Carbon fiber tube preparing method and baking tube and microwave oven

A carbon fiber tube and carbon fiber technology, which is applied in the field of preparation of barbecue tubes, can solve the problems of difficulty in ensuring coaxiality, insufficient carbon fiber strength, insufficient strength of electric heating core, etc., so as to reduce ignition phenomenon, reduce curing treatment requirements, and improve products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

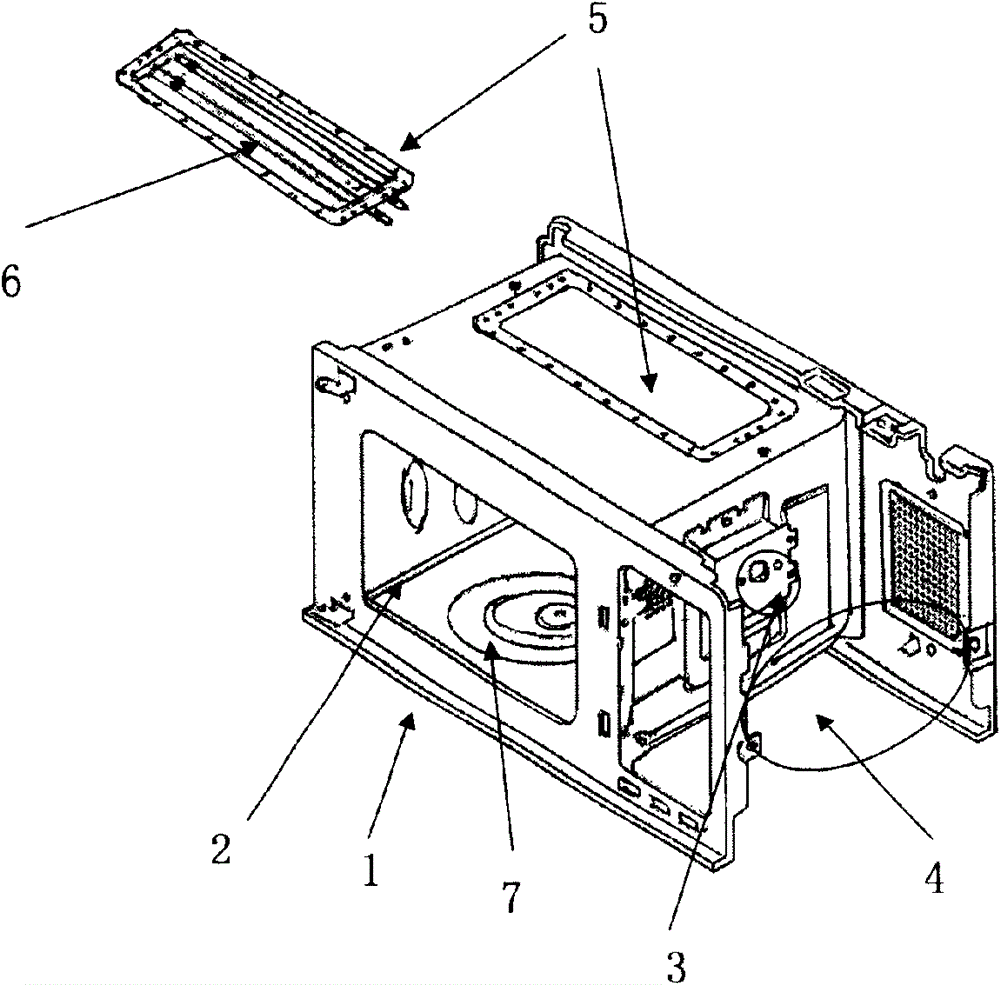

[0019] The present invention provides a novel grill type microwave oven. The microwave oven includes a furnace body, and a cooking chamber is formed in the furnace body. In order to further enable the microwave oven to perform baking and cooking, at least one layer of barbecue racks is arranged in the cooking chamber. . When using the microwave oven to cook food, the grill tube in the cooking chamber of the microwave oven can be driven to generate radiant energy, which can be irradiated on the food on the grill pan, that is, the food can be grilled.

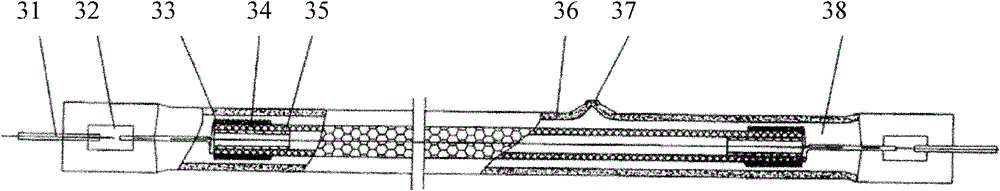

[0020] Such as image 3 As shown, a carbon fiber electric heating core quartz electric heating tube of the present invention includes a quartz tube shell 16, an external electrode 11, a carbon fiber tube 14, and a tubular electrode bracket 15 arranged at both ends of the quartz tube shell and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com