Grilling pipe and microwave oven utilizing same

A barbecue tube and tube shell technology, which is applied in the field of microwave ovens, can solve the problems of reduced heating efficiency of the radiant energy of the grill tube and the impact on the safety of the product, and achieve the effects of improving customer satisfaction, reducing parts, and facilitating disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

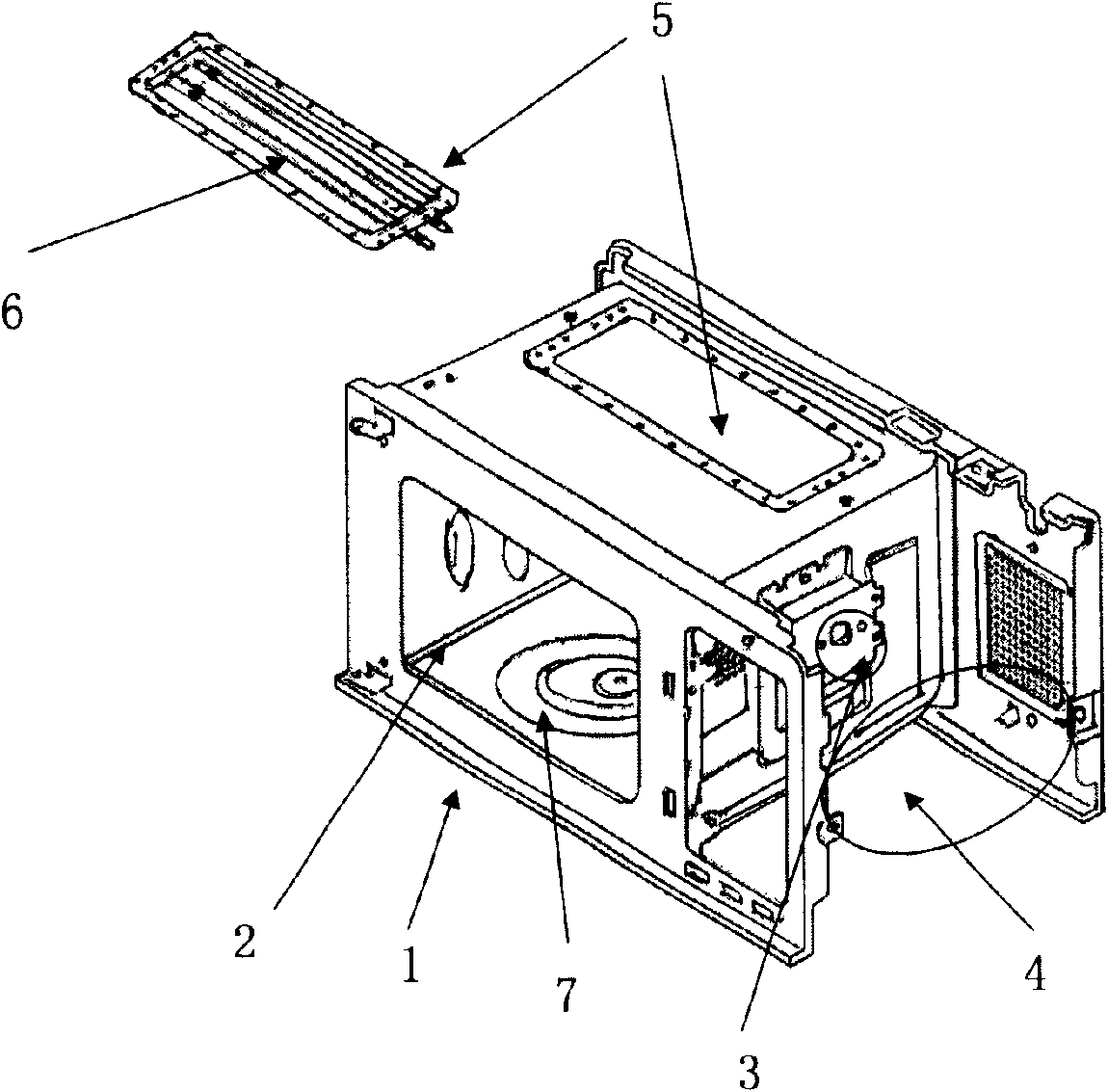

[0024] The invention provides a novel grill type microwave oven. The microwave oven includes a furnace body. A cooking chamber is formed in the furnace body. In order to further enable the microwave oven to perform baking and cooking, a barbecue frame is arranged in the cooking chamber. When using the microwave oven to cook food, the radiant energy can be generated by driving the grill tube in the cooking chamber of the microwave oven, and irradiated on the food on the grill, that is, the food can be grilled.

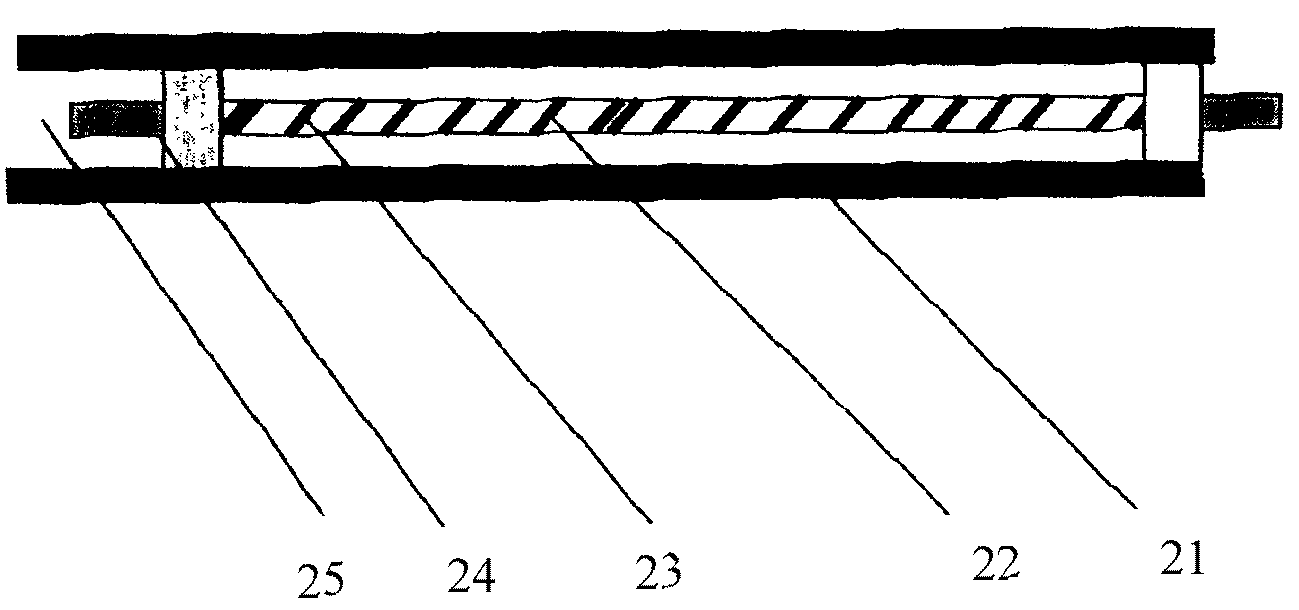

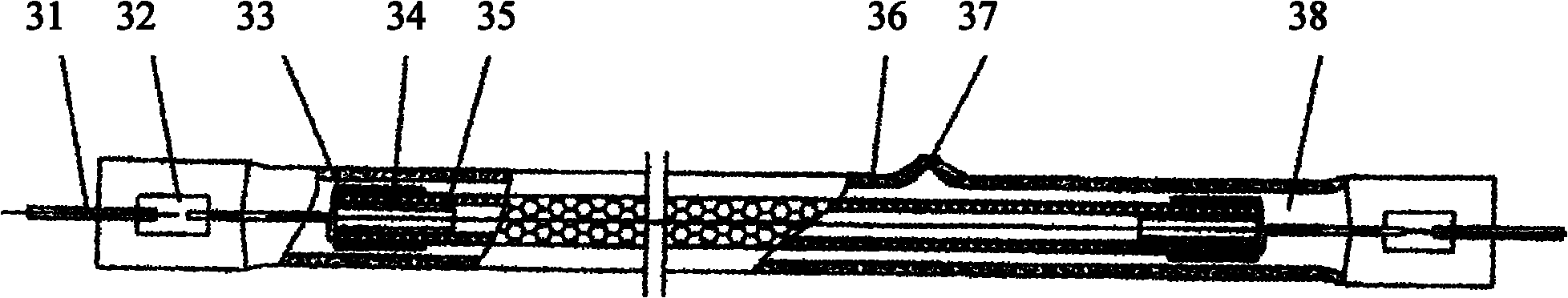

[0025] Such as Figure 4-Figure 6 As shown, the quartz shell of the barbecue tube of the present invention (not shown in the figure), the external electrode (not shown in the figure), the transition piece (not shown in the figure), and the carbon fiber electric heating core 44 are composed, wherein the carbon fiber electric heating The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com