Robot clamp matched with multifunctional machining center

A robot fixture and machining center technology, applied in the direction of manufacturing tools, chucks, manipulators, etc., can solve the problems that affect the overall efficiency of sample processing, reduce the efficiency of equipment operation, and reduce the number of samples, so as to improve the overall work efficiency and reduce the number of samples. Logistics time, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

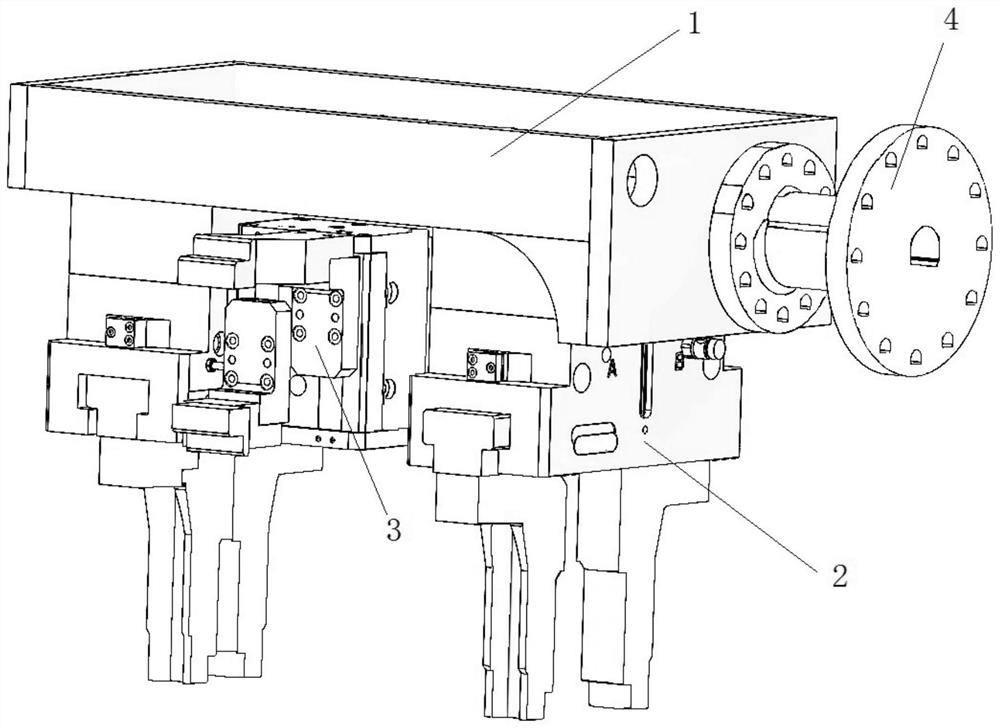

[0018] combine figure 1 As shown, the embodiment of the present invention provides a robot fixture for a multifunctional machining center, including a system control module, a joint robot and a clamp body 1. In this embodiment, the joint robot is a six-axis robot, and the first joint of the six-axis robot It can rotate freely in the horizontal plane, and the last two joints can move in the vertical plane. At the same time, it has one arm and two wrist joints, which can have the ability of human arms and wrists.

[0019] Two clamping jaws 2 and a clamping jaw controller are arranged on the clamping body 1 . Two jaws 2 on the clamp body 1, one jaw is a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com