Artificial floral leaf setting machine

A technology of craft flowers and setting machines, applied in artificial flowers, clothing, applications, etc., can solve the problems of not easy to automate the picking and placing of flowers and leaves, difficult to realize automation, assembly line production, and restrict artificial flower production industry, etc., to achieve The effect of long-term shape retention, simple structure, and convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

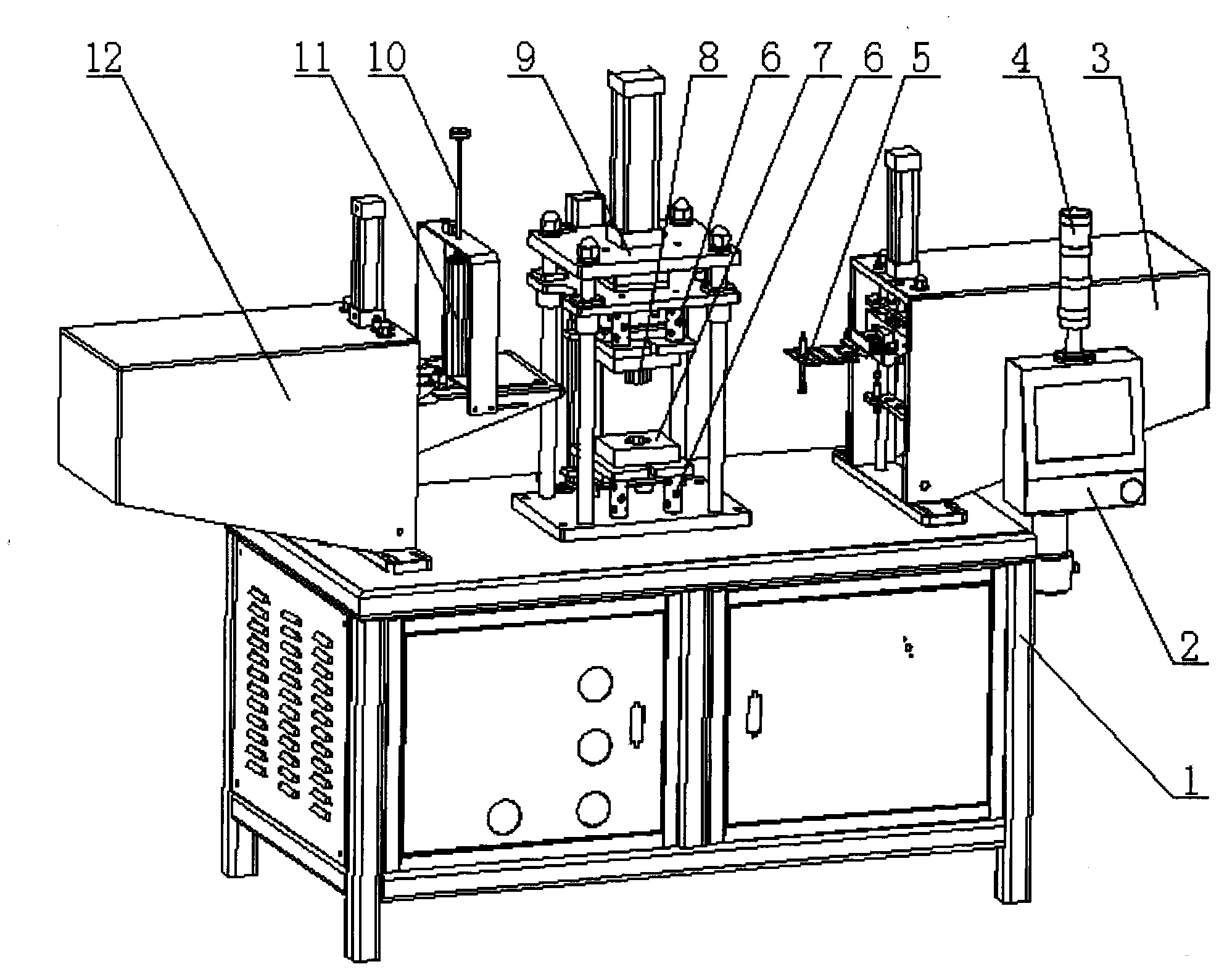

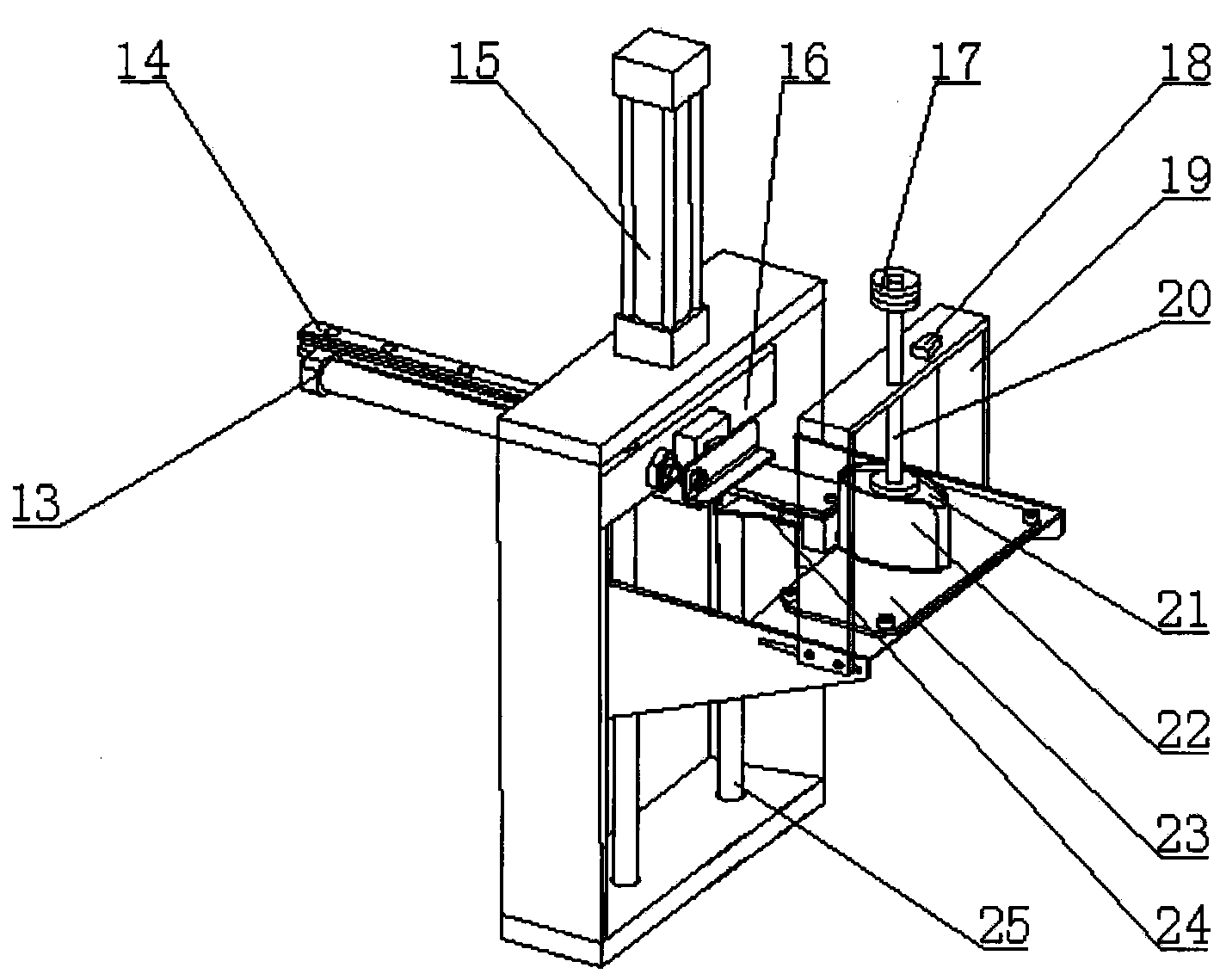

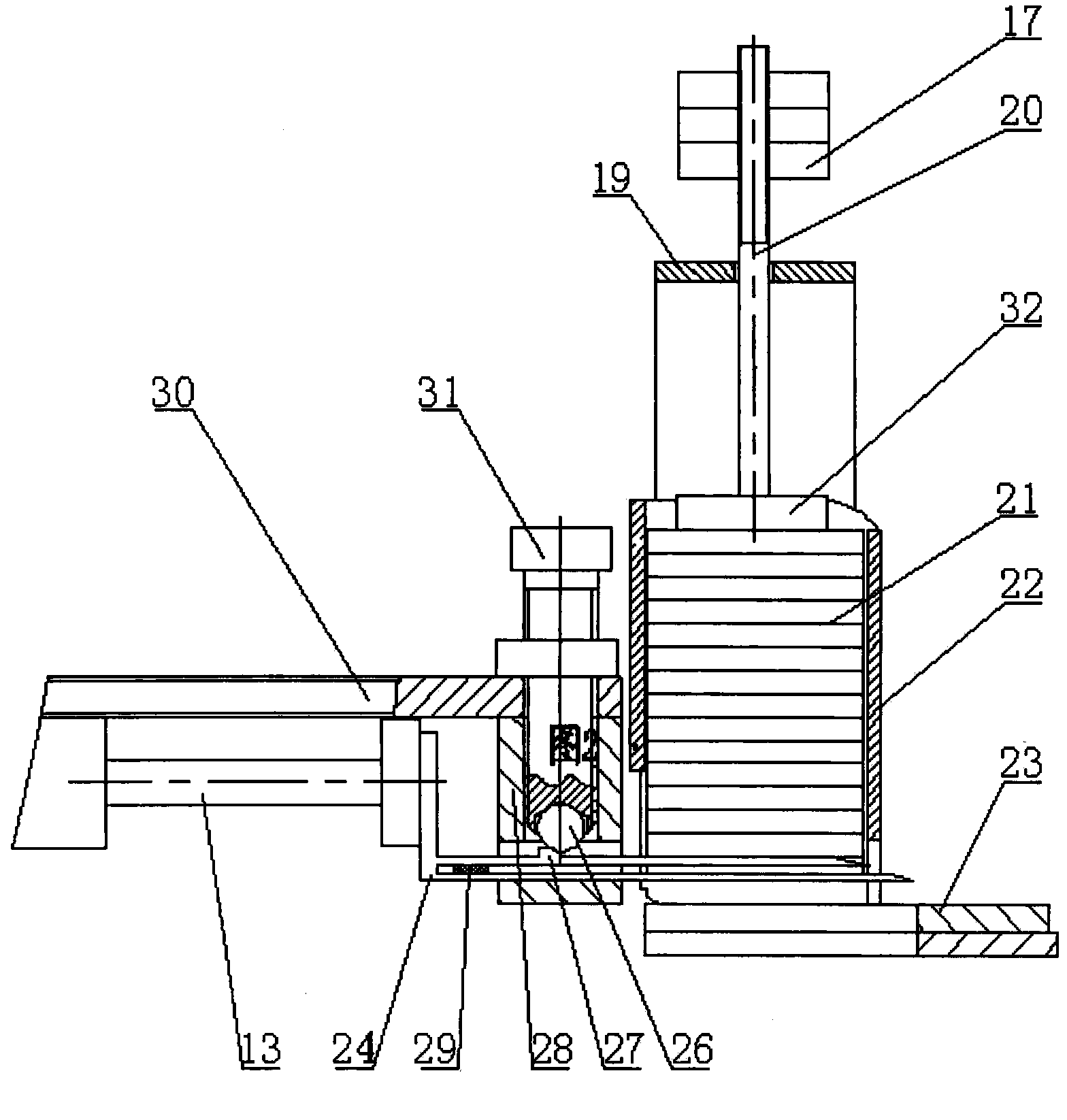

[0021] The structure of the present invention is described below in conjunction with the accompanying drawings.

[0022] as attached Figure 1-7 As shown, the artificial process flower leaf setting machine of the present invention includes a frame 1, an electrical control box 2, a material suction sheet mechanism 3, an alarm lamp 4, a vacuum suction head 5, a heat insulation cover 6, a lower mold 7, and an upper mold 8 , working press 9, counterweight device 10, material releasing device 11, material clamping mechanism 12, horizontal cylinder 13, horizontal guide rail 14, longitudinal cylinder 15, clamping bracket 16, counterweight 17, leaf missing detection switch 18 , discharge bracket 19, counterweight bar 20, sheet box 22, sheet box base 23, clamping sheet tweezers 24, vertical guide post 25, steel ball 26, inclined bump 27, material retaining plate 28, elastic pressing block 29 , support plate 30, pressing tweezers rod 31, pressing block 32, heat dissipation hole 33, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com