High-precision current detection circuit based on CPU (Central Processing Unit)

A current detection circuit and high-precision technology, applied in the power supply field, can solve the problem of low signal sampling accuracy, and achieve the effects of improving competitiveness, reducing dependence, and improving current detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

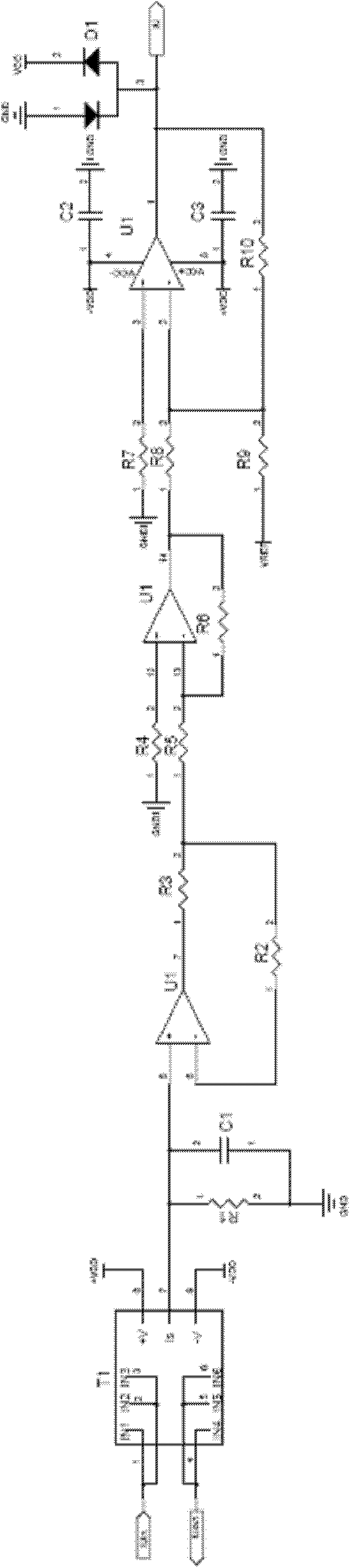

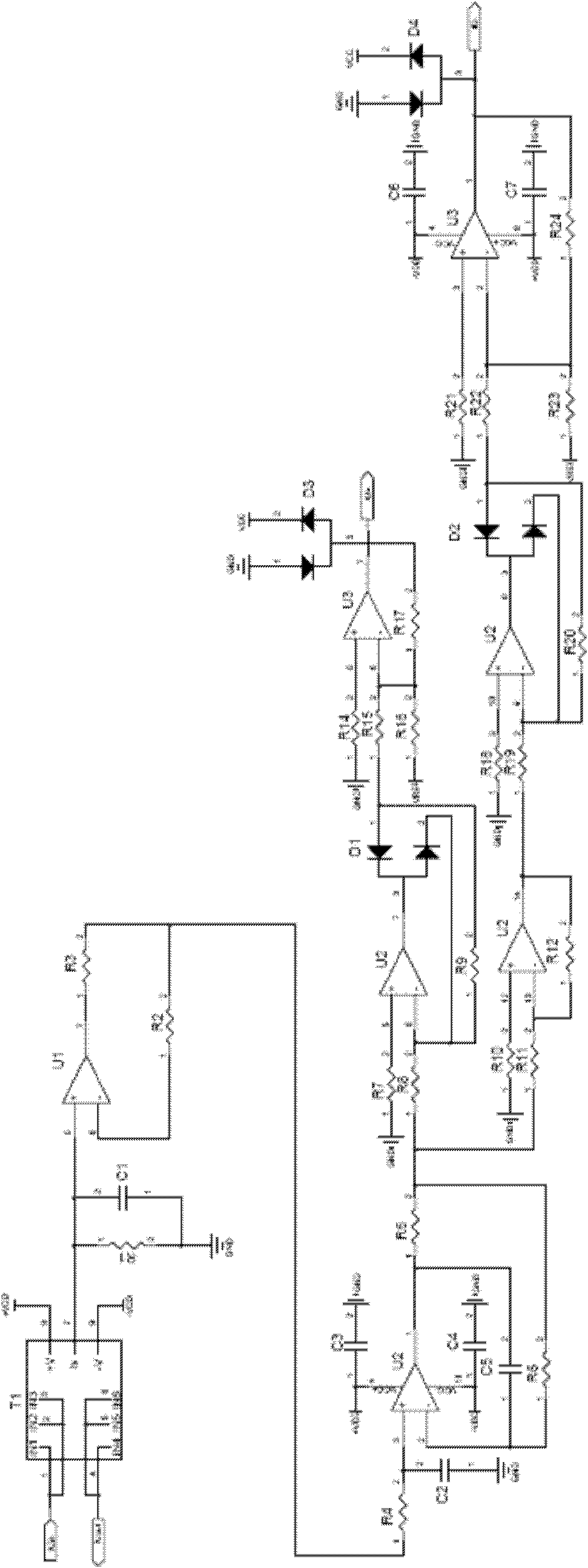

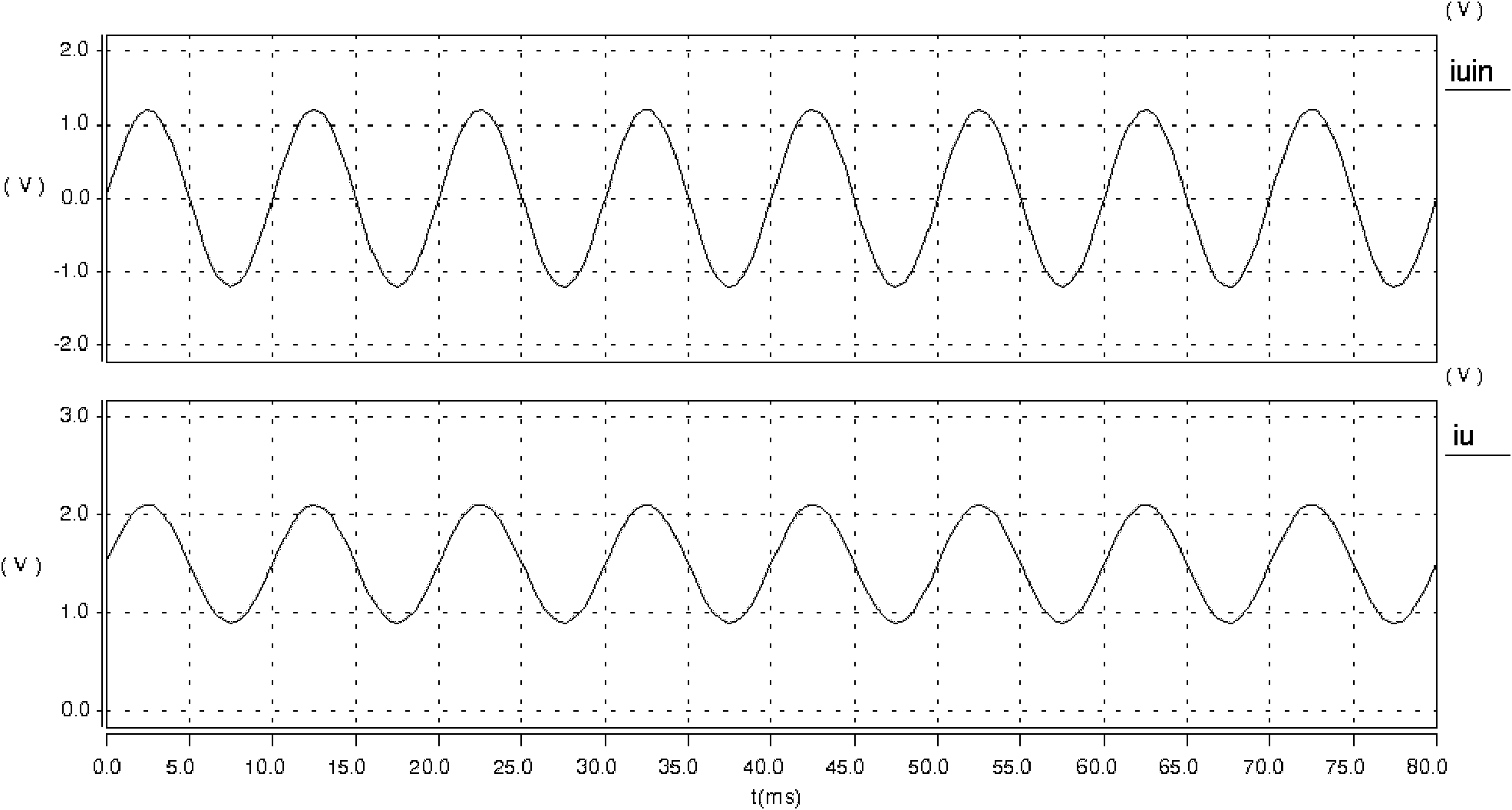

[0020] Based on the CPU high-precision current detection circuit provided by the present invention, see figure 2 , including current Hall sensing circuit, used to convert large current into low voltage signal; current conditioning circuit, used to condition the low voltage signal converted by the sensor into positive and negative half wave signals and send them to the AD port of CPU for detection; for AD The sampling value is obtained by the AD conversion formula and the current sampling combination relationship to obtain the output current value. The measured current IUin becomes a weak current IS after passing through the current Hall sensor T1. Get the voltage value IU corresponding to the circuit under test. The filter capacitor C1 is connected to both ends of the sampling resistor R1. The current IU passing through the current sensor passes through the filter circuit composed of R4 and C2 and is followed by the operational amplifier U2 and then divided into two paths. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com