Improved centrifugal type wind wheel as well as volute and turbine fan assembly

A centrifugal, wind wheel technology, applied in the components, pump components, mechanical equipment, etc. of the pumping device for elastic fluid, can solve the problems of low efficiency, high noise, small air volume, etc., and achieve high noise and low load. , the effect of smooth wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

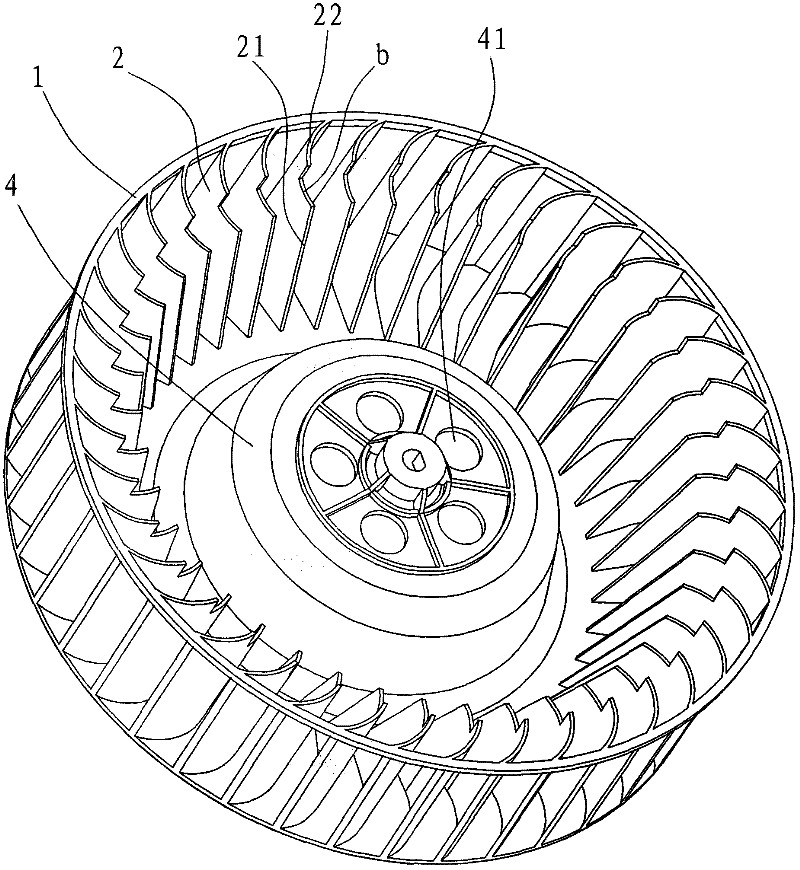

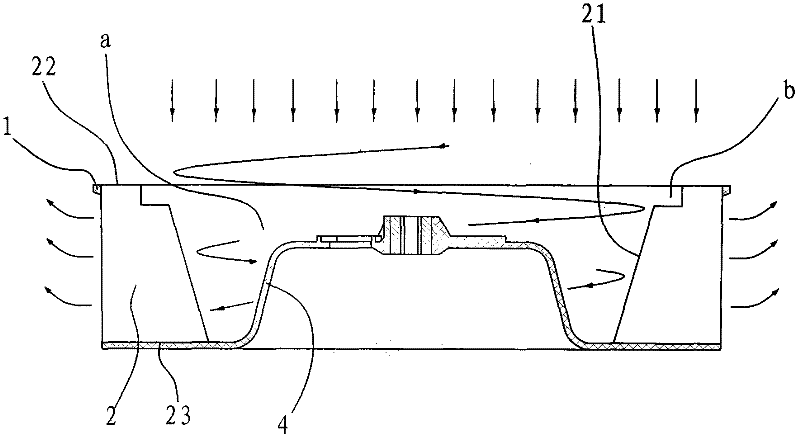

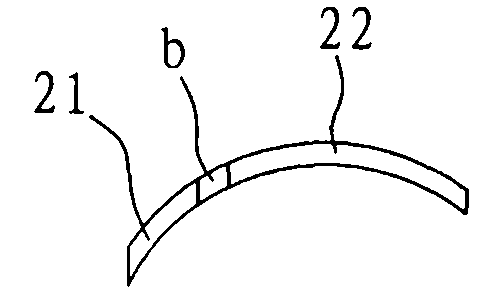

[0035] Such as Figure 1 to Figure 5 As shown, an improved centrifugal wind wheel provided by the present invention includes a base plate 4, blades 2 and stirrups 1, the blades 2 are multiple and distributed on the base plate 4 at intervals, and the stirrups 1 Connect the plurality of blades 2, the plurality of blades 2 and the bottom plate 4 form a negative pressure zone a, the front projection shape of the blades 2 is a right-angled trapezoid, and its hypotenuse 21 faces the negative pressure zone a, the The width of the top edge 22 of the blade 2 is smaller than the width of the bottom edge 23 , and the connecting portion between the hypotenuse 21 and the top edge 22 of the blade 2 is provided with a notch b. Right-angled trapezoid means that one side is a right-angled side, and the other side is a hypotenuse 21, the angle between the hypotenuse 21 and the base 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com