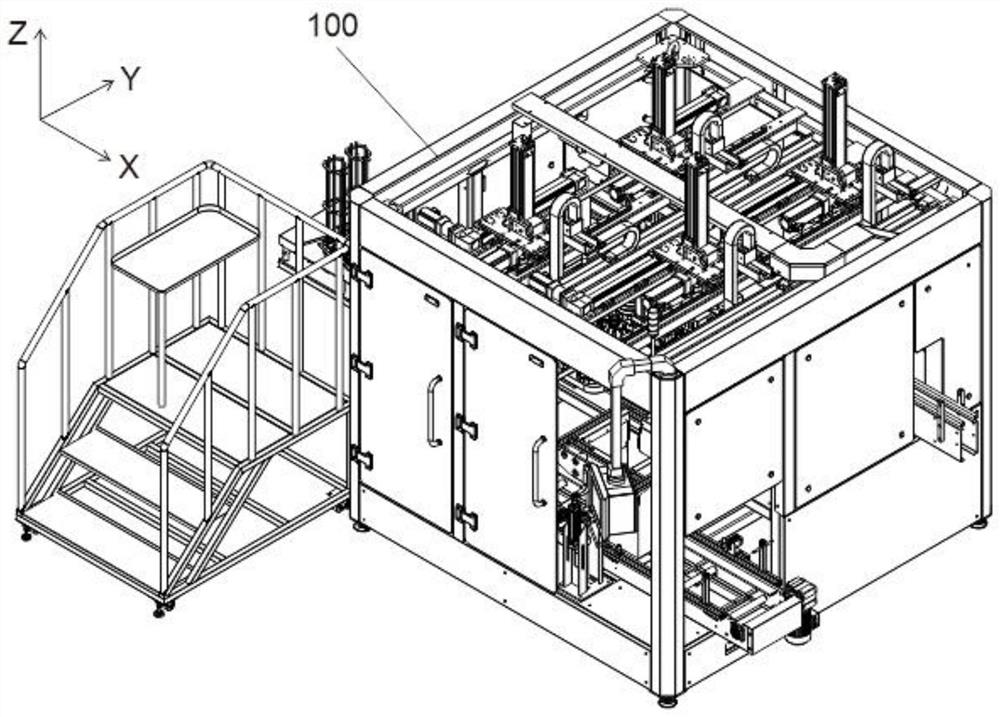

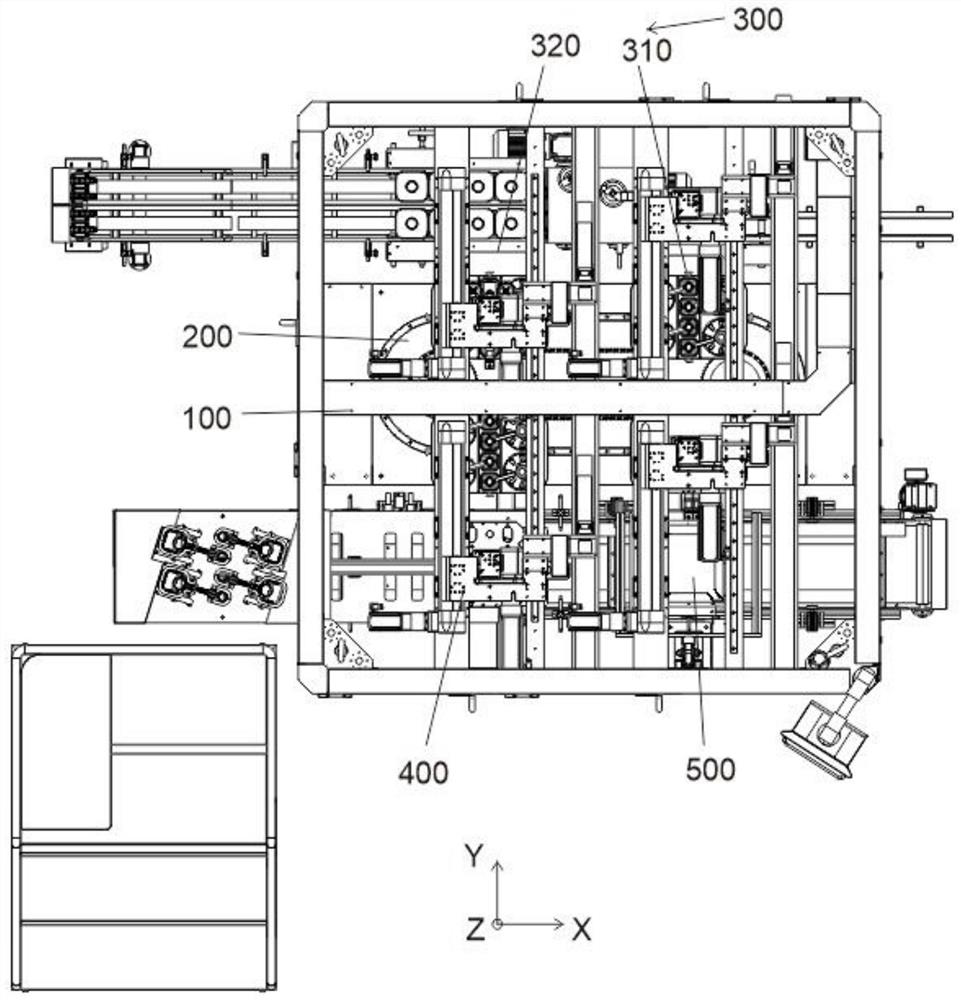

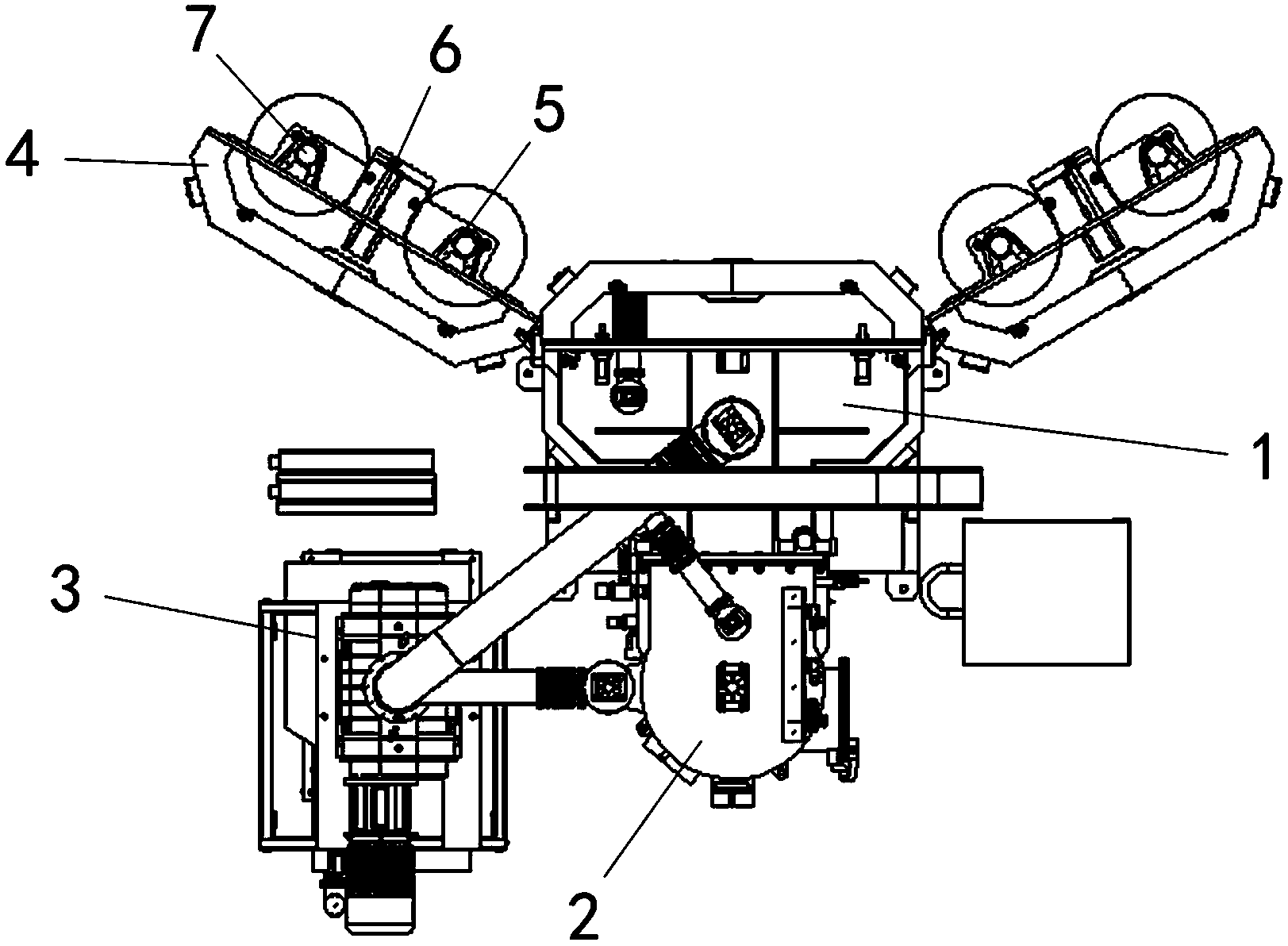

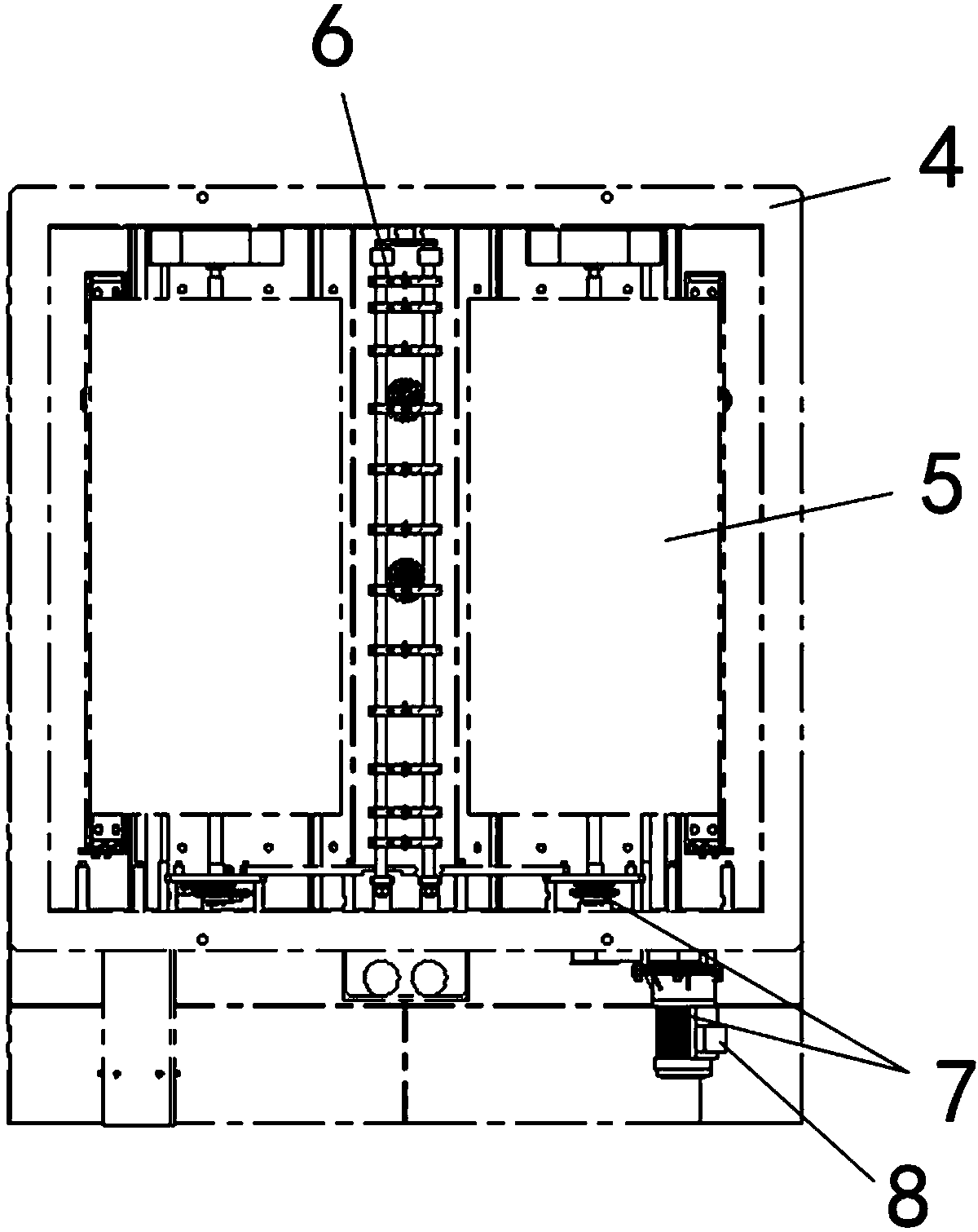

Automatic binding, ring pressing and boxing all-in-one machine

PendingCN112061465AIncrease productivityCompact structurePackaging bottlesLogistics managementBottle

The invention relates to the technical field of packaging equipment, in particular to an automatic binding, ring pressing and boxing all-in-one machine. The automatic binding, ring pressing and boxingall-in-one machine comprises a station conversion device arranged on a rack, wherein a bottle feeding station, a ring pressing station and a boxing station are arranged around the station conversiondevice. According to the structure in which the station conversion device is arranged, and the bottle feeding station, the ring pressing station and the boxing station are arranged around the stationconversion device, so that bottle materials of various specifications are input through the bottle feeding station, batched ring pressing of the bottle materials is achieved through the ring pressingstation, and batched boxing of the bottle materials is achieved through the boxing station; and in addition, dispatching transmission between the stations is achieved through cooperation of the station conversion device and a plurality of trays. Compared with the prior art, the automatic binding, ring pressing and boxing all-in-one machine has the advantages that the integration of multiple process operations such as bottle feeding, ring pressing and boxing in one machine is achieved as a whole, the structure is compact, the logistics time is saved; and simultaneous working at multiple stations is achieved at the same time, so that the production efficiency of packages is improved greatly, and the production cost is reduced.

Owner:福州广泰机械设备有限公司

Double-shaft vacuum coating equipment for car lamp

ActiveCN103451604AReduce weightSimple structureVacuum evaporation coatingSputtering coatingElectrical and Electronics engineeringTungsten filament

The invention discloses double-shaft vacuum coating equipment for a car lamp. The double-shaft vacuum coating equipment is characterized by comprising a vacuum chamber cavity, a main valve cavity and a pump set, wherein the pump set is connected with the vacuum chamber cavity and the main valve cavity, a pair of doors is arranged on the vacuum chamber cavity and hinged with a housing of the vacuum chamber cavity, a workpiece clamp, an evapotranspiring device and a rotating device are arranged at the inner side of each door; the evapotranspiring device is arranged at the middle of the inner side of each door and comprises a bracket, wherein an evapotranspiring unit is arranged on the bracket, and the evapotranspiring unit is formed by connecting an evapotranspiring tungsten filament and an evapotranspiring copper rod. The double-shaft vacuum coating equipment has the beneficial effects that the weight of the whole equipment is greatly reduced, the equipment only rotates, each door is controlled by a single frequency converter, the revolution of shafts can be regulated at any time, the structure is simple, convenience is brought for maintenance, the weight of each door is integrally reduced so that the door is more easily opened in a labor-saving manner, and the evapotranspiring rods are arranged between the two shafts so that paint can be more fully evapotranspired to a product and the pollution to the inner wall is reduced.

Owner:SHANGHAI HANA MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

Robot clamp matched with multifunctional machining center

PendingCN114474120AImprove work efficiencyReduce logistics timeGripping headsMechanical engineeringPhysical medicine and rehabilitation

The invention discloses a multifunctional machining center matched robot clamp which comprises a system control module, a joint robot and a clamp body, two clamping jaws and a clamping jaw controller are arranged on the clamp body, the tail end of a joint arm of the joint robot is detachably connected with the clamp body, and the system control module is connected with the joint robot and the clamping jaw controller. Each clamping jaw is provided with an opening and closing driving mechanism, and the clamping jaw controller controls the opening and closing driving mechanisms to drive the clamping jaws to be opened or closed. A grabbing instruction is sent to the joint robot through the system control module, the joint robot is connected with the clamp body, the clamping jaw controller controls the clamping jaw to be opened, the joint robot aligns one clamping jaw on the clamp body to a sample, and the clamping jaw controller controls the clamping jaw to be closed. And the system control module controls the joint arm of the joint robot to rotate, so that the other clamping jaw on the clamp body grabs the sample to the next process, the working efficiency of the robot clamp is improved, and meanwhile, the logistics time of automatic equipment is shortened.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

A logistics planning method

ActiveCN109087045BEasy to check feedbackReduce logistics costsResourcesLogisticsLogistics managementPlanning method

Owner:SHANGHAI JUNZHENG NETWORK TECH CO LTD

method of logistics

ActiveCN103359417BReduce the burden onReduce logistics timePackage recyclingContainers for annular articlesLogistics managementDistribution method

PROBLEM TO BE SOLVED: To reduce an operator's load in article conveyance, storage and picking, and shorten physical distribution time.SOLUTION: A physical distribution method includes a first step 23 for accommodating an article 19 shipped from a factory into a carton box, a second step 25 for accumulating and storing the carton box, a third step 27 for extracting an article from the stored carton box according to a delivery destination request and replacing it into a shipping carton box, and a fourth step 29 for conveying the shipping carton box through a conveying means, wherein the same shaped carton box is used in all these steps, the carton box is composed of an exclusive tray 15 for accommodating a plurality of articles and a cuboid box-shaped resin-made exclusive container 1 for accommodating the exclusive tray, and at least one of the short side surfaces of the exclusive container is provided with an open / close door 9 available for taking in and out the exclusive tray in the longitudinal direction of the exclusive container.

Owner:SANKYU INC +1

A Butt Welding Tooling for Inner and Outer Fork Parts

ActiveCN108161311BSmall footprintReduce logistics timeWelding/cutting auxillary devicesAuxillary welding devicesButt weldingMechanical engineering

The invention discloses an assembly welding tool of an inner and outer fork part in the field of welding tools. The inner and outer fork part is formed by welding two fork rods, two long shaft sleevesand two short shaft sleeves. Connecting holes are formed in the head, the middle and the tail of each fork rod, and the two fork rods are arranged in parallel. One long shaft sleeve penetrates the connecting holes in the heads of the two fork rods. The other long shaft sleeve penetrates the connecting holes in the tails of the two fork rods. The two short shaft sleeves penetrate the connecting holes in the middles of the two fork rods correspondingly. The assembly welding tool comprises a workpiece mounting rack, a locating mechanism used for locating the fork rods, a jacking mechanism used for jacking the fork rods and a shaft sleeve fastening device used for fastening the long shaft sleeves and the short shaft sleeves, and the locating mechanism, the shaft sleeve fastening device and the jacking mechanism are all fixed to the workpiece mounting rack. All parts of an inner fork and an outer fork are assembled on the welding tool, the fixed point procedure is omitted, a both-way locating and jacking device is adopted, and the number of the locating mechanism and the jacking mechanism is reduced.

Owner:长沙天一智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com