Distillation-free concentration method for alcohol

A technology without distillation and technology, which is applied in the field of ethanol concentration without distillation technology, can solve the problems of limiting the production cost of ethanol, large energy, etc., and achieve the effect of facilitating large-scale industrial production, high purification multiple, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preliminary purification of ethanol solution, concrete steps are as follows:

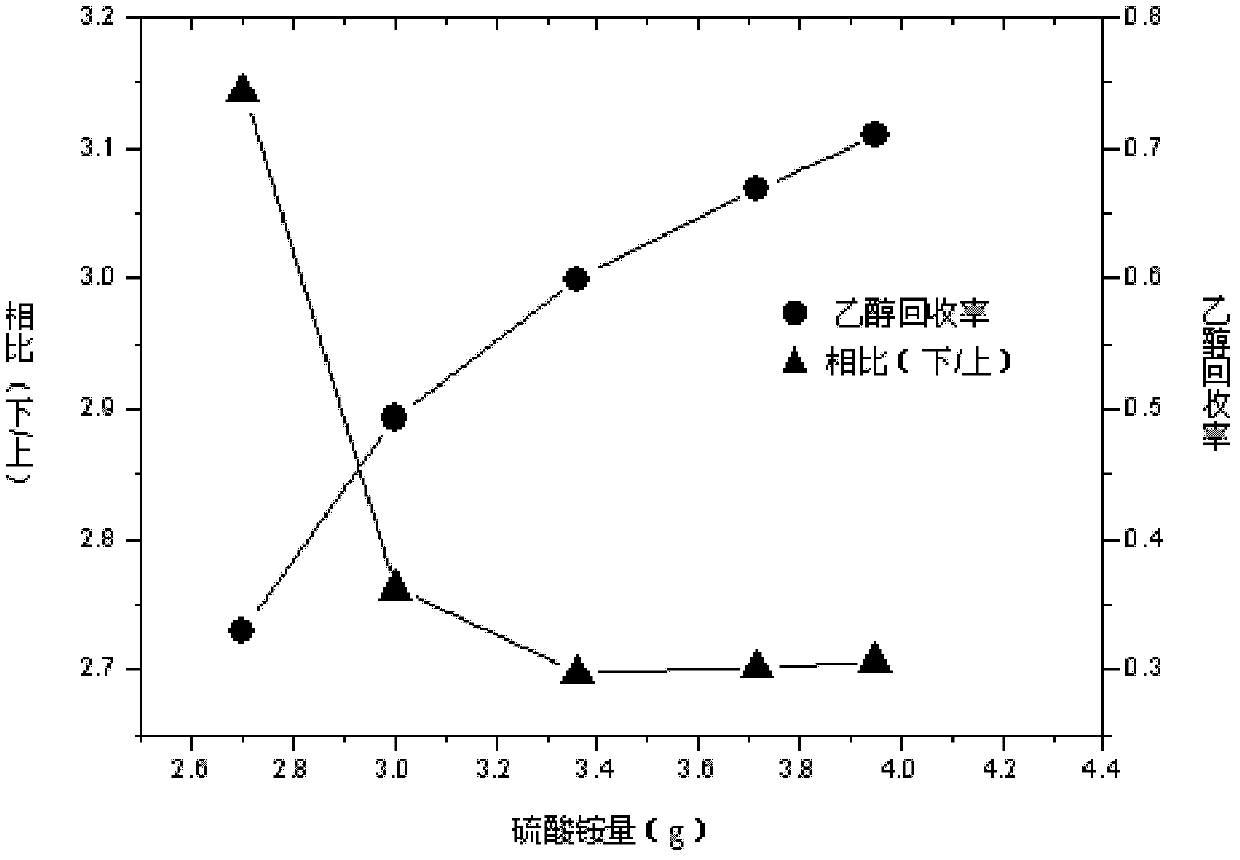

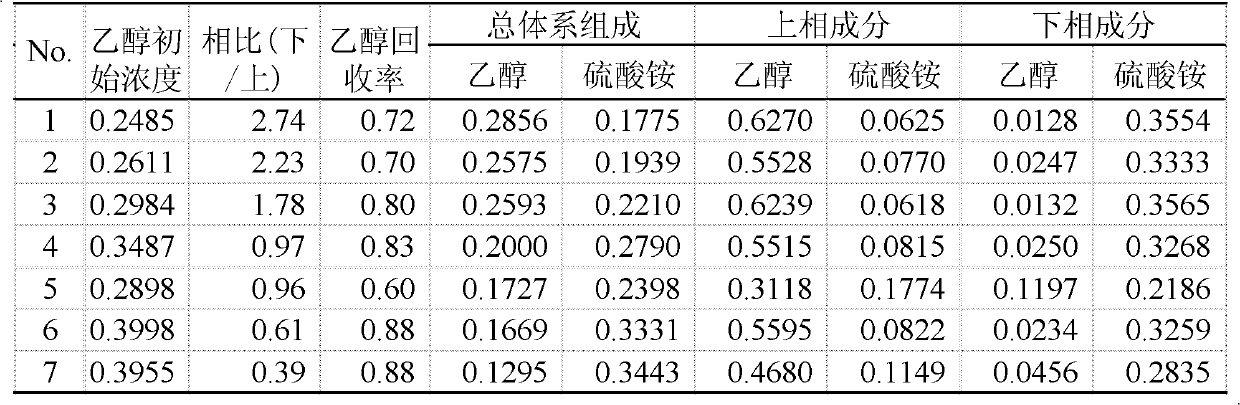

[0025] Add 39.5g of ammonium sulfate in 100g of ethanol solution with a concentration of 24% (w / w), fully stir to make it dissolve; the lower phase is removed, and the upper phase solution has an ethanol concentration of about 57% (w / w) .

[0026] The high-concentration purification of ethanol solution, the specific steps are as follows:

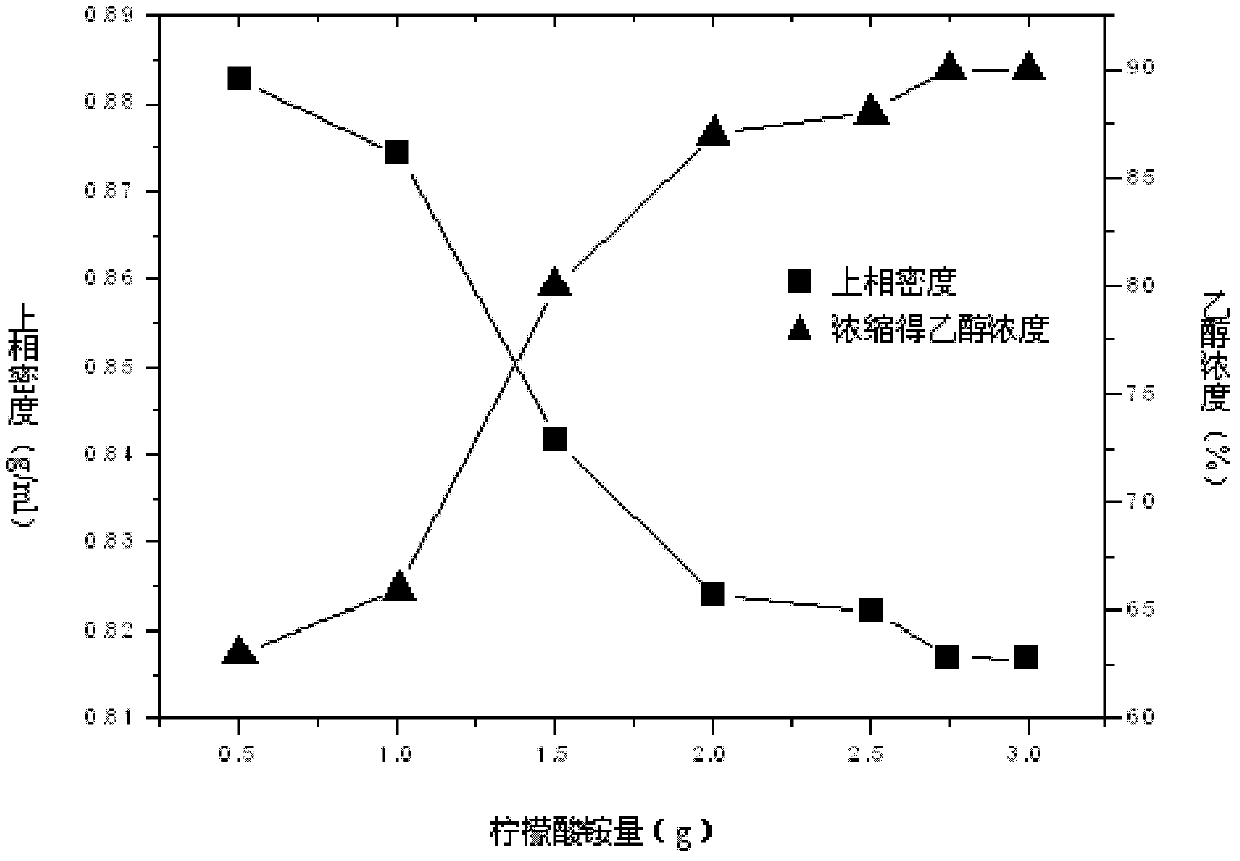

[0027] Add 55g of ammonium citrate per 100g into the upper phase solution, fully stir to dissolve it, remove the lower phase, and the concentration of ethanol in the upper phase is about 90%.

Embodiment 2

[0029] To purify ethanol from low concentration to high concentration, the specific steps are as follows:

[0030] Add 39g of ammonium sulfate in 100g of ethanol solution with a concentration of 25% (w / w), ultrasonically dissolve it, transfer to the separatory funnel to discharge the lower phase, add 50g of ammonium citrate per 100g in the upper phase, and mix well It was dissolved, and the lower phase was discharged, and the ethanol concentration of the upper phase was about 88%.

Embodiment 3

[0032] The purification method from lower concentration to high concentration, the specific steps are as follows:

[0033] Be that the ammonium sulfate of 40g is added in the ethanol solution of 23% in 100g concentration, ultrasonic treatment makes it dissolve, transfer to separatory funnel and discharge lower phase, obtain upper phase liquid, ethanol concentration is about 56% (w / w), press again Add 45g of citric acid to every 100g of the upper phase liquid, mix well, separate the lower phase after standing to separate the layers to obtain the upper phase. According to scheme 2, high-concentration ethanol can be obtained by further separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com