Puncturing synchronous transmission device of paper bag machine

A technology of synchronous transmission and machine stabbing, which is applied in the direction of transmission, packaging, mechanical equipment, etc., can solve the problems of inconvenient replacement of the cutting knife shaft and reduce the production efficiency of the paper bag machine, so as to reduce loss, ensure synchronization and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above-mentioned purpose, features and advantages of the present invention more comprehensible, preferred embodiments will be described in detail below together with the accompanying drawings.

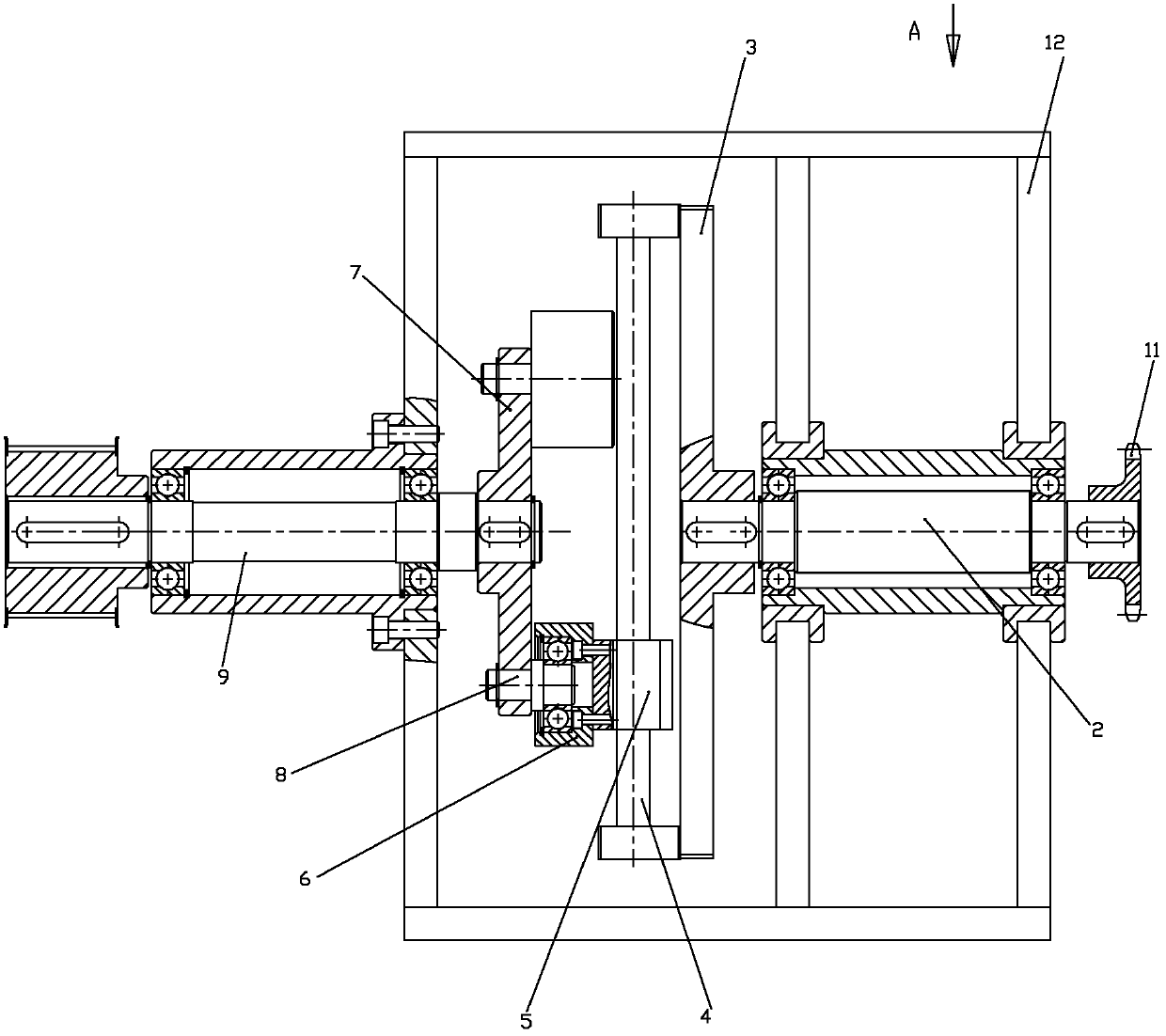

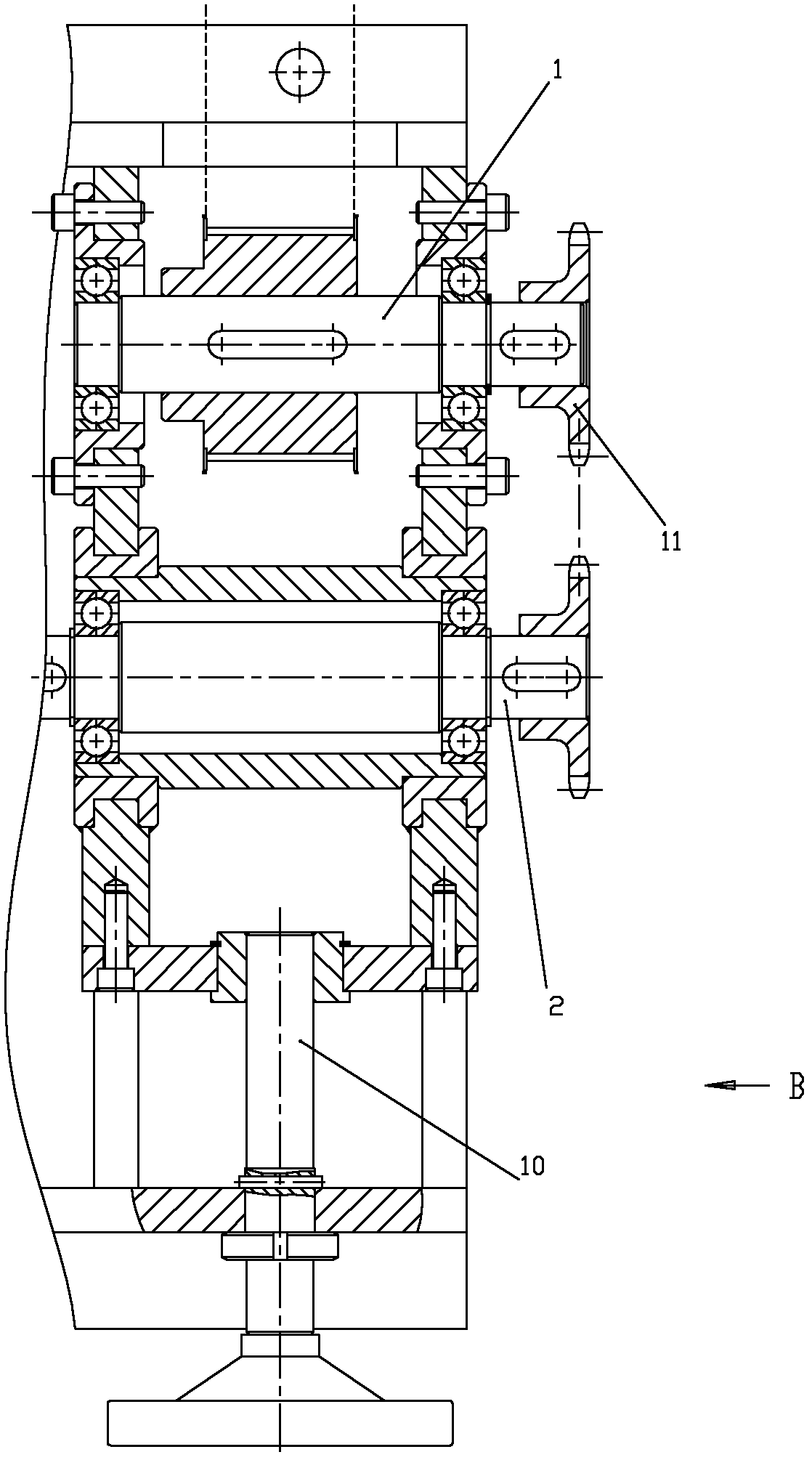

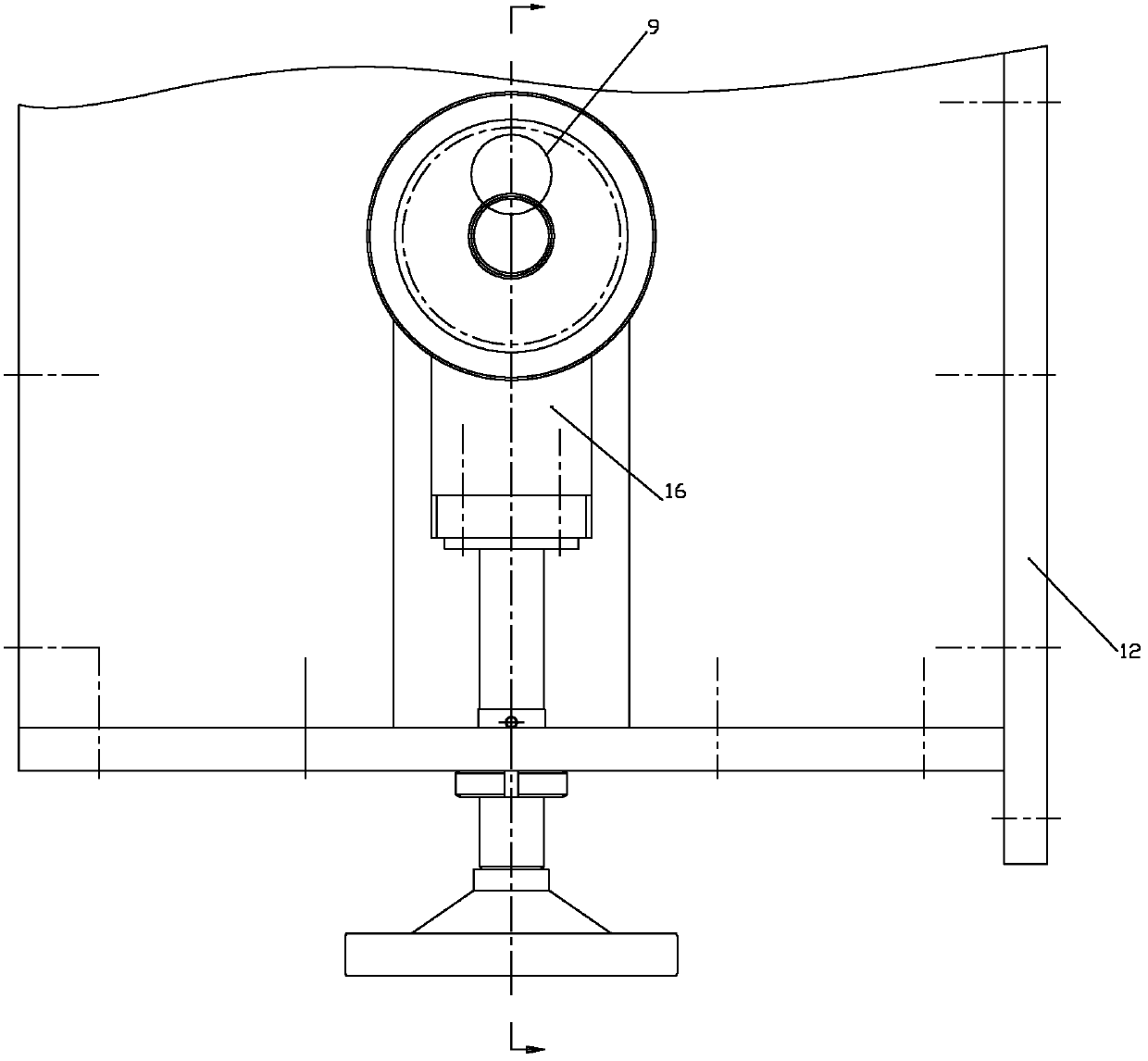

[0014] see Figure 1 to Figure 4 , the present invention includes an input shaft 1, a main drive shaft 2, a connecting plate 3, a sliding shaft 4, a linear bearing 5, a bearing seat plate 6, a driving wheel 7, a dial pin 8, an output shaft 9, an eccentricity adjusting device 10, a sprocket 11 and box 12

[0015] The input shaft 1 drives the main transmission shaft 2 to rotate through the sprocket 11, and the connecting plate 3 is fixed on the main transmission shaft 2 and rotates synchronously with the main transmission shaft 2. Sliding shaft 4 is housed on connecting plate 3, and linear bearing 5 is installed on the sliding shaft 4. When the connecting plate 3 rotates, the linear bearing 5 slides axially along the sliding shaft 4 . Simultaneously, because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com