Processing fixture and assembling method for long-hinge part

A hinged, fixture technology, used in manufacturing tools, metal processing equipment, drilling dies for workpieces, etc., can solve problems such as affecting the surface roughness of parts, inconvenient disassembly, and poor chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

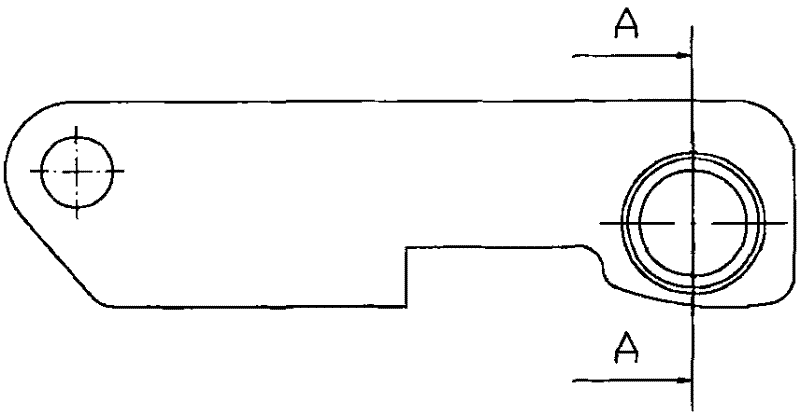

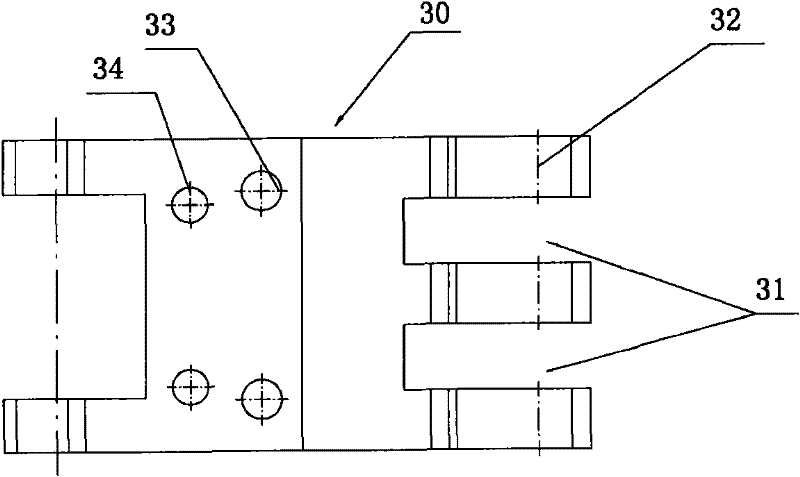

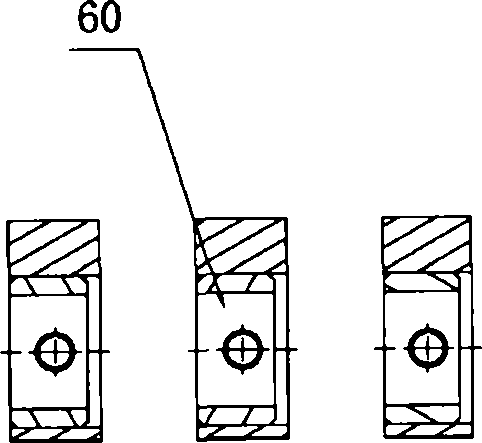

[0040] Such as Figure 5-6 As shown, the processing fixture includes a fixture main body (10), an end drill template (20), a sliding drill template (30) and a pressing piece (40). The fixture main body (10) is substantially a hexahedron with a first positioning surface (11) and a second positioning surface (12). The first positioning surface (11) is located on the right end surface of the clamp body (10), and the second positioning surface (12) is located on the upper end surface of the clamp main body (10), which is perpendicular to the first positioning surface (11) and parallel to on a horizontal plane, wherein the first positioning surface (11) and the second positioning surface (12) are respectively provided with several holes. The end drilling template (20) includes a fixing part (21) and a guide part (22), and several holes are provided on the fixing part (21), and screws (51) and pins (52) are connected with the fixture main body (10). The right end face is fixed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com