Compressor

A technology for a compressor and a compression chamber, applied in the field of compressors, can solve the problems of complex structure of rotary compressors, increased assembly man-hours, and increased manufacturing costs, and achieves the effects of reducing load burden, improving reliability, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

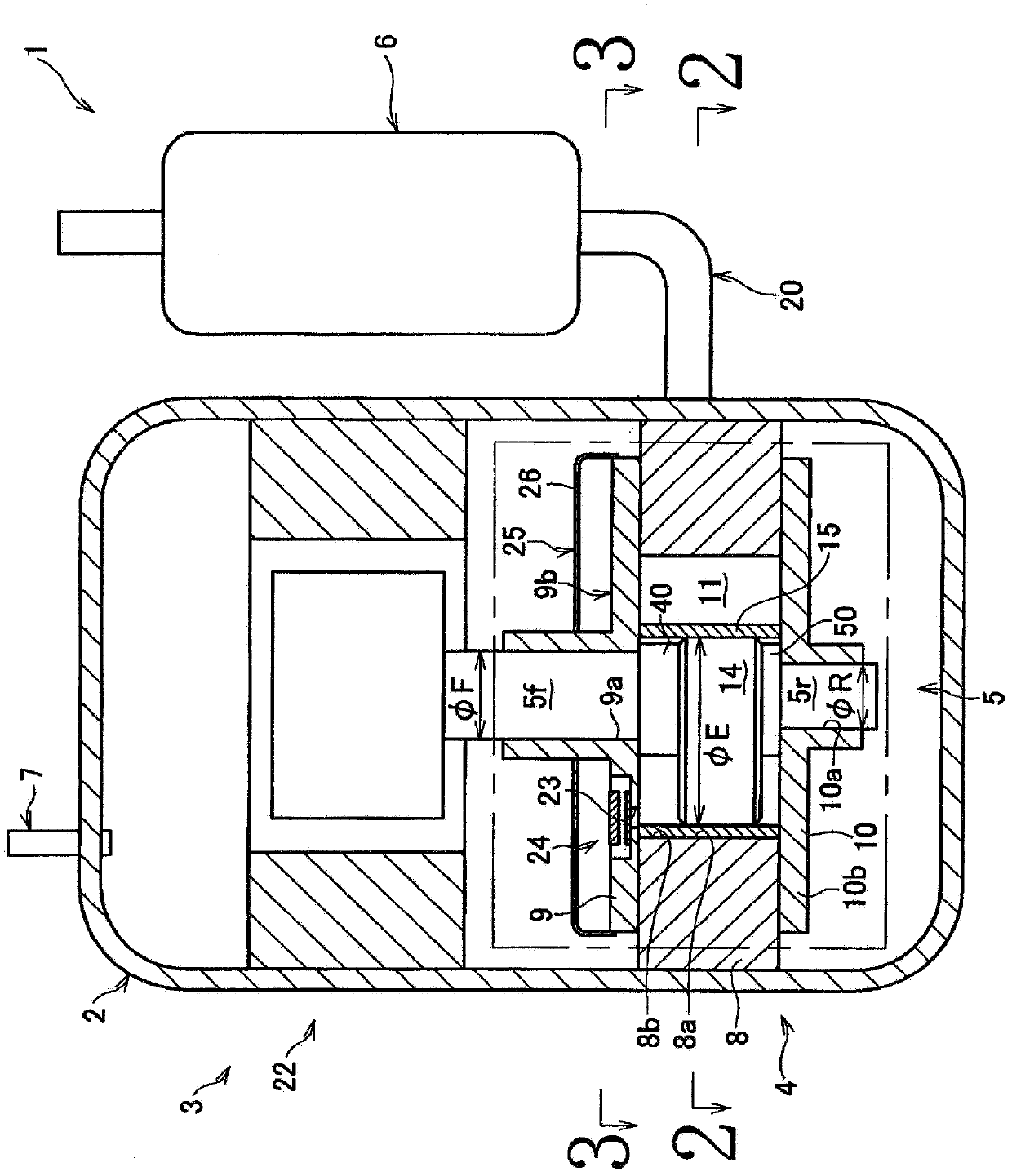

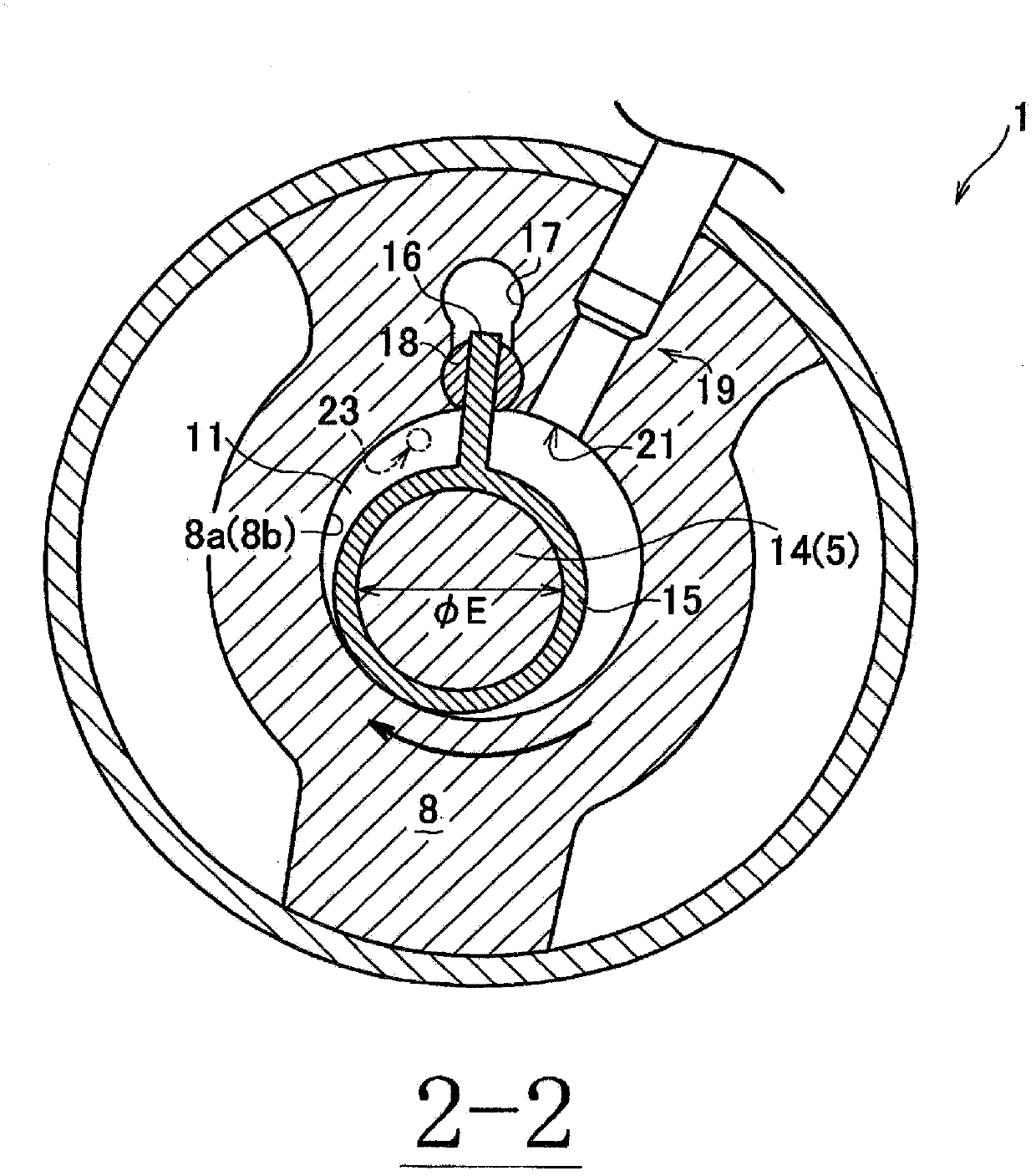

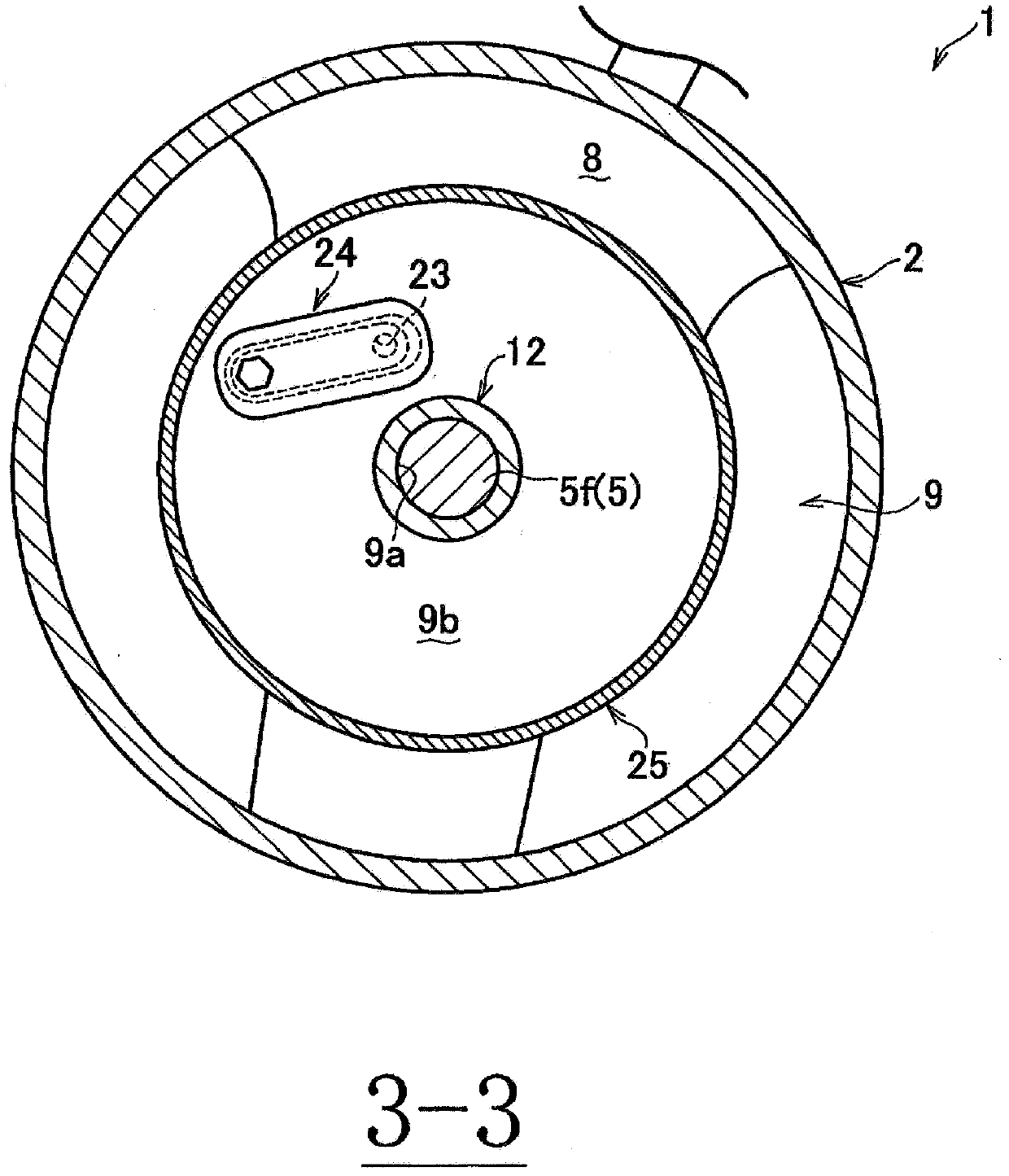

[0038] Next, the configuration of the rotary compressor according to the first embodiment of the present invention will be schematically described. figure 1 It is a vertical cross-sectional view of the rotary compressor according to the first embodiment of the present invention. figure 1The illustrated rotary compressor 1 is used to constitute a part of a refrigeration system such as an air conditioner, for example. That is, the air conditioner mainly includes a condenser, an expansion mechanism, an evaporator, and the above-mentioned rotary compressor 1 , which are not shown in the figure.

[0039] This rotary compressor 1 is constituted as a single-cylinder type rotary compressor for refrigerant, and sucks the CO in the above-mentioned air conditioner. 2 Refrigerant (hereinafter simply referred to as refrigerant), and discharge the refrigerant at a predetermined pressure. As shown in this figure, this rotary compressor 1 is mainly comprised by the airtight container 2, and...

no. 2 Embodiment approach

[0070] Next, a second embodiment of the present invention will be described. Figure 9 It is a vertical sectional view of the rotary compressor of 2nd Embodiment of this invention. Here, the description will focus on the differences from the above-mentioned first embodiment, and the description of overlapping parts will be omitted. The same reference numerals are assigned to components common to the rotary compressor 1 of the first embodiment and the rotary compressor 101 of the second embodiment.

[0071] First, the rotary compressor 1 of the first embodiment is configured as a single-cylinder type rotary compressor for refrigerant, but the rotary compressor 101 of the second embodiment is configured as a two-cylinder type rotary compressor for refrigerant. Furthermore, in the first embodiment, only one cylinder main body 8 was provided, but in this embodiment, two cylinder main bodies 8 are provided in parallel in the axial direction of the crankshaft 5 . Furthermore, an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com