Method for gasification fracturing of liquid nitrogen in hydrocarbon reservoirs

A technology of oil and gas reservoirs and nitrogen, which is applied in coal gasification, earthwork drilling, mining fluids, etc., can solve problems such as not meeting the process requirements, achieve the effect of not being limited by water resources, realizing large-scale fracturing, and having no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

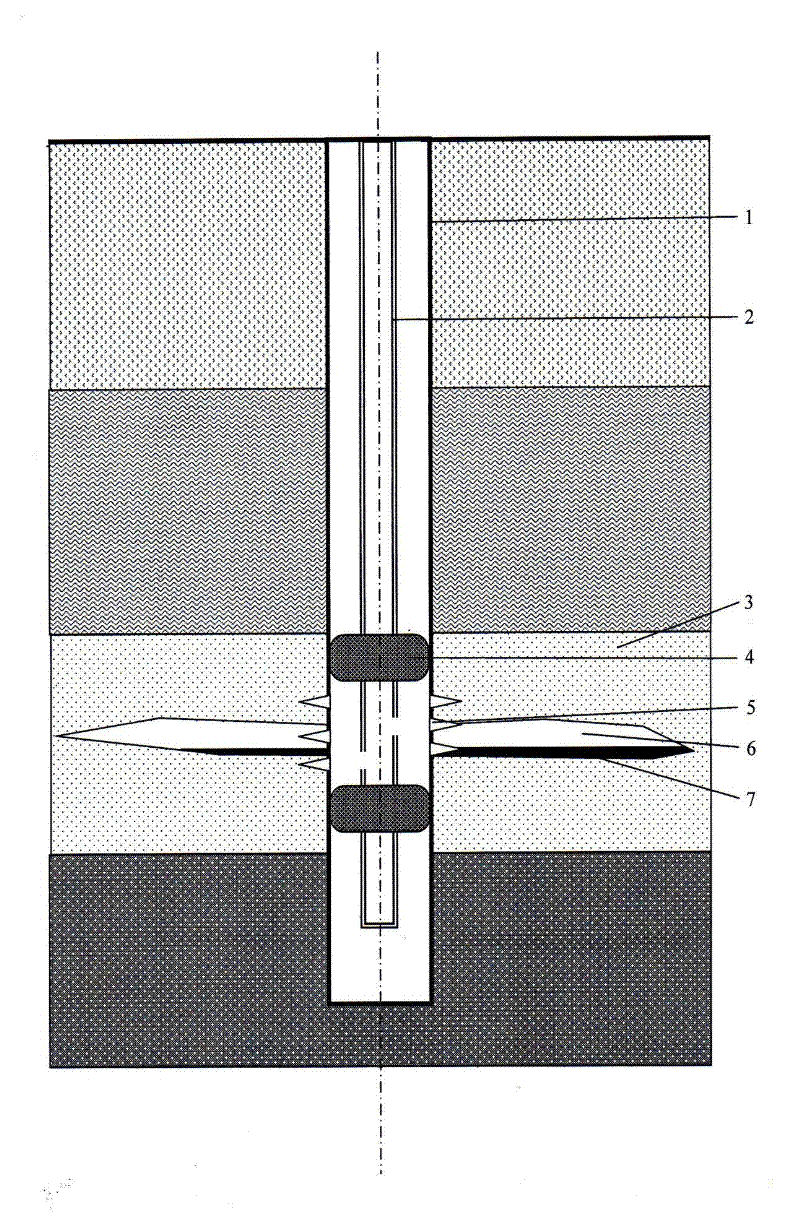

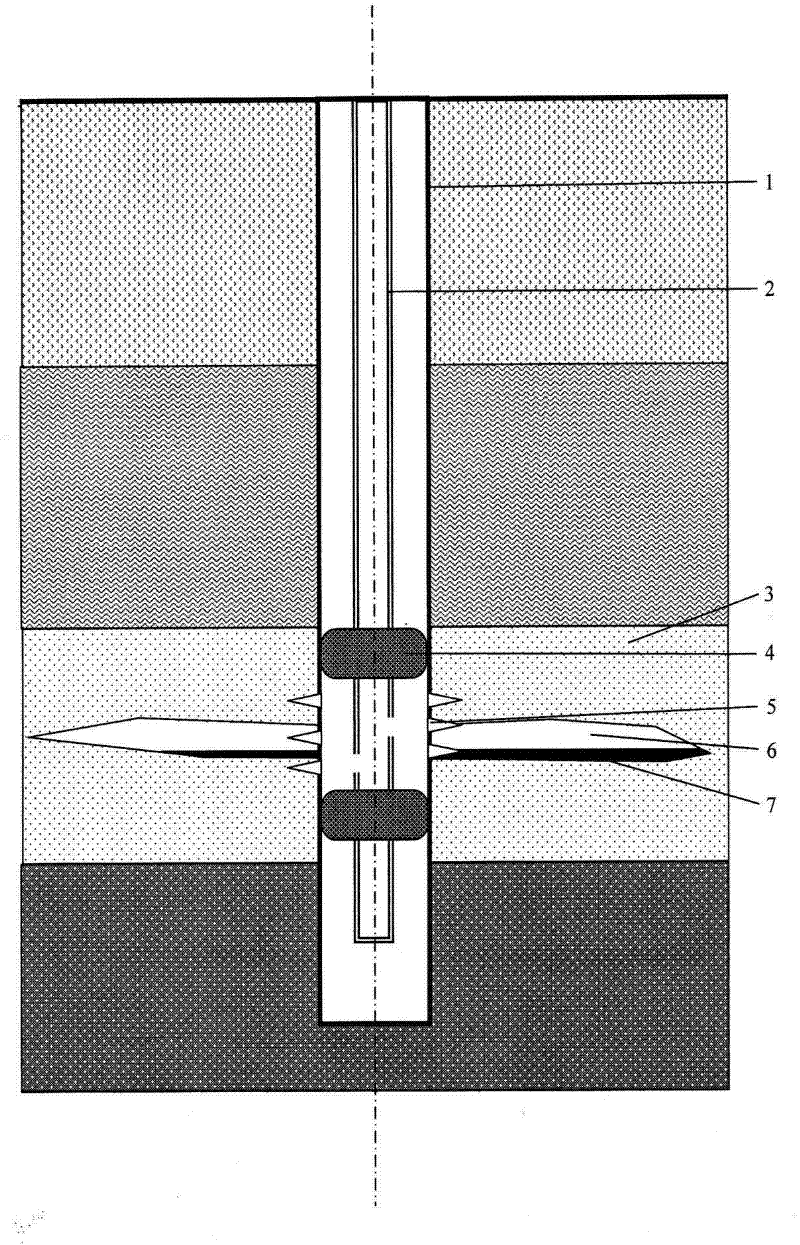

[0012] exist figure 1 In the schematic diagram of the liquefied nitrogen gasification and fracturing method shown in the oil and gas layer, a double-layer heat-insulated oil pipe 2 is inserted into the casing 1 driven into the underground oil-gas layer 3, and the two packers in the heat-insulated oil pipe 4 Openings are provided on the left and right sides of the middle part, and a number of holes 5 are oiled with perforating guns on the casing, and liquefied nitrogen gas 7 is pressed from the ground into the cracks in the formation through the heat-insulated oil pipe and the holes injected. Close the well or stew the well on the ground or underground. The liquefied nitrogen absorbs heat and gasifies in the formation, the pressure of the fluid in the fracture increases, the temperature of the rock decreases, the volume shrinks, and the fracture expands. until the formation returns to its original temperature. To prevent fracture closure, proppants can be added to the liquefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com