Sparerib lotus root soup product and production method thereof

A production method and technology for pork ribs, which are applied in food preparation, application, food science and other directions, can solve the problems of loss of lotus root texture in pork ribs and lotus root soup, low total soluble sugar content, etc., and achieve the effect of improving life rhythm, stable quality and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

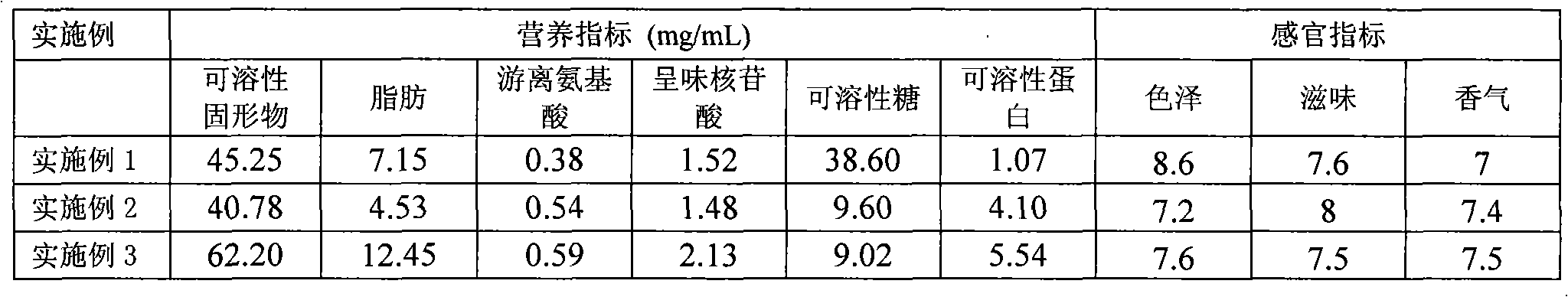

Embodiment 1

[0023] Wash the pork ribs and tube bones with cold water, chop the ribs into 5-6cm long, 3-4cm wide pieces, cut the lotus root into 5-6cm, 3-4cm wide lotus root pieces, pre-treat the ribs, and put them in the Pre-fry in a hot oil pan with lard, and fry quickly until the surface of the ribs is golden brown. Each pot uses a total of 300 parts of pork ribs and tube bones, 20 parts of deodorizing agent, and 1200 parts of water, and stirs evenly. Cook at 100°C for 45 minutes in a 900w electric furnace at high temperature and high power. Then add the cleaned lotus root to the container, and cook it for 75 minutes at 100°C with a power of 500w electric furnace at high temperature and low power. Add 5.7 parts of umami flavoring agent to the above mixed raw materials, and pack into cans. Under the condition of keeping the pressure inside and outside the tank consistent, place the tank at 60°C for 30 minutes to obtain the traditional ribs and lotus root soup. The above-mentioned prod...

Embodiment 2

[0025] Wash the pork ribs and tube bones with cold water, chop the ribs into 5-6cm long and 3-4cm wide pieces, cut the lotus root into 5-6cm, 3-4cm wide lotus root pieces, pre-treat the ribs, and place them in boiling water Medium, heat for 2 to 3 minutes, remove and set aside. Each pot uses a total of 300 parts of pork ribs and tube bones, 20 parts of deodorizing agent, and 1200 parts of water, and stirs evenly. Cook at 100°C for 45 minutes in a 900w electric furnace at high temperature and high power. Then add the cleaned lotus root to the container, and cook it for 75 minutes at 100°C with a power of 500w electric furnace at high temperature and low power. Add 5.7 parts of umami flavoring agent to the above mixed raw materials, and pack into cans. Under the condition of keeping the pressure inside and outside the tank consistent, place the tank at 60°C for 30 minutes to obtain the traditional ribs and lotus root soup. The above-mentioned products are packaged and put int...

Embodiment 3

[0027] Wash the pork ribs and tube bones with cold water, chop the ribs into 5-6cm long, 3-4cm wide pieces, cut the lotus root into 5-6cm, 3-4cm wide lotus root pieces, pre-treat the ribs, and put them in the Pre-fry in a hot oil pan with lard, and fry quickly until the surface of the ribs is golden brown. Each pot uses a total of 300 parts of pork ribs and tube bones, 20 parts of deodorizing agent, and 900 parts of water, and stirs evenly. Cook at 100°C for 45 minutes under high temperature and high power of a 900w electric furnace. Then add the cleaned lotus root to the container, and cook it for 75 minutes at 100°C with a power of 500w electric furnace at high temperature and low power. Add 5.7 parts of umami flavoring agent to the above mixed raw materials, and pack into cans. Under the condition of keeping the pressure inside and outside the tank consistent, place the tank at 60°C for 30 minutes to obtain the traditional ribs and lotus root soup. The above-mentioned pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com