Multiple-degree-of-freedom vibration isolator and multiple-degree-of-freedom vibration isolating system for effective load and satellite

A technology for payloads and vibration isolators, applied in the direction of inertial effect shock absorbers, aerospace vehicle guides, etc. Deviation and other problems, to achieve the effects of not being affected by the space environment, reliable performance, and no leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

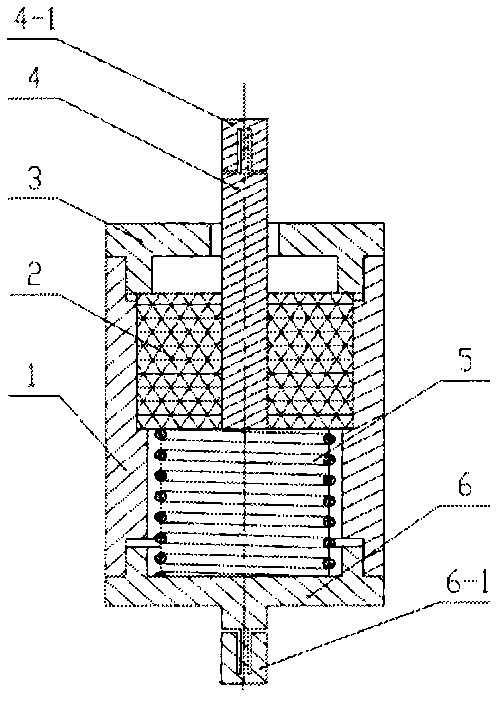

[0021] Such as figure 1 As shown, the vibration isolator consists of a shell 1, an upper end cover 3 of the shell, a lower end cover 6 of the shell, a metal network material member 2, a moving guide rod 4, a fine-tuning spring 5, a flexible hinge 4-1 of the moving guide rod, and a flexible lower end cover. Hinge 6-1 composition.

[0022] The housing 1 is cylindrical, and the upper and lower ends are respectively fixedly connected with the upper end cover 3 of the housing and the lower end cover 6 of the housing;

[0023] The fine-tuning spring 5 is placed inside the housing 1, and its bottom end is fixedly connected with the lower end cover 6 of the housing;

[0024] The metal network material component 2 is a hollow cylinder, placed inside the housing 1, placed on the fine-tuning spring 5, and the outer periphery is fixedly connected to the inner wall of the housing 1;

[0025] The upper end cover 3 of the housing has a round hole, and the guide rod 4 penetrates through the...

Embodiment approach 1

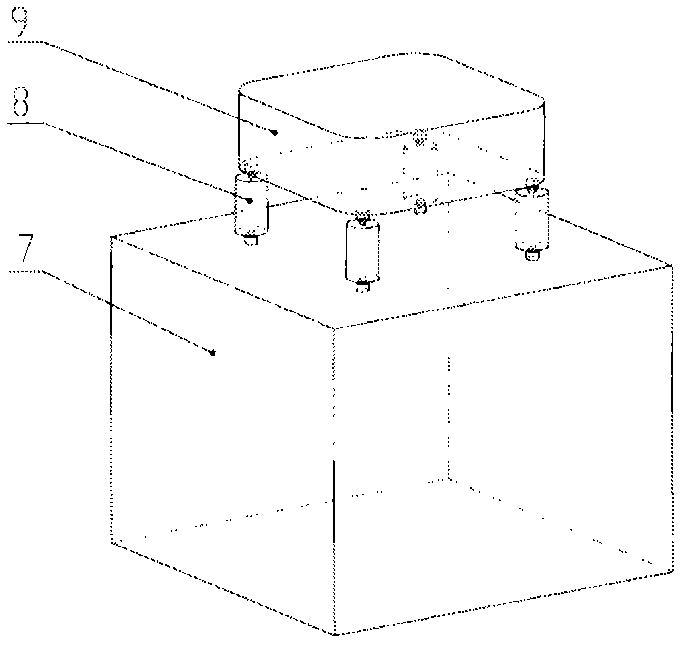

[0031] Such as figure 2 As shown, the embodiment of the vibration isolation system is composed of several vertically installed vibration isolators 8 provided by the present invention installed between the existing mounts of the payload 9 and the corresponding satellite 7 supporting structures, the vibration isolators The quantity is based on the number of existing mounts for the payload. The upper and lower ends of the vibration isolator are respectively connected to the payload and the satellite platform through the flexible hinge 4-1 of the motion guide rod and the flexible hinge 6-1 of the lower end cover. For example, when the payload has 4 mounts, a vibration isolator can be placed between each mount and the satellite structure to achieve vibration isolation. The advantage of a vibration isolation system constructed in this way is that changes to existing payloads and satellite structures can be minimized.

[0032] According to the requirement of the payload for the is...

Embodiment approach 2

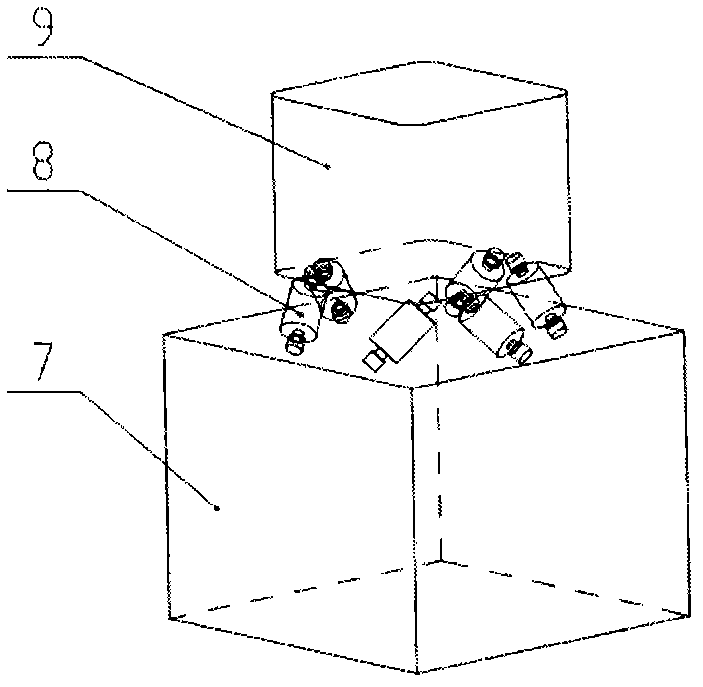

[0034] Such as image 3 As shown, the embodiment of the vibration isolation system is composed of six obliquely installed vibration isolators 8 provided by the present invention installed between the payload 9 and the satellite 7 . The six vibration isolators are divided into three groups, and each group consists of two vibration isolators to form an "eight" shape. Three sets of vibration isolators are evenly distributed on a circle and support the payload together. The upper and lower ends of the vibration isolator are respectively connected to the payload and the satellite platform through the flexible hinge 4-1 of the motion guide rod and the flexible hinge 6-1 of the lower end cover. The vibration isolation system constructed in this way has the advantage that each vibration isolator can work approximately in the state of axial tension and compression, and the lateral stiffness of the single-piece vibration isolator is not high, reducing the parameters of the single-piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com