Etchant composition for the formation of a metal line

A composition and etching technology, which is applied in the direction of surface etching composition, electrical components, circuits, etc., can solve the problems of reducing productivity, underlying film and equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

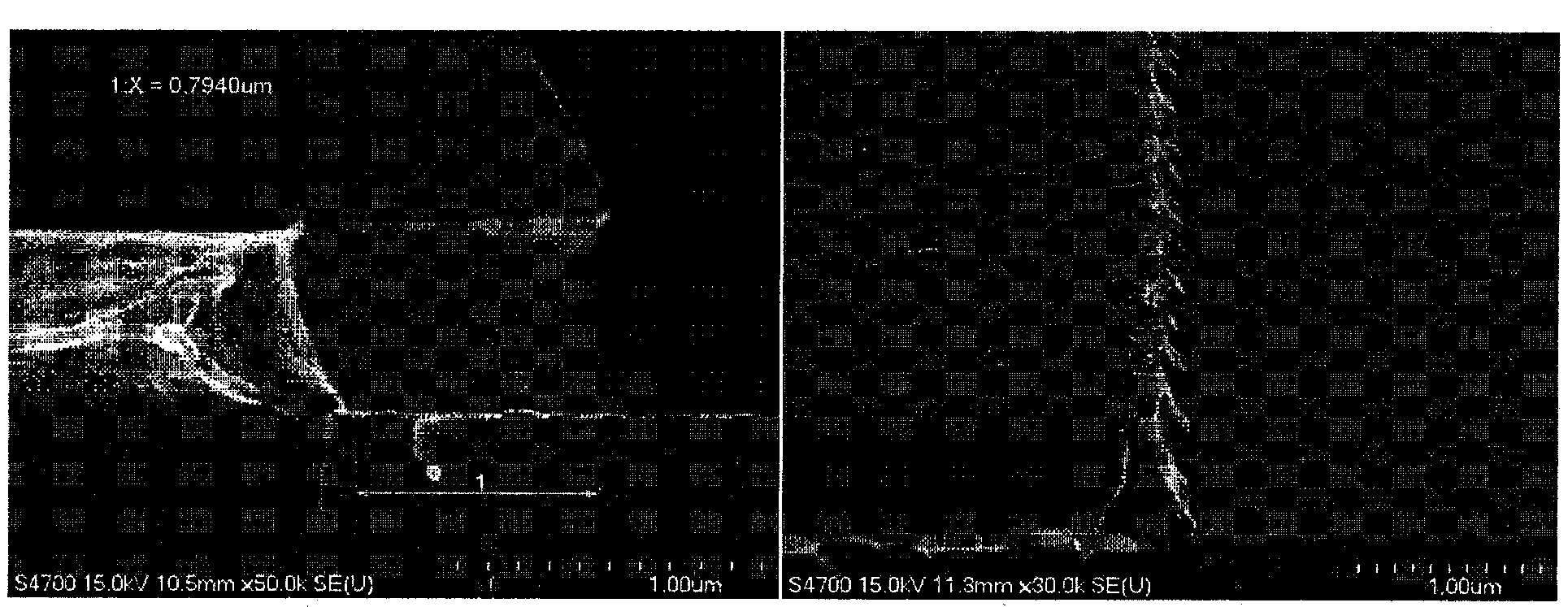

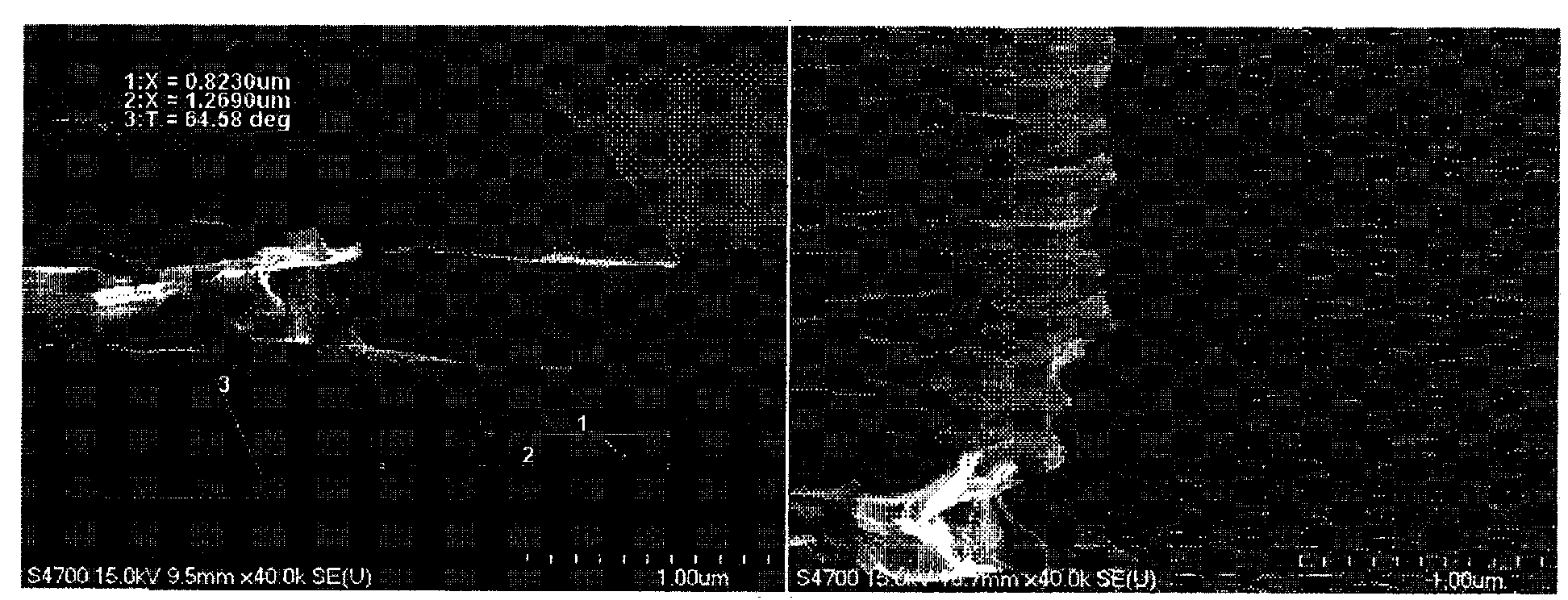

Image

Examples

Embodiment 1 to 11 and comparative example 1 to 5

[0035] Examples 1 to 11 and Comparative Examples 1 to 5: Preparation of Etching Compositions

[0036] The ingredients and composition ratios required for each etching composition to prepare 180kg are given in the following table 1

[0037] [Table 1]

[0038]

h 2 o 2

NH 4 FHF

iminodiacetic acid

ammonium nitrate

C6H5N3

CH 3 COOH

water

Example 1

25

1

3

3

0

0

68

Example 2

20

1

5

1

0

0

73

Example 3

15

1

3

0.5

0

1

79.5

Example 4

15

1.2

4

2

0

0

77.8

Example 5

10

1

5

3

0

0

81

Example 6

25

1

3

3

0

3

65

Example 7

20

1

5

1

0

4

69

Example 8

15

1.2

4

2

0

2

75.8...

Embodiment 11

[0057] As shown in the above table 3, it can be determined that the variation of the side etching of the etching composition of Example 11 depending on the number of etching layers is greater than the variation of the side etching of the etching composition of Example 10, and the etching of the etching composition of Example 11 is linear Less linear than the Example 10 etching composition. Meanwhile, it was confirmed that the etching compositions of Examples 10 to BLK did not vary much in side etching, and that the etching composition of Example 10 was excellent in etching linearity even in the case of 1000 layers.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap