Determination apparatus for dew point of gas

A technology for measuring device and dew point, which is applied in the direction of material moisture content, etc., can solve the problems of equipment corrosion aggravation, dew point corrosion and other problems, and achieve the effect of prolonging the service life and preventing dew point corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

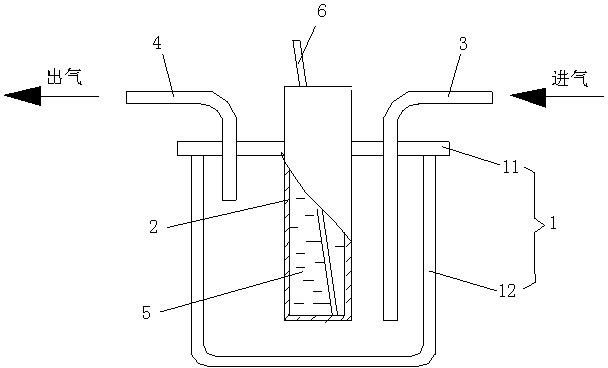

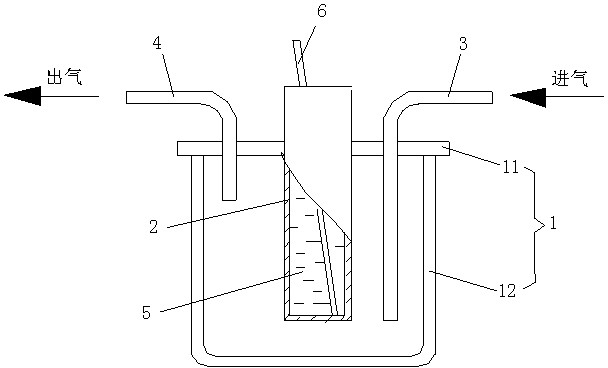

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Such as figure 1 The gas dew point measuring device shown includes a closed transparent cup 1 and a copper cup 2 inserted into the transparent cup 1. There is a gap between the cup bottom of the copper cup 2 and the cup bottom of the transparent cup 1. The transparent cup 1 includes The cup body 11 and the cup cover 12, the cup cover 12 is provided with an air inlet pipe 3 and an air outlet pipe 4, the upper end of the copper cup 2 is open, that is, the upper end of the copper cup 2 is open, and acetone liquid 5 and a mercury thermometer 6 are arranged in the copper , as a preferred version of the present invention, the outer surface of the copper cup 2 is chrome-plated and polished to a mirror surface, and the outlet position of the air inlet pipe 3 coincides with the position of the cup bottom of the copper cup 2, so that the dew point of the gas can be observed mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com