Method for performing curtain grouting construction on tunnel by water rich fault influence zone

A technology of curtain grouting and construction method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as water seepage and sudden water gushing, and achieve safe and reliable construction schemes, short construction period, and reduce large water gushing The effect of the likelihood of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

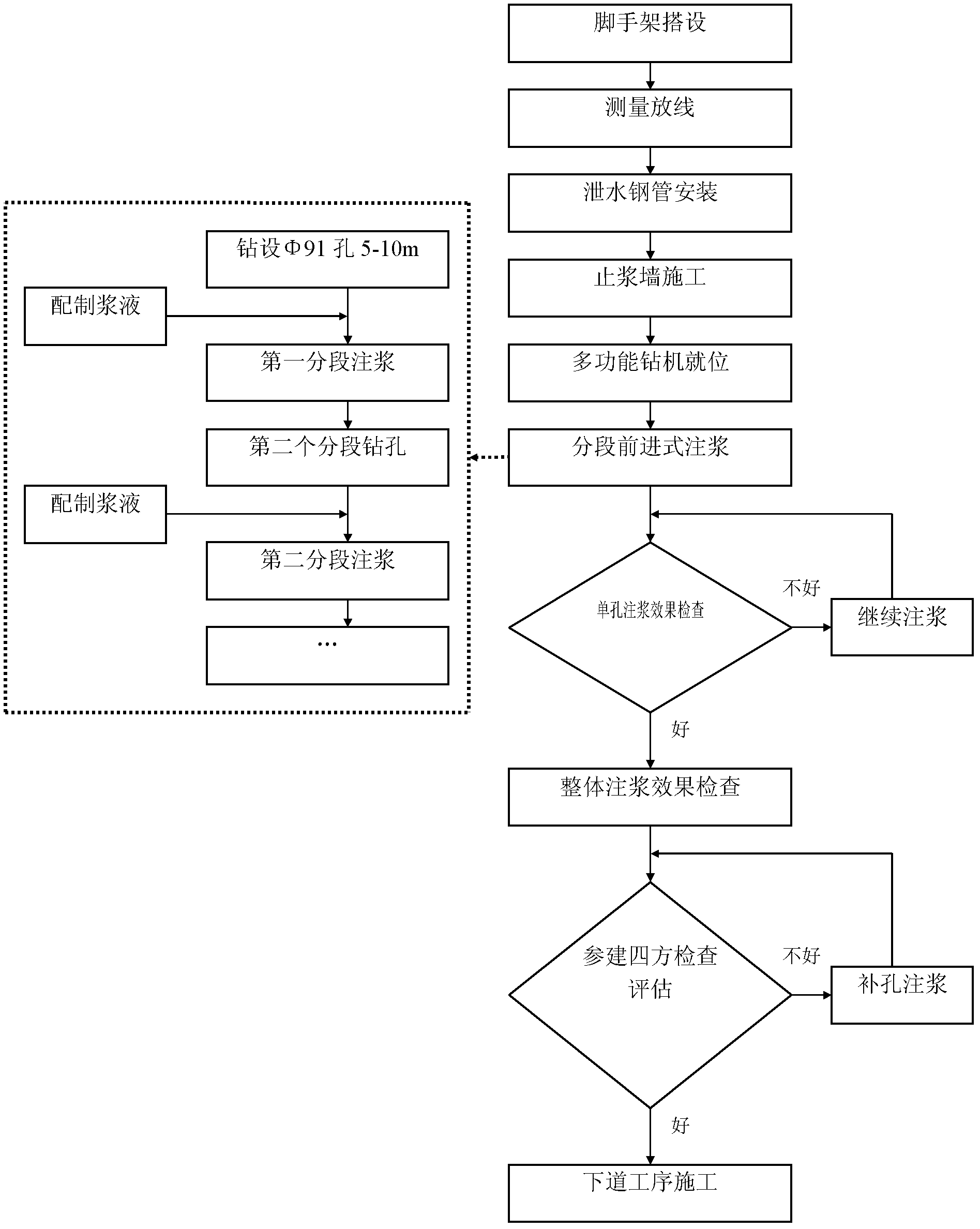

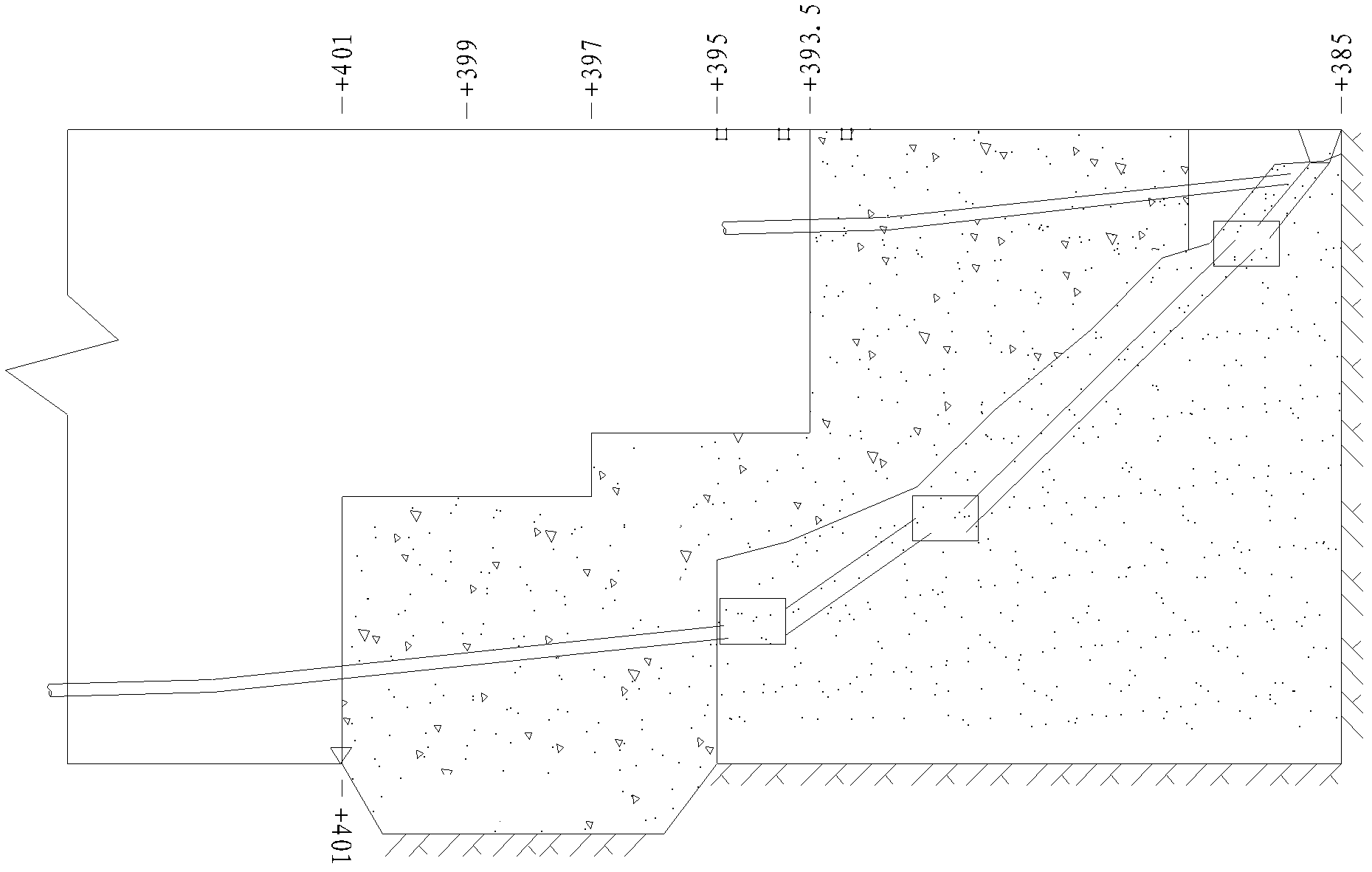

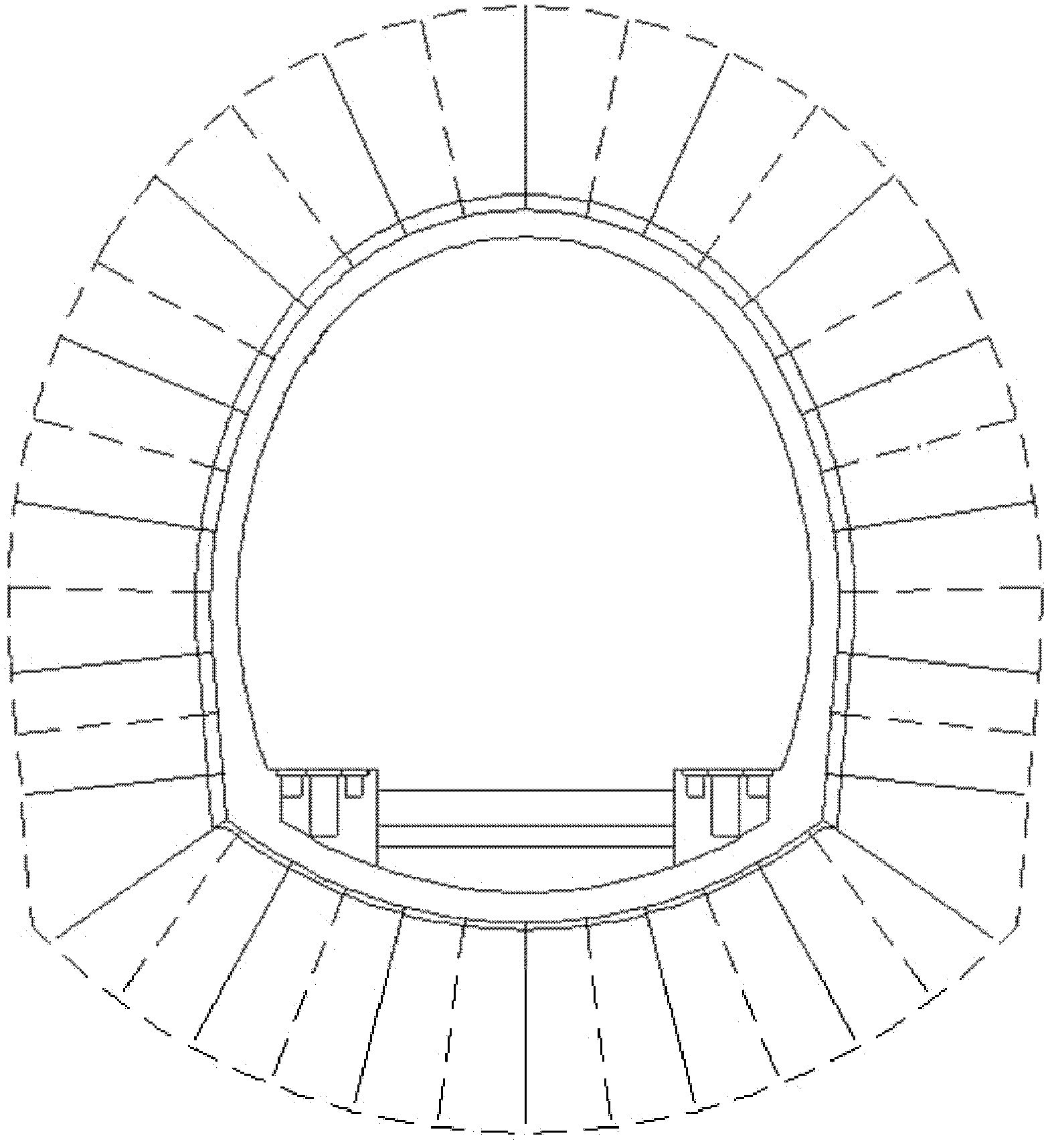

[0052] see Figure 1 to Figure 11 , the present embodiment passes through the curtain grouting construction method of the tunnel affected by the water-rich fault zone, comprising the following steps:

[0053] a. Construction of a grout-stop wall; a grout-stop wall is built inside the operation face, and a gap of 2m is provided between the grout-stop wall and the operation face in the radial direction;

[0054] b. Backfill the gap between the grout stop wall and the tunnel face;

[0055] c. Mark the drilling position and hole number on the slurry wall;

[0056] d, pulping; prepare cement, water glass double fluid slurry, wherein the water-cement ratio of cement is 0.6: 1~1: 1, the water glass concentration is 30~40Be, and the volume ratio of cement: water glass is 1: 0.5~1 : 1;

[0057] e. Drilling and grouting are completed by step-by-step grouting, and the footage per cycle is 5m.

[0058] Through the combination of building a grout-stop wall on the operation face and ste...

Embodiment 2

[0060] see Figure 1 to Figure 11 , the present embodiment passes through the curtain grouting construction method of the tunnel affected by the water-rich fault zone, comprising the following steps:

[0061] a. Construction of a grout-stop wall; build a grout-stop wall inside the operation face, and a gap of 5m is set between the grout-stop wall and the operation face in the radial direction;

[0062] b. Backfill the gap between the grout stop wall and the tunnel face;

[0063] c. Mark the drilling position and hole number on the slurry wall;

[0064] d, pulping; prepare cement, water glass double fluid slurry, wherein the water-cement ratio of cement is 0.6: 1~1: 1, the water glass concentration is 30~40Be, and the volume ratio of cement: water glass is 1: 0.5~1 : 1;

[0065] e. Drilling and grouting are completed by step-by-step grouting, and the footage per cycle is 10m.

Embodiment 3

[0067] see Figure 1 to Figure 11 , the present embodiment passes through the curtain grouting construction method of the tunnel affected by the water-rich fault zone, comprising the following steps:

[0068] a. Construction of a grout-stop wall; build a grout-stop wall inside the operation face, and a gap of 5m is set between the grout-stop wall and the operation face in the radial direction;

[0069] b. Backfill the gap between the grout stop wall and the tunnel face;

[0070] c. Mark the drilling position and hole number on the slurry wall;

[0071] d, pulping; prepare cement, water glass double fluid slurry, wherein the water-cement ratio of cement is 0.6: 1~1: 1, the water glass concentration is 30~40Be, and the volume ratio of cement: water glass is 1: 0.5~1 : 1;

[0072] e. Carry out surrounding rock reinforcement and water blocking inside the tunnel;

[0073] f. Drilling and grouting are completed by step-by-step grouting, and the footage per cycle is 10m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com