Laminated battery pole piece cleaning device

A battery pole piece and cleaning device technology, applied in the directions of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of manual operation of pole pieces, uneven force on pole pieces, creases, etc., so as to improve cleaning efficiency, The effect of improving battery performance and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Combine below Figure 1 to Figure 4 , the present invention is further described:

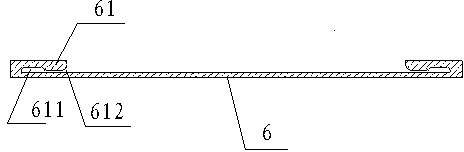

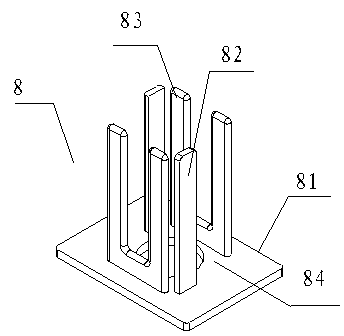

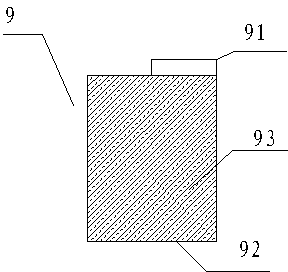

[0038] like figure 1 As shown, a stacked battery pole piece cleaning device includes a conveyor belt conveying device, and a first pole piece cleaning work area 71 and a second pole piece cleaning work area 72 are set on the conveyor belt conveying device. In the first pole piece cleaning work area 71 The equipment includes the first upper bristles 31, the first lower bristles 211 and the first cleaner 21, and the equipment in the second pole piece cleaning work area 72 includes the second upper bristles 32, the second lower bristles 221 and the second cleaner 22. The battery pole piece 9 is placed on the conveyor belt 4 of the conveyor belt conveying device, and the width of the battery pole piece 9 is greater than the width of the conveyor belt 4, the battery pole piece 9 will be positioned between the upper bristle and the lower bristle when the conveyor belt 4 moves, and the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com