Automatic pressure-regulating explosion-proof device of storage battery for explosion-proof forklift

A technology of automatic voltage regulation and explosion-proof device, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of difficult processing, difficult to accurately control the depth of indentation, and difficult to ensure explosion-proof reliability, and achieve a simple structure. , The effect of easy processing and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

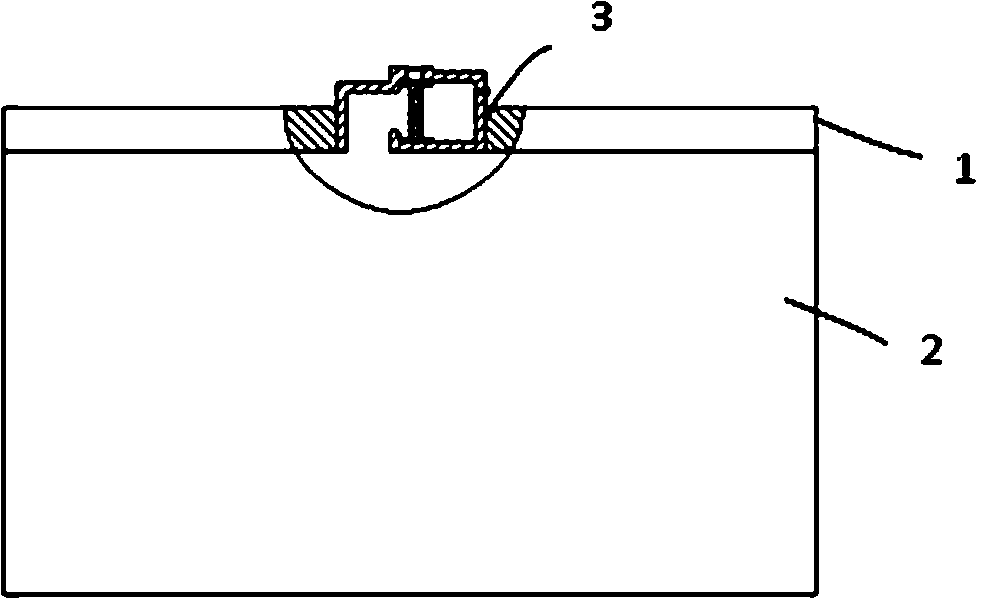

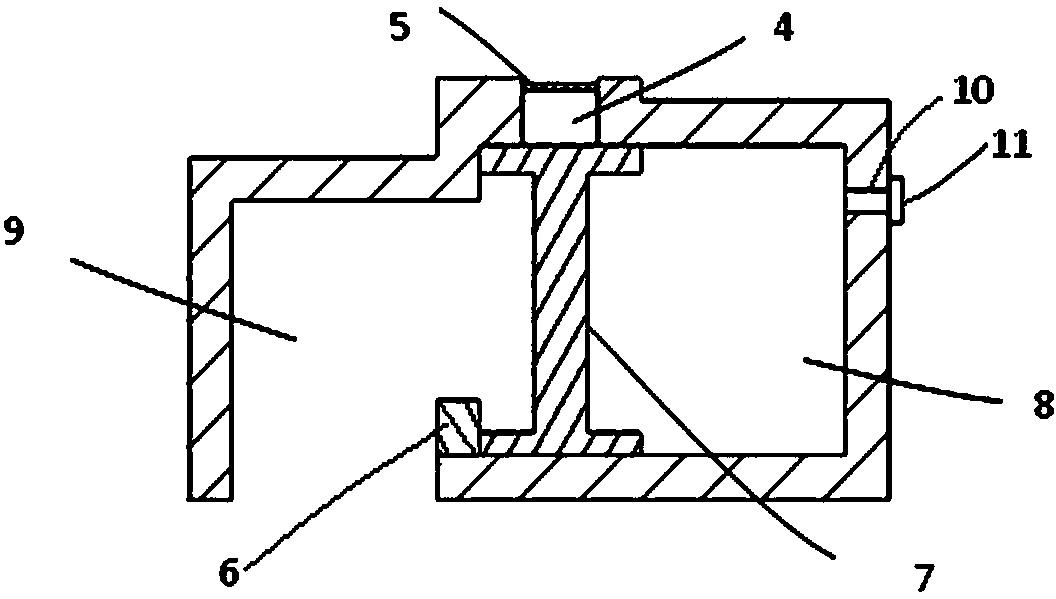

[0020] Reference figure 1 , 2 This embodiment includes an automatic pressure-regulating explosion-proof device body 3 provided on the battery box 2. A pressure-adjusting slider 7 is provided in the internal cavity of the automatic pressure-regulating explosion-proof device body 3. The pressure adjusting slider 7 will automatically adjust the pressure and the explosion-proof device The internal cavity of the body 3 is divided into two parts, one is the pressure chamber 8, the other is the communication chamber 9. The pressure chamber 8 is provided with a high-pressure gas injection port 10, and the high-pressure gas injection port 10 is provided with a sealing fastener 11 for communication The chamber 9 communicates with the inside of the battery box 2. The upper part of the automatic pressure-regulating explosion-proof device body 3 is provided with an exhaust port 4 that communicates with the atmosphere. The upper part of the pressure adjusting slider 7 is in contact with the lo...

Embodiment 2

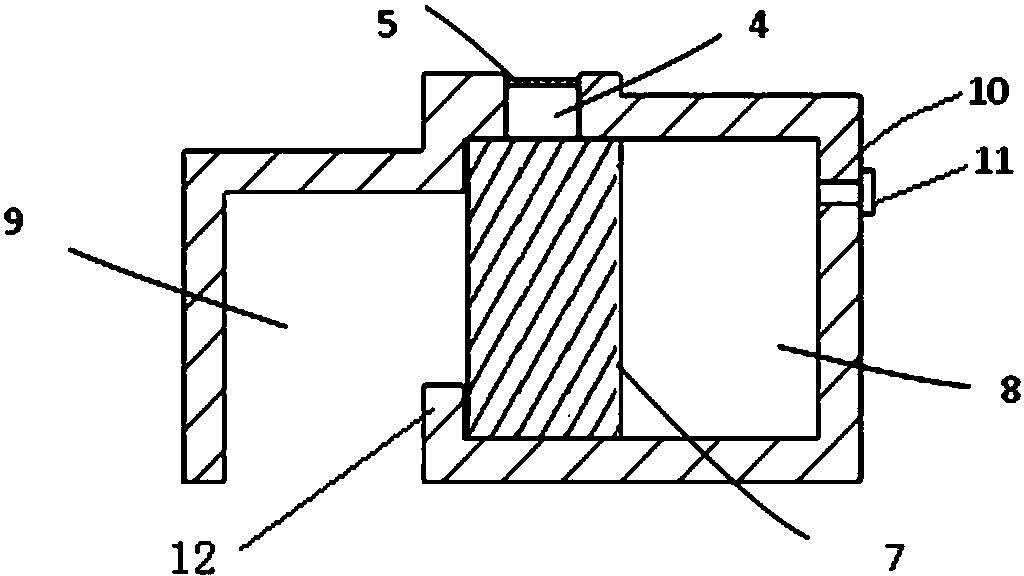

[0028] Reference image 3 The difference between this embodiment and embodiment 1 is that: the pressure adjusting slider 7 is a hexahedral slider with a rectangular cross section; the limiting block and the automatic pressure regulating and explosion-proof device body 3 are an integral structure, and the limiting block is composed of A protrusion 12 provided at the lower part of the main body 3 of the automatic pressure regulating and explosion-proof device is replaced. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com