Laser divergence angle measuring device and measuring method based on full-automatic hole alignment method

A measuring device and fully automatic technology, applied in the field of optical detection, can solve the problems of accurate judgment of the center of the beam and the center of the small hole, large error in the measurement result, and inability to accurately measure, etc., to achieve the effect of accurate laser divergence angle and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

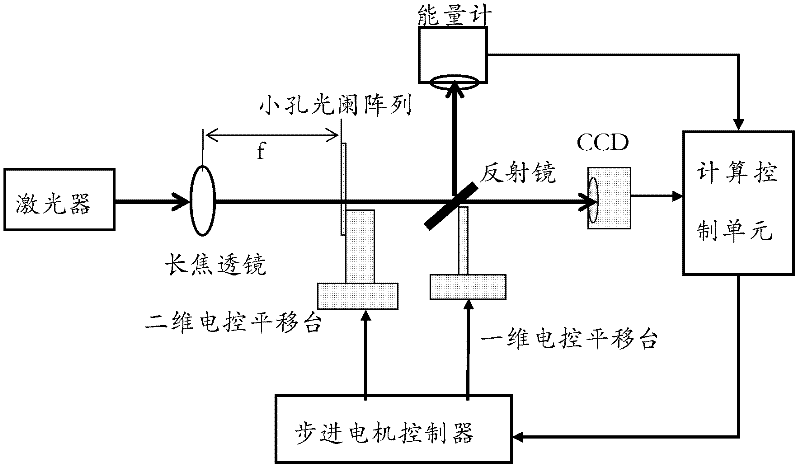

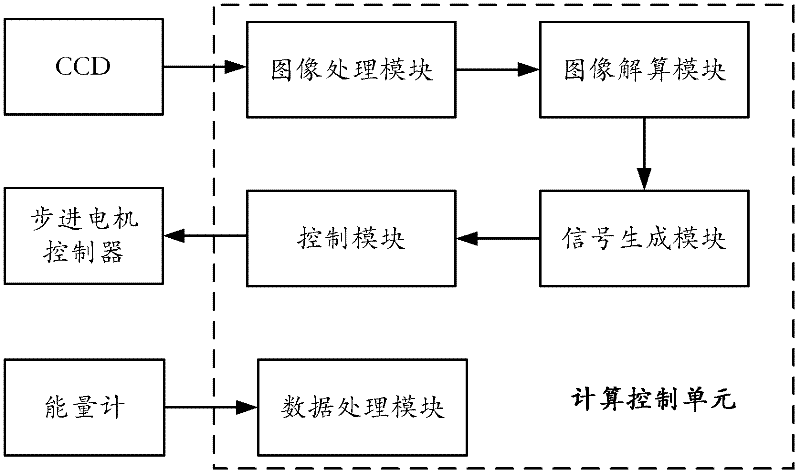

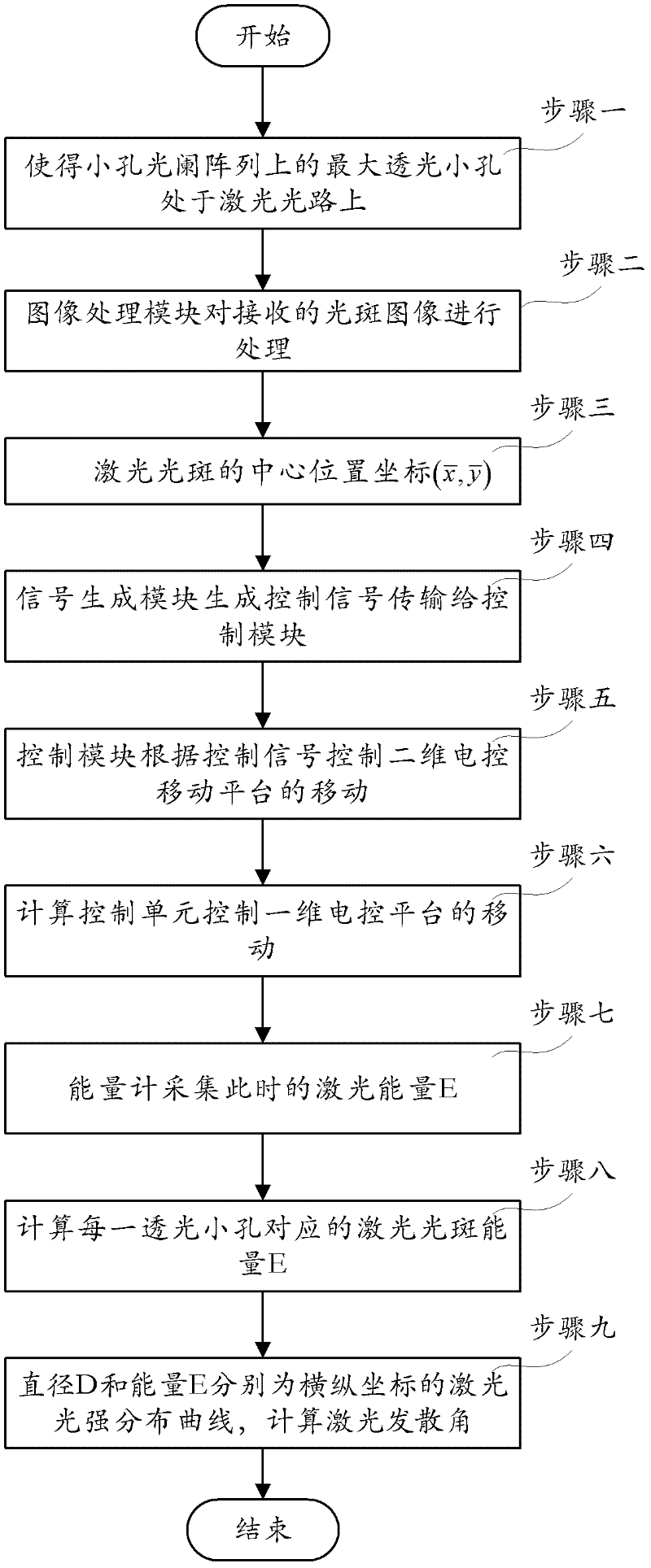

[0031] like figure 1 As shown, the present invention is based on the measurement device of the laser divergence angle of the automatic trepanning method, including a calculation control unit, a stepping motor controller and a laser, and a telephoto lens is arranged successively along the horizontal advancing direction of the laser beam generated by the laser, with a Aperture aperture array, mirror and CCD with multiple light-transmitting apertures, wherein the aperture aperture array is on the focal length of the telephoto lens, and the reflector and the laser beam form an angle of 45 degrees; the laser beam is reflected by the reflector An energy meter is installed on the formed vertical optical path; a two-dimensional electronically controlled translation stage is connected to the aperture diaphragm array, and a one-dimensional electronicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com