Special tool for assembling steel wire process of automobile wheel cover body

A wheel cover and body technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

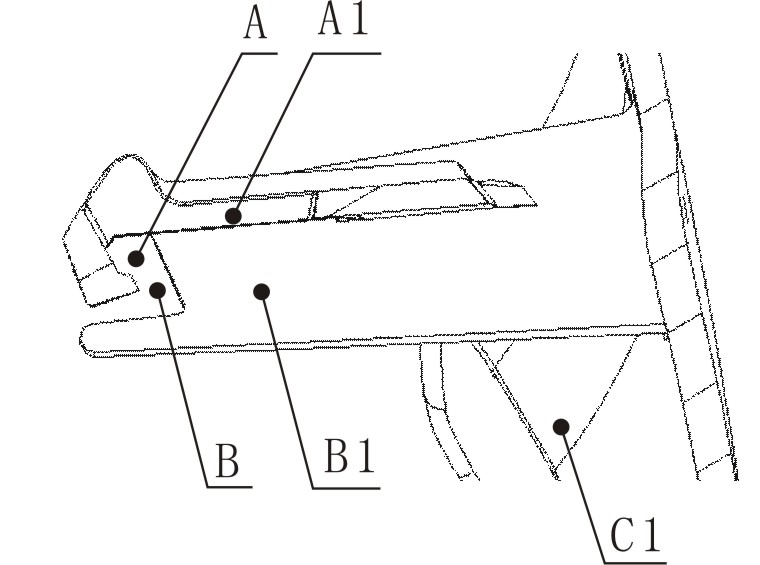

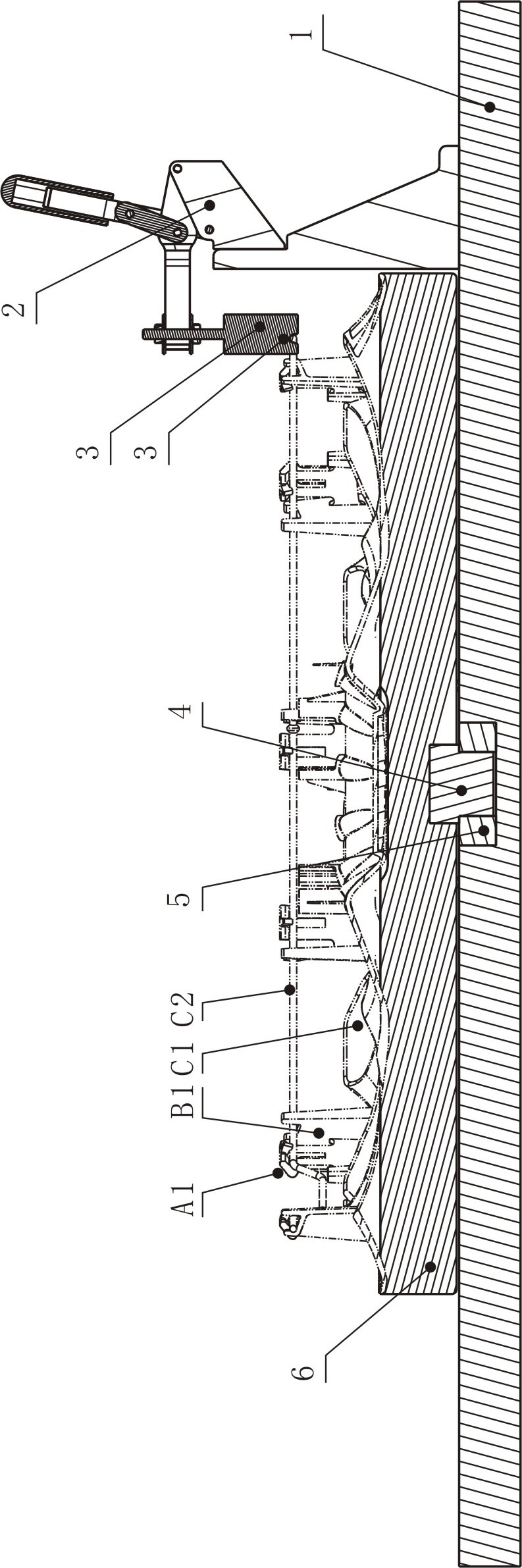

[0022] Such as image 3 As shown, the tooling is specially used for the steel wire loading process of the automobile wheel cover body, and includes a base plate 1, a quick clamp 2 and a membrane 6, the membrane 6 is installed on the base plate 1 through a rotating shaft 4 and a bearing 5, and the membrane 6 A quick clamp 2 is arranged next to it.

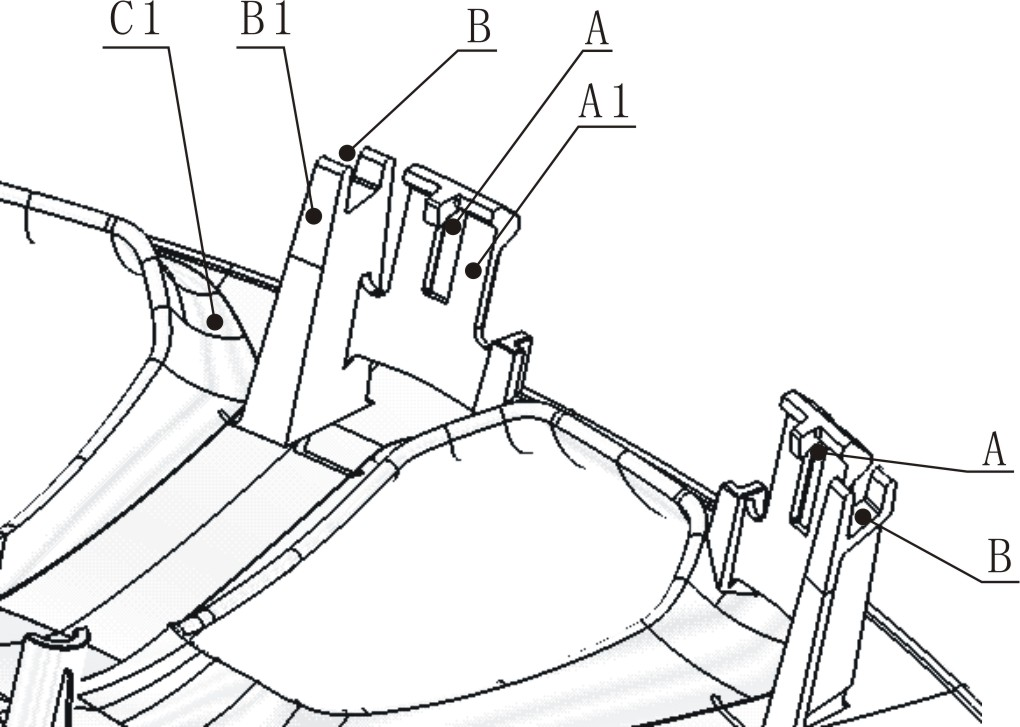

[0023] In order to control the stability of the steel wire, the end surface of the pressure head 3 of the quick clamp 2 is provided with a groove 31 for engaging the steel wire C2.

[0024] Generally, the surface of the wheel cover body C1 is sprayed, polished or required to have no crushing or scratch defects. In order to protect the surface of the wheel cover body, the tire film 6 is covered with a protective layer. The protective layer is cloth, rubber film or flexible resin, or other flexible and sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com