Pneumatic liquid material conveying device

A conveying device and pneumatic liquid technology, which is applied in the field of pneumatic liquid material conveying devices, can solve the problems of complex equipment structure, low extraction efficiency, waste, etc., and achieve the effects of low manufacturing and use costs, high extraction efficiency, and fast extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

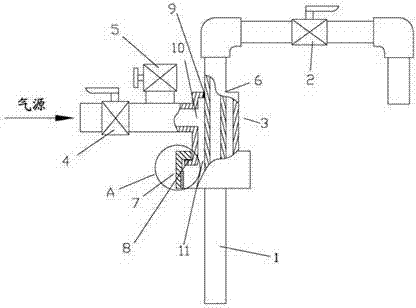

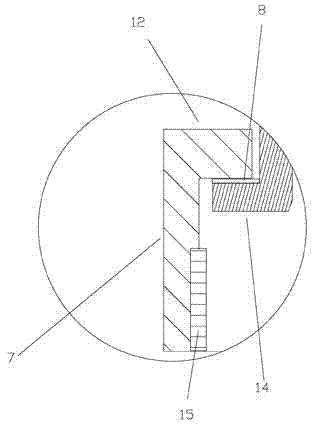

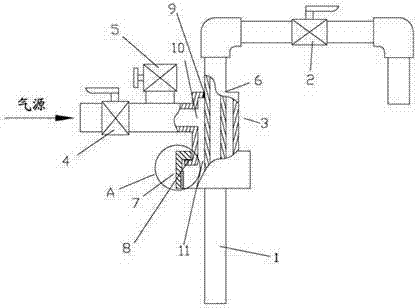

[0013] like figure 1 As shown, the pneumatic liquid material conveying device includes a pump body 3 and a discharge pipe 1. The pump body 3 is a cavity, and an air inlet 10 and an air outlet 11 are arranged on the cavity. The air inlet 10 passes through the pipe The air inlet valve 4 is connected to the pump body, a round hole 6 is arranged on the pump body, and a locking screw cap 7 that can be threadedly connected with the barrel mouth of the liquid material barrel is connected at the air outlet end, and the discharge pipe 1 passes through the pump body The round hole 6 and the locking screw cover 7 on the top, the cavity of the pump body 3 is connected with the cover cavity of the locking screw cover 7, the discharge valve 2 is installed on the discharge pipe 1, and the pump body starts from the inlet valve 4. The air inlet 10, the cavity, the air outlet 11, the cover cavity of the locking screw cap and the inner cavity of the liquid material barrel form a closed and airti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com