Papermaking and pulping method capable of obtaining black liquor at high concentration

A high-concentration, black liquor technology, applied in the direction of pulping with inorganic alkali, can solve the problem of low black liquor concentration, and achieve the effect of reducing pollution load and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

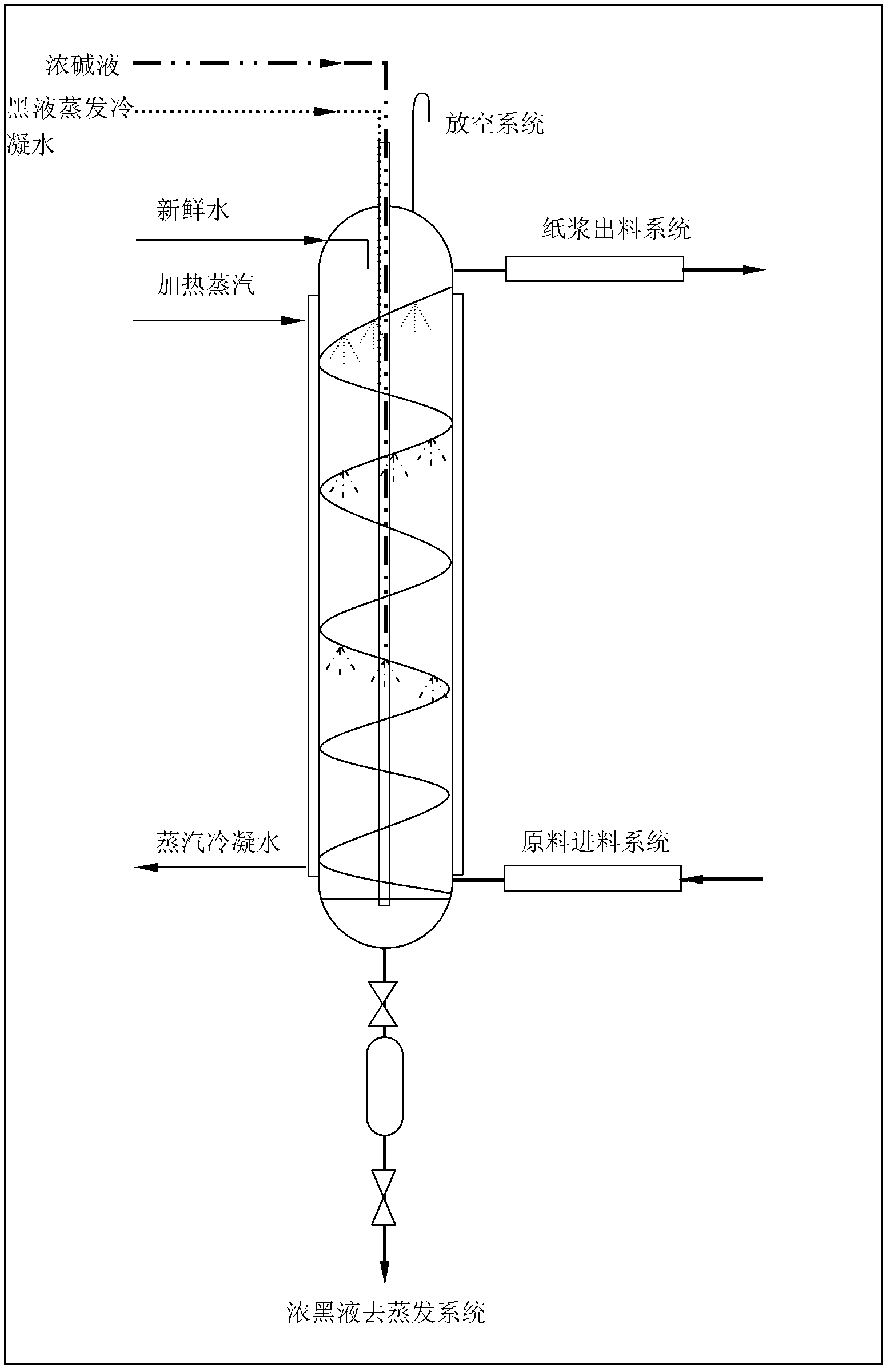

[0014] This embodiment adopts the vertical countercurrent cooking process of feeding at the bottom of the cooking tower, such as figure 1 It is shown that the solid phase raw material is fed from the bottom of the digestion tower in this process. The solid phase wood chips or forage raw materials are fed from the bottom of the cooking tower by the raw material feeding system, and the inside of the cooking tower is equipped with a screw elevator, which gradually lifts the solid phase materials entering the cooking tower to the top of the tower, and then is fed by the pulp Material discharge system discharge. The interior of the cooking tower is equipped with distributors for fresh water, evaporative condensed water (from MVR) and concentrated lye, and the above water or solution is pumped into the tower, sequentially from the top to different positions. The evaporative condensed water produced during the concentration process of black liquor by mechanical vapor recompression i...

Embodiment 2

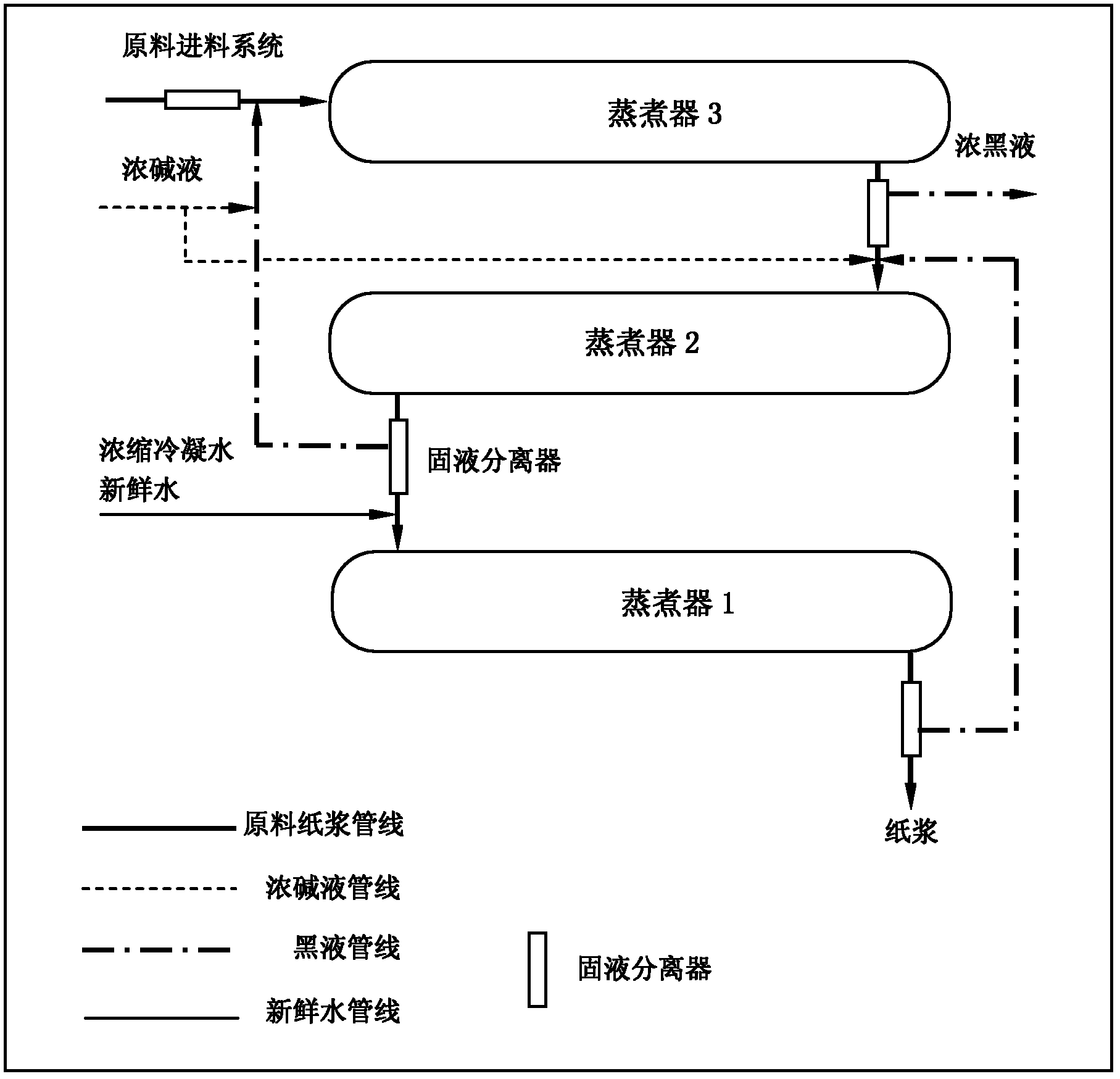

[0016] This embodiment adopts the overall countercurrent single digester parallel flow process, such as figure 2 Show. Single parallel flow of digesters is a more common pulping method at present. According to the theory of fluid plug flow and full mixed flow mode, combined with the back-mixing situation in actual flow operation, a single digester in multi-stage series can be used for continuous operation, which can also achieve approximate The operation effect of push flow. Therefore, in this embodiment, slurry washing, concentrated alkali liquor cooking and black liquor precooking are connected in series to achieve the purpose of overall countercurrent continuous operation. A solid-liquid separator and a material conveying system are installed between each single digester to form a countercurrent continuous operation system. In order to achieve a better washing effect, the slurry washing with black liquor after cooking can also be operated in the same single-stage paralle...

Embodiment 3

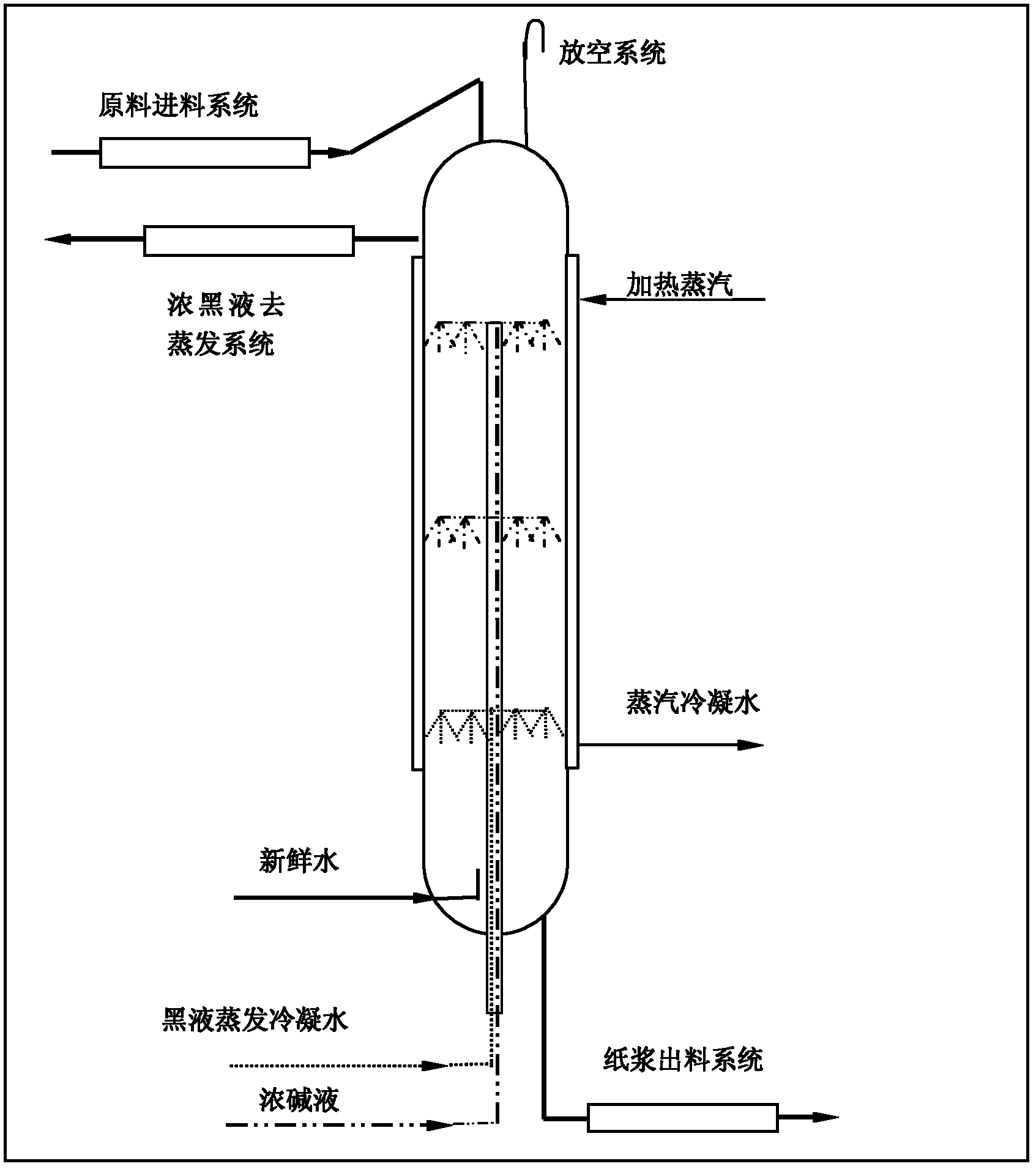

[0018] This embodiment adopts the vertical countercurrent cooking process of feeding at the top of the cooking tower, such as image 3 As shown, the solid phase material is fed from the top of the digestion tower in this process. Solid-phase wood chips or forage raw materials are fed from the top of the cooking tower by the raw material feeding system, and there is no screw elevator inside the cooking tower. The solid phase material entering the tower moves to the bottom of the tower through settling, and a pulp discharge system is installed at the bottom of the tower. Distributors for fresh water, steam condensed water and concentrated lye are still installed inside the cooking tower. Fresh water, evaporative condensed water generated during the concentration process, and concentrated lye are pumped into different sections of the tower from different positions downward from the top of the tower. the distributor. Adjust the liquid ratio in the cooking device to be 3-5:1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration gradient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com