Method for producing high magnetic induction oriented silicon steel strip through batch nitriding

A high magnetic induction orientation, intermittent technology, applied in coating, metal material coating process, solid diffusion coating, etc., can solve the problem of few effective inhibitors, unreasonable distribution structure of precipitated phase, affecting product market competitiveness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

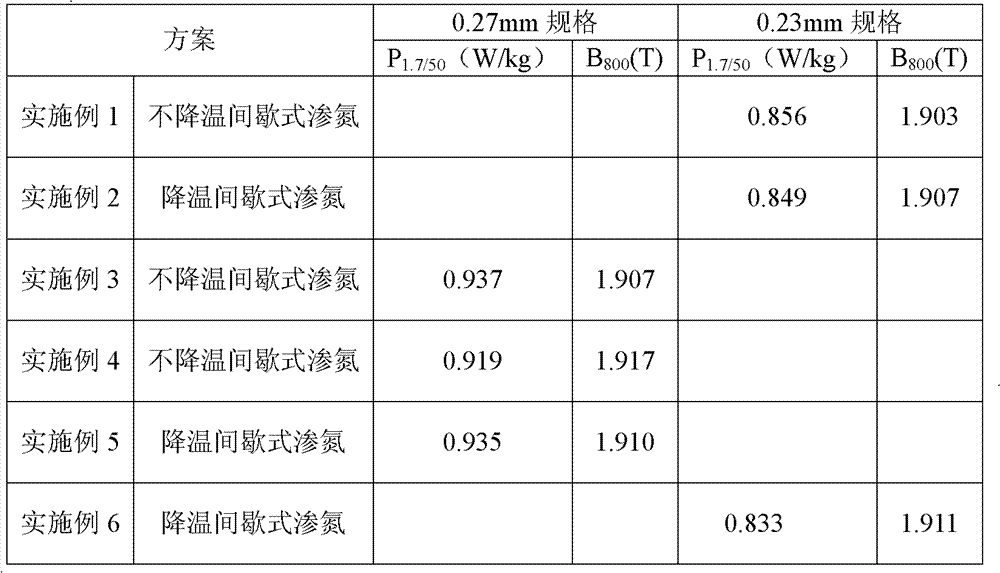

Examples

Embodiment 1

[0021] Experimental conditions: heat preservation intermittent nitriding method, hot-rolled plate thickness 2.3mm, product thickness 0.23mm, steel composition and weight percentage: C: 0.045%, Si: 3.0%, Mn: 0.05%, Cr: 0.01% , S: 0.003%, Als: 0.02%, N: 0.003%, and the rest are Fe and unavoidable impurities.

[0022] Its steps:

[0023] 1) After smelting and continuous casting, the billet is heated to 1140-1150°C, hot-rolled, normalized, cold-rolled to 0.23mm specification, and decarburized;

[0024] 2) Carry out heat preservation intermittent nitriding: in dry H 2 or N 2 or H 2 with N 2 Three nitriding treatments were carried out under the mixed atmosphere, each nitriding temperature was 760-770°C, each nitriding time was 5 seconds, and the final nitrogen content was controlled at 135PPm; The holding temperature is 760-770°C, and the holding time is 5 seconds each time;

[0025] 3) Natural cooling to room temperature: in dry H 2 or N 2 or N 2 and H 2 cooling in a mixe...

Embodiment 2

[0028] Experimental conditions: Adopt cooling intermittent nitriding method, hot-rolled plate thickness 2.3mm, product thickness 0.23mm, steel composition and weight percentage: C: 0.045%, Si: 3.0%, Mn: 0.05%, Cr: 0.01% , S: 0.003%, Als: 0.02%, N: 0.003%, and the rest are Fe and unavoidable impurities.

[0029] Its steps:

[0030] 1) After smelting and continuous casting, the billet is heated to 1140-1150°C, hot-rolled, normalized, cold-rolled to 0.23mm specification, and decarburized;

[0031] 2) Perform cooling intermittent nitriding: in dry H 2 or N 2 or H 2 with N 2 Carry out nitriding at least three times under mixed atmosphere, each nitriding temperature is 650-660°C, each nitriding time is 3 seconds, and the final nitrogen content is controlled at 142PPm; The cooling time on hold is 3 seconds, and the temperature drop is controlled at 50-55°C each time;

[0032] 3) Natural cooling to room temperature: in dry H 2 or N 2 or N 2 and H 2 cooling in a mixed atmosph...

Embodiment 3

[0035] Experimental conditions: heat preservation intermittent nitriding method, hot-rolled plate thickness 2.3mm, product thickness 0.27mm, steel composition and weight percentage: C: 0.052%, Si: 3.2%, Mn: 0.11%, Cr: 0.048% , S: 0.009%, Als: 0.029%, N: 0.006%, and the rest are Fe and unavoidable impurities.

[0036] Its steps:

[0037] 1) After smelting and continuous casting, the billet is heated to 1180-1190°C, hot-rolled, normalized, cold-rolled to 0.27mm specification, and decarburized;

[0038] 2) Carry out heat preservation intermittent nitriding: in dry H 2 or N 2 or H 2 with N 2 Three nitriding treatments were carried out under the mixed atmosphere, each nitriding temperature was 650-660°C, each nitriding time was 3 seconds, and the final nitrogen content was controlled at 210PPm; The holding temperature is 650-660°C, and the nitriding time is 3 seconds each time;

[0039] 3) Natural cooling to room temperature: in dry H 2 or N 2 or N 2 and H 2 cooling in a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com