Double-shaft vacuum coating equipment for car lamp

A vacuum coating machine and car lamp technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problem of increasing equipment cost and power configuration, increasing the production cycle of the furnace, reducing equipment utilization, etc. problems, to achieve the effect of reducing the time required for loading and unloading products, reducing logistics time and area occupied by logistics, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

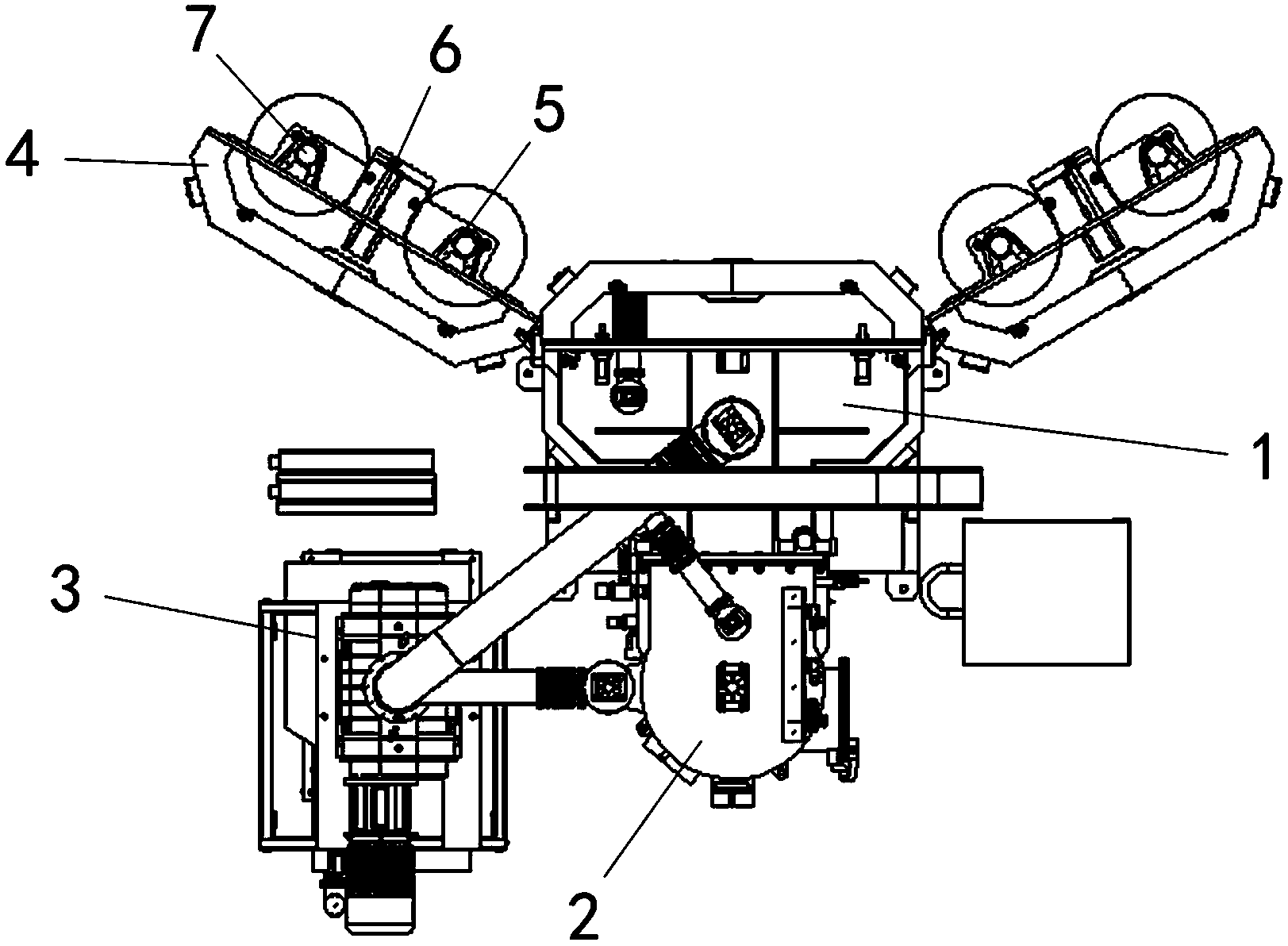

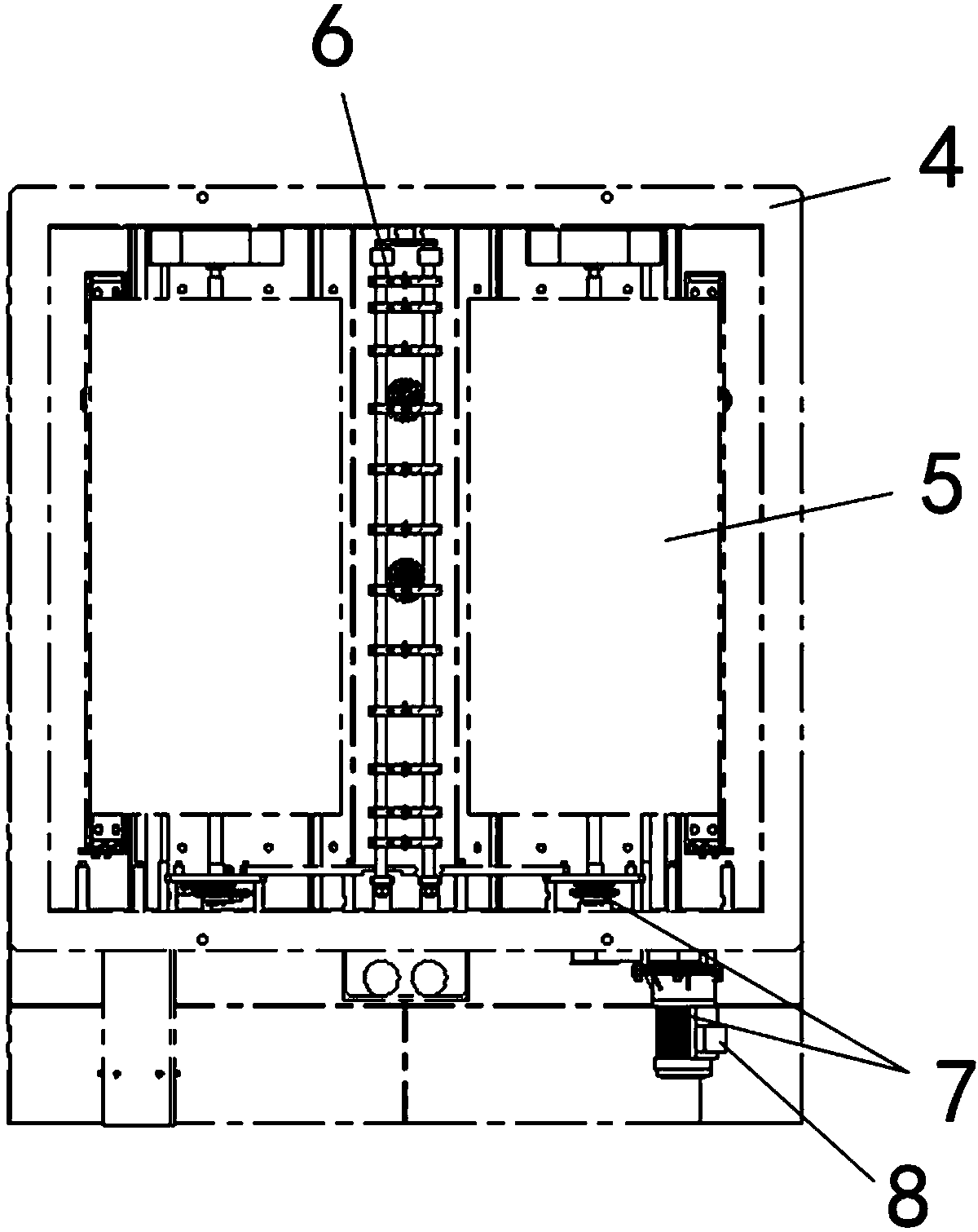

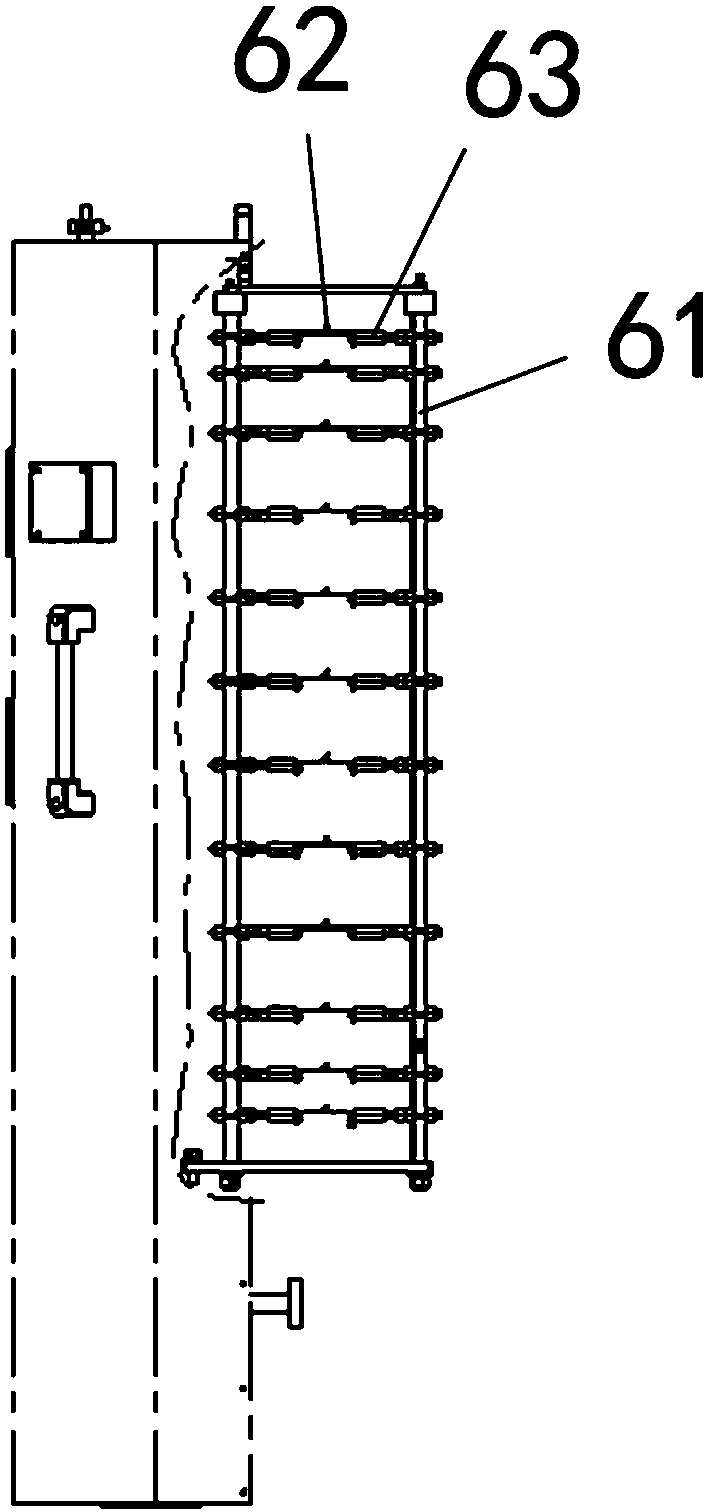

[0017] Such as Figure 1 to Figure 5 As shown, this specific embodiment adopts the following technical solutions: a double-axis car lamp vacuum coating machine, which includes a vacuum chamber cavity 1, a main valve cavity 2, and a pump unit 3, and the pump unit 3 is connected to the vacuum chamber cavity 1 and the main valve. Cavity 2, the vacuum chamber cavity 1 is provided with a pair of doors 4, the door 4 is hinged with the shell of the vacuum chamber cavity 1, and the inside of the door 4 is provided with a workpiece fixture 5, an evaporative device 6 and a rotating device 7, The evapotranspiration device 6 is arranged in the middle part of the inner side of the door, and the evapotranspiration device 6 is composed of a bracket 61, on which an evapotranspiration unit is arranged, and the evapotranspiration unit is formed by connecting an evaporative tungsten wire 62 and an evaporative copper rod 63; the rotating device 7 includes a motor 71, Synchronous pulley 72, magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com