Cuttlefish line mark calibrating line

An assembly line and line marking technology, which is applied in fish farming, application, climate change adaptation, etc., can solve the problems of continuous regeneration of fish fins, and achieve fast marking speed, high recognizability rate and reliable marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

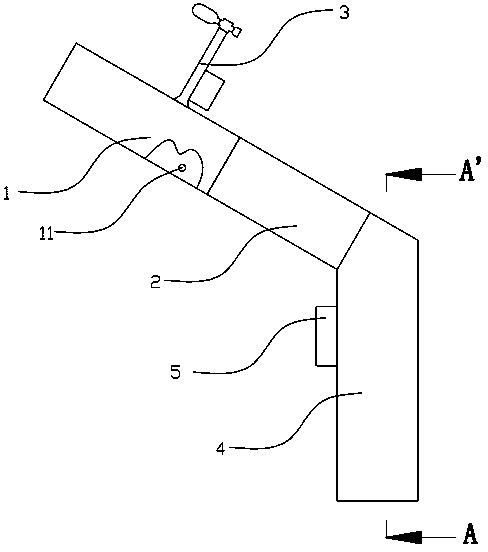

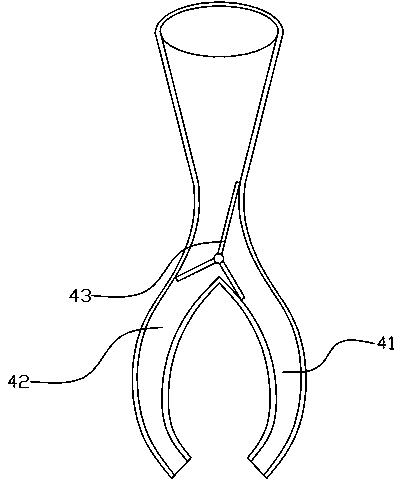

[0019] Example: refer to Figure 1 to Figure 6 , squid line standard calibration assembly line, including chute 1, wherein: line mark injection gun 3 is installed on chute 1; metal detection device 2 is connected to chute 1; The device 2 is also connected with a sorter 4 which can perform a sorting operation according to the detection results of the metal detection device 2 through pipelines. The sorter separates the marked squid from the unmarked squid according to the results of the metal detection device, and re-transports the marked squid back to the chute through the external conveyor belt for re-marking to complete the supplementary marking. The conveyor belt is preferably a hopper conveyor belt. Refer to the relevant components mentioned in the Chinese invention "Aquatic Product Bag Packing Machine" patent No. ZL200910096007.7, and will not repeat them here.

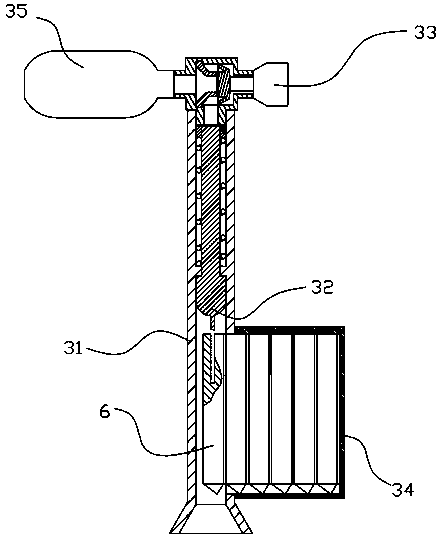

[0020] The line marking injection gun 3 has a pipe body 31; the pipe body 31 is provided with an electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com