Method for producing daptomycin by fermentation

A technology of daptomycin and fermentation broth is applied in the fields of producing antibiotics and fermenting daptomycin to achieve the effects of no environmental pollution, low price and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

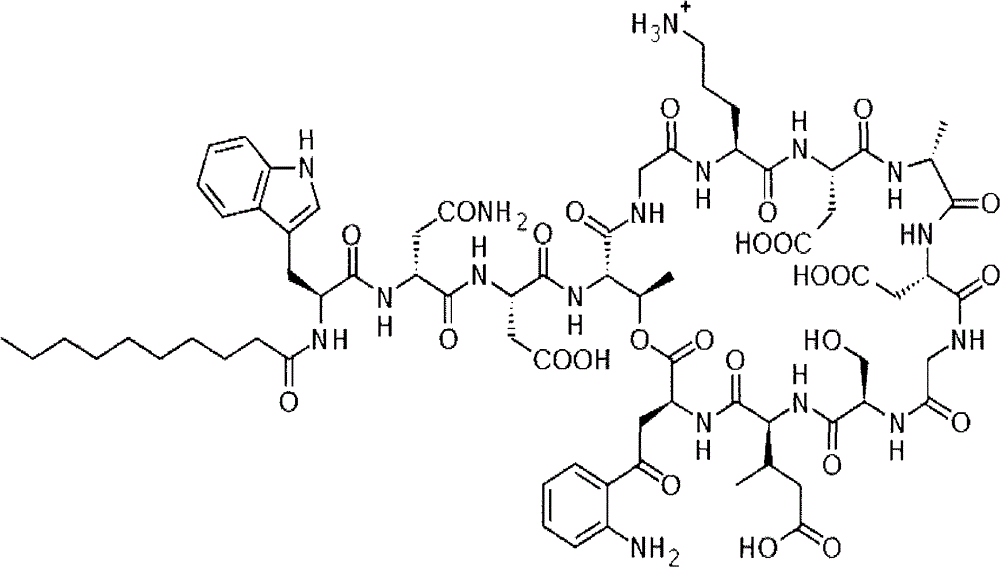

AI Technical Summary

Problems solved by technology

Method used

Image

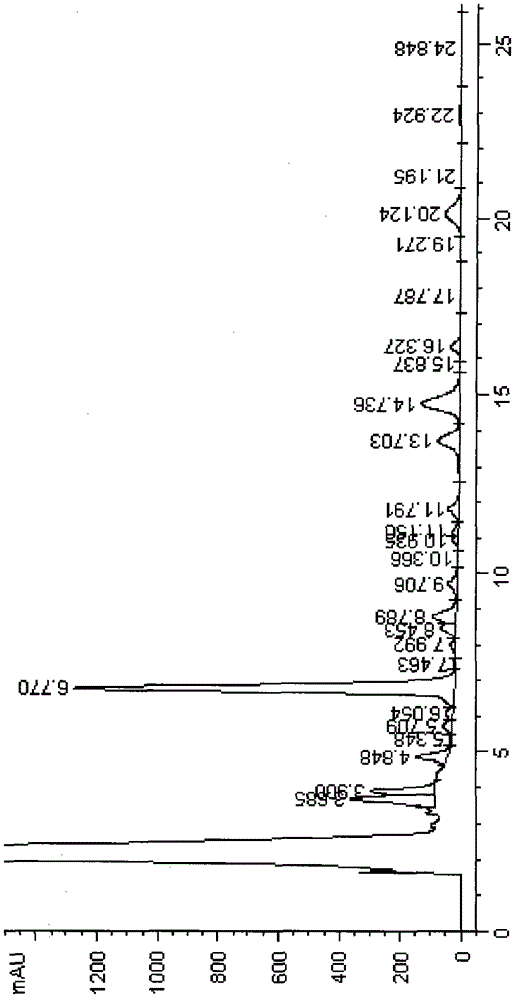

Examples

Embodiment 1

[0078] 1. Preparation of amino acid solution:

[0079] Weigh amino acids with the following components and masses:

[0080] L-kynurenine: 3.67g, 3-methylglutamic acid: 2.86g, D-serine: 1.85g, D-alanine: 1.57g, L-ornithine: 2.33g, glycine: 2.65g , L-threonine: 2.10g, L-aspartic acid: 7.04g, L-asparagine: 2.33g, L-tryptophan: 3.60g; the total weight of the above amino acids is 30g.

[0081] Add the above-mentioned weighed amino acid into purified water, stir to dissolve it fully, and set the volume to 10L to obtain a compound amino acid aqueous solution with a concentration of 3.0g / L; sterilize the compound amino acid aqueous solution at 121°C for 15 minutes by high-pressure steam , cooled to obtain sterile compound amino acid aqueous solution.

[0082] 2. Fermentation and cultivation of Streptomyces roseospora NRRL11379 strain according to the following method:

[0083] The spores were inserted into 150 ml of seed medium, and the proportion of the medium was: vegetable prote...

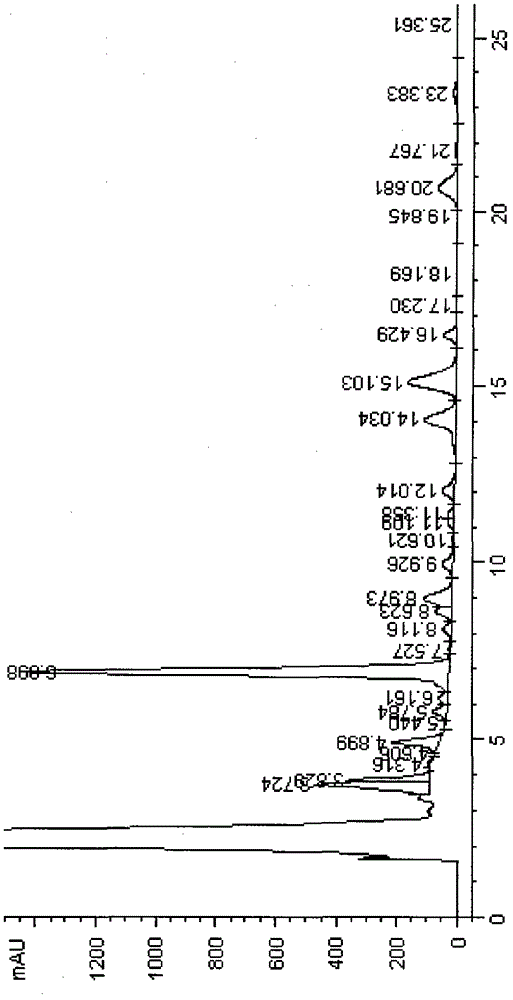

Embodiment 2

[0090] 1. Preparation of amino acid solution:

[0091] The crude product of industrial compound amino acid contains the following amino acid composition and mass ratio:

[0092] Aspartic Acid: 7.28%, Threonine: 3.04%; Serine: 4.53%; Glutamic Acid: 8.01%; Glycine: 2.76%; Alanine: 2.54%; Cysteine: 0.79%; Valine: 2.63%; Methionine: 0.71%; Isoleucine: 1.72%; Leucine: 2.43%; Tyrosine: 0.52%; Phenylalanine: 1.35%; Lysine: 1.98%; Histidine: 1.35 %; Arginine: 5.32%; Proline: 4.01%. The total amount of amino acids is: 50.97%.

[0093] Weigh 110 g of the above-mentioned industrial compound amino acid crude product and add it into purified water, stir to make it fully dissolve, and set the volume to 10 L to obtain a compound amino acid aqueous solution with a concentration of 11.0 g / L; sterilize the compound amino acid aqueous solution at 121 ° C for 15 Minutes, cooled to obtain sterile compound amino acid aqueous solution.

[0094] 2. Fermentation and cultivation of Streptomyces ros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com