Power device

A power plant and power technology, applied in power plant, transmission, pneumatic power plant, etc., can solve the problems of reducing the degree of freedom of the first rotary machine, increasing the size of the power plant, increasing the manufacturing cost, and reducing the degree of freedom of the power plant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

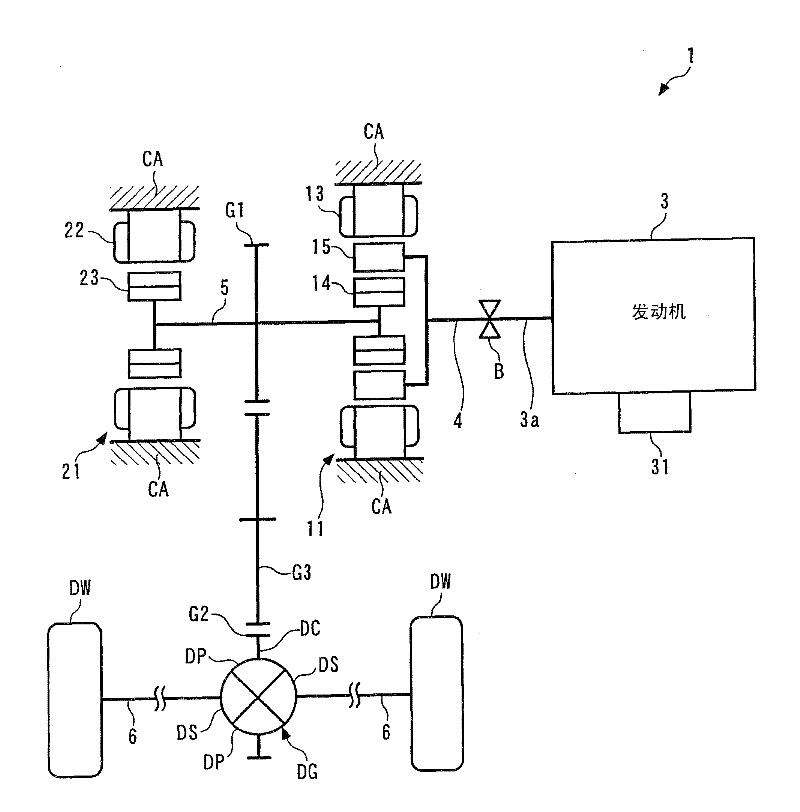

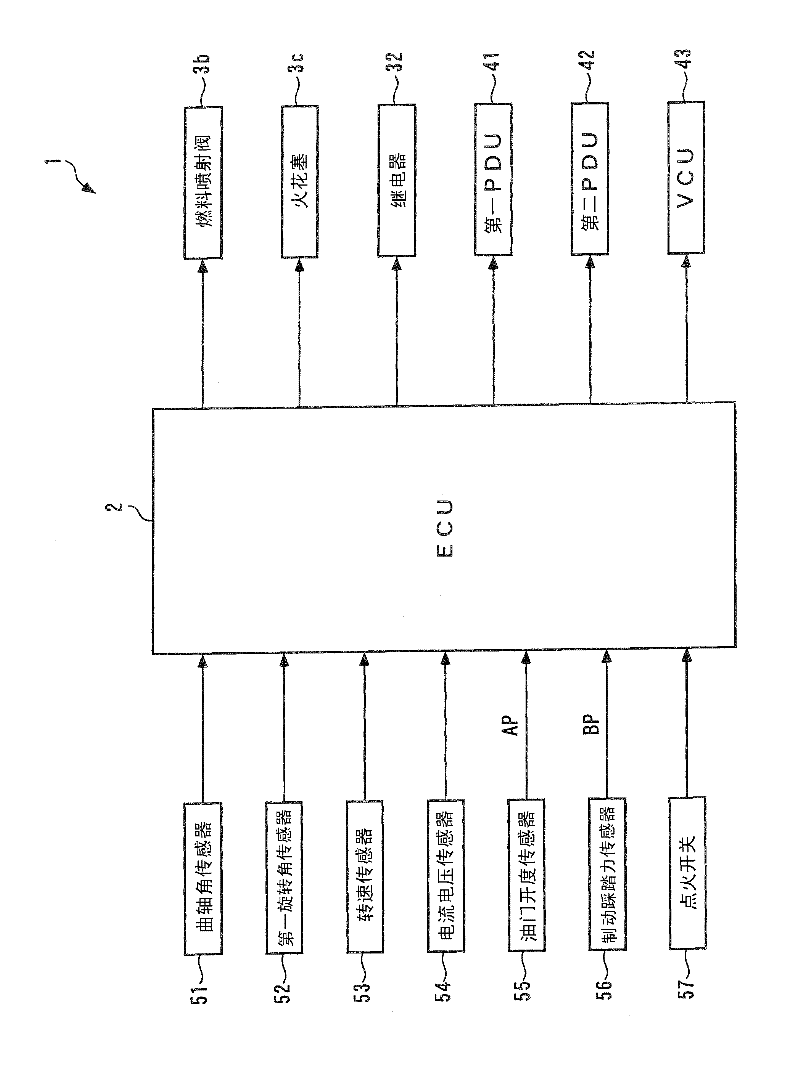

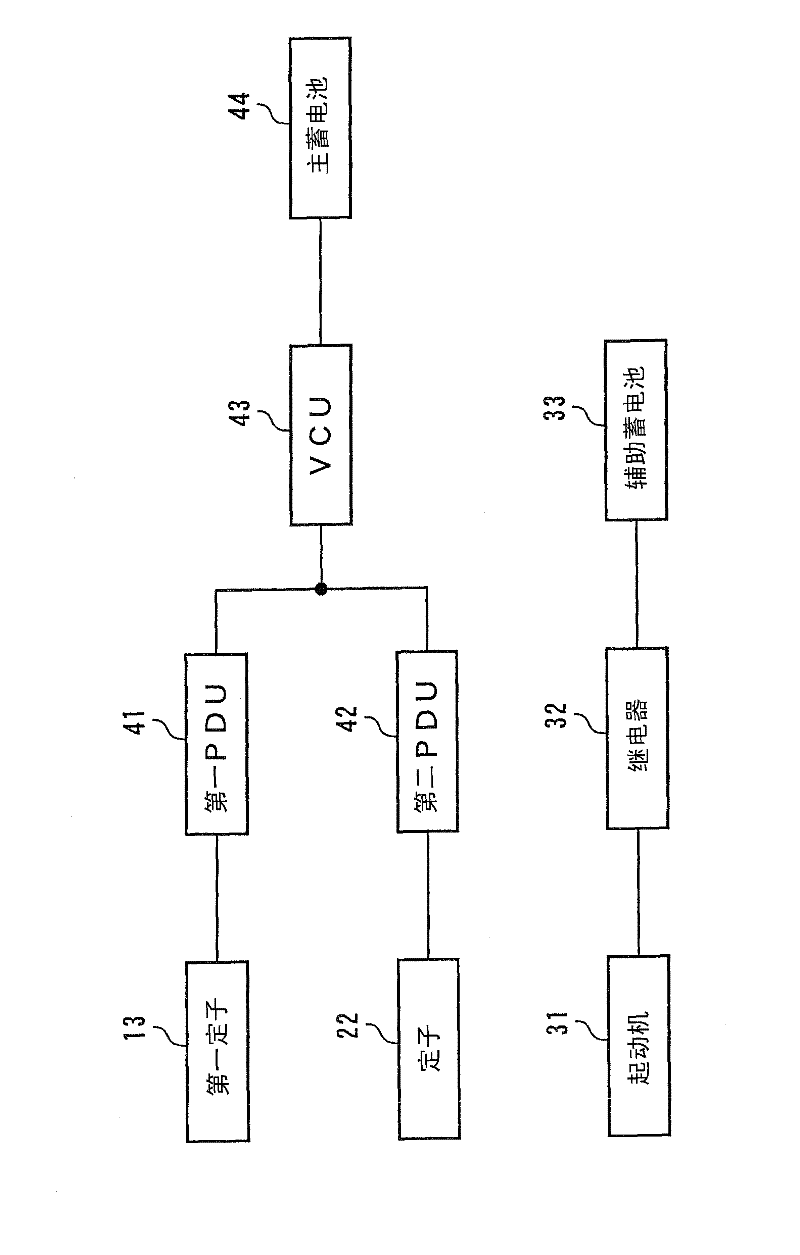

[0243] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. figure 1 and figure 2 The shown power plant 1 according to the first embodiment of the present invention is used to drive left and right drive wheels DW, DW of a vehicle (not shown), and includes an internal combustion engine 3 as a power source, a first rotary machine 11, and a second rotary machine. The machine 21, the differential device DG for transmitting power, and the ECU 2 for controlling the operations of the internal combustion engine 3 and the first and second rotary machines 11 and 21 described above. It should be noted that, in figure 1 In other drawings to be described later, hatching of parts showing cross sections is appropriately omitted. In addition, in the following description, the case where each element is directly connected by a shaft etc. without passing through a transmission mechanism, such as a gear, is called "direct co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com