Photoelectric control yarn feeding equipment

A photoelectric control and yarn feeding technology, which is applied in textiles, papermaking, knitting, etc., can solve the problems of complex control circuit of the yarn feeding device, unfavorable mass production, and inability to guarantee the quality of fabrics, etc., so that the detection results are intuitive and easy to implement , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

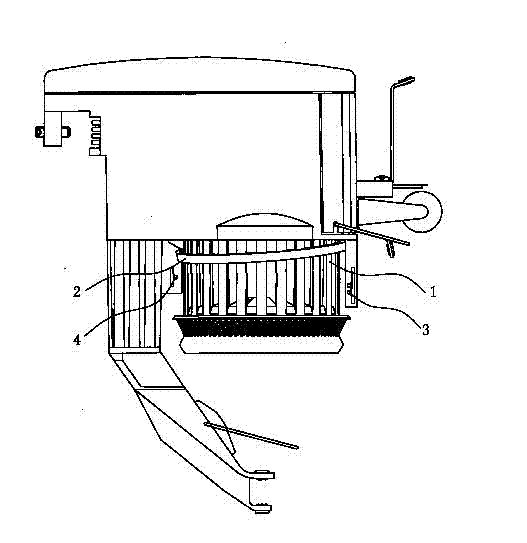

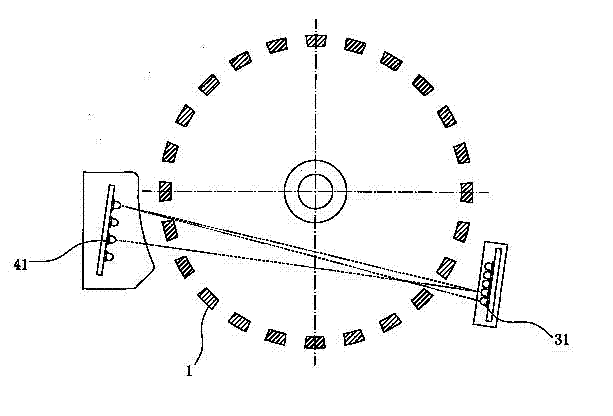

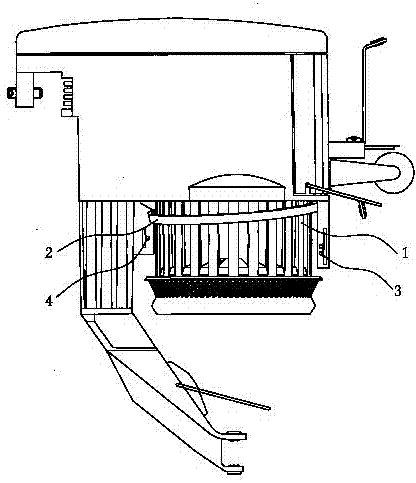

[0013] Such as Figure 1 ~ Figure 2 As shown, the yarn feeding device with photoelectric detection function includes a motor (not shown in the figure) controlled by a control circuit, a yarn storage device 1 driven by the motor, and a yarn pressing ring 2 arranged on the upper part of the yarn storage device 1 A detector composed of a pair of transmitting device 3 and receiving device 4;

[0014] Wherein, the transmitting device 3 is arranged on one side of the yarn storage device 1, and faces the scanning area provided on the surface of the yarn storage device 1, and the receiving device 4 is arranged relative to the transmitting device 3 and is located at the side of the yarn storage device 1. On the other side, the transmitter 3 is controlled by the control circuit to start its work, and the output terminal of the receiver 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com