Glass spotlight cup light source mounting hole forming equipment

A molding equipment and spotlight technology, which is applied in the field of molding corresponding equipment, can solve the problems that the lamp cup cannot return to the starting position in time, the consistency of the glass spotlight cup is poor, and affects the normal operation of the equipment, so as to improve the positioning accuracy and repeatability, improve Conveying speed and positioning accuracy, effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

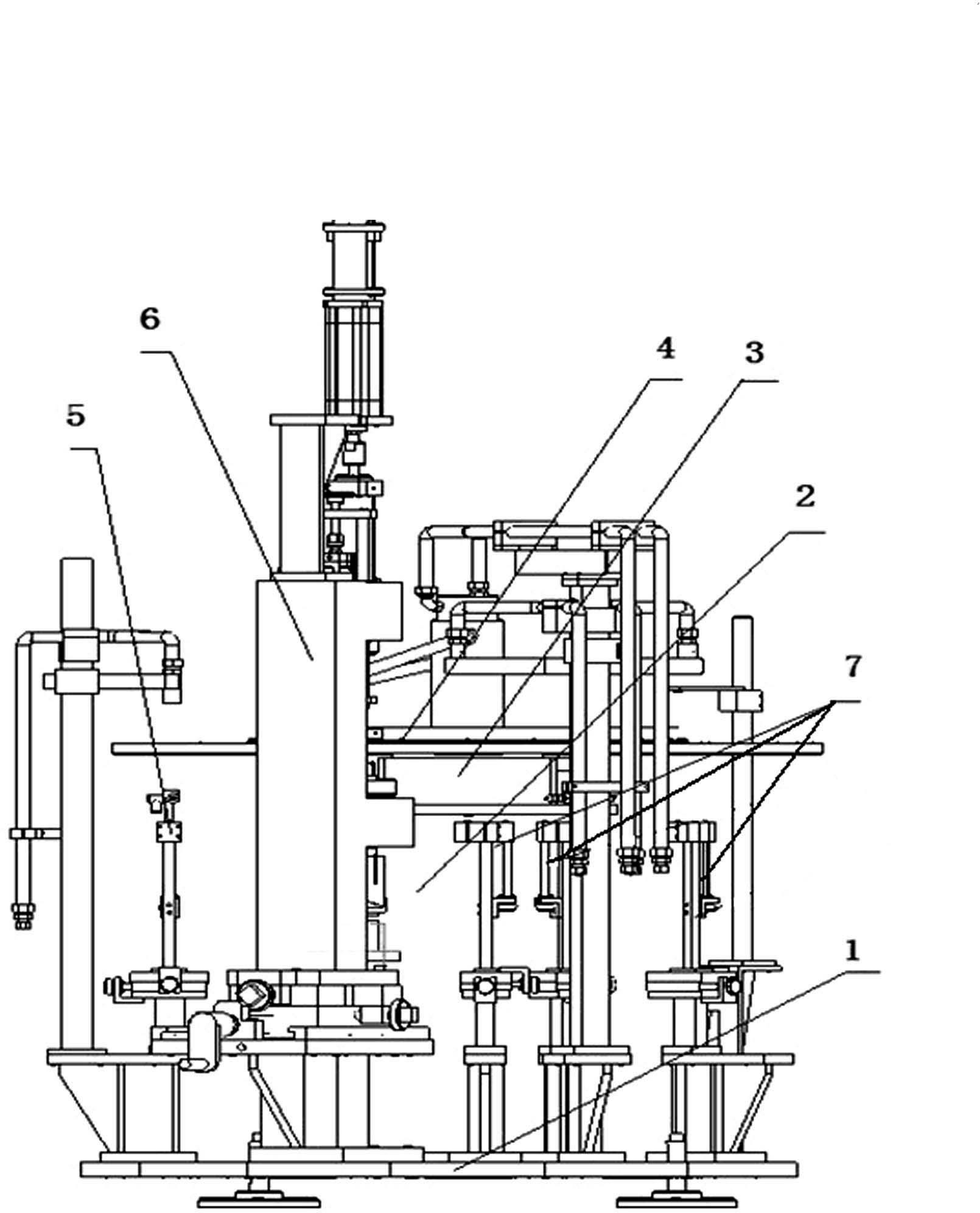

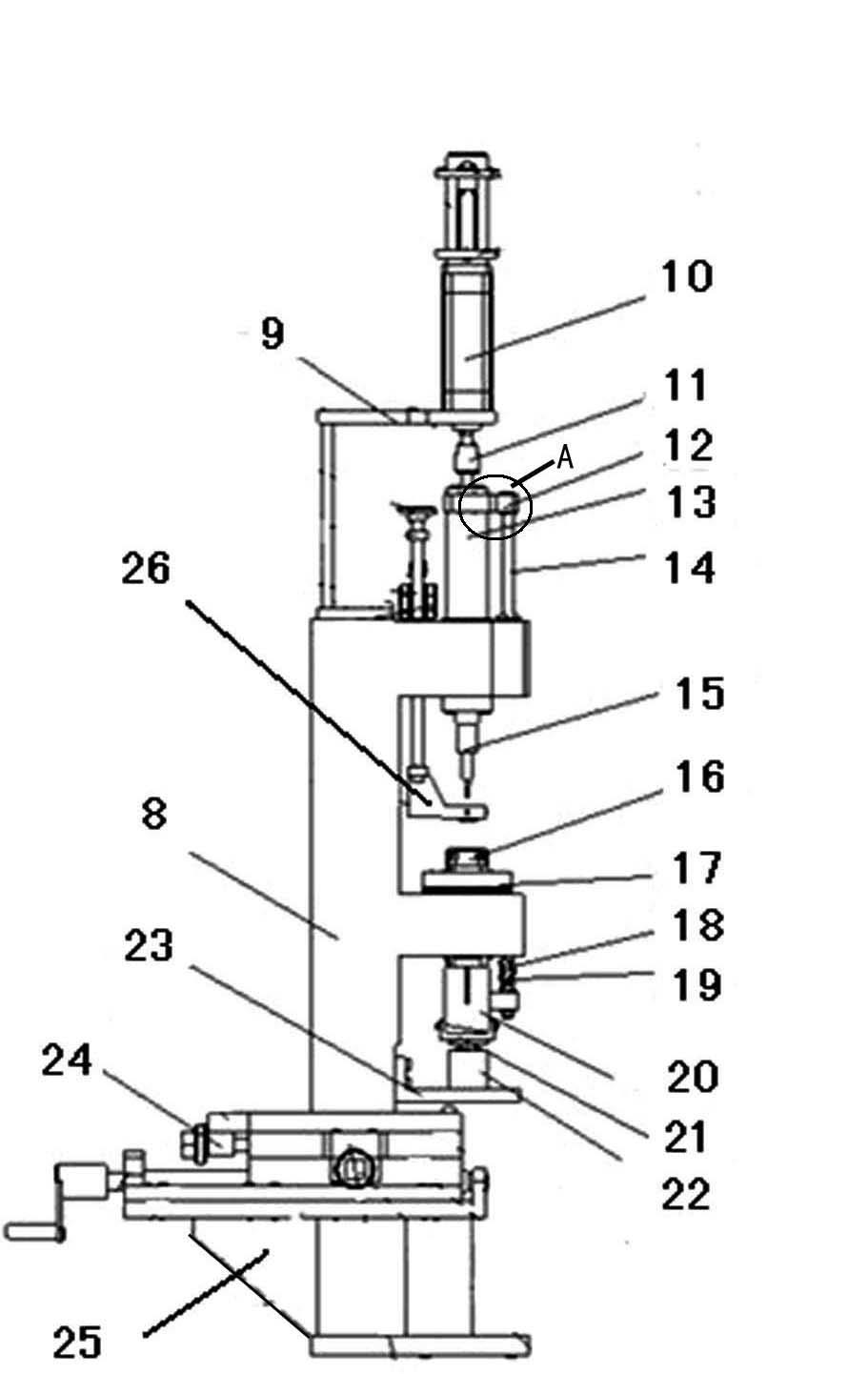

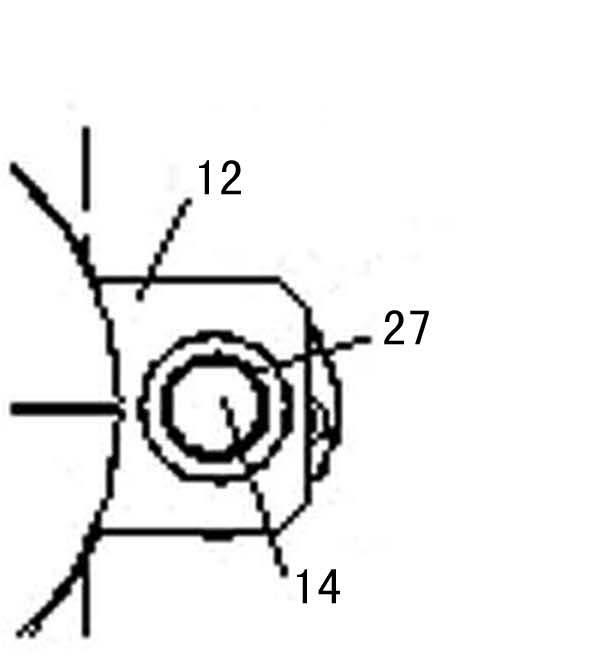

[0018] see reference figure 1 , figure 2 , image 3 The shown glass spotlight cup light source installation hole forming equipment includes a circular bottom plate 1 and a pneumatic punching machine 6 is installed on it, and a softening combustion heater 5 is installed at the lower part of the pneumatic punching machine 6, and is also distributed on the bottom plate 1. 7 of the three combustion heaters. A disc servo motor 3 is arranged on the motor mounting seat 2 at the middle part of the body of the pneumatic punching machine 6 , and the disc servo motor 3 is connected with the rotary conveying indexing disc 4 . In the present invention, the rotary conveying index plate 4 is used to place the glass spotlight cup to be formed with the light source installation hole. The softening combustion heater 5 and the combustion heater 7 are located at the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com