Testing method of COG (chip on glass) product of PMOLED (passive matrix organic light emitting diode) based on tape carrier package

A technology of product testing and thin-film packaging, which is applied in the field of PMOLED COG product testing, can solve the problems of low substrate utilization, high testing cost, processing accuracy and cutting alignment accuracy, and achieve low cost and convenient testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] Aiming at the low utilization rate of the substrate caused by the test method of COF products in the traditional technology and the high test cost caused by the test method of COG products, there are problems of processing accuracy and cutting alignment accuracy, the present invention proposes a COG product test based on thin-film packaged PMOLED Method, this test method comprises two big steps: 1. the making step of test point; 2. test step;

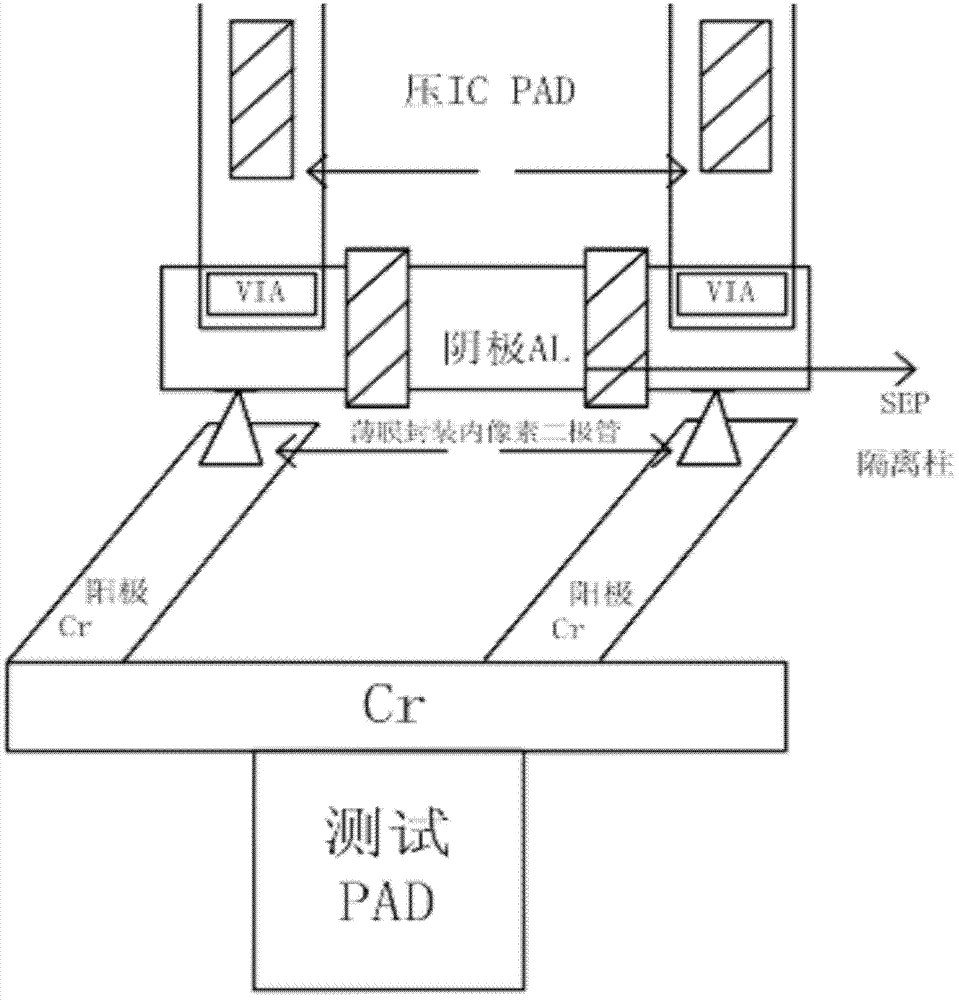

[0010] see figure 1 , the production process of the test point (test PAD) is as follows: set a diode at each IC pin, and divide the metal Cr on the screen used to connect the IC pin (press IC PAD) into three sections functionally: A piece of metal Cr is used to connect the anode of the diode, and a via (VIA) is made on the second piece of metal Cr, so that the voltage on the cathode of the diode can be transmitted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com