Moisture control method for glass fiber insulating product

A glass fiber and moisture control technology, used in transportation, packaging, storage devices, etc., can solve problems such as affecting users' use, reducing the insulation performance of glass fiber insulation products, and increasing the water content of glass fiber insulation products, preventing insulation performance. , the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

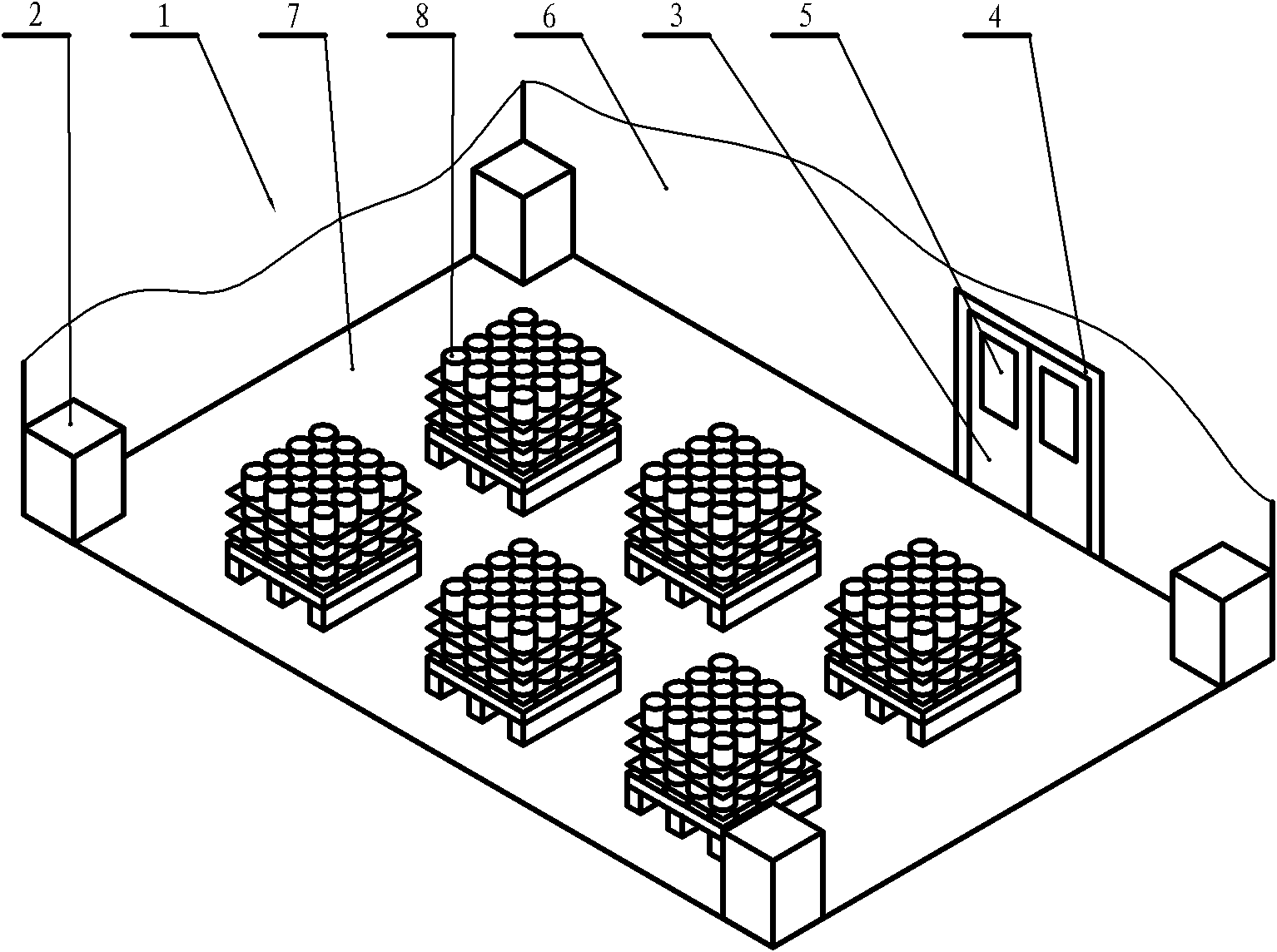

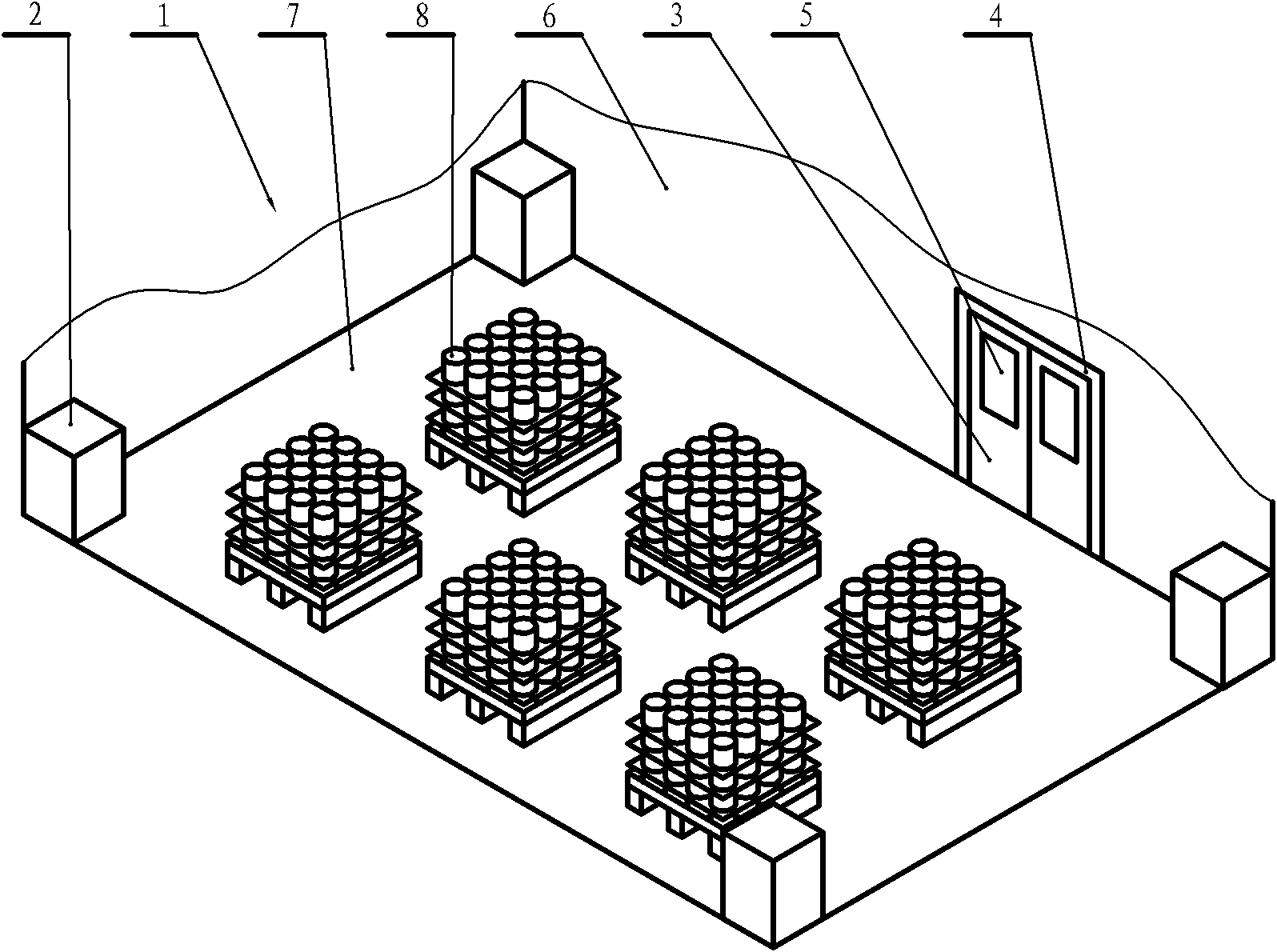

[0029] The internal schematic diagram of the storage room of the glass fiber insulation product moisture control method of the present invention is as follows figure 1 As shown, the glass fiber insulation product 8 is dried, wound into yarn balls, and then stored in the storage room 1 after inner packaging. The door 3 and the window of the storage room 1 are closed, and the air in the storage room 1 is dehumidified. The humidity of the air meets the storage environment requirements of glass fiber insulation products.

[0030] The moisture control method of glass fiber insulation products, the dehumidifier 2 is installed in the storage room 1, and the dehumidification capacity of the dehumidifier 2 is adapted to the dehumidification amount required in the storage room 1; The process of packaging is kept in dry conditions.

[0031] In the moisture control method for glass fiber insulation products, multiple dehumidifiers 2 are installed, and the multiple dehumidifiers 2 are eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com