Shield sealing contact surface restoring method

A repair method and contact surface technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as high cost, temporary solution, and poor performance of driving and sealing performance, and achieve low cost and short repair period Short, excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

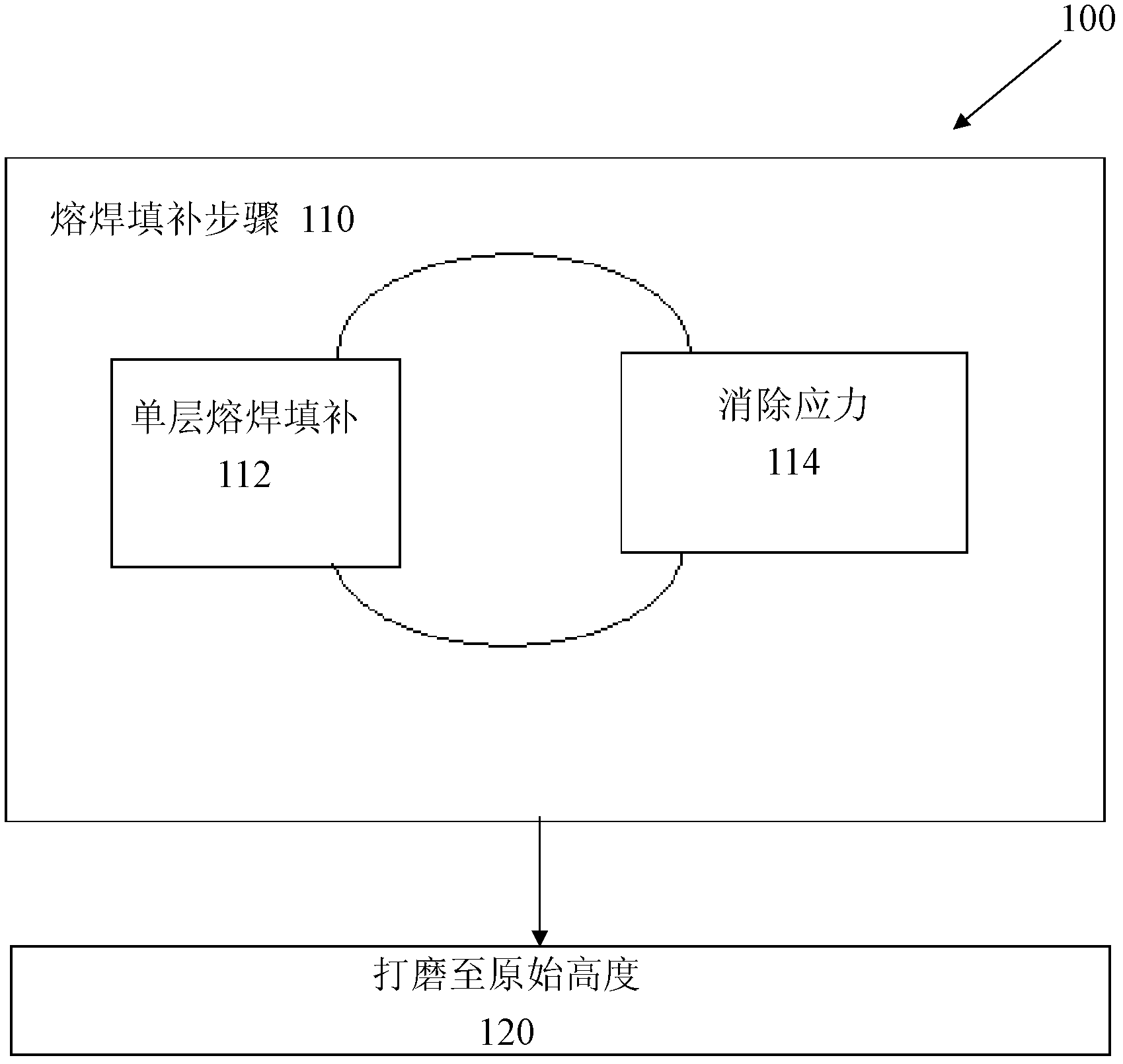

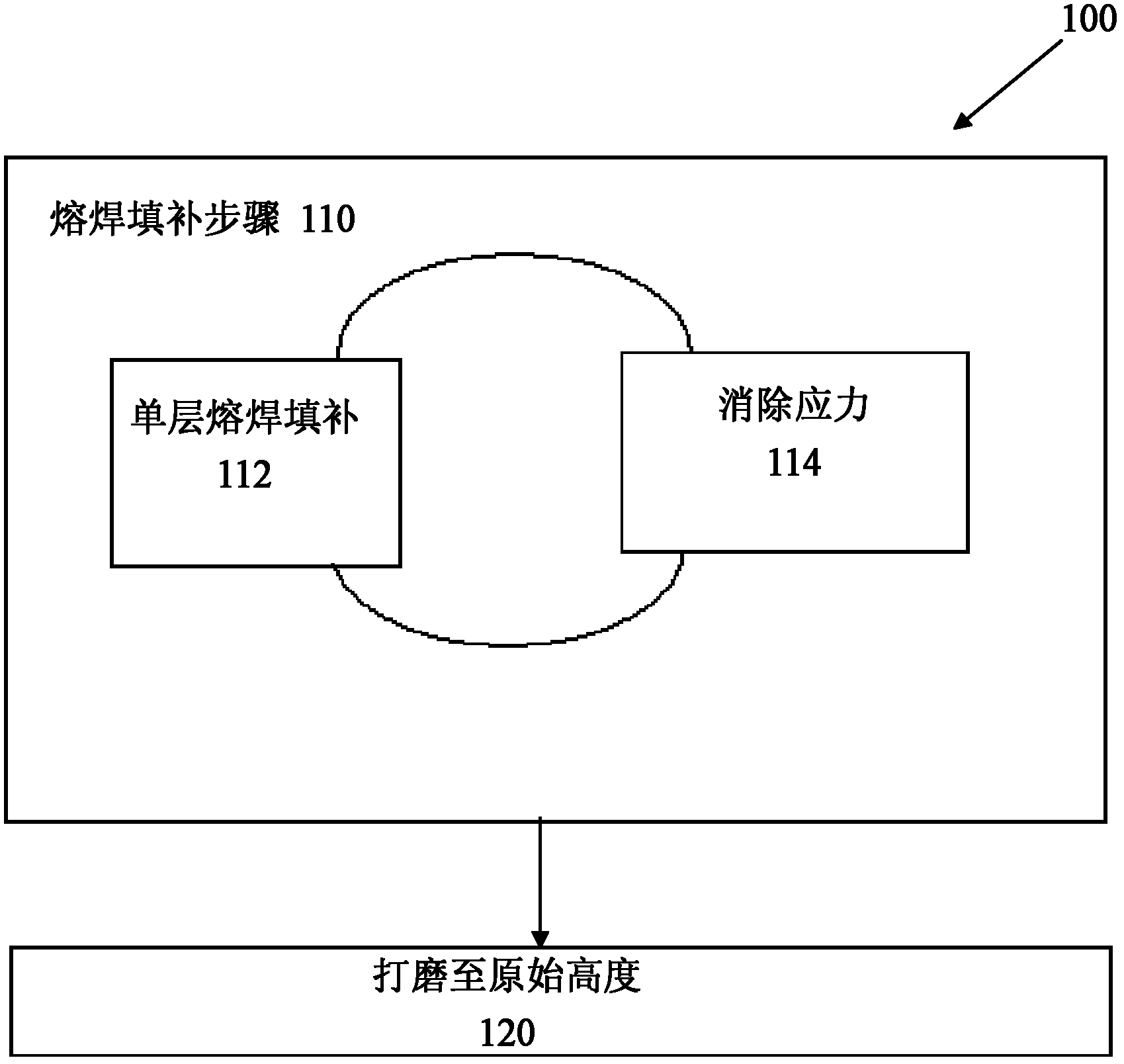

[0018] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0019] The repair of the lip contact plane of the key parts of the shield has the following two characteristics:

[0020] 1. The size of the parts is large. Since the worn part and the notch ring are welded as a whole, the overall size is large, which objectively brings greater repair difficulties.

[0021] 2. The requirements for plane repair are high. Since the function of the worn part is to provide a sealing plane, there are high clear requirements for the repaired surface finish, flatness, surface hardness and wear resistance.

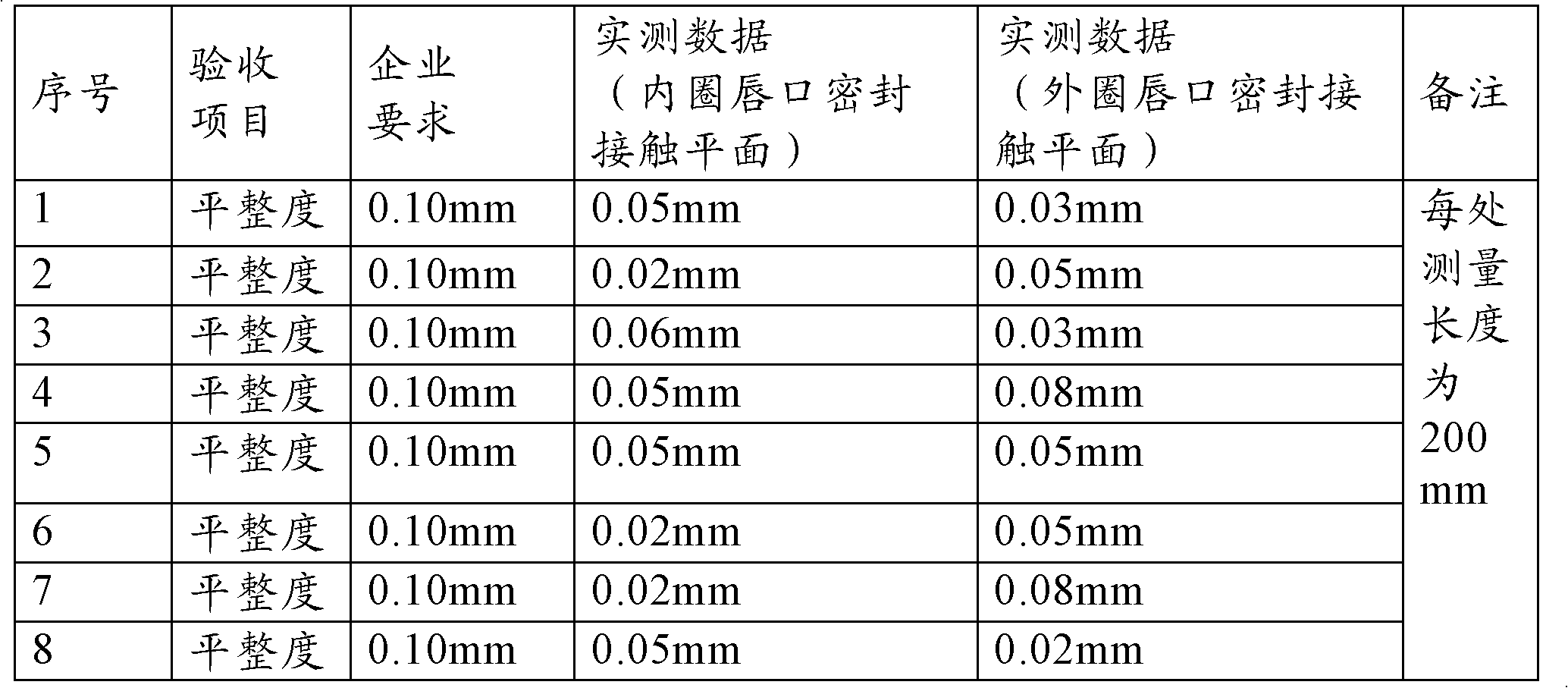

[0022] According to the flatness industry standard, the flatness of the lip seal contact plane is ≤0.1mm; the surface finish must not be lower than the accuracy of micro-discrimination of the direction of the machining trace; the surface hardness and wear resistance must meet the construction requirements.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com