Deep-hole drill bit

A deep hole drill bit and head technology, which is applied in the direction of drilling/drilling equipment, drill repairing, drilling tool accessories, etc., can solve problems such as single structure, difficult maintenance, and increased cost, and achieve quick replacement, convenient disassembly, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

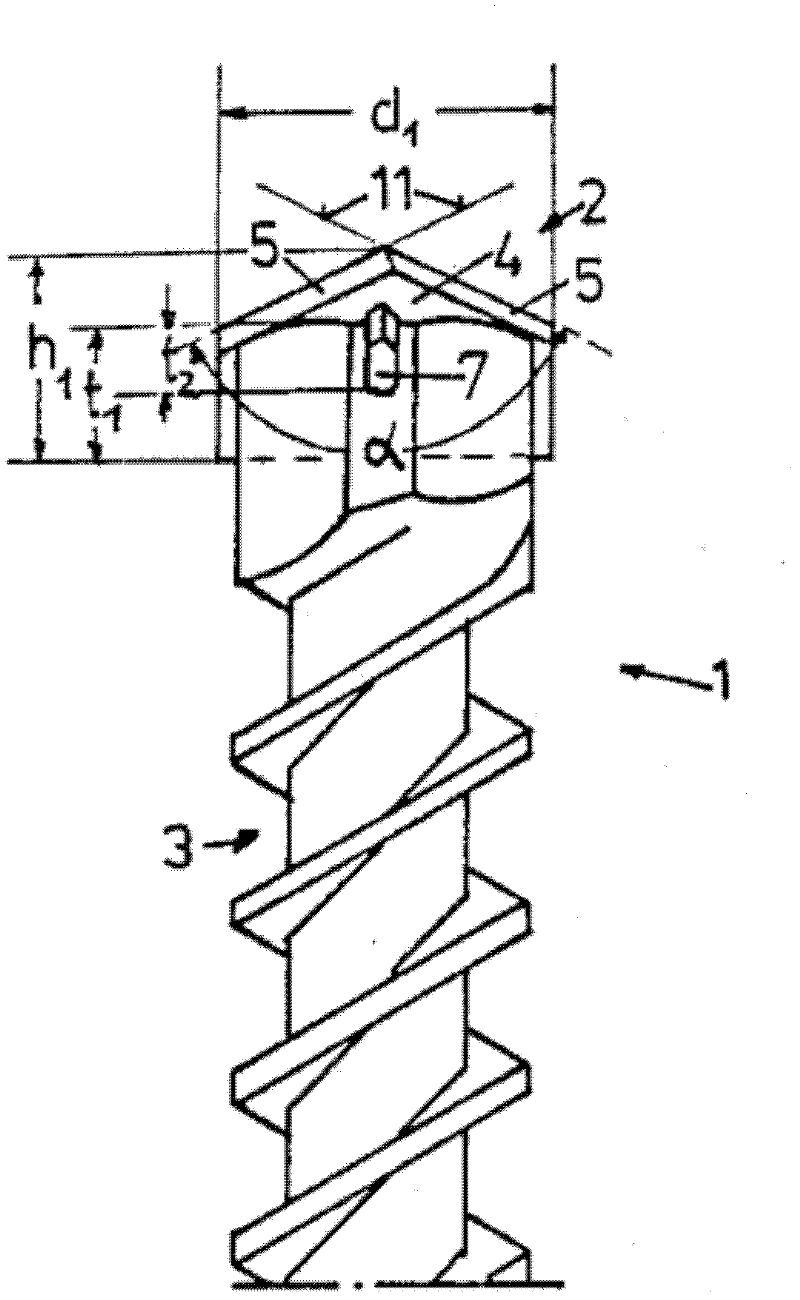

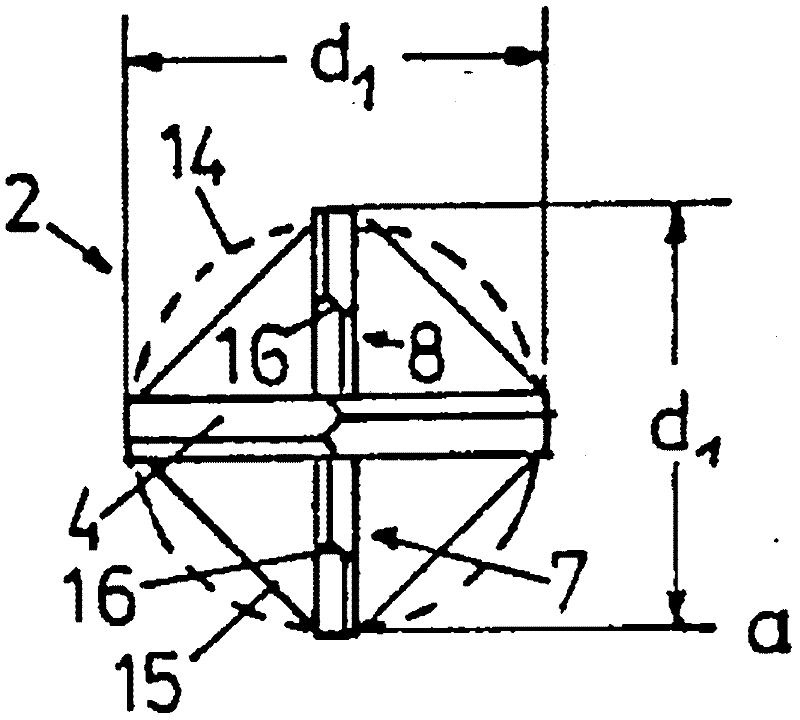

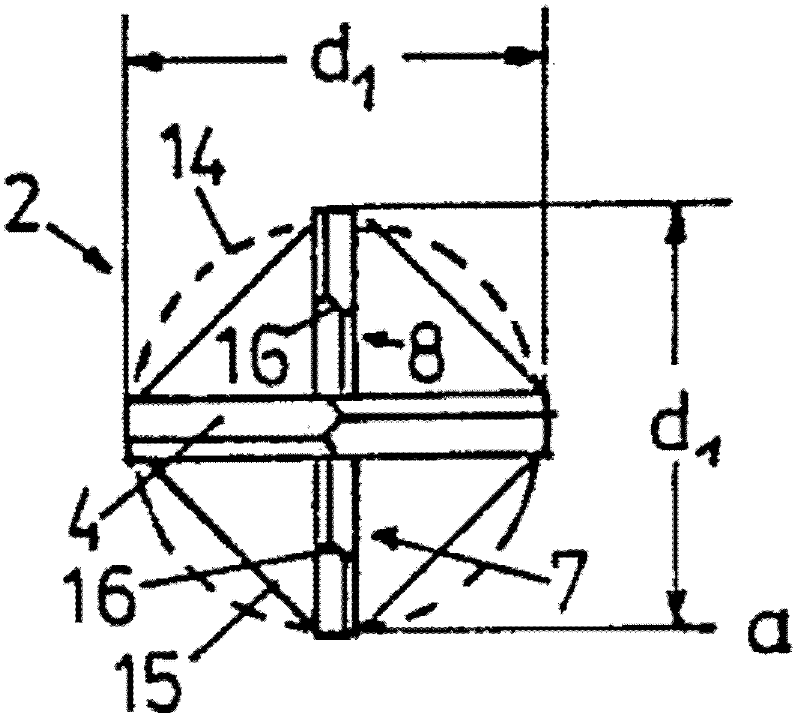

[0021] see Figure 1 to Figure 2 , shows a specific embodiment of the deep hole drill bit of the present invention.

[0022] The deep hole drill 1 includes a rod body 3 and a head 2. The rod body 3 is a cylinder. The rod body 3 has a helical part forming a chip removal channel, and the helical part includes at least one helical line.

[0023] The helix extends to the back of the head and ends, and the head 2 is a square cylinder (see figure 2 ), the top of which forms a partial spherical body, wherein a slot is formed transversely in the middle of the partial spherical body, the slot is opened along the diagonal of the square cylinder, and a replaceable blade 4 is arranged in the slot, the blade 4 is plate-shaped, the lower end forms a strip shape with a height of t1 to be inserted into the slot, and the upper end forms a triangular blade 5, the entire height of the blade 4 is h1, and the two sides of the triangular blade 5 respectively form cutting edges, preferably Yes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com