Electric liquid pump for automobile starting and stopping system

An electro-hydraulic pump and automobile technology, applied in the field of auto parts, can solve problems such as increasing automobile exhaust emissions, and achieve the effects of low energy consumption, low noise and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

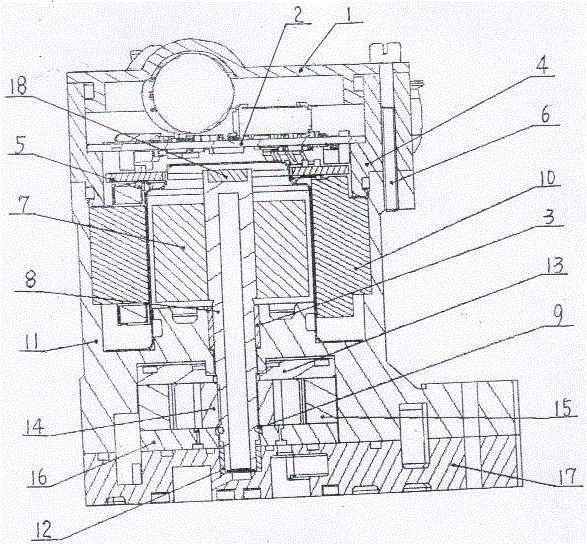

[0009] Examples, see attached figure 1 , The controller 2 of the electro-hydraulic pump for the automobile start-stop system is fixed on the controller bracket 4 with screws, and the upper cover 1, the controller bracket 4, and the housing 11 are connected with fastening bolts 6 . The motor stator 10 is fixed in the upper end of the housing 11, the motor rotor 7 is fixed on the upper end of the hollow shaft 8, the spacer sleeve 5 is fixed on the housing 11 with screws, the spacer sleeve 5 isolates the motor stator 10 from the motor rotor 7, and The motor rotor 7 is placed in a wet environment, the hollow shaft 8 is respectively installed in the sliding bearing 1 3 and the sliding bearing 2 12, the sliding bearing 1 3 is fixed on the housing 11, and the sliding bearing 2 12 is fixed on the oil pump cover 17 On, magnetic steel 18 is fixedly installed on the upper end of hollow shaft 8. The side plate 13, the oil pump stator 15, and the pressure plate 16 are mounted on the oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com