Patents

Literature

38results about How to "Fully disengaged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

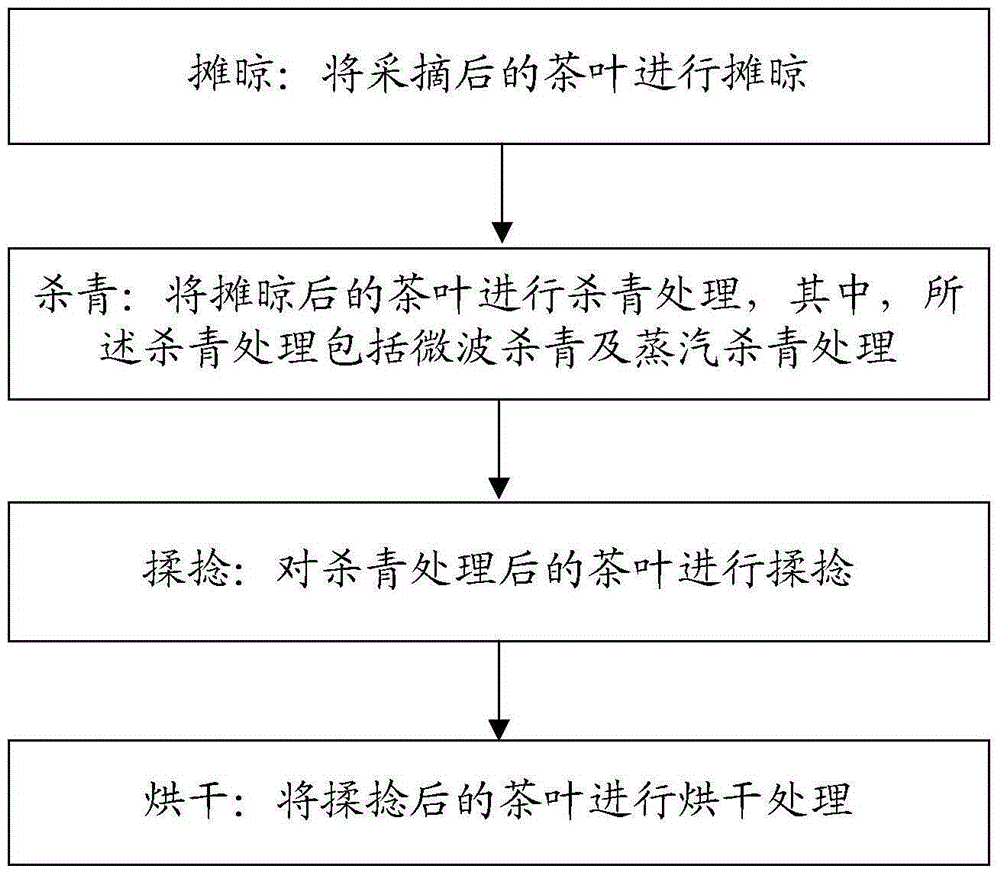

Processing method for green tea

Provided is a processing method for green tea. The method comprises the following steps: spreading and airing are carried out, namely, picked tea leaves are spread and aired; enzyme deactivating is carried out, namely, the tea leaves after spreading and airing is subjected to enzyme deactivating processing, and the enzyme deactivating processing comprises microwave enzyme deactivating processing and steam enzyme deactivating processing; rolling is carried out, namely, the tea leaves after enzyme deactivating is rolled; drying is carried out, namely, the tea leaves after rolling is subjected to drying processing. Through combination of microwave enzyme deactivating and steam enzyme deactivating processing technologies, the defects of uneven penetration, red stalks, red leaves, burnt edges, burst points and the like in a traditional enzyme deactivating technology are overcome, full separation of tea water can be ensured further, bitter taste is reduced, the product flavor is mellow, the freshness degree is high, nutrient components of the tea cannot be lost, and therefore the purpose of raising the tea quality is achieved.

Owner:张晶

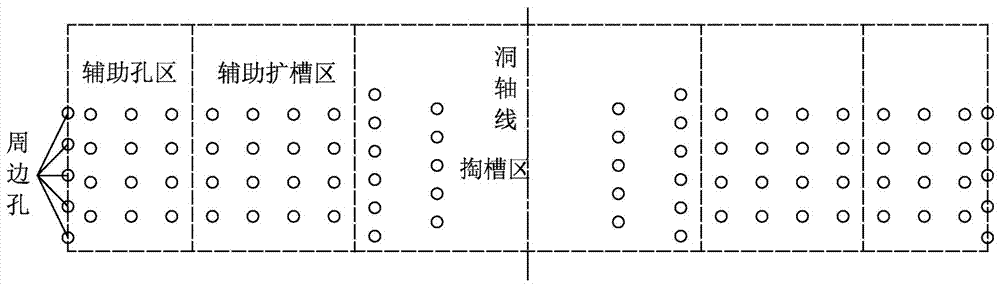

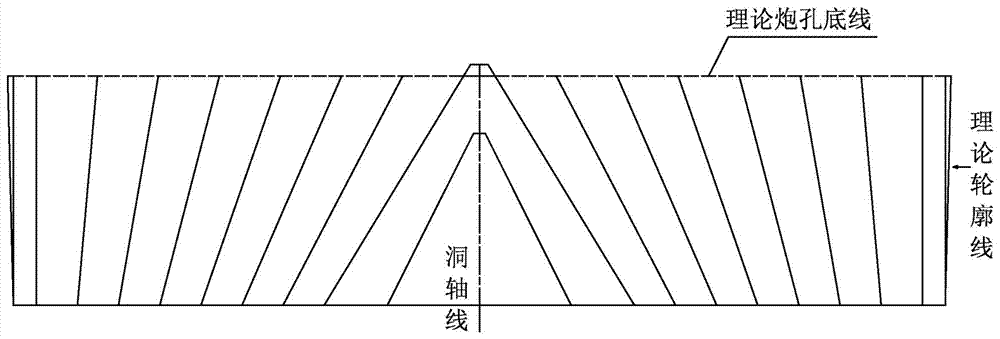

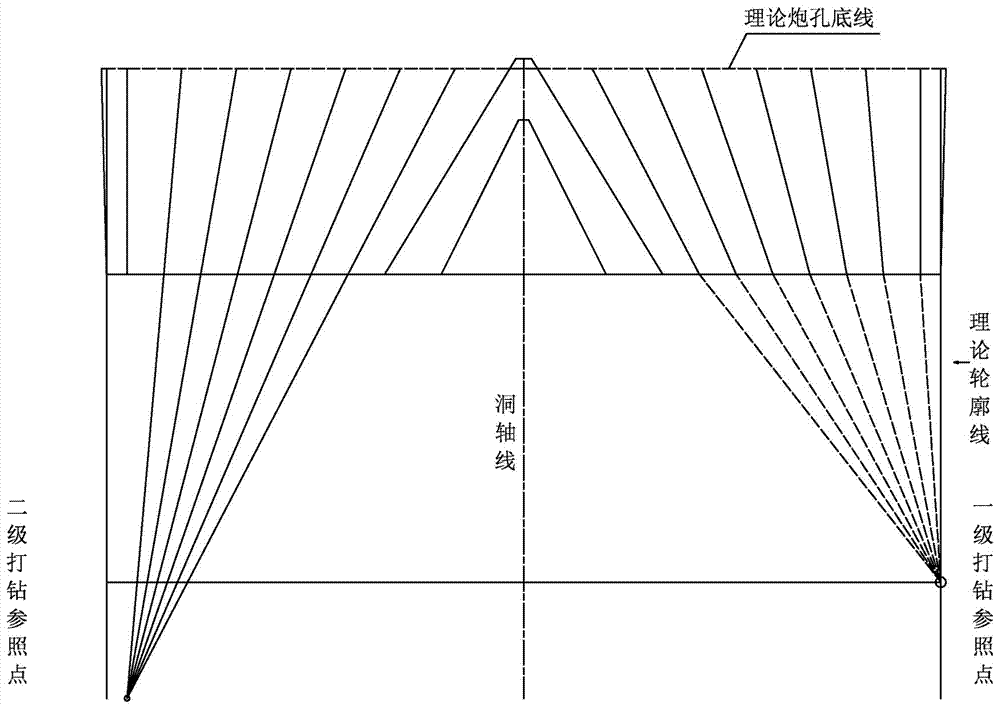

Blasting construction method adopting equal-distance fan-shaped hole distributing method for tunnel slotting and enlarging area

The invention discloses a blasting construction method adopting an equal-distance fan-shaped hole distributing method for a tunnel slotting and enlarging area. The blasting construction method is characterized in that a graphing method is adopted for performing equal-distance hole distributing for face holes, hole toes and the like, so that a joint of extending lines of blast holes with fan-shapeddistributed holes is taken as a precise reference point for drilling. Mapping results are utilized for perpendicularly drawing out a perpendicular line on a profile surface at the position of the joint, a sampling rod or an existing anchor rod is fixedly arranged on the perpendicular line; a hanging nylon rope is taken as a drilling and sampling line, and fan-shaped sampling is adopted on the horizontal plane, so that hole-bottom resisting lines between cutting holes and enlarging holes are uniformly distributed at equal distance according to fan-shaped characteristics; and each row of blastholes has evidence in drilling direction, angle, depth and position, and the theoretical method and practice can verify and inspect with each other. The construction method can eliminate an uneven hole distributing phenomenon of three-dimensional blind-region holes in bottoms of the blast holes between an inclined-hole wedge-shaped slotting area and the enlarging area, so that explosive energy distribution in the inclined-hole wedge-shaped slotting area and the enlarging area is uniform and reasonable, and therefore, combined effects of holes is further strengthened.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

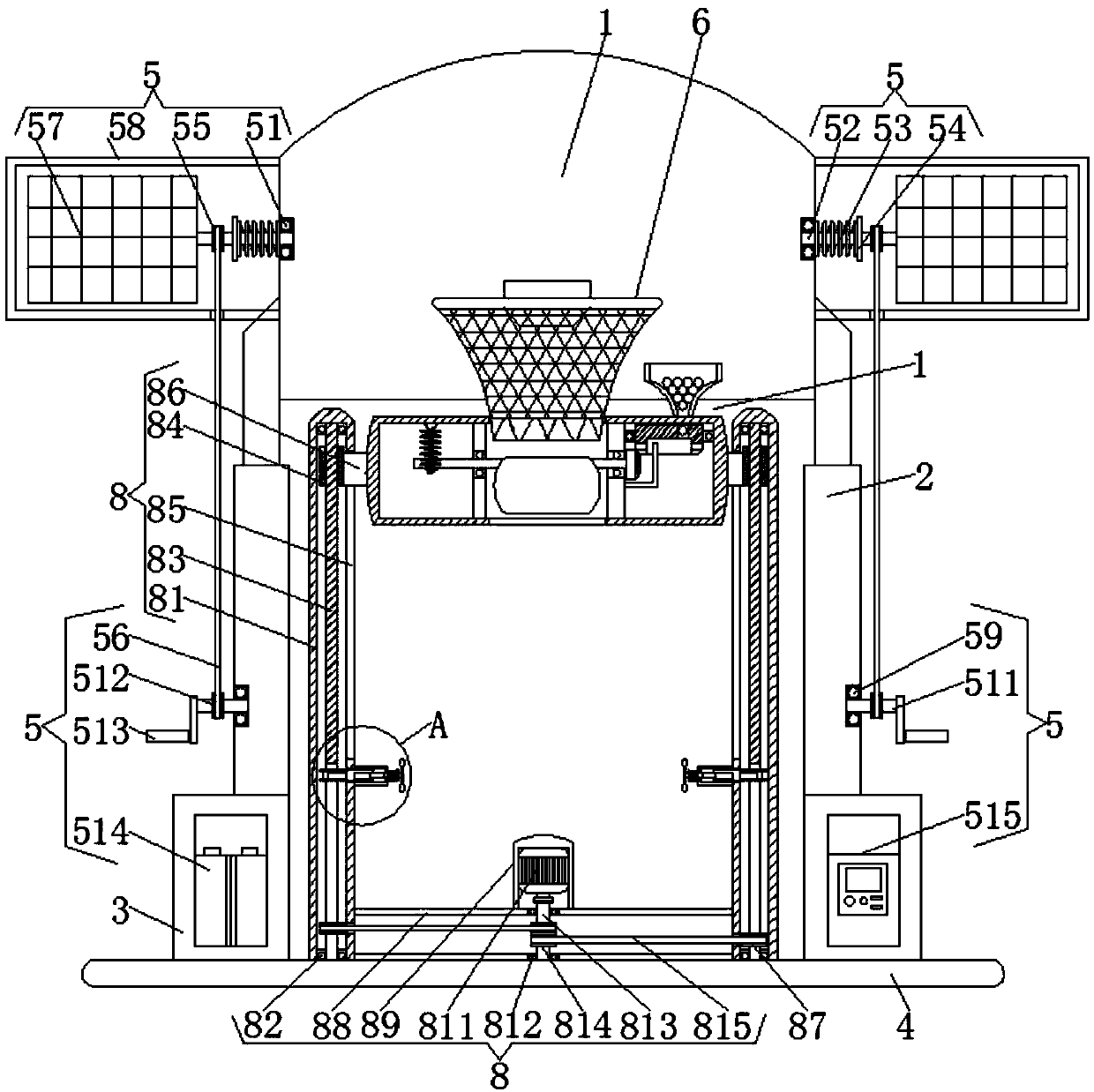

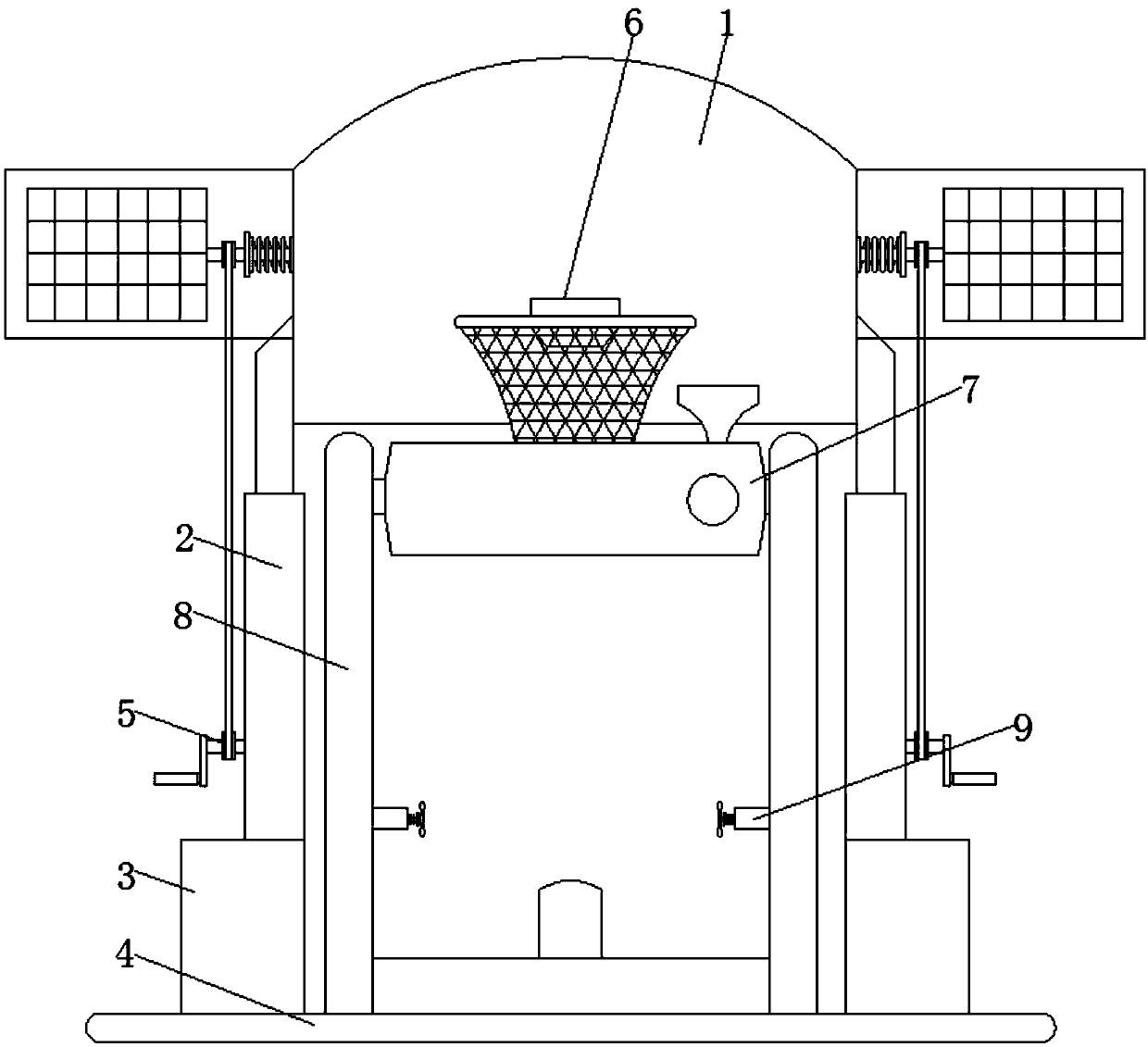

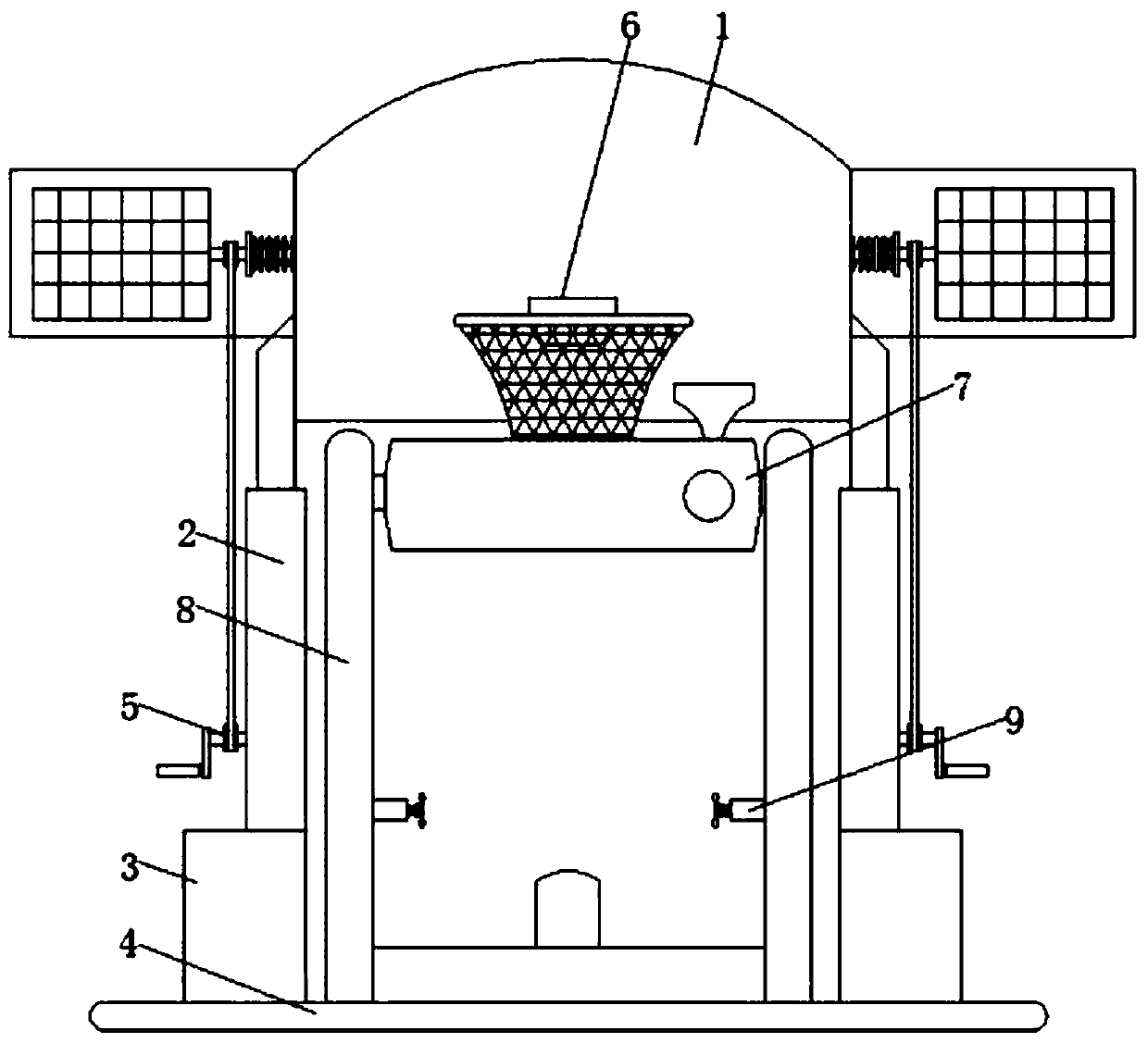

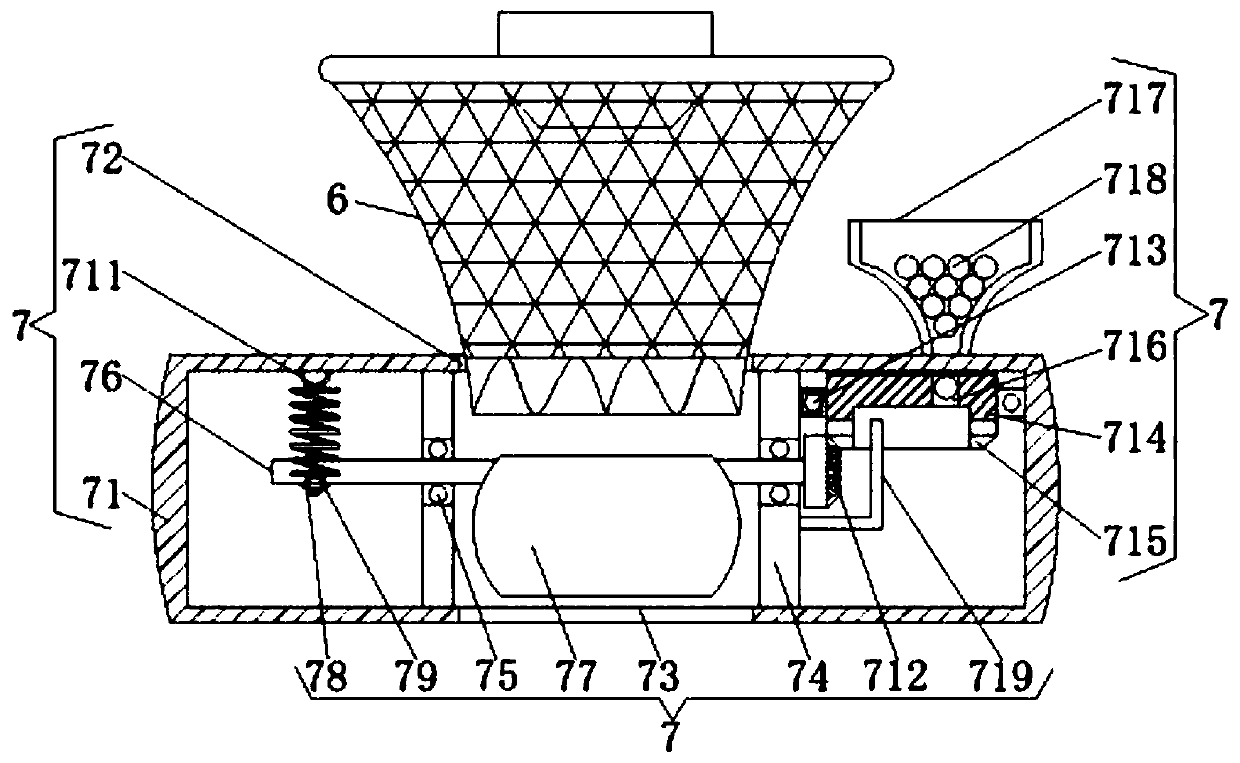

Environment-friendly shooting device for basketball training

InactiveCN108671507ATake advantage ofImprove convenienceBatteries circuit arrangementsBall sportsEngineeringCounter device

Owner:SHANDONG JIUZHOU AUTOMOBILE MFG

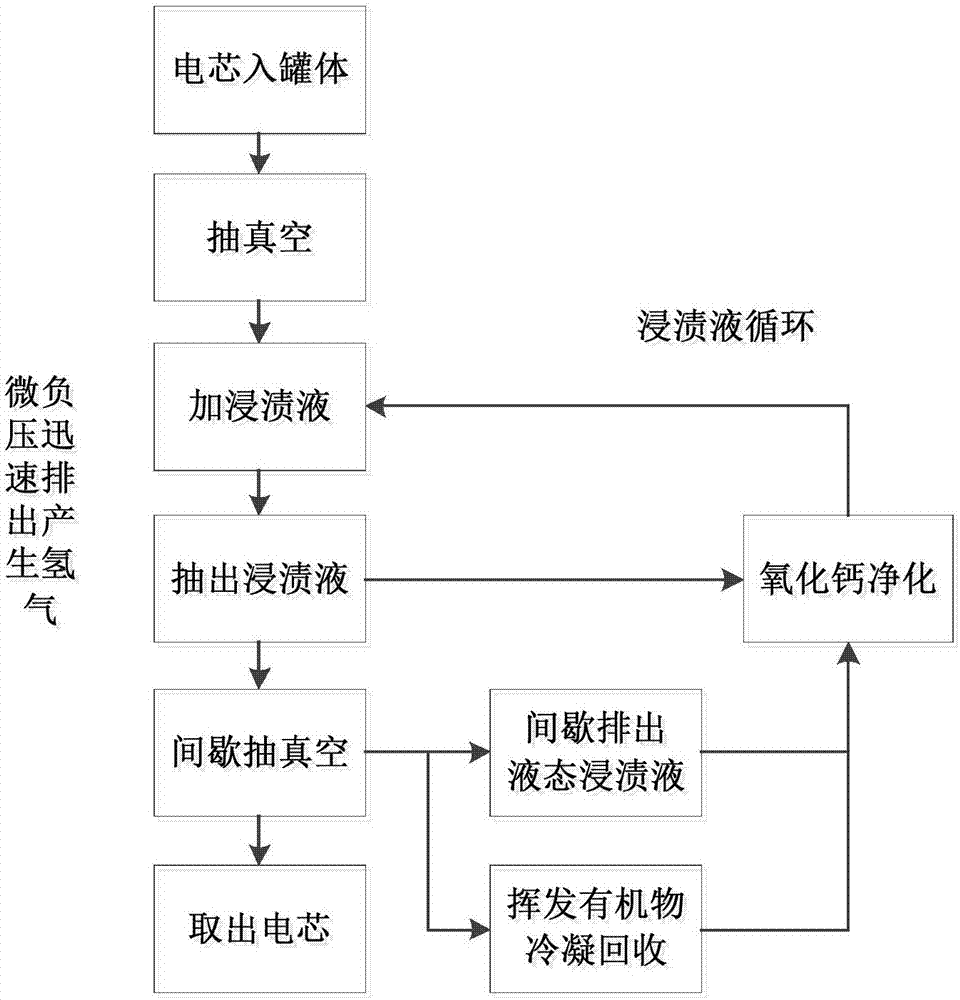

Method and device for safety treatment on lithium ion battery before recovery and recycling, and lithium ion battery safe recovery method

ActiveCN106941199AAvoid enrichmentImprove securityWaste accumulators reclaimingBattery recyclingRecovery methodReaction rate

The invention relates to a method and device for safety treatment on a lithium ion battery before recovery and recycling, and a lithium ion battery safe recovery method. The method for safety treatment comprises 1) placing an open lithium ion battery or cell in a sealed cavity, and carrying out vacuum pumping on the sealed cavity, and 2) adding an immersion liquid into the sealed cavity, carrying out immersion treatment, wherein the immersion liquid is a mixed solution of water-soluble organic matters and water according to a mass ratio of (3-19): 1, and discharging the immersion waste liquid. The method for safety treatment utilizes the mixed solution of water-soluble organic matters and water as a treatment liquid so that a residual lithium reaction rate in water and cell is reduced, enrichment of flammable gas such as H and heat is avoided and safety is high. The method can realize thorough elimination of residual lithium and LiPF6. The treated battery or cell can be dismantled or crushed without a protection atmosphere so that safety and dismantling efficiency of the later cell dismantling and recovery processes are improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Tunnel mine drawing groove area equidistant sectoral hole arrangement blast construction method

The invention discloses a tunnel mine drawing groove area equidistant sectoral hole arrangement blast construction method. The method comprises the steps of 1, designing a drawing, wherein blast holes are reasonably arranged according to the tunnel lithology grade and the tunnel blast design requirement, and an equidistant sectoral hole arrangement method is utilized to conduct CAD software drawing; 2, erecting an instrument and conducting surveying and lofting, wherein the drawing in the first step is utilized, a vertical line is made in the profile plane of the joint of the blast holes, a lofting rod or a ready-made anchor rod is arranged and fixed on the vertical line, and a nylon rope is hung and serves as a drill lofting line; 3, conducting drilling, wherein the drawing in the first step is utilized, and a drill reference point construction method is adopted to conduct construction; 4, conducting charge blast, wherein powder charging, blocking, blast network connection, alerting and blast initiating are conducted according to the designed detailed requirement for segmentation of the powder charge volume of each blast hole, and the powder charging structure. The tunnel mine drawing groove area equidistant sectoral hole arrangement blast construction method is easy to learn and operate, and hole arrangement and lofting on a palm mine drawing groove area are precisely conducted.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG +1

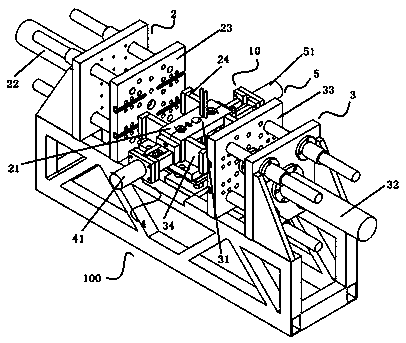

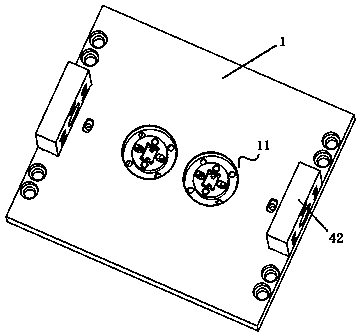

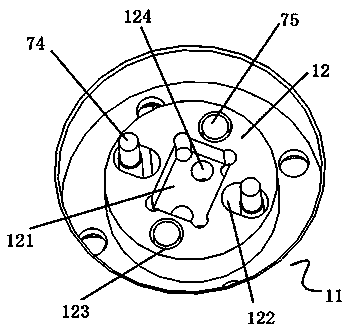

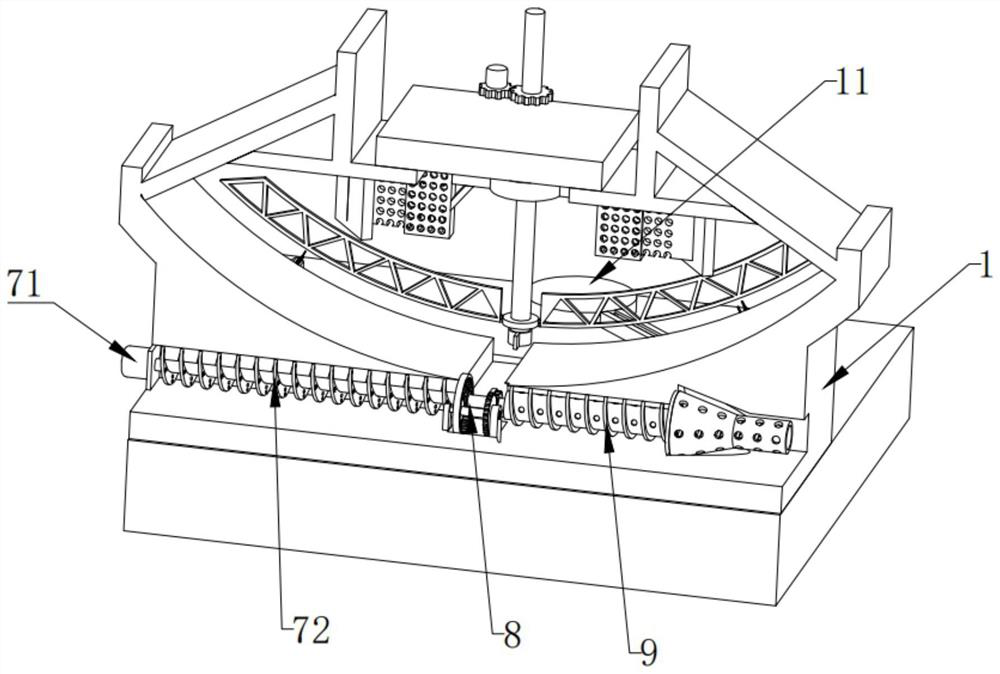

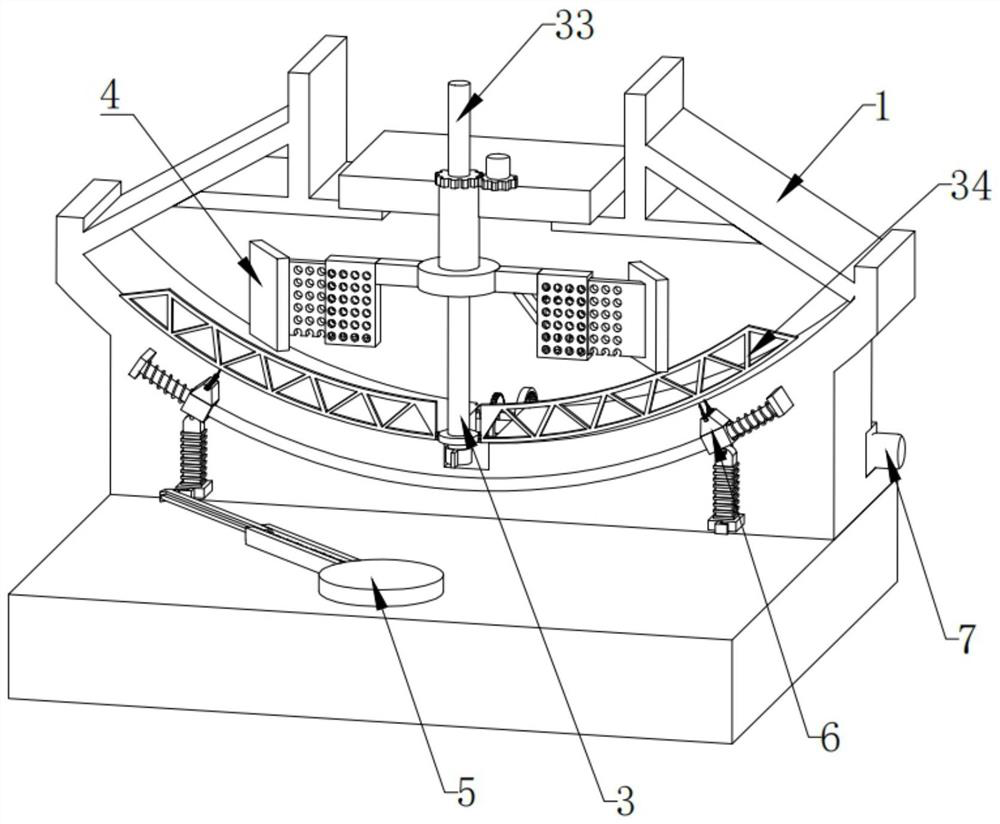

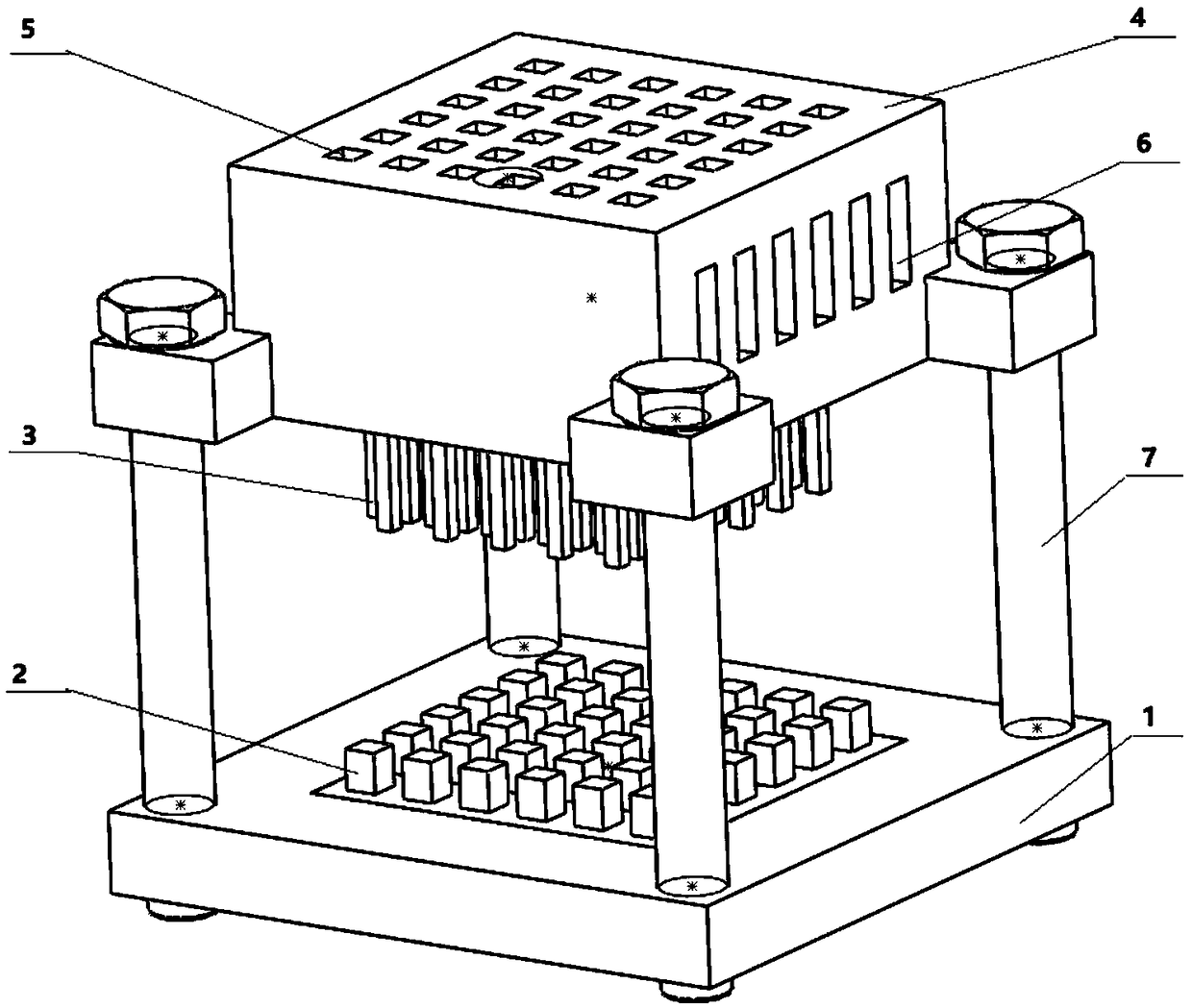

T-shaped connecting piece molding equipment and processing method thereof

PendingCN109648050AIncrease productivityReduce defectsFoundry mouldsFoundry coresFixed frameSemi automatic

The invention provides metal T-shaped connecting piece molding equipment, and a processing method thereof. The molding device comprises a fixing frame, wherein a ram proof core-pulling assembly is arranged on the fixing frame, and comprises a supporting plate frame; a first traverse moving assembly and a second traverse moving assembly are symmetrically arranged at two sides of the upper part of the supporting plate frame; and a third traverse moving assembly and a fourth traverse moving assembly are symmetrically arranged at the other two sides of the upper part of the supporting plate frame;one side of the third traverse moving assembly is connected to a core-pulling part; and one side of the fourth traverse moving assembly is connected to the core-pulling part. According to the metal T-shaped connecting piece molding equipment, a metal mold core which can be reused is adopted, and a set of production equipment used in combination with the mold core is provided. The production equipment of the metal T-shaped connecting piece molding equipment greatly improves the efficiency of collection after product molding in a ramp roof core-pulling manner, and realizes the full detaching ofthe mold core and the product and the semi-automatic and efficient production of T-shaped connecting pieces, effectively improves the batch production process of the product, reduces the production cost of the enterprise, and improves the economic benefit of the enterprise.

Owner:佛山市南海力格模具五金有限公司

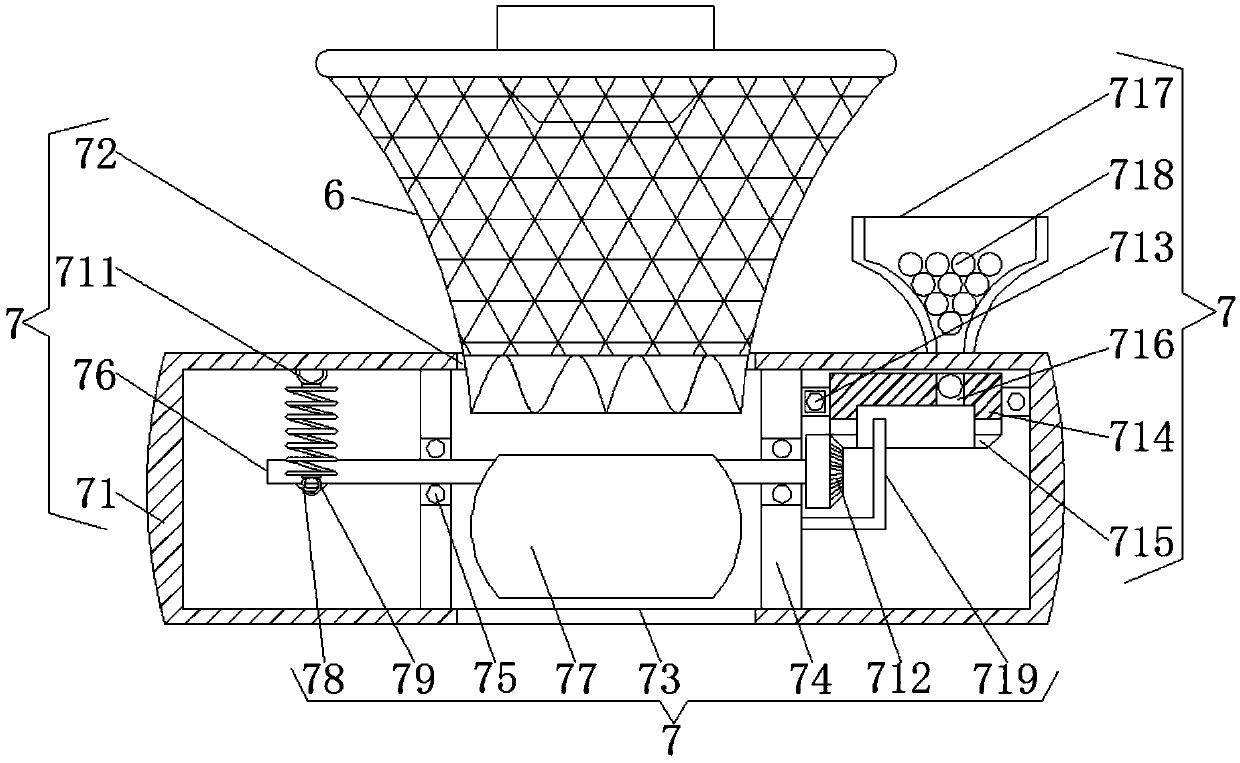

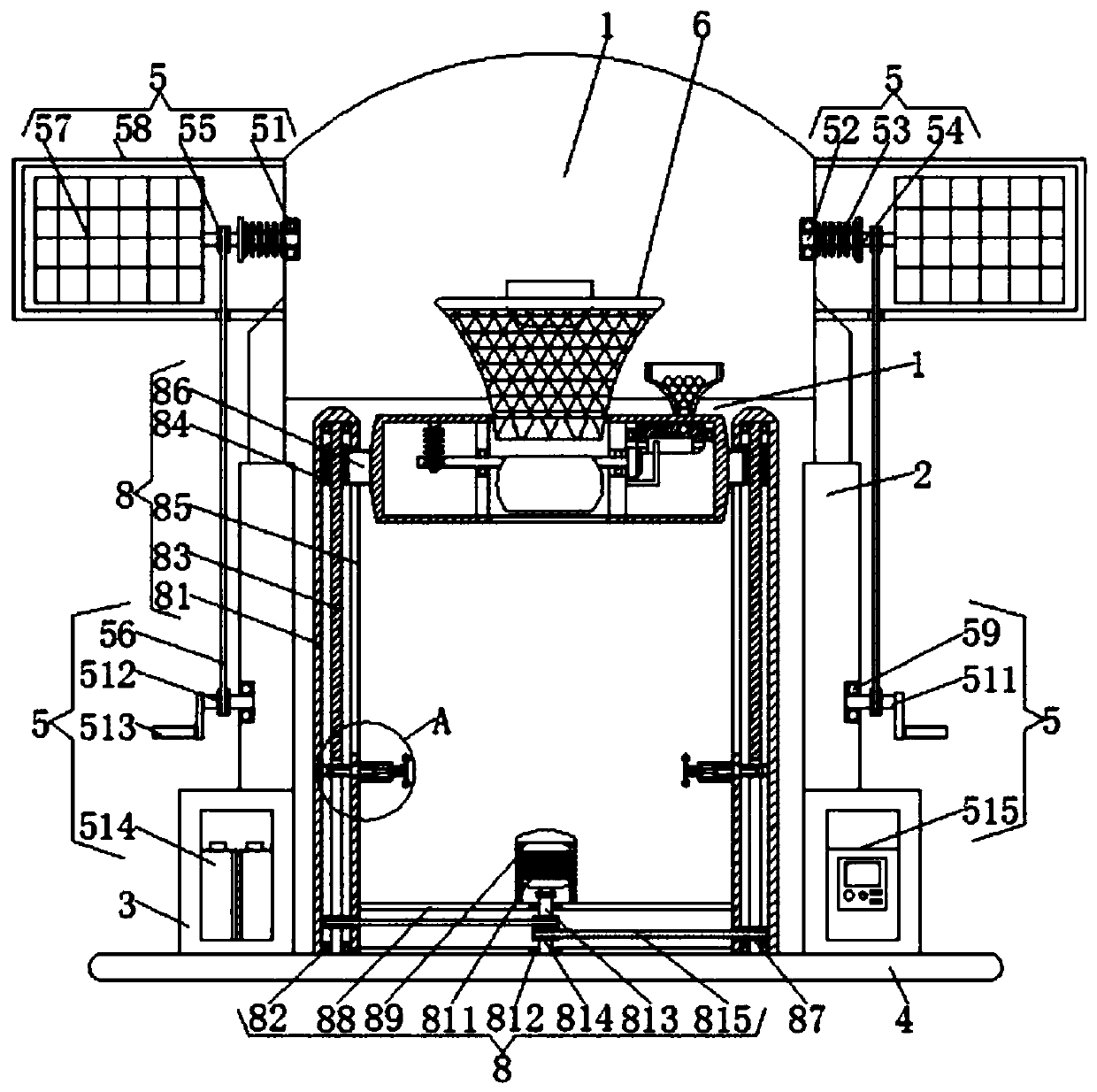

Environment-friendly basketball shooting device for basketball training and usage method

ActiveCN111330241ATake advantage ofImprove convenienceBatteries circuit arrangementsBall sportsSimulationMechanical engineering

The invention discloses an environment-friendly basketball shooting device for basketball training and a usage method, and relates to the technical field of sporting goods. The environment-friendly shooting device for basketball training comprises a backboard, the bottoms of the two side faces of the backboard are fixedly connected with two stabilizing columns. Two stabilizing boxes are fixedly connected to the bottom of the stabilizing column, supporting plates are fixedly connected to the bottoms of the two stabilizing boxes, electric power storage devices are arranged at the tops of the twoside faces of the backboard and in the stabilizing boxes, a basket is fixedly installed in the center of the front face of the backboard, and a counting device is arranged below the basket. The invention discloses an environment-friendly shooting device for basketball training. The power storage device, the counting device, the lifting device and the positioning device are matched for use; by means of the basketball pitching training device, an athlete can be promoted to complete basketball pitching training by himself / herself, the demanded quantity of trainees is reduced, the athlete can usethe basketball pitching training device more conveniently, and therefore the basketball pitching training efficiency of the athlete is further improved.

Owner:绍兴东巍体育科技有限公司

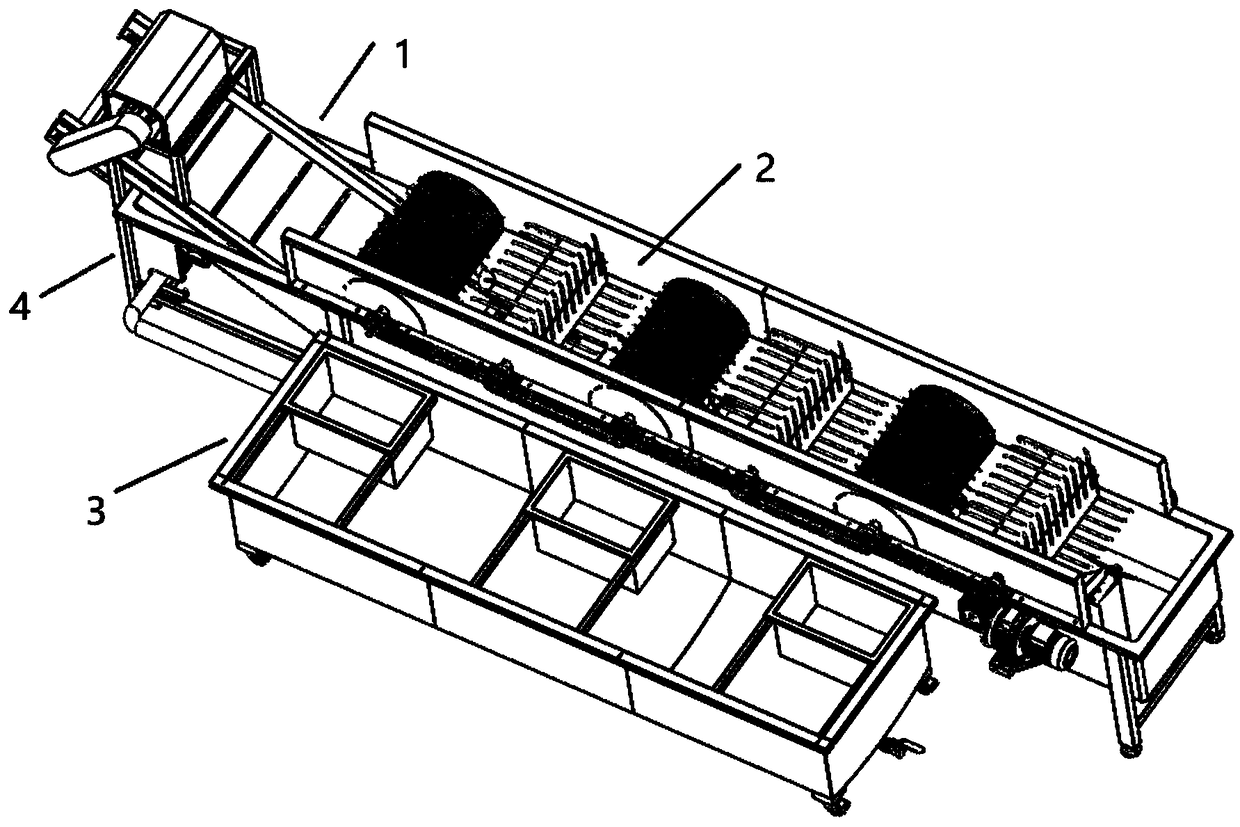

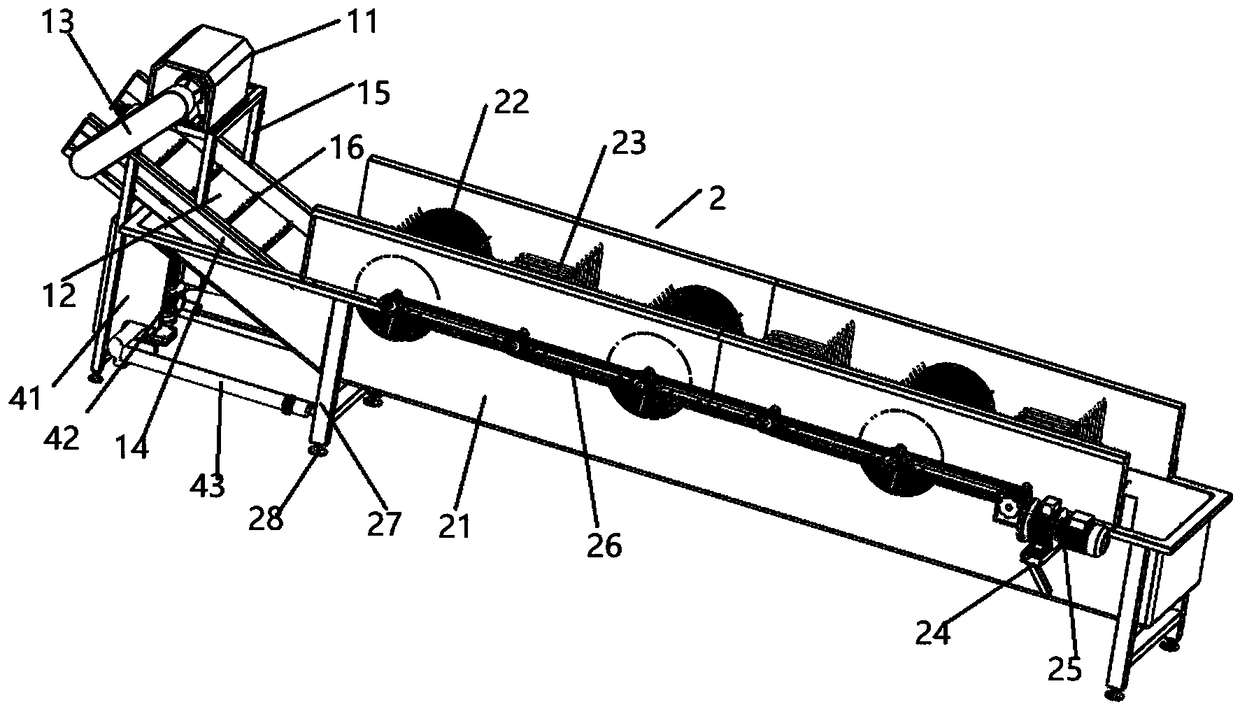

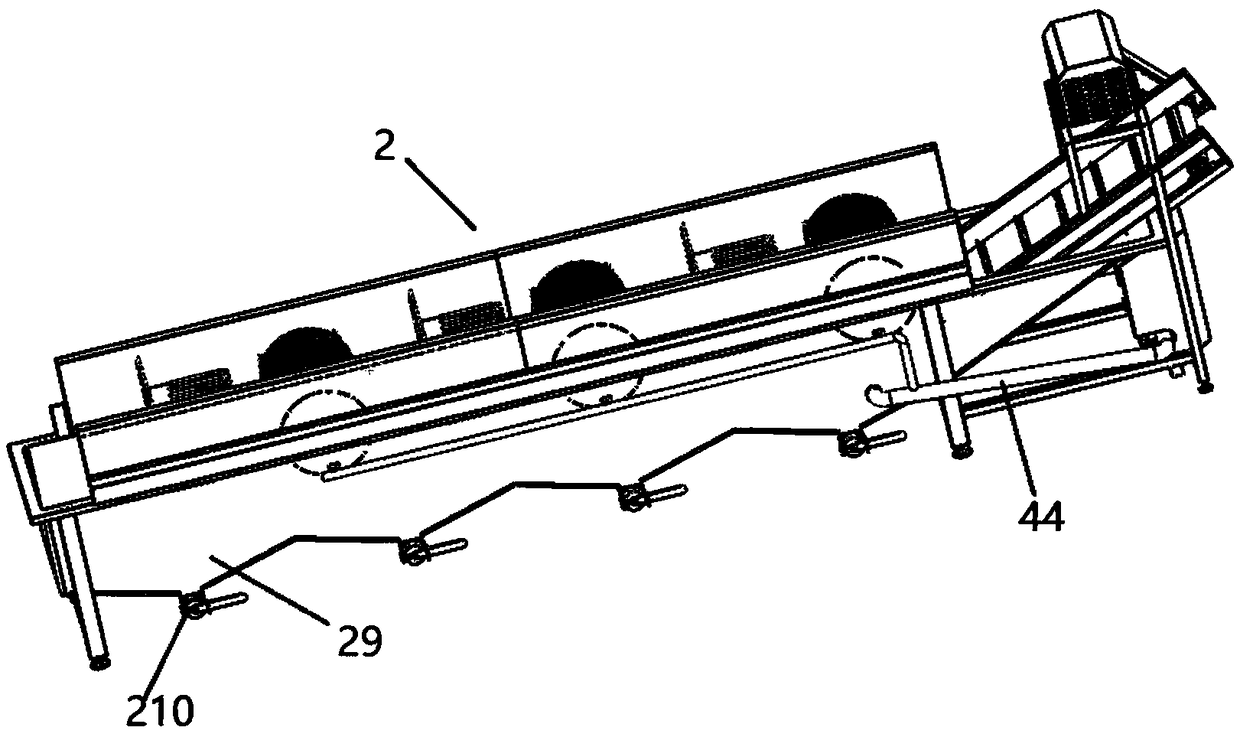

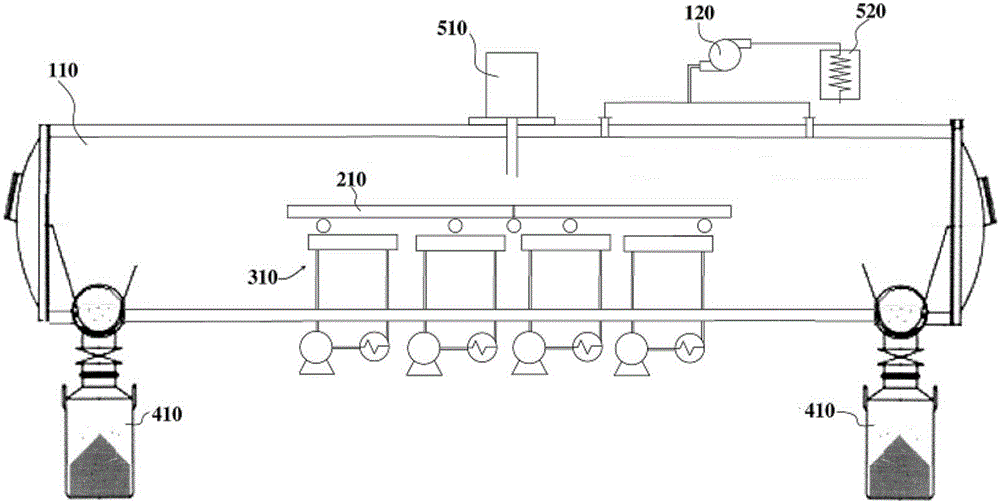

Bean sprout cleaning device for school canteen

InactiveCN109316096AImprove quality and efficiencyImprove cleaning efficiencyClimate change adaptationKitchen equipmentEngineering

The invention discloses a bean sprout cleaning device for a school canteen and relates to the technical field of bean sprout cleaning application. The device includes a feeding mechanism, a cleaning mechanism, a rinsing mechanism and a circulating mechanism. The device has the advantages that since rotary drums and cleaning rollers are arranged on the cleaning mechanism in sequence, the rotary drums and the cleaning rollers can be utilized to overturn and clean bean sprouts, and the cleaning quality and the cleaning efficiency are effectively improved; by arranging the rinsing mechanism and utilizing the rinsing mechanism to rinse the cleaned bean sprouts again, the bean sprouts can be fully separated from dirt, so that the cleaning quality is effectively improved; after the circulating mechanism is arranged and utilized to connect the cleaning mechanism with the rinsing mechanism, water in the rinsing mechanism can be collected into the cleaning mechanism by the circulating mechanismfor reutilization, and therefore the water for usage is effectively saved. The bean sprout cleaning device effectively improves the quality and efficiency of cleaning the bean sprouts and saves the water for usage.

Owner:嘉善县惠民小学

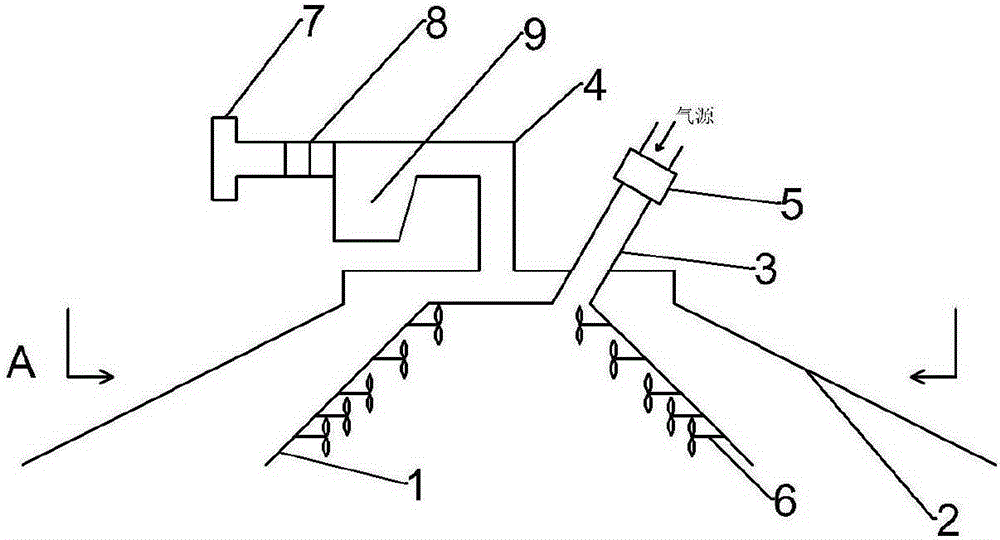

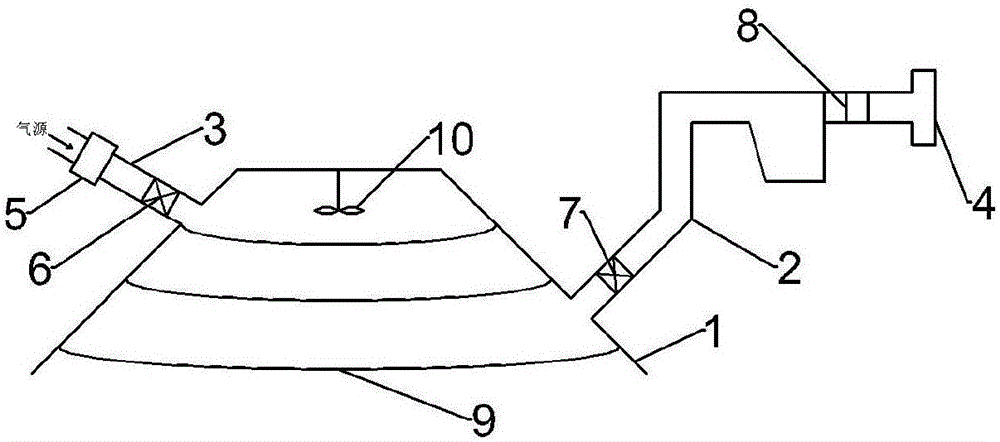

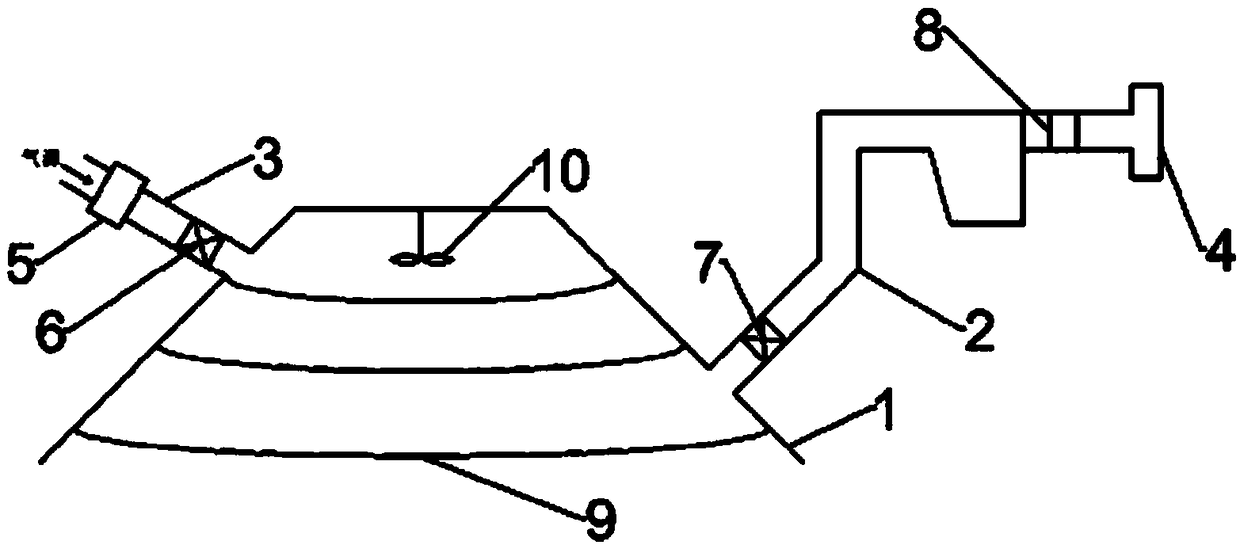

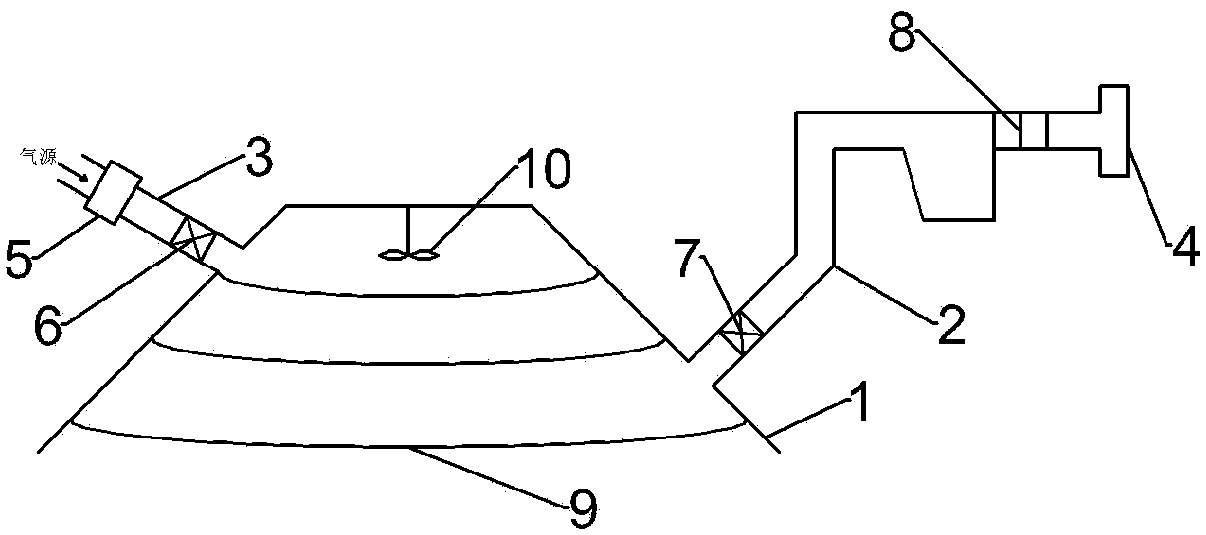

Dust removal device for carpet

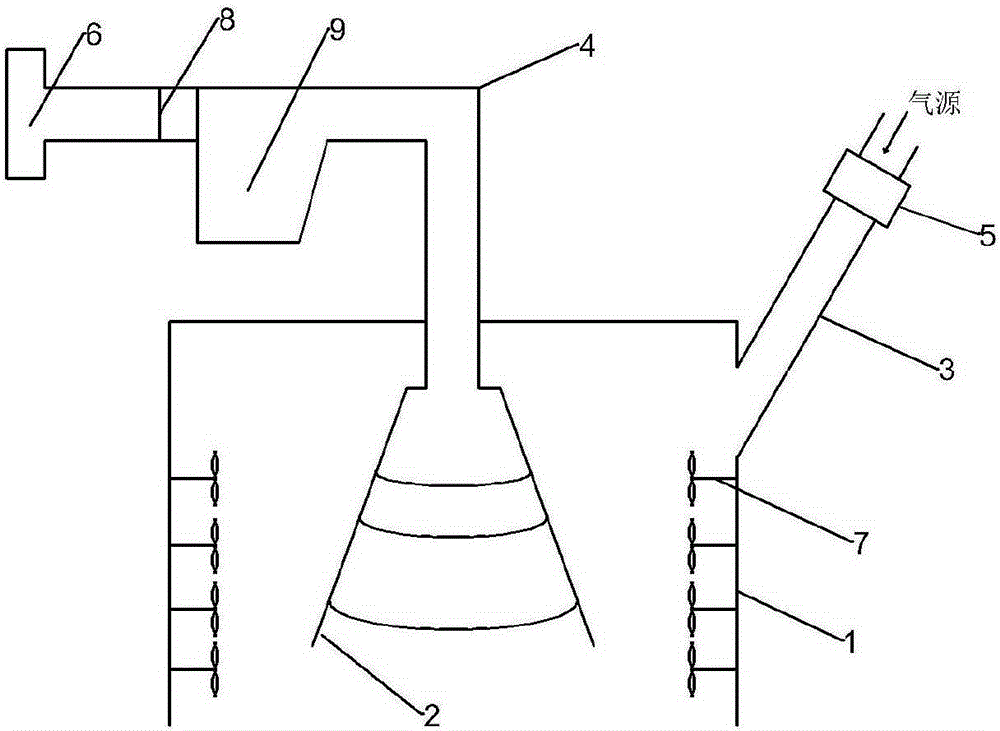

InactiveCN105193347AImprove dust removal efficiencyIncreased turbulenceSuction cleanersStructural engineeringDust control

The invention discloses a dust removal device for a carpet. The dust removal device comprises an inner shell and an outer shell, wherein the inner shell is arranged above the carpet; the inner shell is in a circular table-shaped structure with an opening in the lower end; a blow hole is formed in the top of the inner shell and is connected with an air source through an air blow pipe; a plurality of fans are arranged in the inner shell; the outer shell is in the circular table-shaped structure with the opening in the lower end; the outer shell is arranged outside the inner shell to form an accommodating space; a plurality of air suction pipes are arranged in the accommodating space; for any air suction pipe, the pipe wall of the air suction pipe clings to the outer wall of the inner shell and the inner wall of the outer shell; the plurality of air suction pipes penetrate through the outer shell and are communicated with a master air suction pipe; the master air suction pipe is communicated with an air suction device; and an air inlet end of the air suction device and the lower end of the inner shell are located on the same horizontal plane. The dust removal device is good in dust removal effect, high in dust removal efficiency and low in energy consumption.

Owner:泉州齐美电子科技有限公司

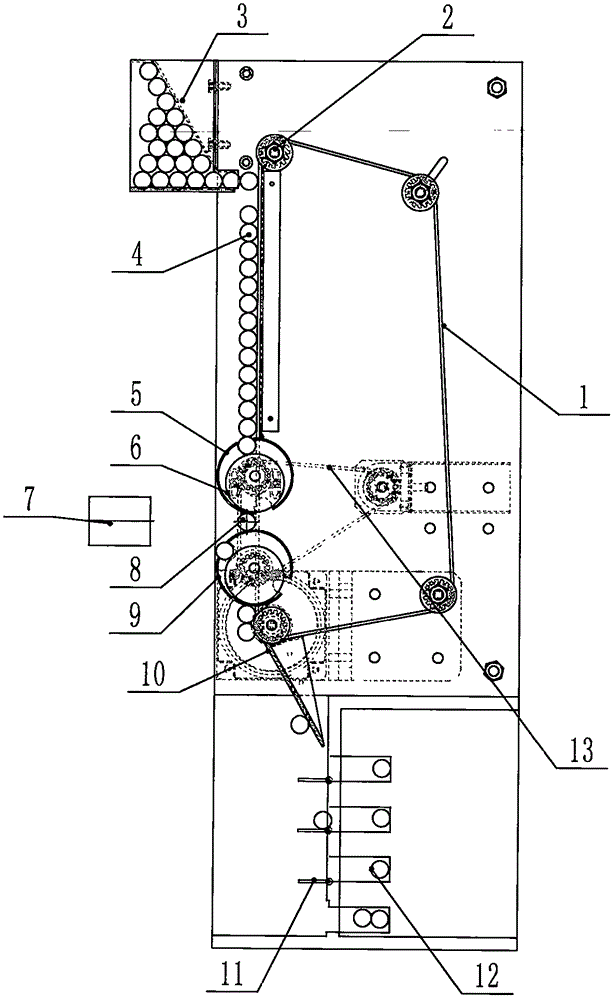

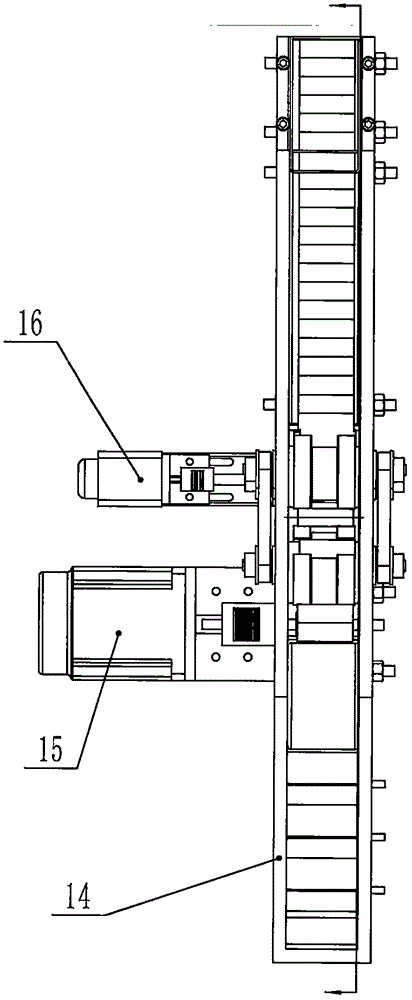

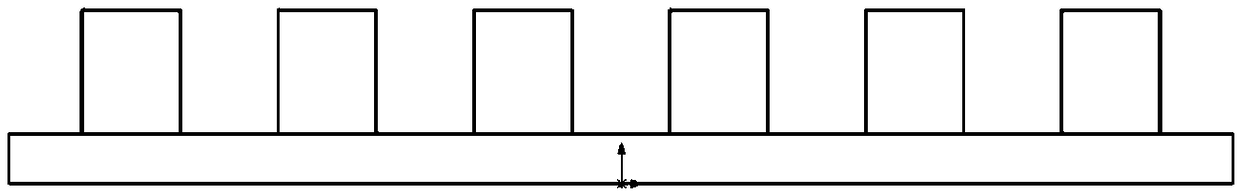

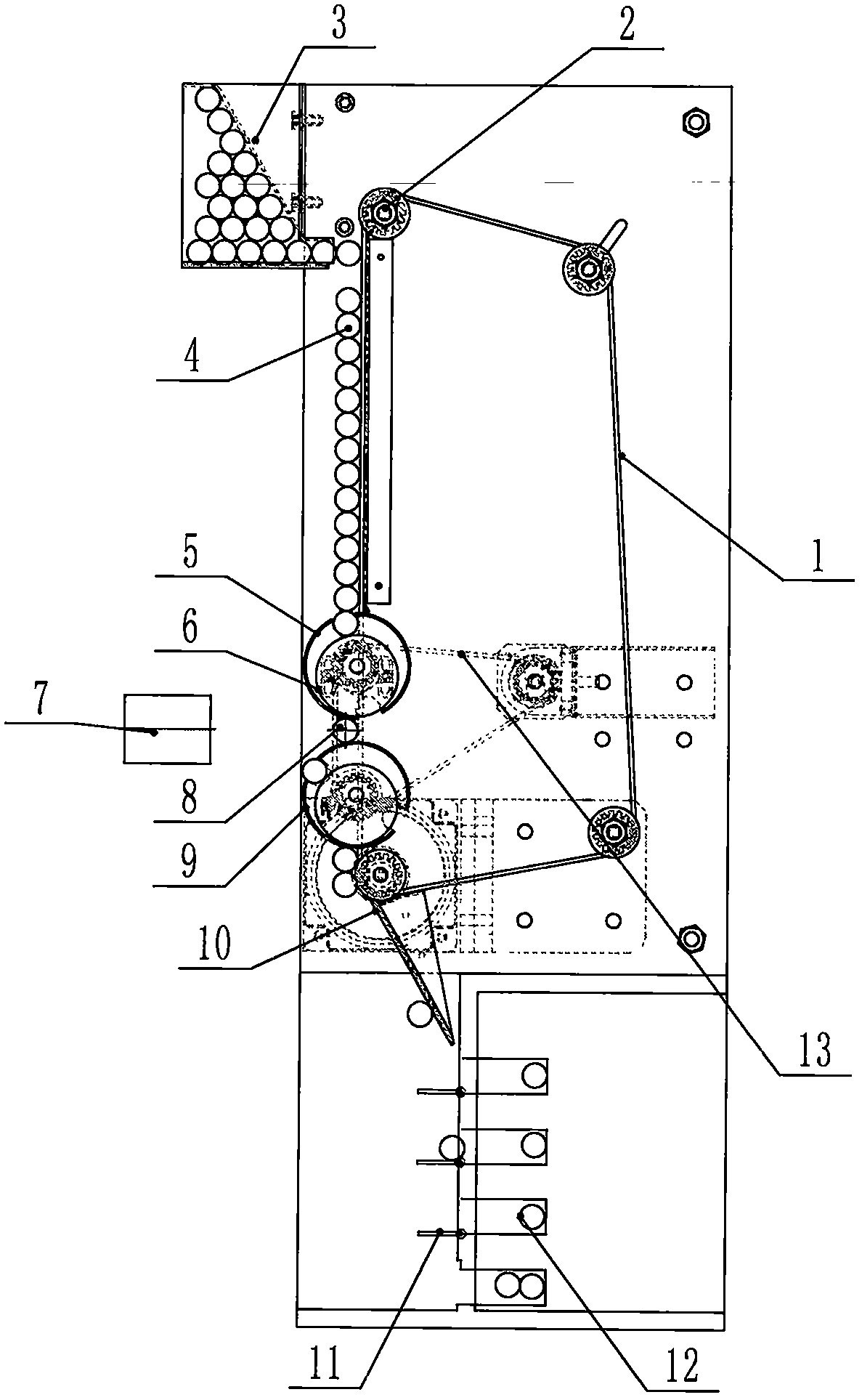

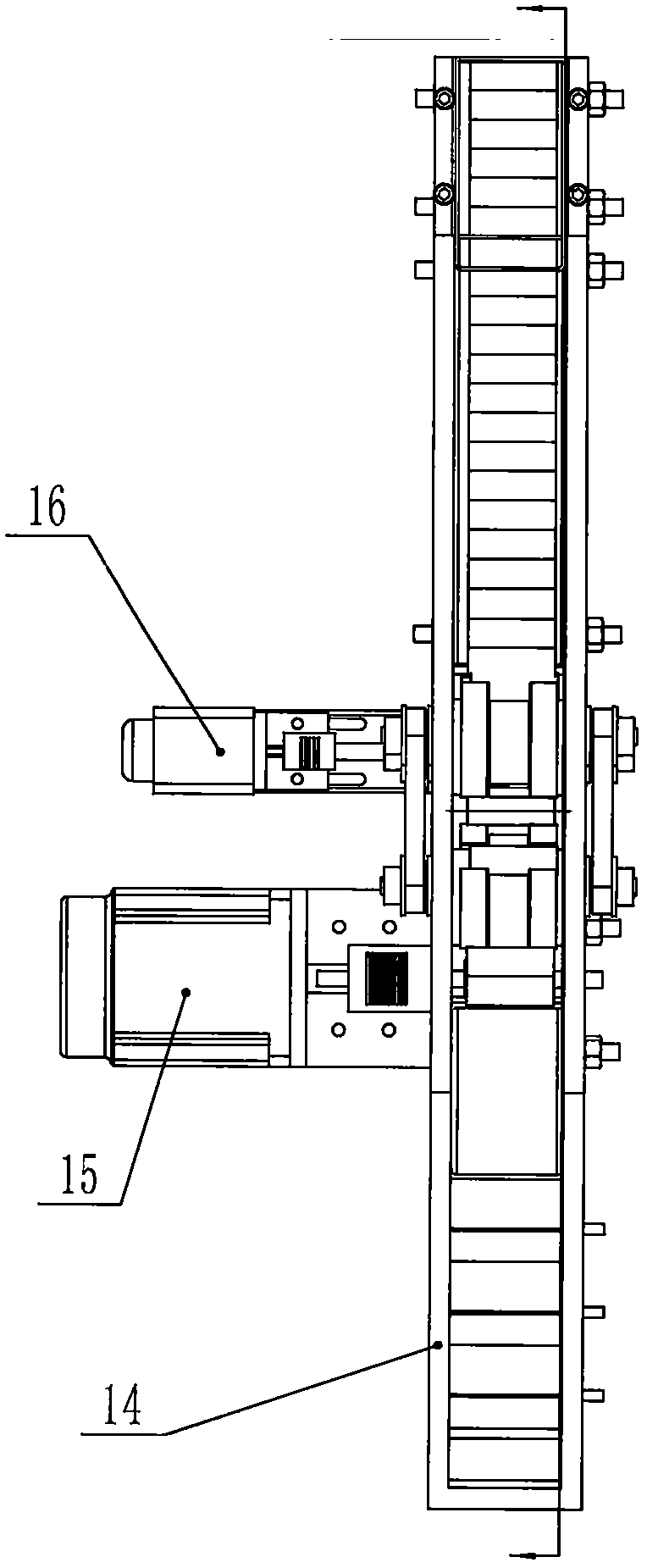

Bar image detection mechanism

Disclosed is a bar image detection mechanism. The mechanism is simple in structure and free of a vacuum system. The mechanism comprises a feeding synchronous belt, synchronous wheels, a storage box, bars, a feeding transferring wheel, eccentric wheels, a detection head, a detection position, a discharging transferring wheel, a discharging plate, a dividing plate, a dividing groove, a rotating synchronous belt, a discharging box, a feeding motor and a rotating motor; each transferring wheel is composed of two half wheels, the feeding synchronous belt passes the middles of the transferring wheels, the gap between the two transferring wheels is adjustable, and due to arrangement of the number of clamping grooves in the transferring wheels, the arc line between two clamping grooves can drive the bars to sufficiently rotate on the detection position; due to the depth of the clamping grooves, the bars are clamped and cannot fall off, and the next bars cannot be disturbed; the eccentric wheels are arranged in the transferring wheels, and deviate from the discharging position, and it is ensured that during feeding, the bars are sufficiently clamped in the clamping grooves, and during discharging, the bars are sufficiently separated from the clamping grooves. The dividing plate and the dividing groove are arranged in the discharging box, due to the dividing plate, the bars pass through or enter the dividing groove, and clamping and separation of the bars can be achieved through the eccentric wheels and the transferring wheels.

Owner:北京凯视佳光电设备有限公司

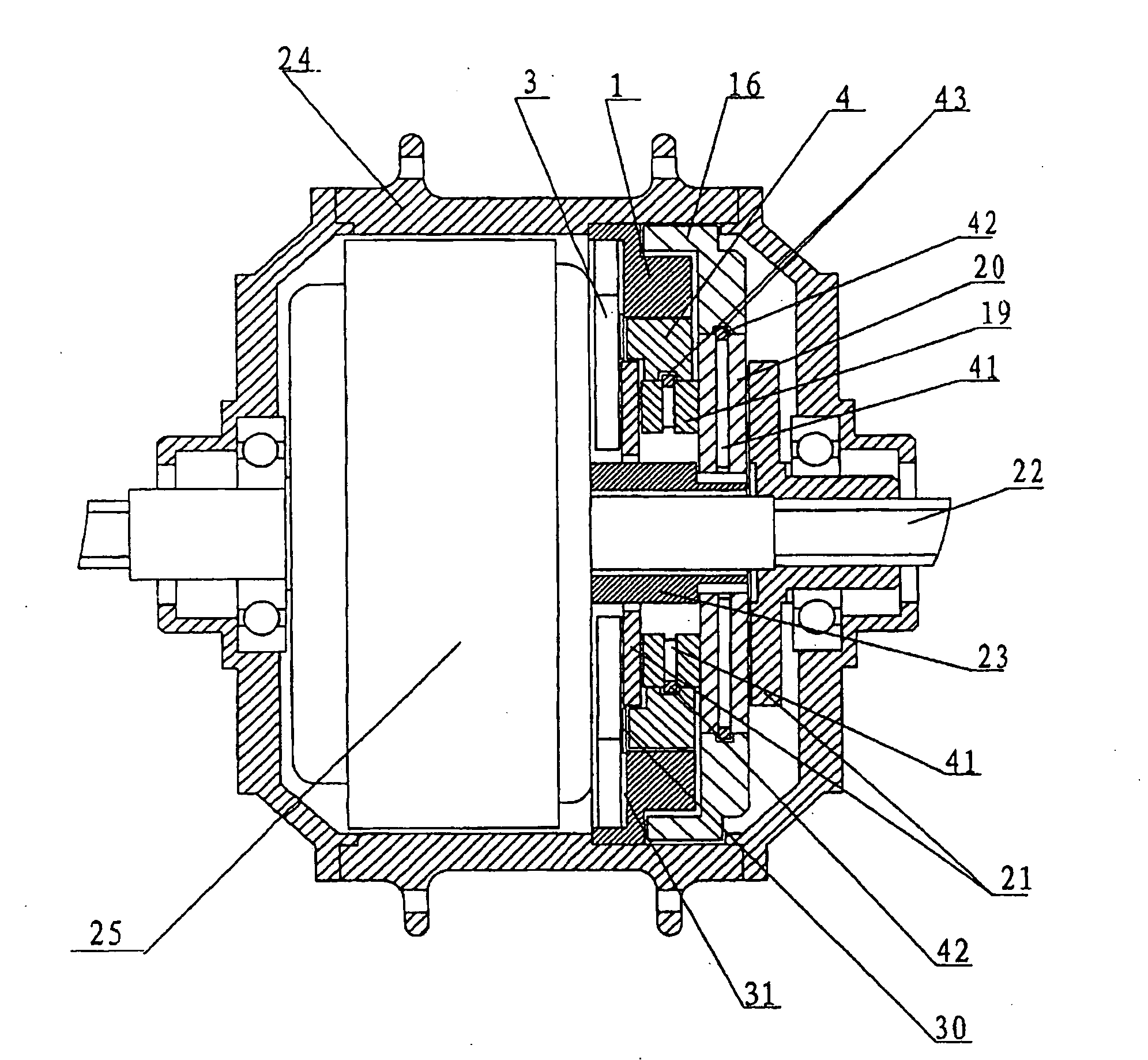

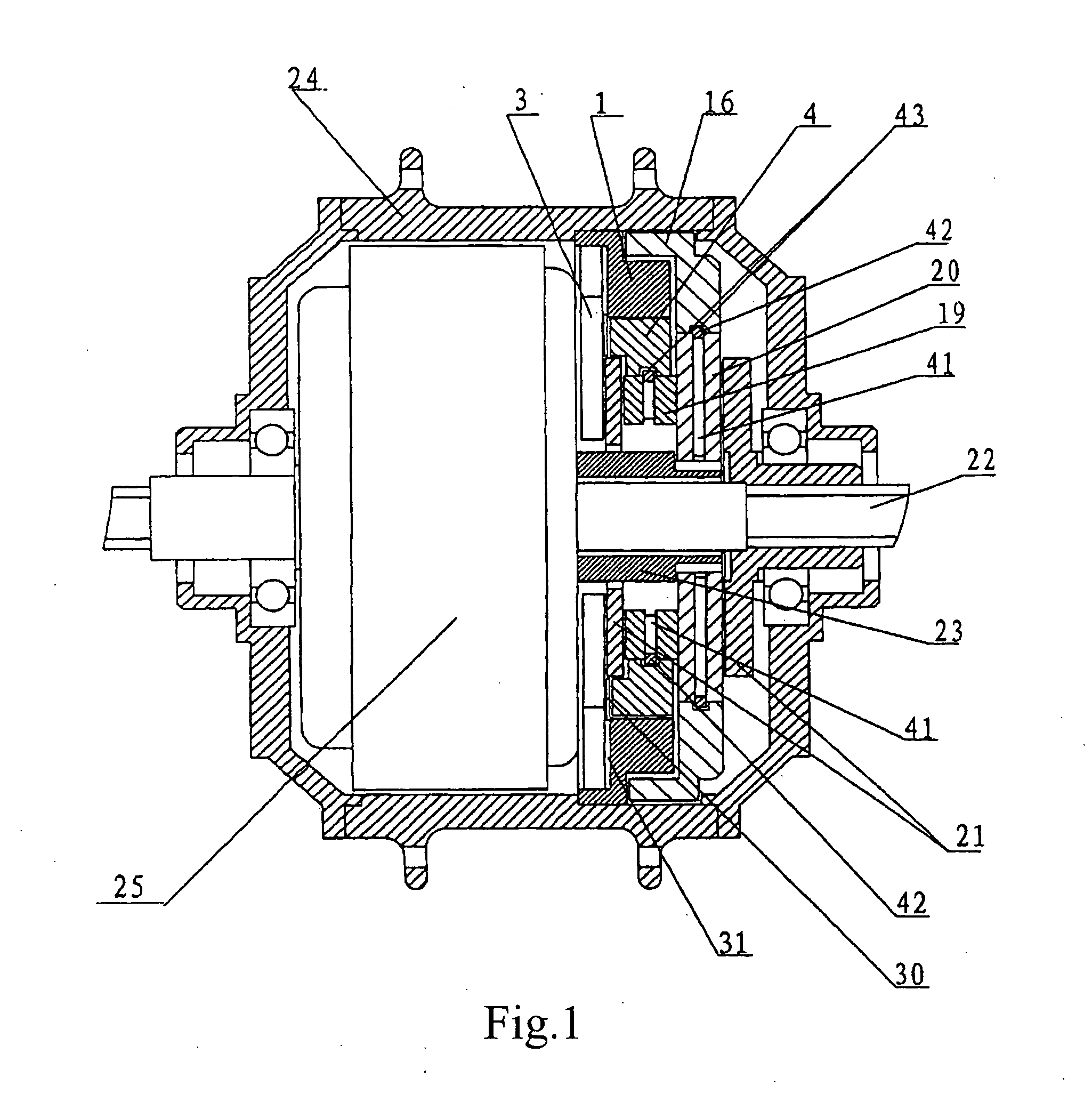

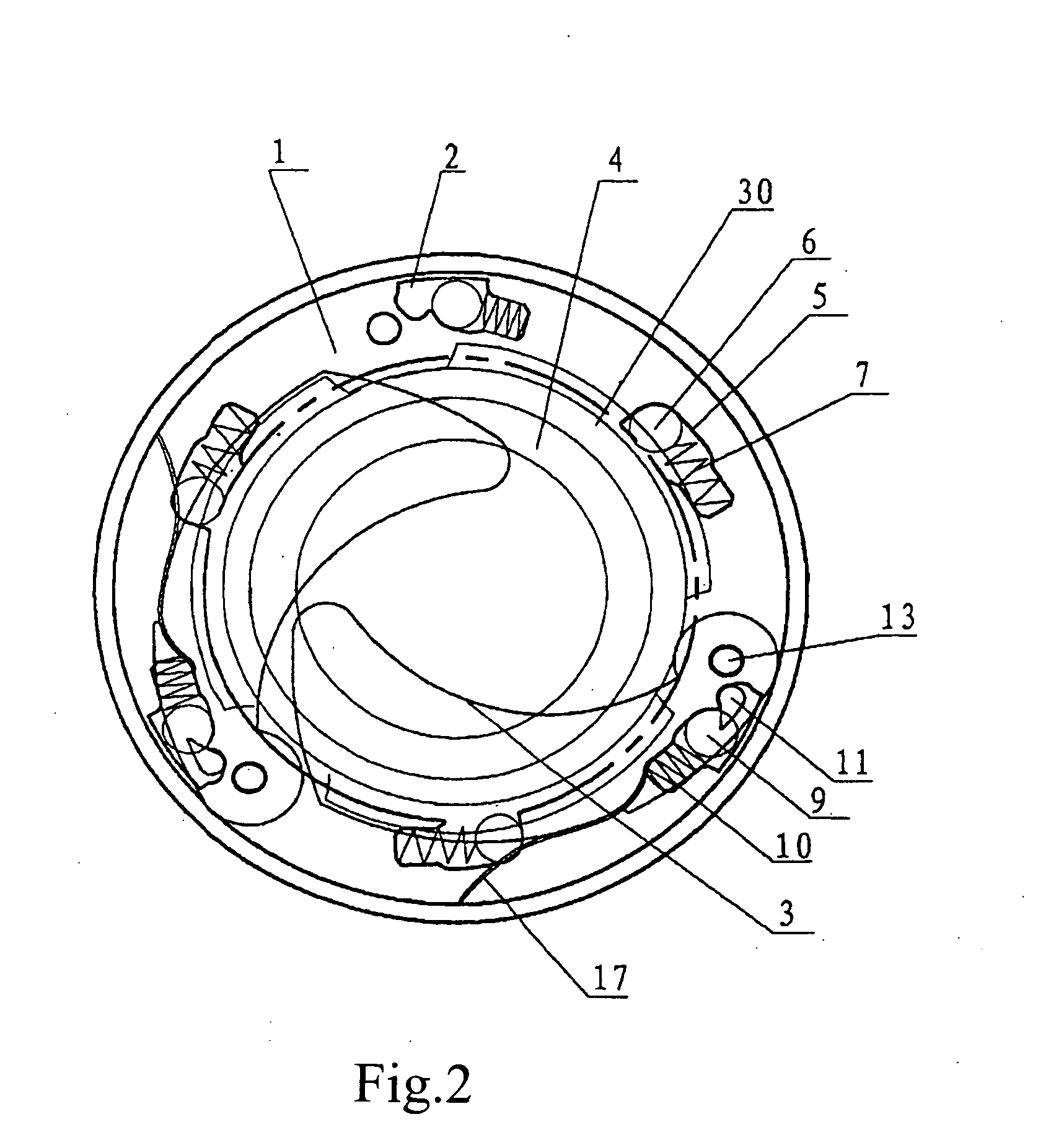

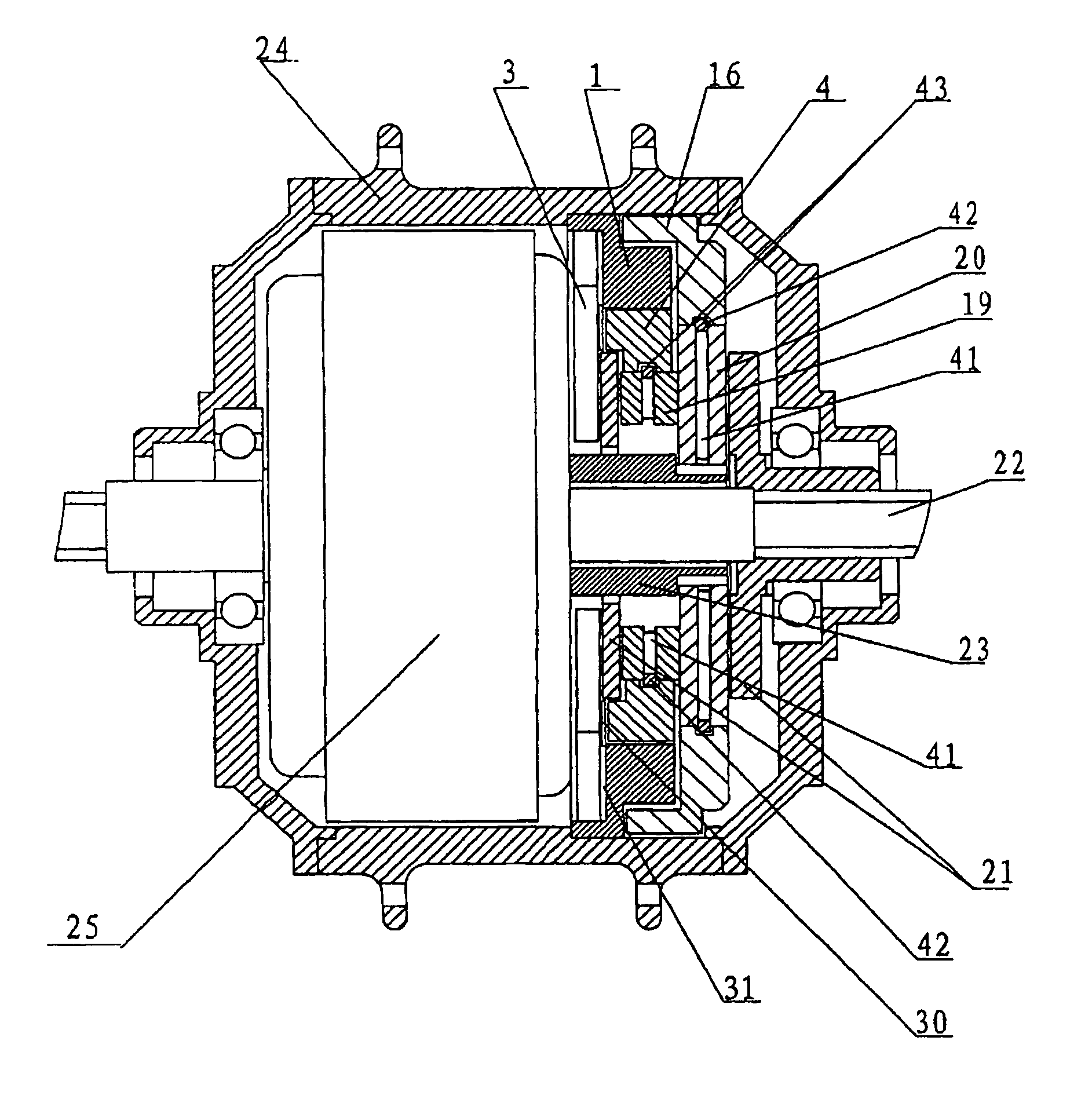

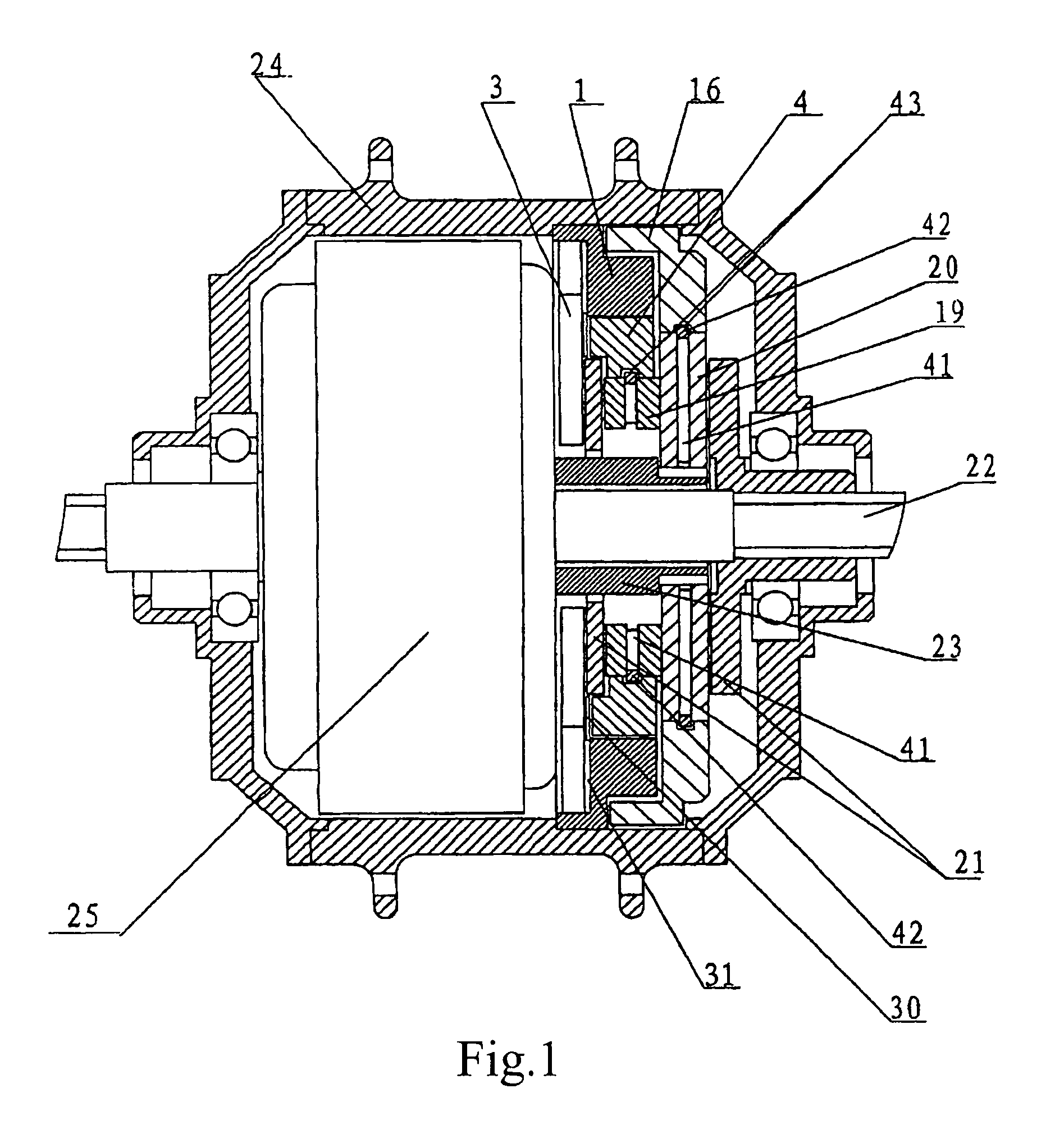

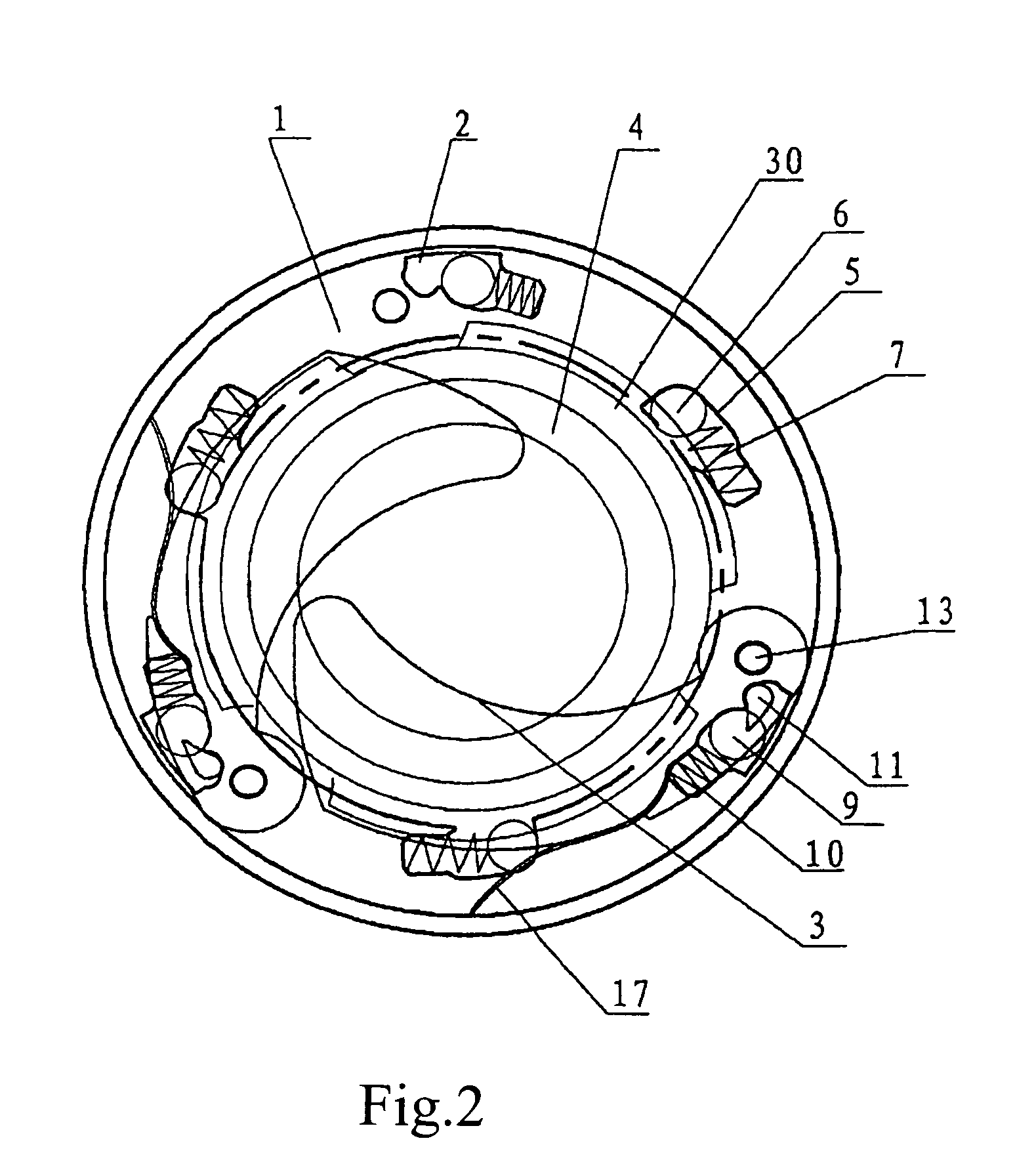

Automatic transmission for electric vehicle hub

ActiveUS20090026727A1Simple structureReduce noiseChain/belt transmissionToothed gearingsAutomatic transmissionGear wheel

An automatic transmission for an electric vehicle hub includes an external motor rotor fixedly connected with a motor shaft; a sun gear; at least three primary planet gears which are engaged with the sun gear; and at least three secondary planet gears coaxially fixed with the primary planet gears. The primary and the secondary planet gears are engaged with a primary and a secondary internal gears, and the secondary internal gear has a diameter greater than that of the primary internal gear. The rotating disk is arranged between the primary internal gear and the secondary internal gear, and a hub is fixed to exterior of the rotating disk. The automatic transmission further includes a clutch device, making the rotating disk and the primary internal gear contact with each other for a transmission of slower rpm, and when the rpm reaches critical, at a high-speed rotation.

Owner:FAIRLY BIKE MFG +1

Automatic transmission for electric vehicle hub

ActiveUS8137231B2Simple structureReduce noiseToothed gearingsGearing detailsAutomatic transmissionEngineering

An automatic transmission for an electric vehicle hub includes an external motor rotor fixedly connected with a motor shaft; a sun gear; at least three first planet gears; and at least three second planet gears coaxially fixed with the corresponding first planet gears and which are engaged with the sun gear. The first and the second planet gears are respectively engaged with first and second internal gears, and the second internal gear has a diameter greater than that of the first internal gear. The rotating disk is arranged between the first internal gear and the second internal gear, and a hub is fixed to exterior of the rotating disk. The automatic transmission further includes a clutch device, making the rotating disk and the first internal gear contact with each other for a transmission of slower rpm, and when the rpm reaches critical, at a high-speed rotation.

Owner:FAIRLY BIKE MFG +1

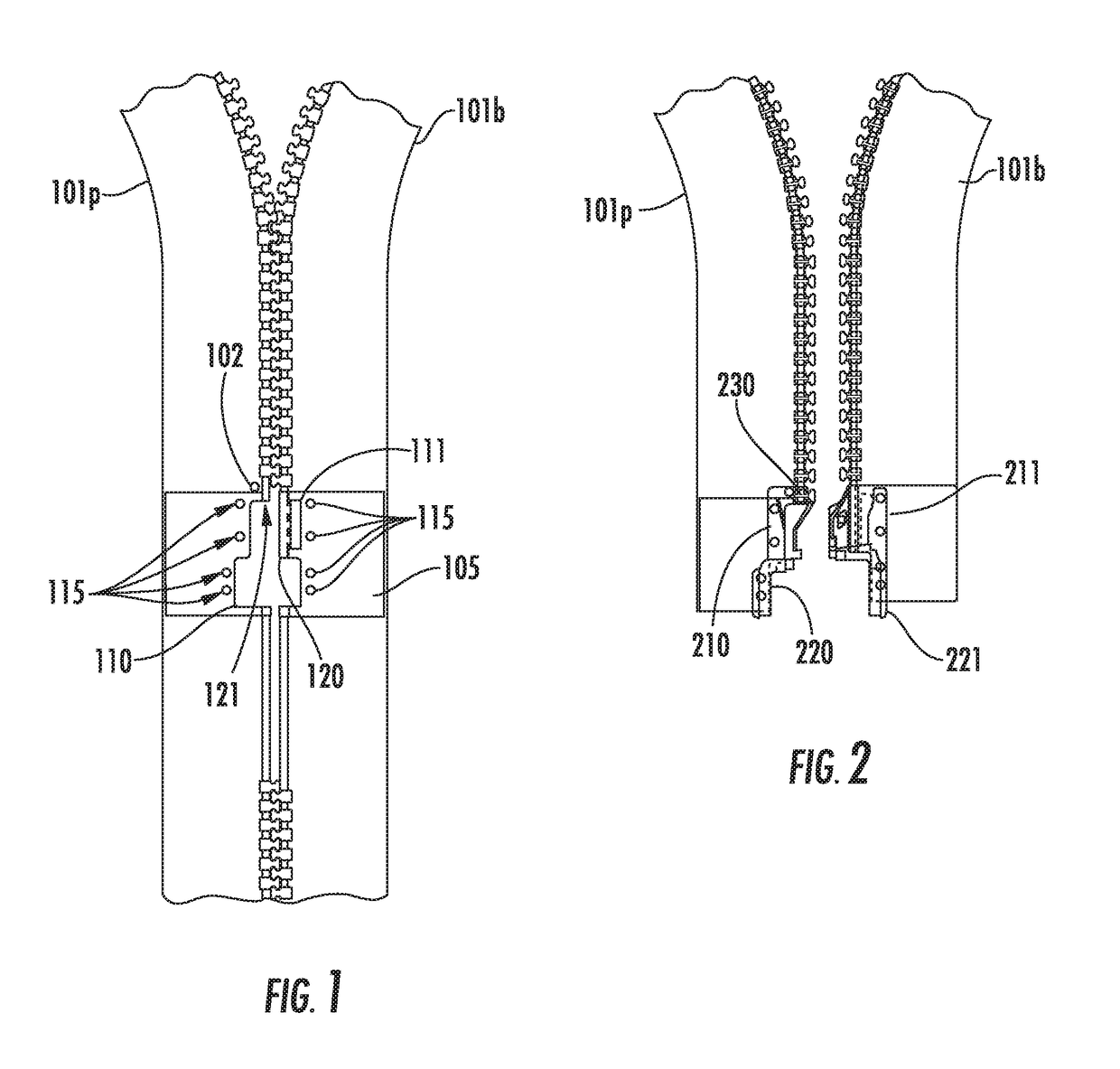

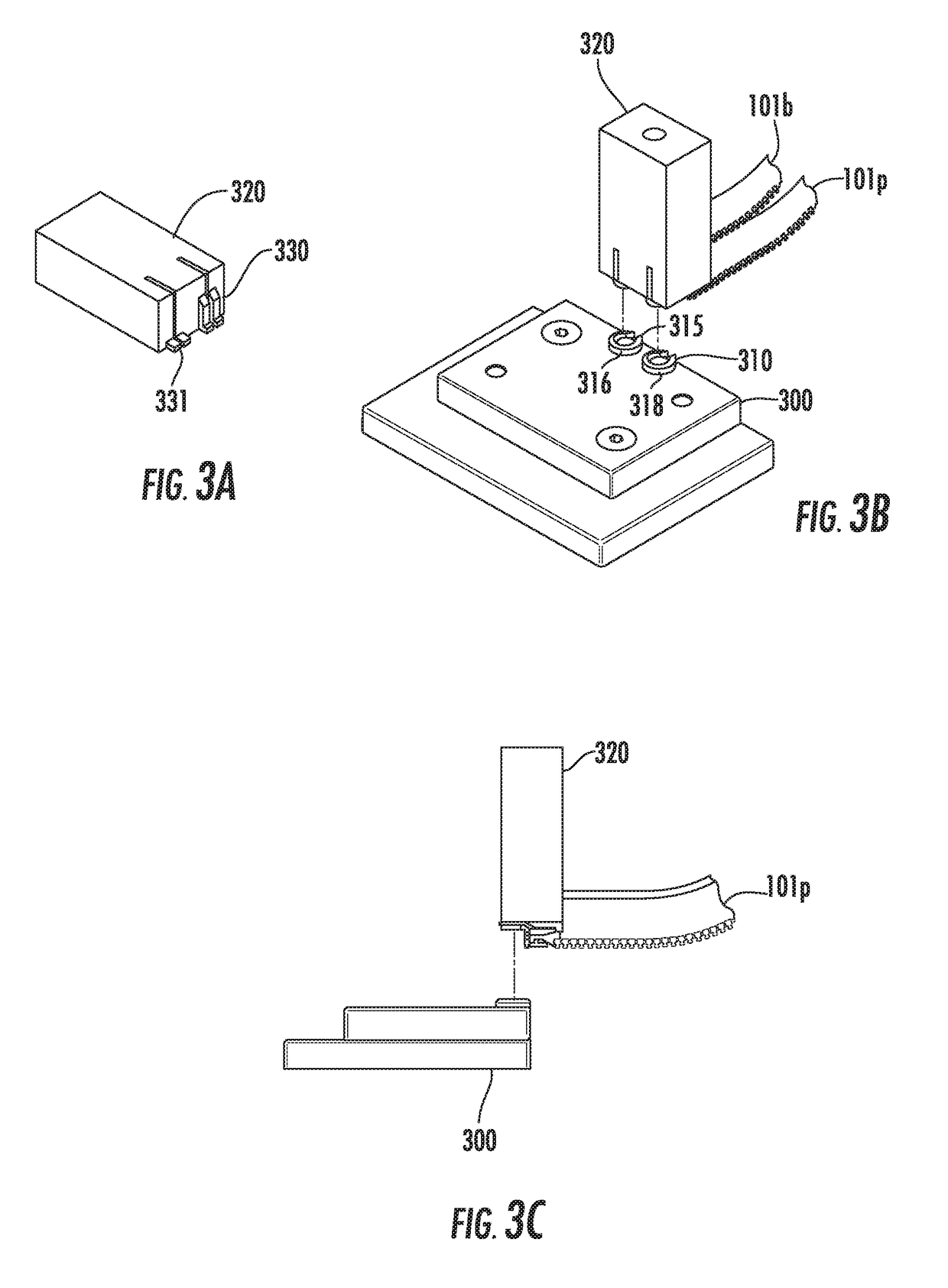

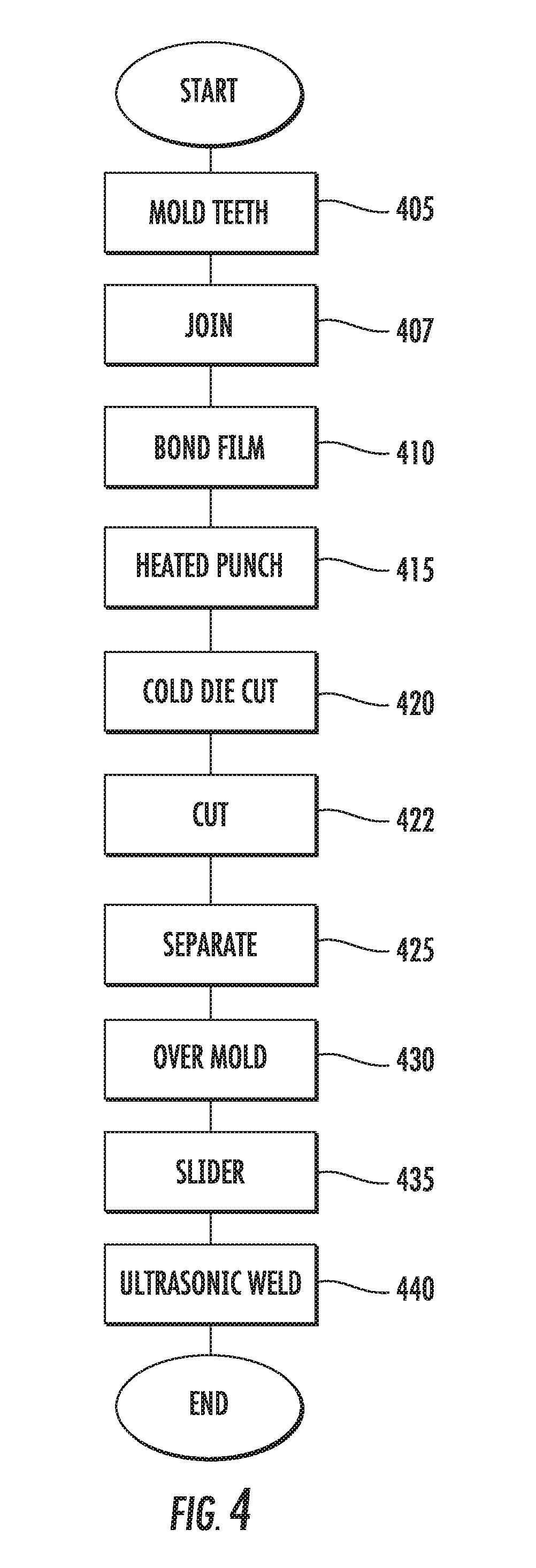

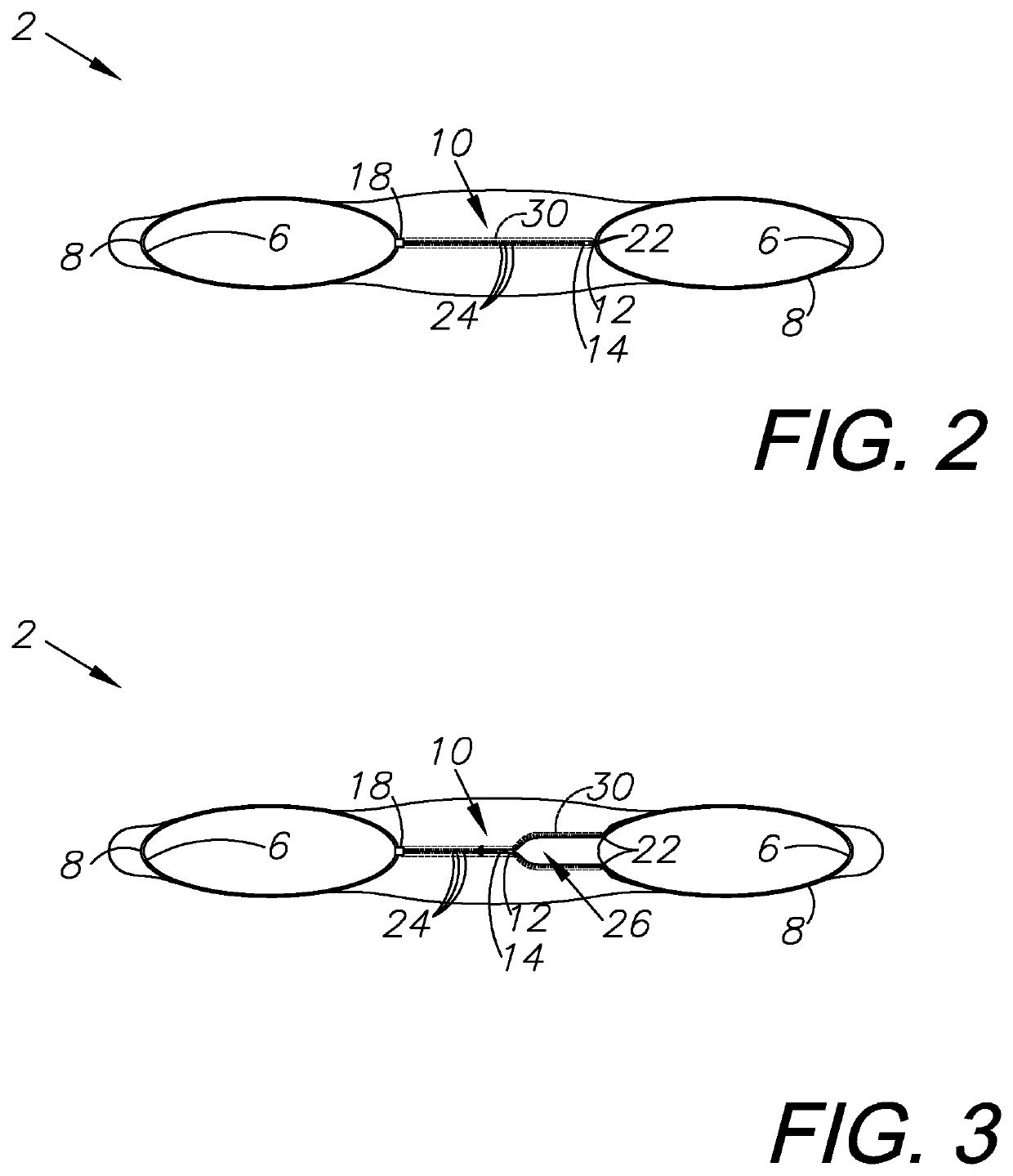

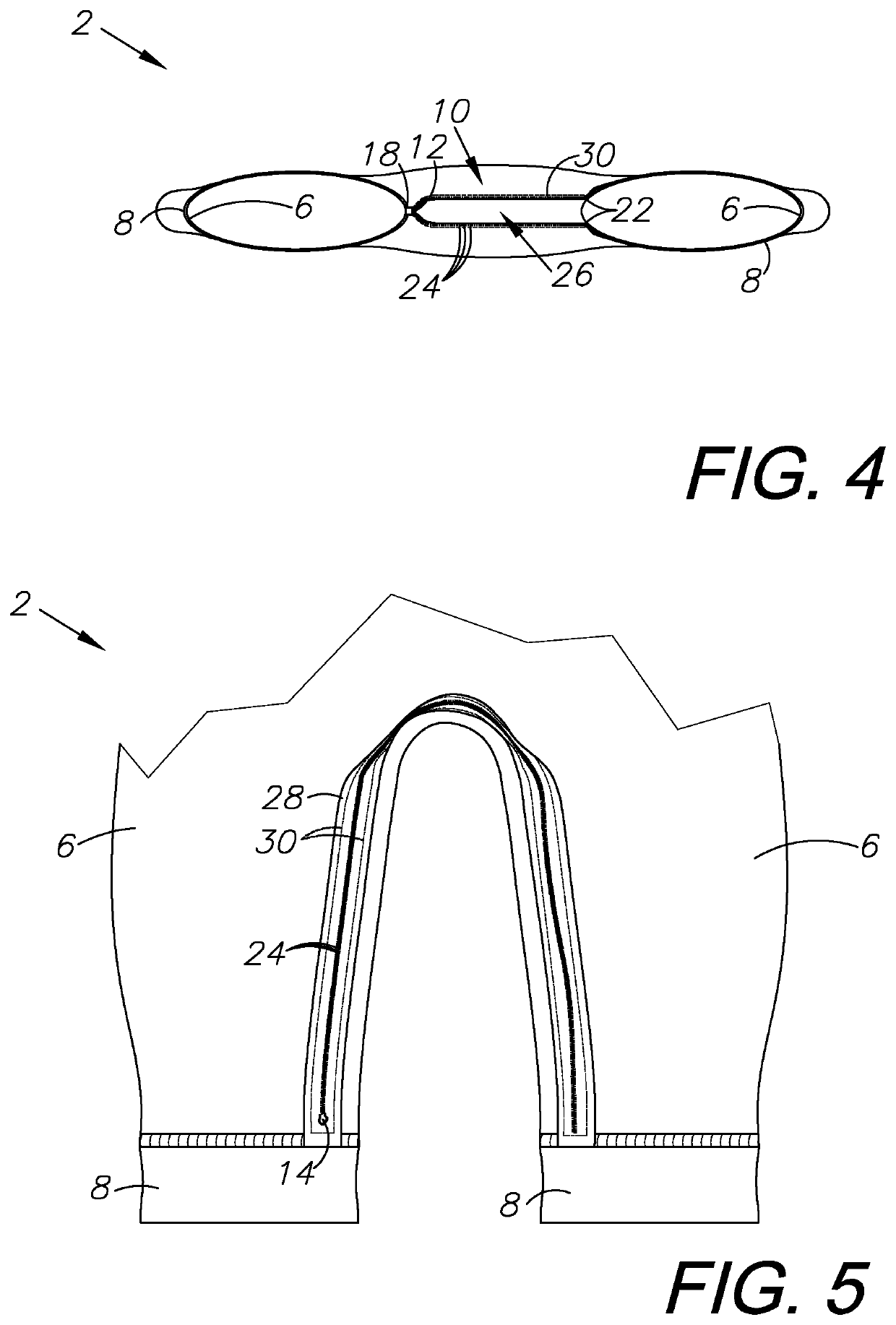

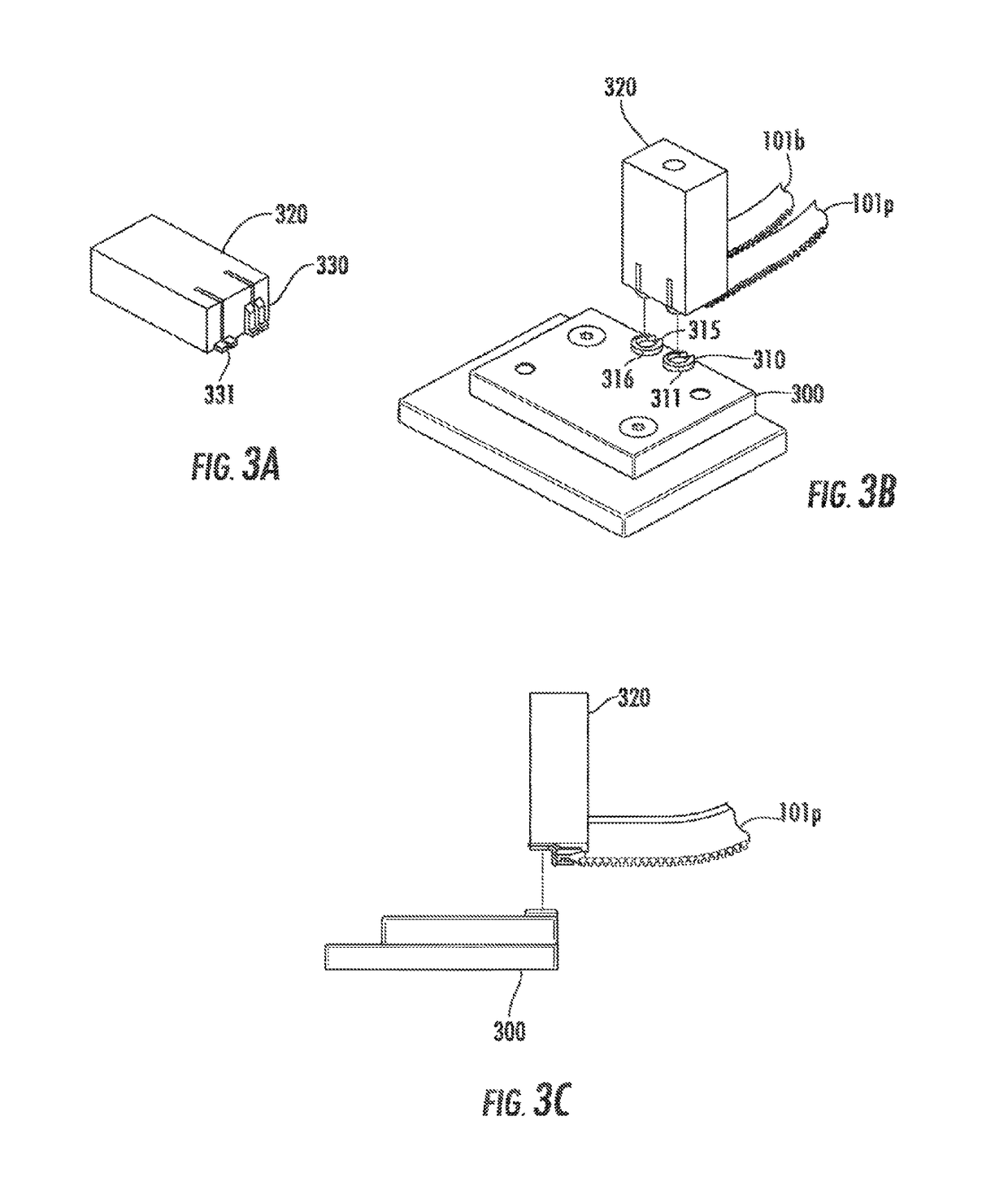

Methods for manufacturing slide fastener with overmolded components

ActiveUS10144186B1Fully disengagedOvercome the inherent weakness of a zipperDomestic slide fastenersEngineeringInjection molding process

Zippers components such as a traditional pin and box assembly may be affixed to zipper stringer tapes by a simple injection molding process. When a non-traditional magnetic alignment assembly is used in place of a traditional pin and box assembly, other means are needed to adequately affix the components of the magnetic alignment assembly to the zipper stringer tapes in order to provide a durable finished zipper.

Owner:IDEAL FASTENER CORP

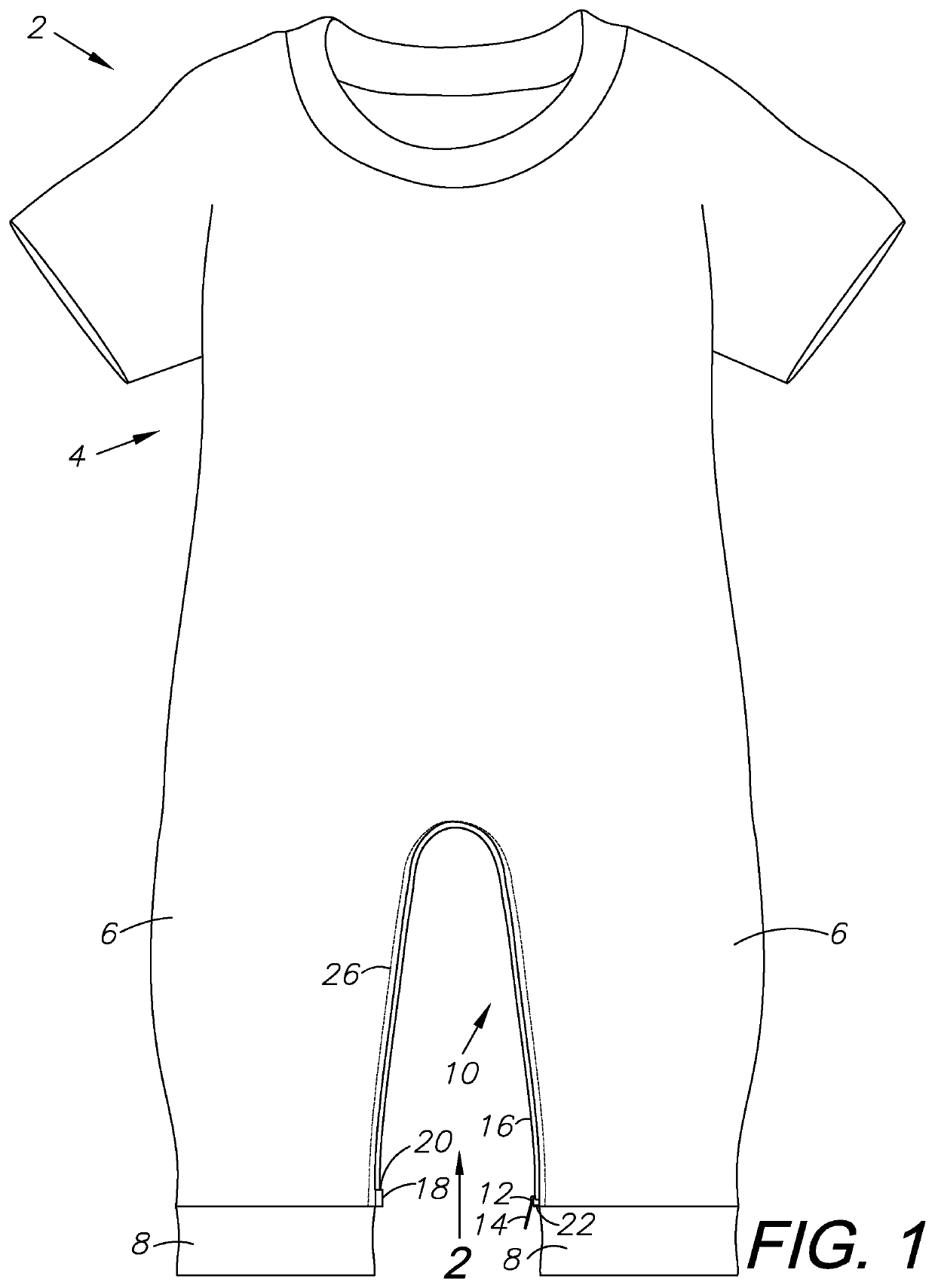

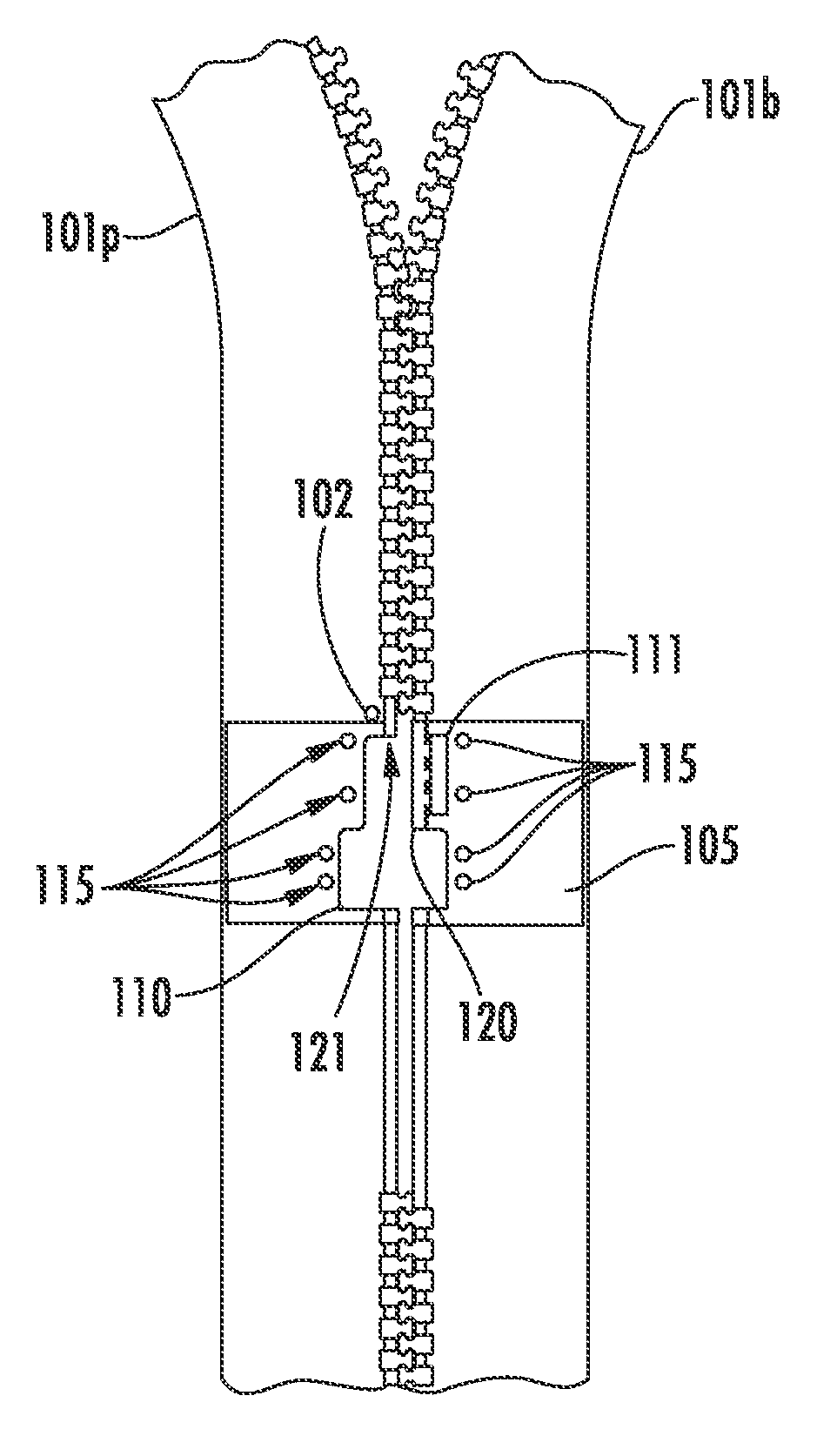

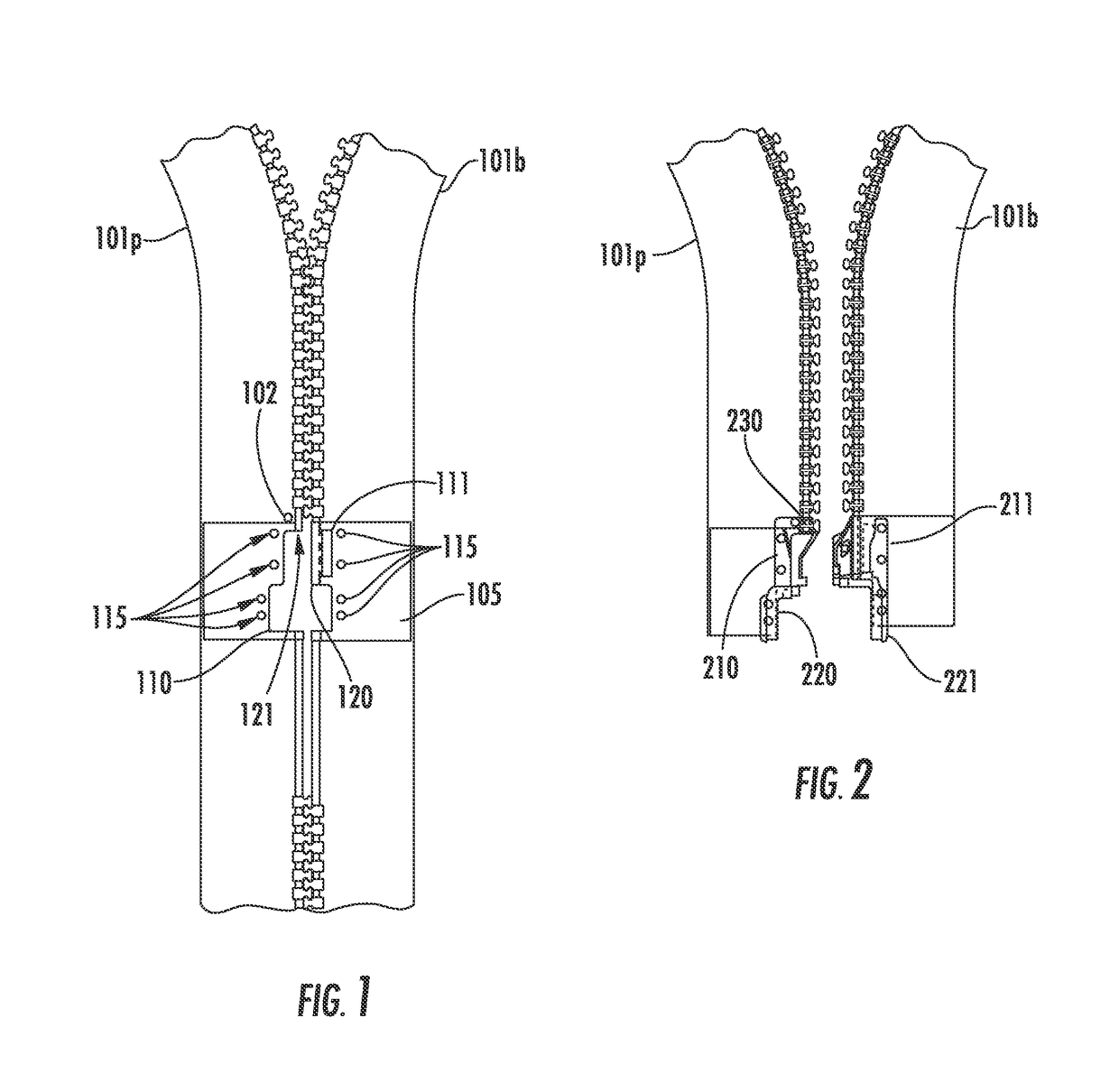

Child clothing device with reinforced zipper access, method of use, and method of manufacture

InactiveUS20210120887A1Easy and fast accessEasy to carryHandkerchiefsBaby linensPhysical medicine and rehabilitationEngineering

A child's romper or other one-piece clothing outfit which has a reinforced zipper between the legs of the garment to allow for quick and easy access for changing the child's diaper. There is no need to completely undress the child. The zipper element runs from one ankle to the other and allows the child's legs to easily be taken out of the garment for quick and easy diaper changes. The zipper element is reinforced to the inseam of the garment and includes a top stitch around the edges of the zipper to hold it down Ankle cuffs are used at each ankle end point and stitches are placed over the portion of the zipper tape attached to the ankle cuff. An embodiment may not use ankle cuffs and allows complete opening of the garment from ankle to ankle.

Owner:HORAK TAELER I

Method for separating graphite from graphite granulated explosive powder

ActiveCN106431786AFully disengagedFully removedExplosive working-up apparatusAfter treatmentOrganic solvent

The invention provides a method for separating graphite from graphite granulated explosive powder. The method comprises the following steps: 1) mixing the graphite granulated explosive powder with water to obtain suspension; 2) mixing the suspension with a surfactant to obtain first mixed liquid; 3) layering and separating the first mixed liquid to obtain a primary lower layer material liquid; 4) mixing the primary lower layer material liquid with an organic solvent to obtain second mixed liquid; 5) layering and separating the second mixed liquid to obtain secondary lower layer material liquid; 6) mixing the secondary lower layer material liquid with water, and then filtering. The method provided by the invention can fully separate the graphite from the explosive powder granules and a binder contained in the explosive powder granules, thereby fully removing the graphite. Experimental results show that the content of graphite in graphite-removed explosive powder obtained after treatment through the separation method provided by the invention is extremely low, and the content of graphite is lower than 0.02%.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

Methods for manufacturing slide fastener with overmolded components

ActiveUS9944028B1Fully disengagedOvercome the inherent weakness of a zipperDomestic slide fastenersEngineeringInjection molding process

Zippers components such as a traditional pin and box assembly may be affixed to zipper stringer tapes by a simple injection molding process. When a non-traditional magnetic alignment assembly is used in place of a traditional pin and box assembly, other means are needed to adequately affix the components of the magnetic alignment assembly to the zipper stringer tapes in order to provide a durable finished zipper.

Owner:IDEAL FASTENER CORP

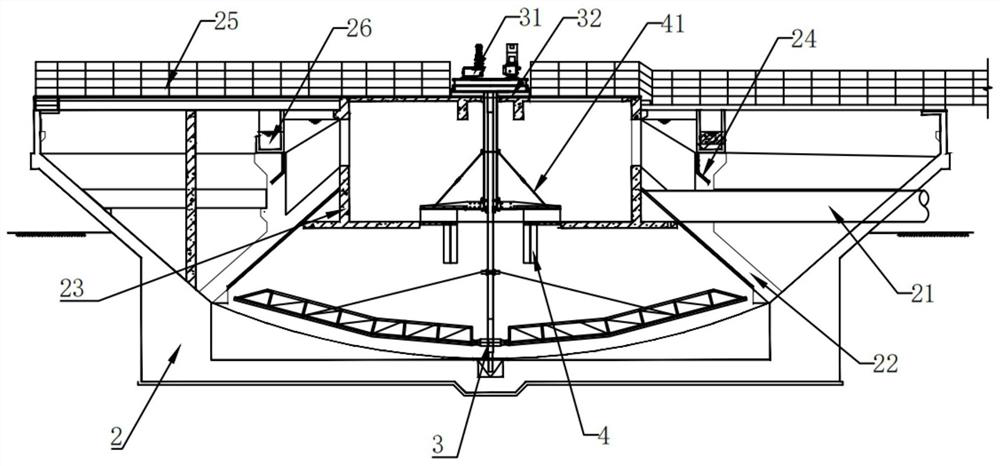

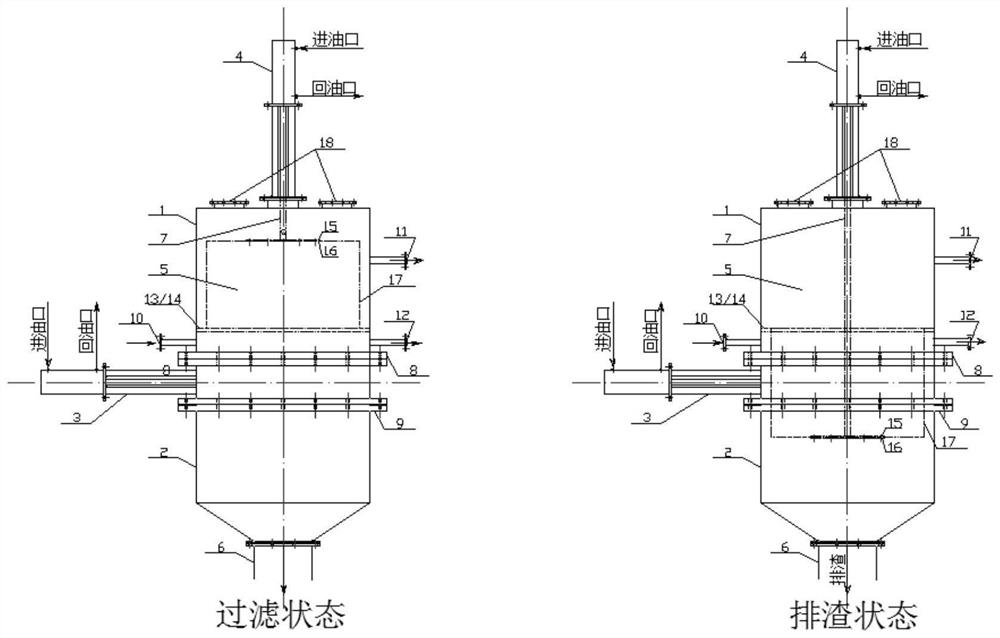

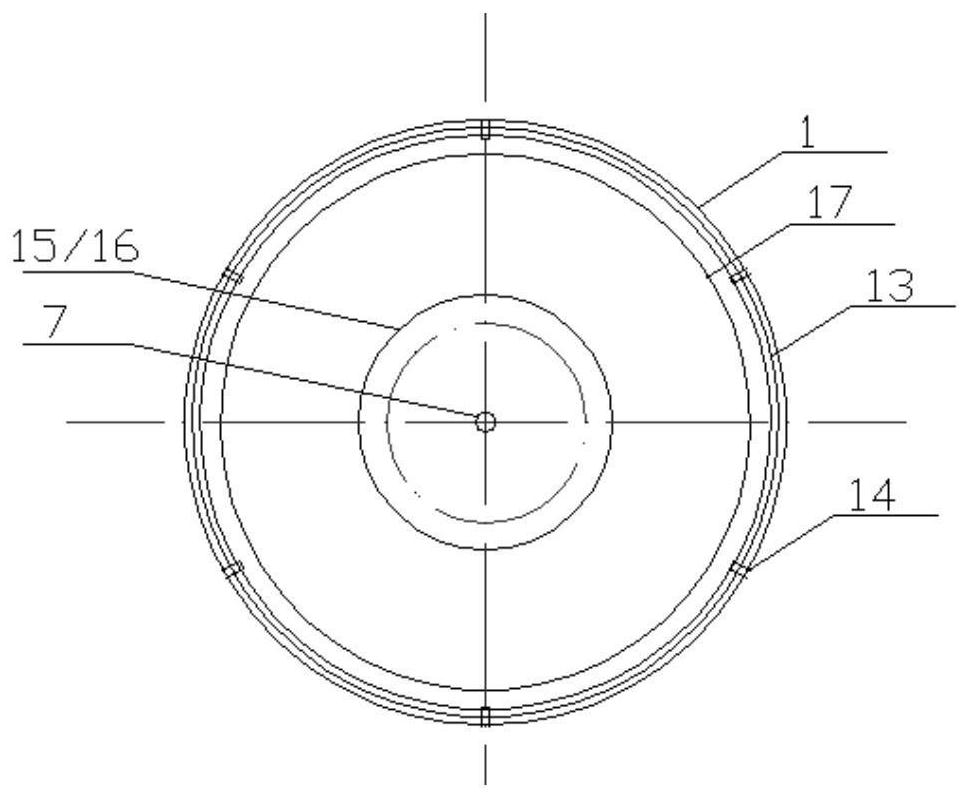

Stirring and sludge scraping system for mechanical acceleration clarification tank and use method of stirring and sludge scraping system

InactiveCN113713442AWell mixedImprove sedimentation efficiencySedimentation settling tanksSludgeProcess engineering

The invention discloses a stirring and sludge scraping system for a mechanical acceleration clarification tank and a use method of the stirring and sludge scraping system, and belongs to the technical field of sludge treatment. The stirring and sludge scraping system comprises a tank body, a sludge scraping mechanism, a stirring mechanism, a cleaning mechanism and a slag discharging mechanism, the sludge scraping mechanism is rotationally installed on the tank body, the stirring mechanism is installed on the tank body, and the cleaning mechanism is slidably installed on the tank body. The cleaning mechanism comprises a driving mechanism and two cleaning assemblies, the driving mechanism is installed on the tank body, the two cleaning assemblies are both installed on the driving mechanism in a sliding mode, and the slag discharging mechanism is rotatably installed on the tank body. According to the stirring and sludge scraping system for the mechanical acceleration clarification tank and the use method of the stirring and sludge scraping system, sediments generated in the clarification tank are scraped, meanwhile, the sediments left on the sludge scraping mechanism are cleaned, then water and the sediments are discharged separately, and the invention further provides the use method of the sludge scraping mechanism.

Owner:JIANGSU YIHUAN GROUP

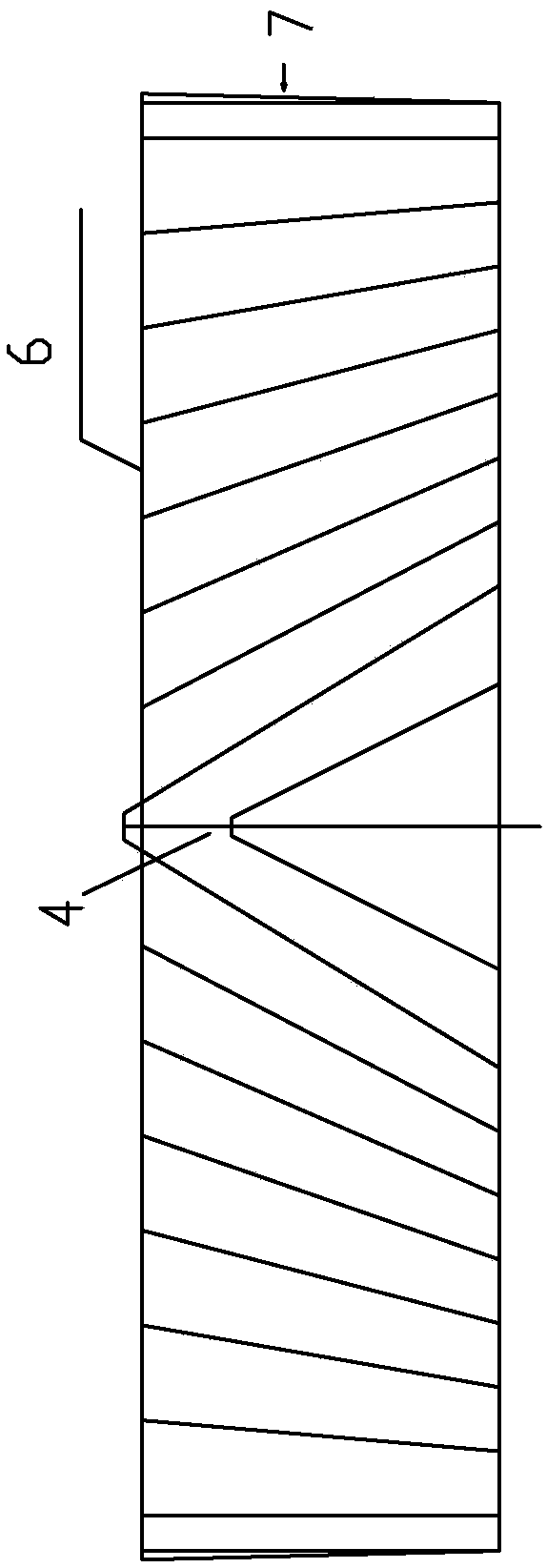

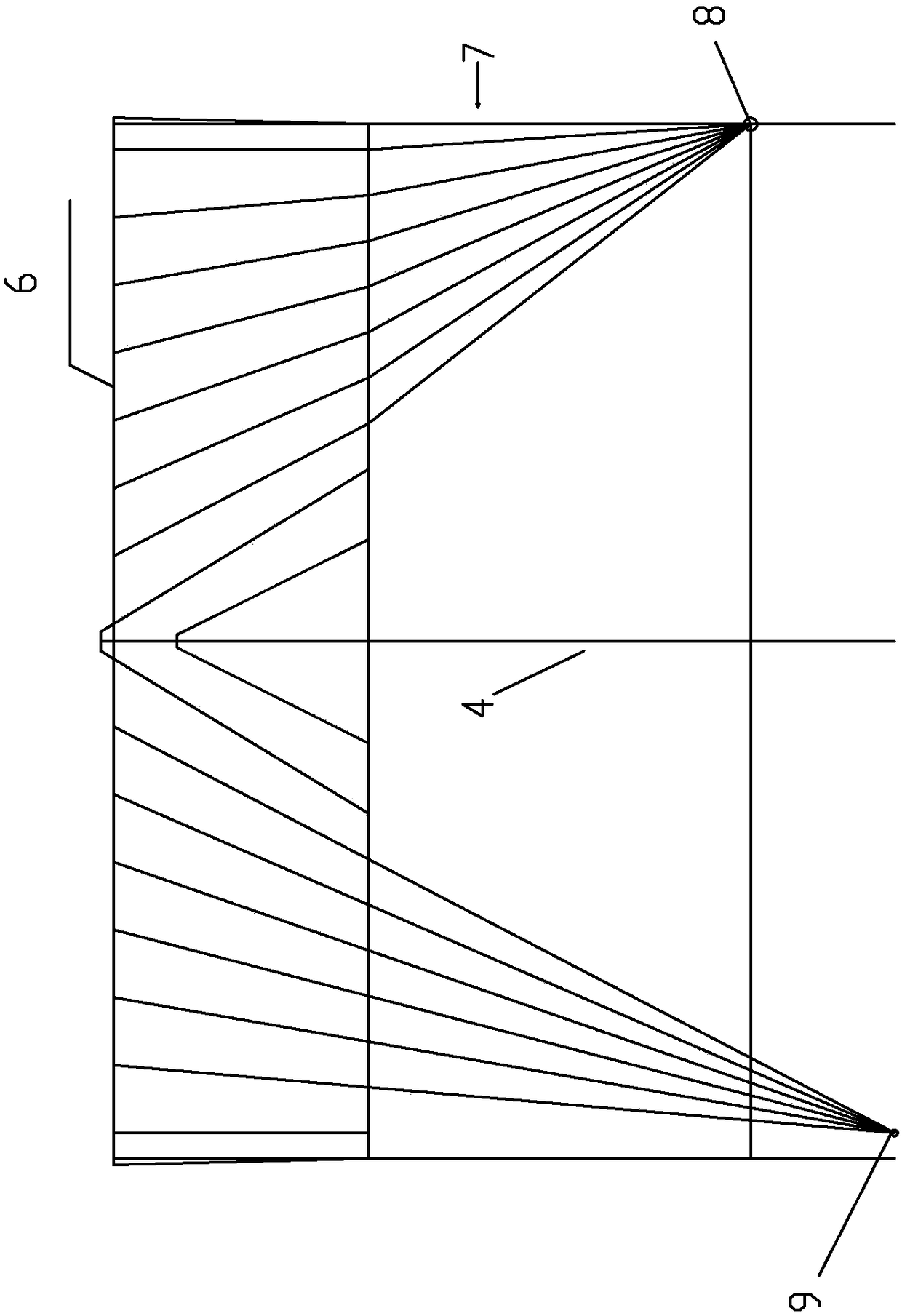

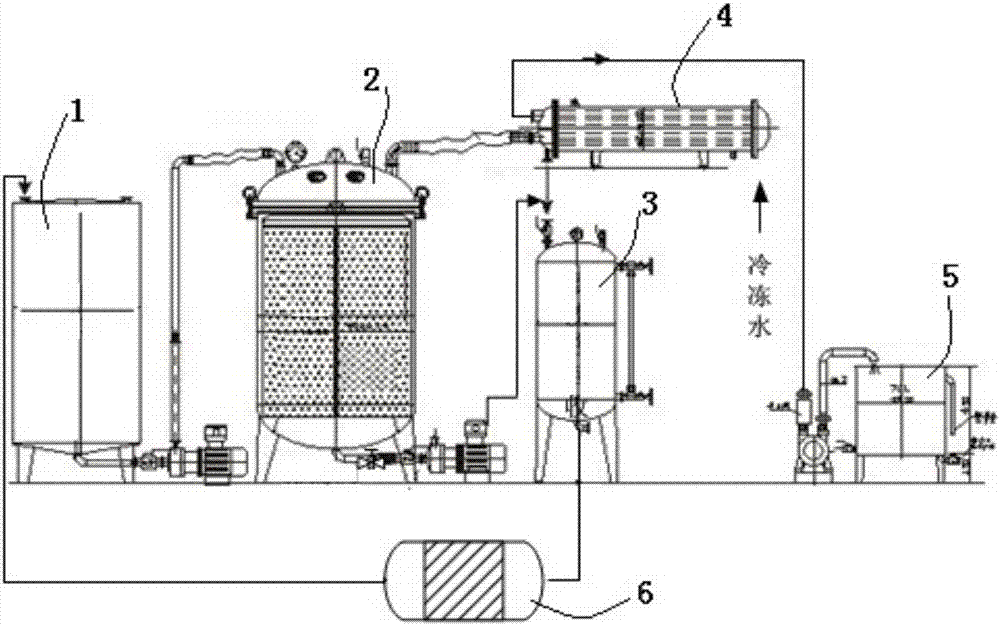

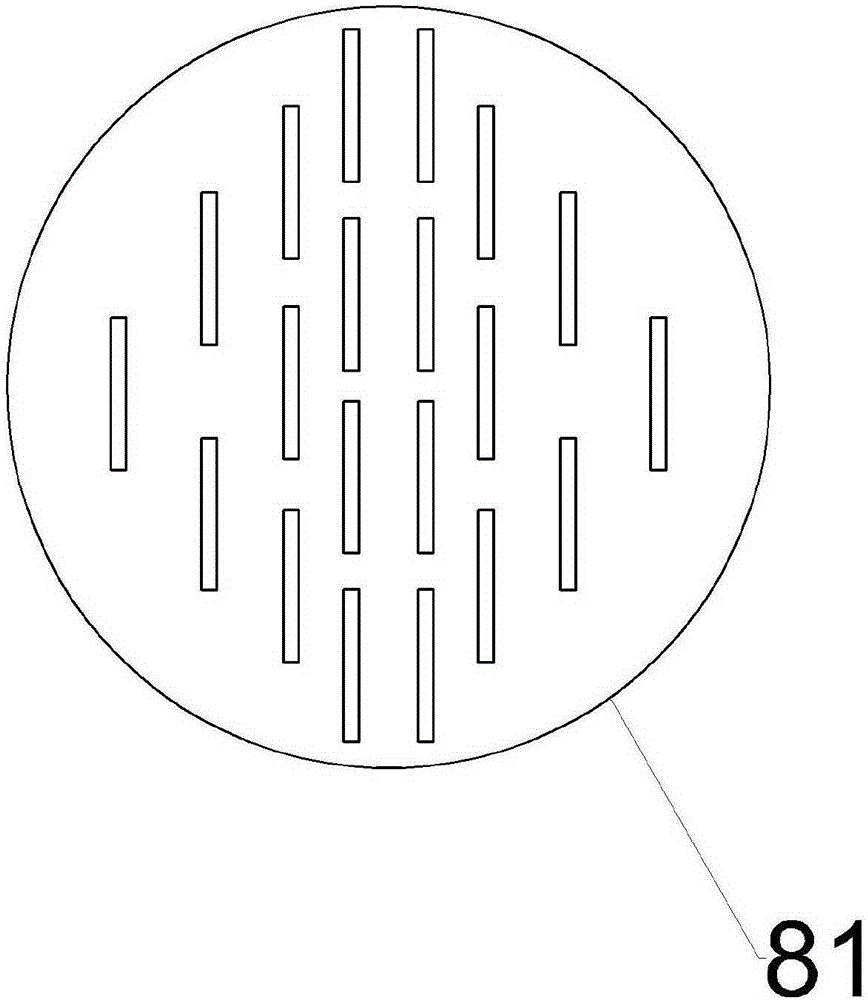

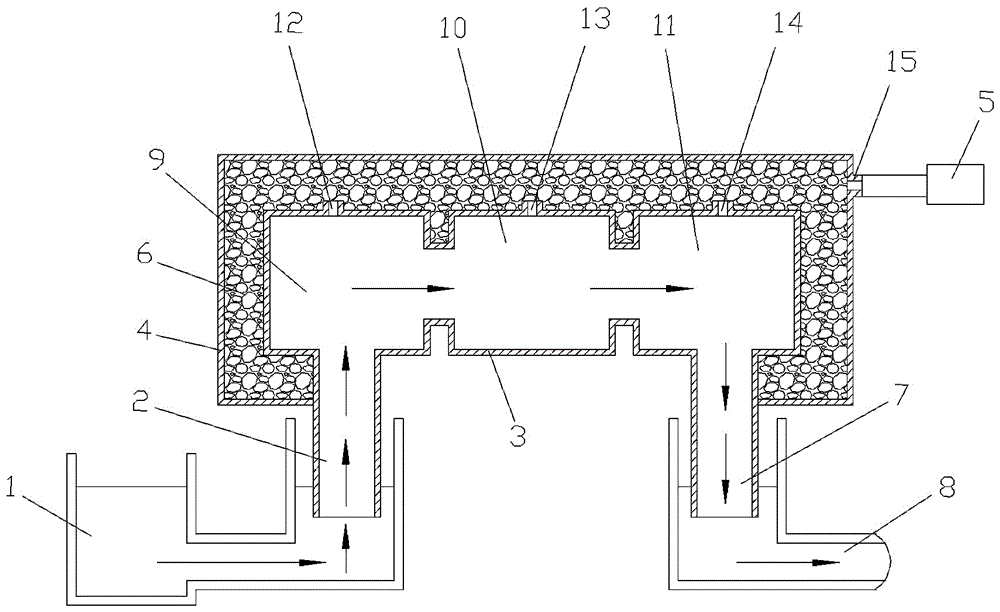

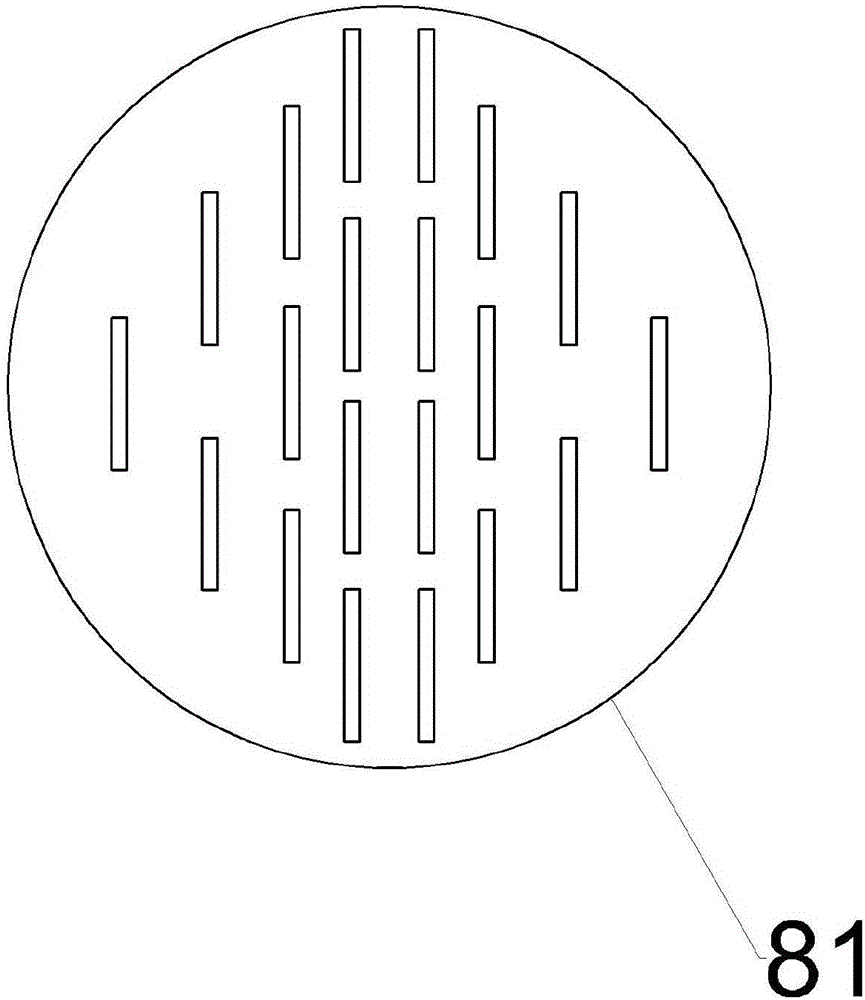

Ladder type decompression de-foaming device for increasing clear quality of molten glass

PendingCN106830624AImprove clarification qualityReduce energy consumptionGlass furnace apparatusChemistryMolten glass

The invention relates to a ladder type decompression de-foaming device for increasing the clear quality of molten glass. The device comprises a melting tank (1), wherein the melting tank (1) is connected with a decompression de-foaming tank (3) through an ascending pipe (2); a set of exhaust vents are formed in the decompression de-foaming tank (3); an outer shell (4) is arranged on the outer side of the decompression de-foaming tank (3); a vacuum pump (5) is connected with the outer shell (4); a heat-insulating material (6) is filled between the outer shell (4) and the melting tank (1); and the decompression de-foaming tank (3) is connected with a reflux tank (8) through a descending pipe (7). The invention has the advantages that the device is used for performing ladder type decompression on the molten glass; after the pressure is reduced, the foam diameters of the foams in the molten glass are gradually increased and the foams quickly overflow, so that the de-foaming and clearing effects are achieved; and compared with a traditional fixed target negative pressure method, the device can more fully separate air bubbles from the molten glass, the clear quality of the molten glass is increased, and the energy consumption is greatly lowered.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Carpet dust collection device suitable for fixed-point dust collection

The invention discloses a carpet dust collection device suitable for fixed-point dust collection. The carpet dust collection device comprises a first shell and a second shell, wherein the first shell adopts a cylindrical hollow structure with an opening in the lower end, and is vertically arranged above a carpet; a plurality of air blowing holes are formed in the side wall of the first shell, and are respectively communicated with an air blowing pipe; the air blowing pipe is connected with an air source; a plurality of fans are arranged in the first shell; the second shell adopts a hollow structure with an opening in the lower end, and is arranged in the first shell; a distance between the lower end of the second shell and the carpet is longer than that between the first end and the carpet by 5cm; the inner surface of the second shell is an Archimedes spiral surface; an air suction hole is formed in the top of the second shell, and is communicated with an air suction device through an air suction pipe. The carpet dust collection device is good in dust collection effect, high in dust collection efficiency and suitable for fixed-point dust collection.

Owner:泉州齐美电子科技有限公司

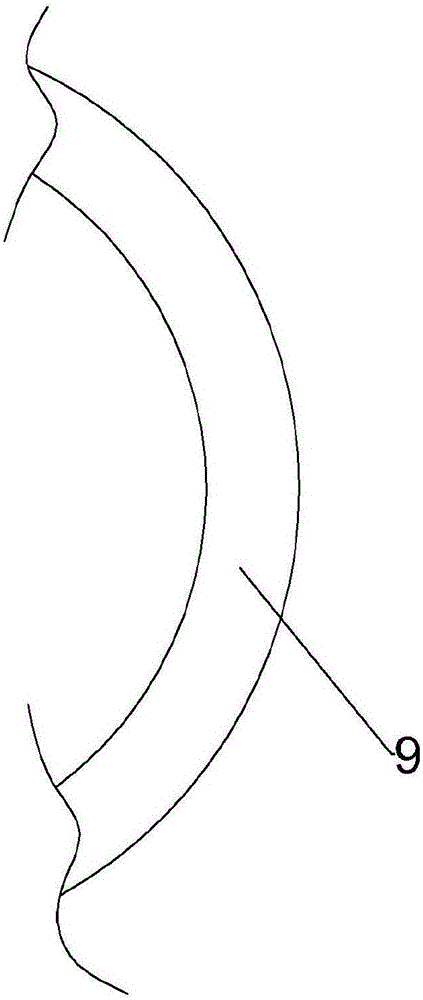

Portable carpet dust remover

InactiveCN105725917AImprove dust removal efficiencyEliminate static electricitySuction filtersMechanical suction controlEngineeringEnergy consumption

The invention discloses a portable carpet dust remover. The portable carpet dust remover comprises a shell, a first solenoid valve, a second solenoid valve and a controller; the shell is of a circular-truncated-cone-shaped hollow structure with the lower end opened, the shell is arranged on a carpet, the side wall of the shell is provided with a blow hole and a suction hole, the blow hole is connected with an air source through a blow pipe, an Archimedes-screw-shaped guide plate is arranged in the shell along the inner wall, the start point of the guide plate is aligned with the position of the blow hole, a fan is horizontally arranged on the top inside the shell, and the suction hole is communicated with a suction device through a suction pipe; the first solenoid valve is arranged on the blow pipe, and the second solenoid valve is arranged on the suction pipe; the controller controls the first solenoid valve to be switched on and then switched off after 60 seconds, and then the controller controls the second solenoid valve to be switched on and then switched off after 30 seconds. The portable carpet dust remover is good in dust removal effect, high in dust removal efficiency, less in energy consumption and low in manufacturing cost.

Owner:徐州宇飞电力科技有限公司

Dust remover

InactiveCN108991990AFully absorbedImprove dust removal efficiencySuction filtersMechanical suction controlSpiral flowElectromagnetic valve

Owner:QUANZHOU YOUSHI ELECTRONIC COMMERCE CO LTD

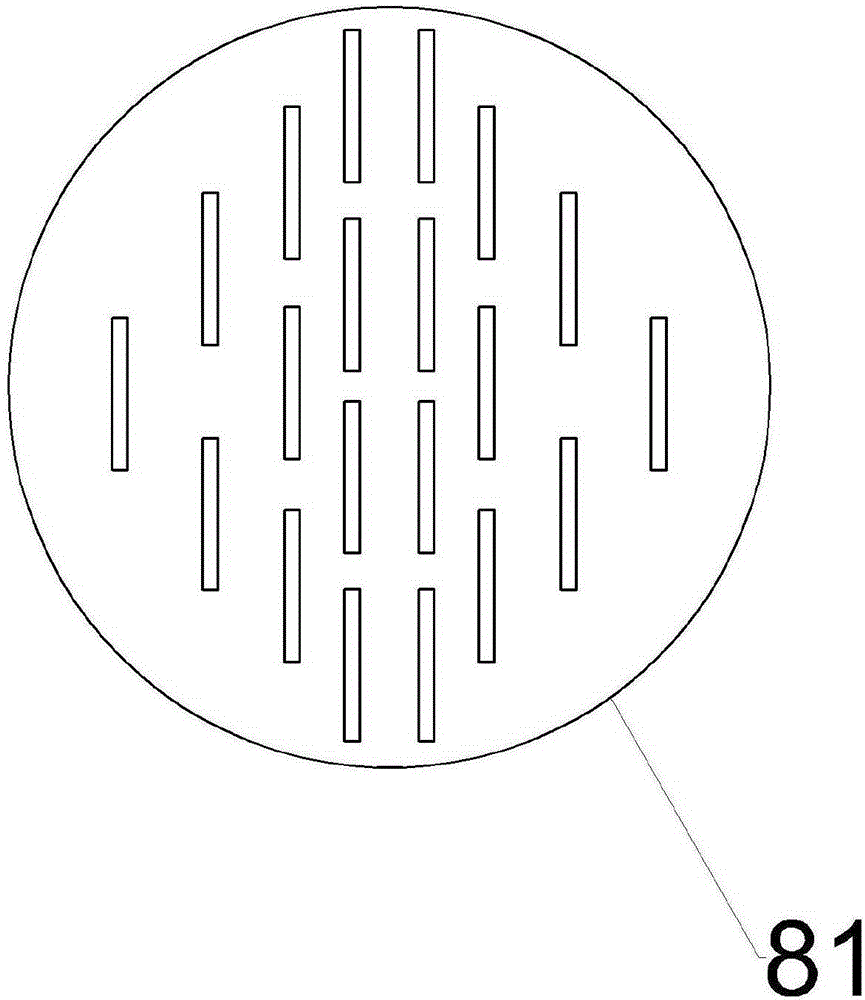

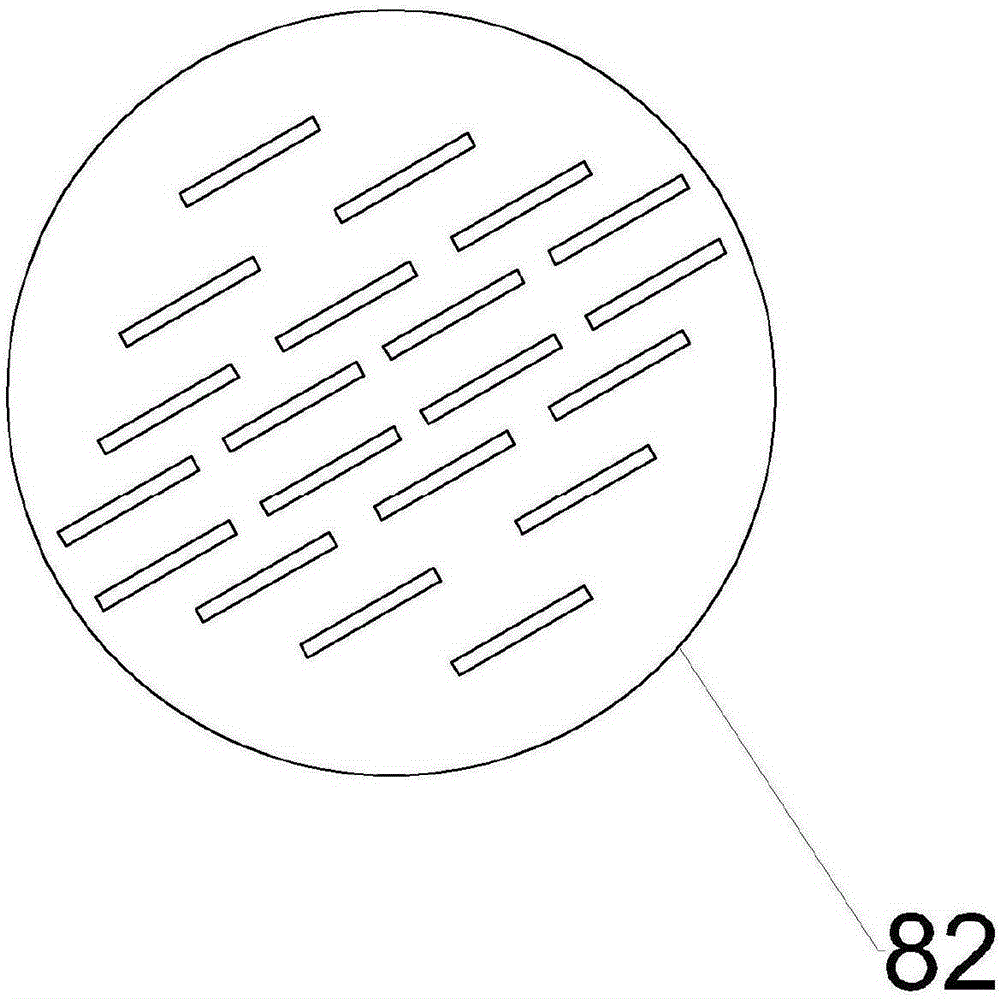

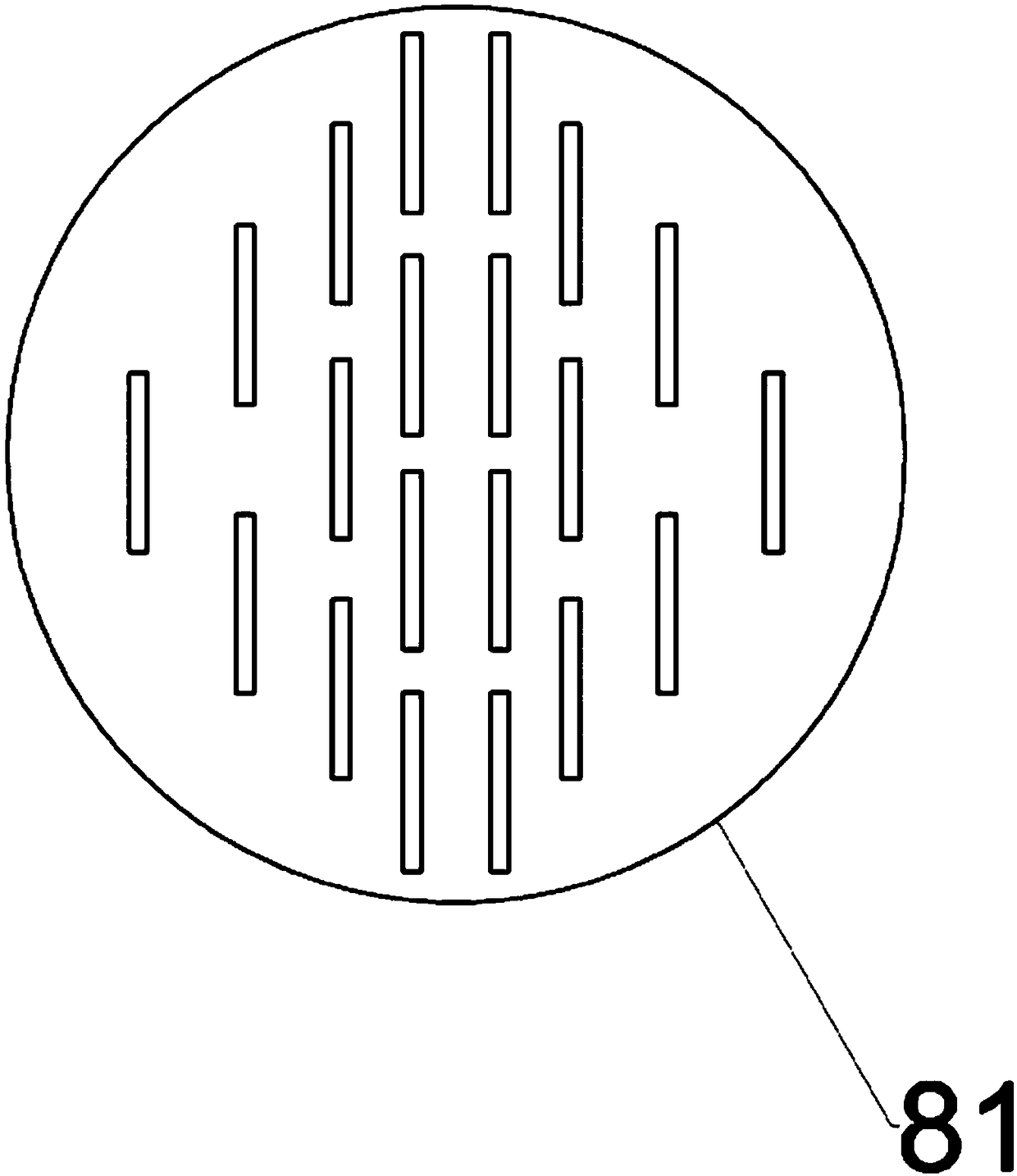

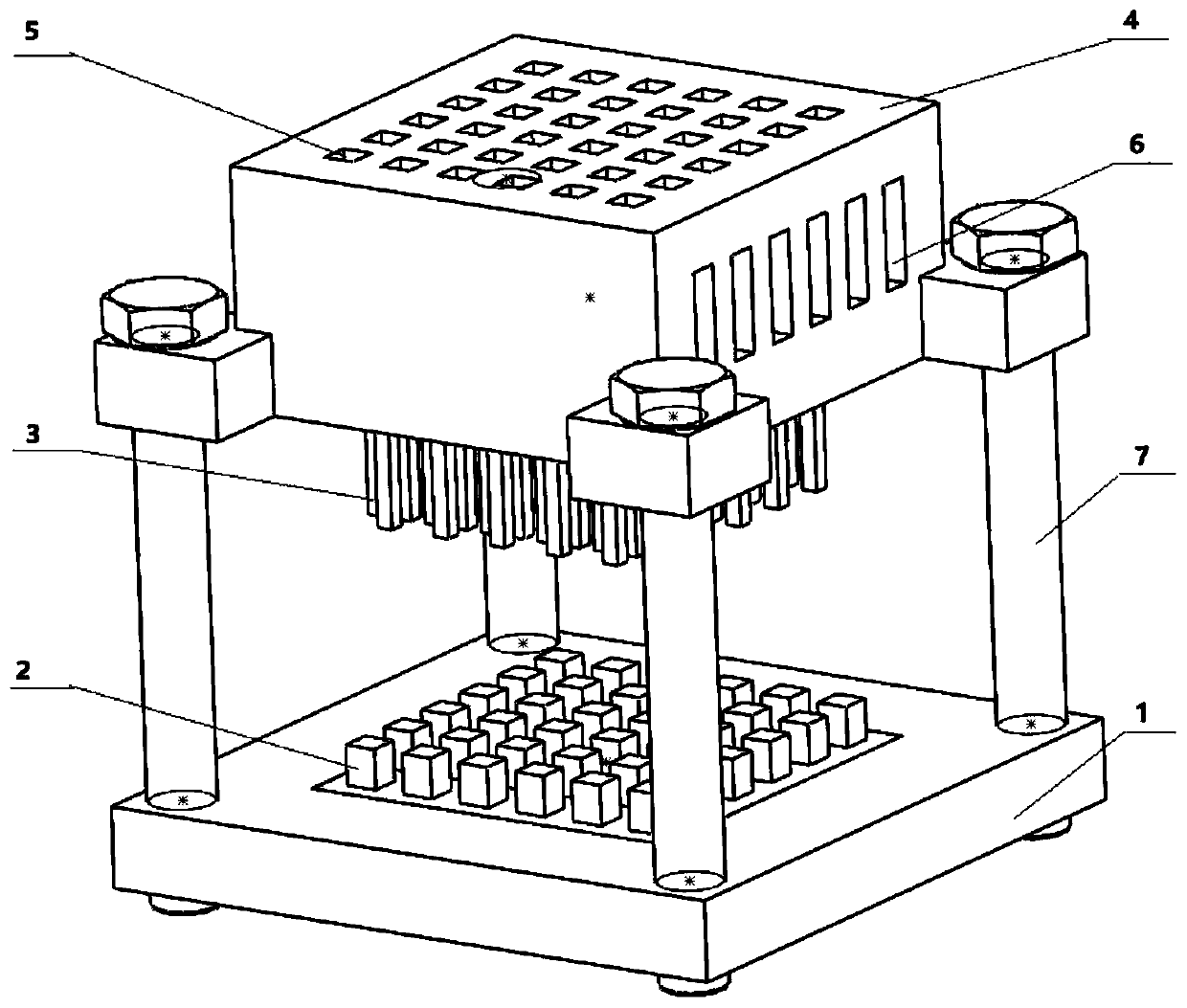

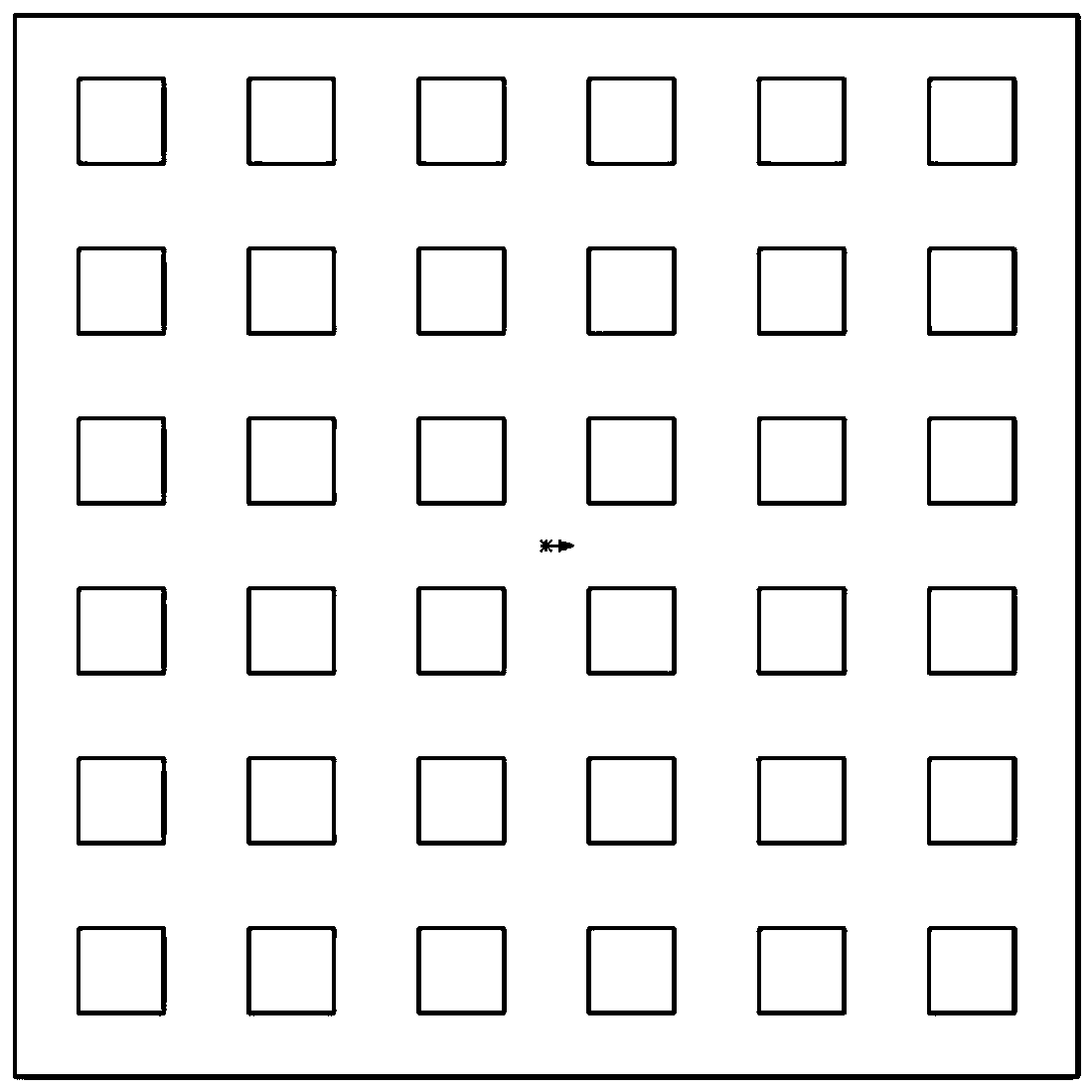

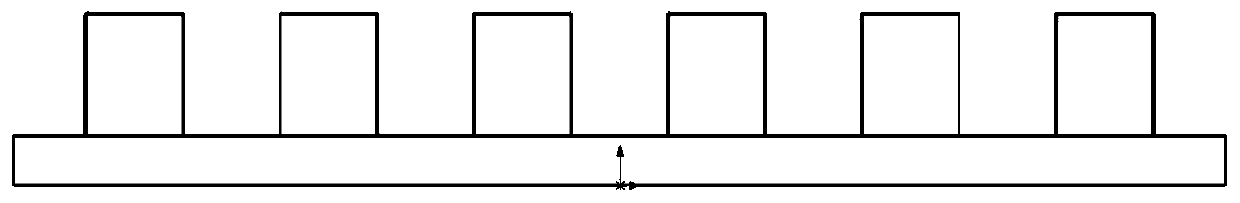

Device for strengthening rapid separation of bubbles on boiling surface and manufacturing method of device

ActiveCN108878388AIncreased efficiency and critical heat fluxIncrease critical heat fluxSemiconductor/solid-state device detailsSolid-state devicesEngineeringHydrophobic surfaces

The invention discloses a device for strengthening rapid separation of bubbles on a boiling surface and a manufacturing method of the device. The device comprises a base table, and a strengthening boiling heat exchange structure is arranged in the middle of the base table; the outer edge of the base table is connected with a condenser through a plurality of distance adjusting studs, and the condenser is located right above the strengthening boiling heat exchange structure; a plurality of run-through air channel channels are formed in the upper surface of the condenser, and a bubble auxiliary separating structure is arranged on the lower surface of the condenser; a plurality of run-through cooling working medium channels are arranged in the side surface of the condenser; and the outer surfaces of the condenser and the bubble auxiliary separation structure are hydrophobic surfaces, and the inner wall of the air channel is a hydrophilic surface. According to the invention, the separationsize of the bubbles can be reduced, the bubbles can be driven to be quickly separated, and the aggregation of the bubbles can be avoided, meanwhile, the liquid supplementing capability is enhanced, and the boiling heat transfer coefficient and the critical heat flux density can be remarkably improved.

Owner:XI AN JIAOTONG UNIV

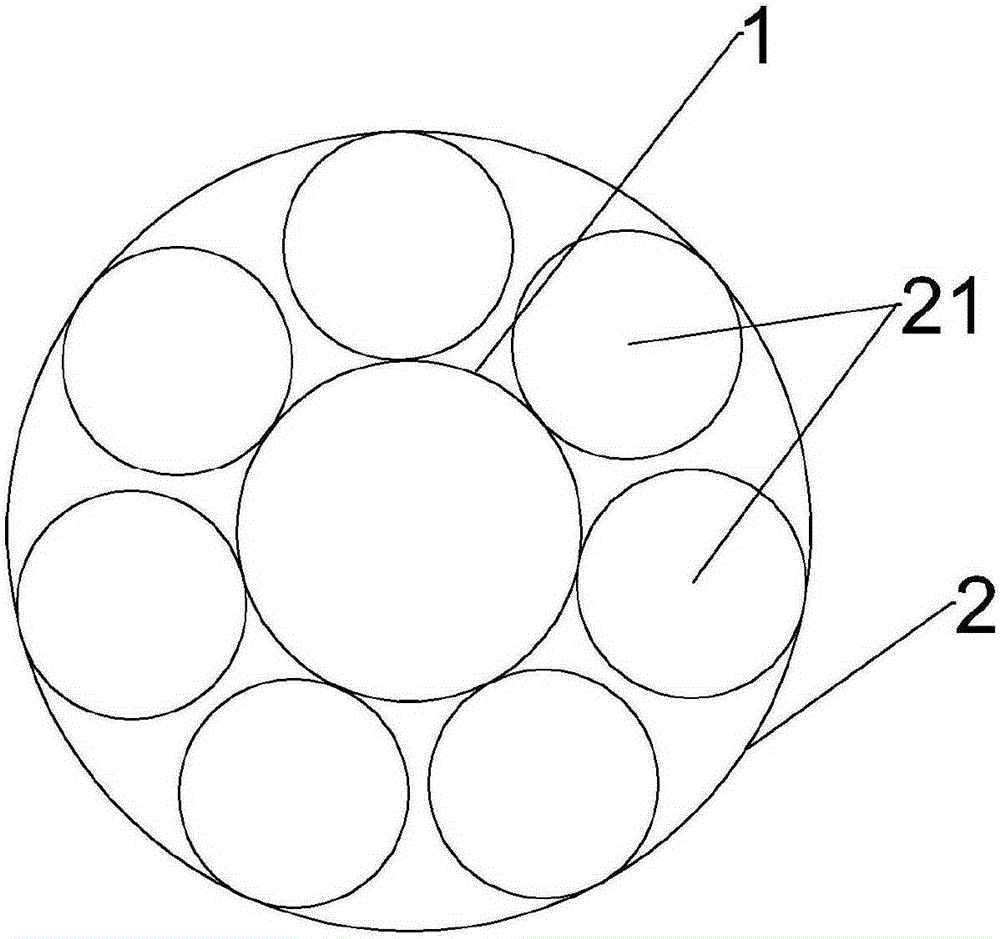

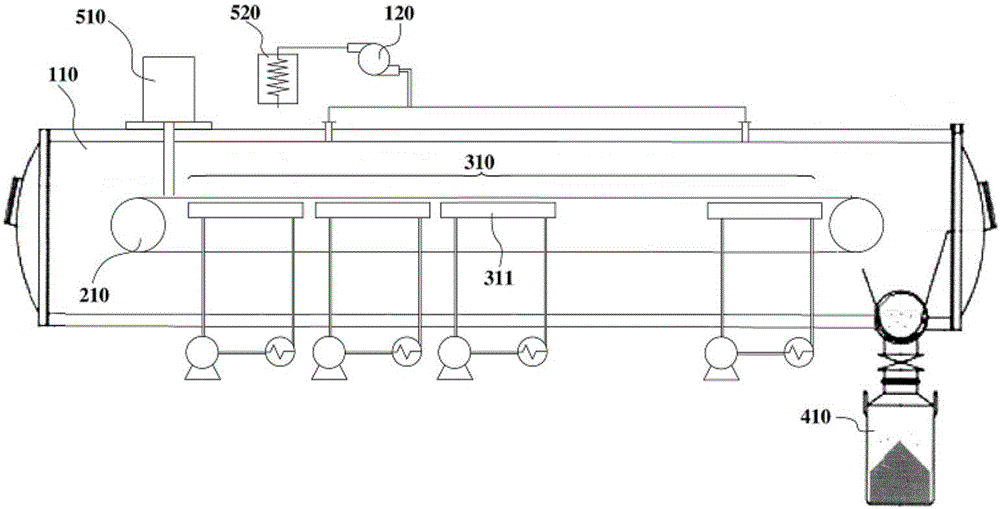

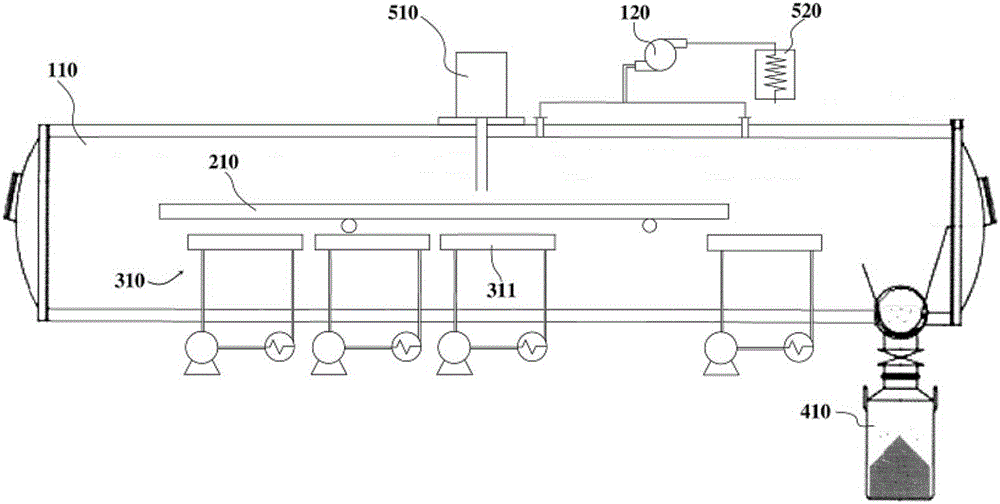

Bag type solid-liquid separation device and solid-liquid separation method

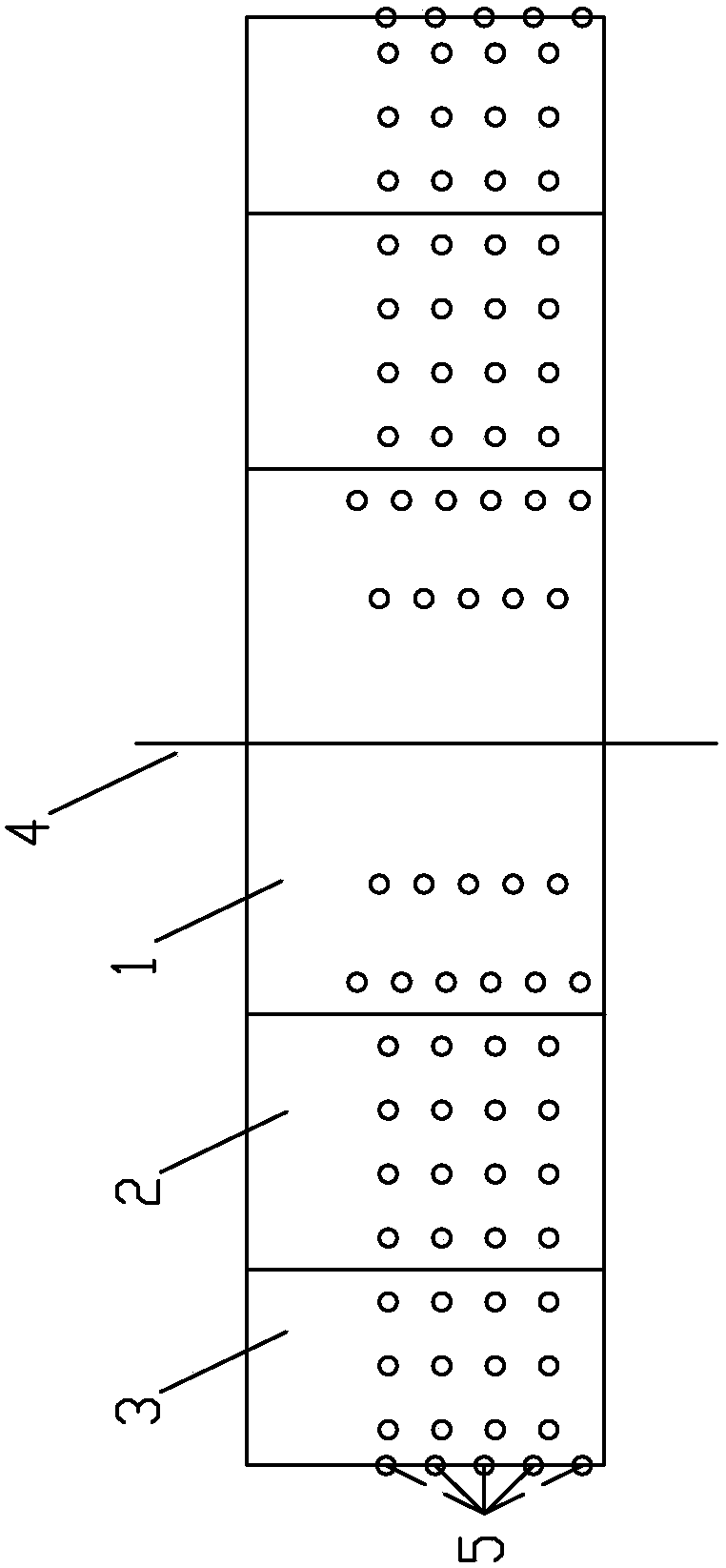

ActiveCN113018938ASimple structureAvoid manual removalGravity filtersStationary filtering element filtersGate valvePhysics

The invention discloses a bag type solid-liquid separation device. The bag type solid-liquid separation device comprises an upper barrel (1), a lower barrel (2), a gate valve (3) located between the upper barrel (1) and the lower barrel (2), a driving device (4) located on the upper barrel (1) and a cloth bag mechanism (5) located in the upper barrel (1), wherein a transmission rod (7) of the driving device (4) penetrates through the upper barrel (1) and is connected with the cloth bag mechanism (5). In addition, the invention also discloses a method for carrying out solid-liquid separation by adopting the device. According to the device disclosed by the invention, a filter bag is reversed to shake off a solid material enriched on the filter bag, so the use of backwashing liquid is avoided, the moisture content of the solid material is low, the filter bag is not manually disassembled, operation efficiency is improved, and the risk that the material harms a human body is reduced. The device overcomes problems existing in the prior art in a targeted mode and can be applied to related industrial production.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A lightweight carpet duster

InactiveCN105725917BFully absorbedImprove dust removal efficiencySuction filtersMechanical suction controlSolenoid valveEngineering

The invention discloses a portable carpet dust remover. The portable carpet dust remover comprises a shell, a first solenoid valve, a second solenoid valve and a controller; the shell is of a circular-truncated-cone-shaped hollow structure with the lower end opened, the shell is arranged on a carpet, the side wall of the shell is provided with a blow hole and a suction hole, the blow hole is connected with an air source through a blow pipe, an Archimedes-screw-shaped guide plate is arranged in the shell along the inner wall, the start point of the guide plate is aligned with the position of the blow hole, a fan is horizontally arranged on the top inside the shell, and the suction hole is communicated with a suction device through a suction pipe; the first solenoid valve is arranged on the blow pipe, and the second solenoid valve is arranged on the suction pipe; the controller controls the first solenoid valve to be switched on and then switched off after 60 seconds, and then the controller controls the second solenoid valve to be switched on and then switched off after 30 seconds. The portable carpet dust remover is good in dust removal effect, high in dust removal efficiency, less in energy consumption and low in manufacturing cost.

Owner:徐州宇飞电力科技有限公司

Solvent separating device for closed isocyanate crystal and preparation method of closed isocyanate crystal

ActiveCN106582055AEasy to separateImprove separation efficiencyCarbamic acid derivatives preparationOrganic compound preparationSolventPrecipitation

The invention relates to a solvent separating device for a closed isocyanate crystal and a preparation method of the closed isocyanate crystal, and belongs to the technical field of preparation of isocyanate. A crystal is heated under an air isolating condition and in an airtight container, a solvent in the crystal is separated from the crystal in the heating process, the crystal grains are kept relatively still in the process of heating the solvent to be separated from the crystal, and the crystal and the solvent are separated; after the solvent is separated from the crystal, closed isocyanate particles are obtained. The crystal is separated with the solvent through direct heating, the use proportion of the solvent is significantly reduced, and the precipitation efficiency of the crystal is improved; the centrifugal separation process of the crystal and mother liquor is avoided, and the harm of the solvent to the environment is eliminated.

Owner:徐峰

A device for enhancing the rapid detachment of bubbles on a boiling surface and a manufacturing method thereof

ActiveCN108878388BHigh speedSpeed up condensationSemiconductor/solid-state device detailsSolid-state devicesEngineeringBoiling heat transfer

The invention discloses a device for strengthening rapid separation of bubbles on a boiling surface and a manufacturing method of the device. The device comprises a base table, and a strengthening boiling heat exchange structure is arranged in the middle of the base table; the outer edge of the base table is connected with a condenser through a plurality of distance adjusting studs, and the condenser is located right above the strengthening boiling heat exchange structure; a plurality of run-through air channel channels are formed in the upper surface of the condenser, and a bubble auxiliary separating structure is arranged on the lower surface of the condenser; a plurality of run-through cooling working medium channels are arranged in the side surface of the condenser; and the outer surfaces of the condenser and the bubble auxiliary separation structure are hydrophobic surfaces, and the inner wall of the air channel is a hydrophilic surface. According to the invention, the separationsize of the bubbles can be reduced, the bubbles can be driven to be quickly separated, and the aggregation of the bubbles can be avoided, meanwhile, the liquid supplementing capability is enhanced, and the boiling heat transfer coefficient and the critical heat flux density can be remarkably improved.

Owner:XI AN JIAOTONG UNIV

A method for separating graphite in fine powder of graphite granulated explosive

ActiveCN106431786BFully disengagedFully removedExplosive working-up apparatusExplosive AgentsOrganic solvent

The invention provides a method for separating graphite from graphite granulated explosive powder. The method comprises the following steps: 1) mixing the graphite granulated explosive powder with water to obtain suspension; 2) mixing the suspension with a surfactant to obtain first mixed liquid; 3) layering and separating the first mixed liquid to obtain a primary lower layer material liquid; 4) mixing the primary lower layer material liquid with an organic solvent to obtain second mixed liquid; 5) layering and separating the second mixed liquid to obtain secondary lower layer material liquid; 6) mixing the secondary lower layer material liquid with water, and then filtering. The method provided by the invention can fully separate the graphite from the explosive powder granules and a binder contained in the explosive powder granules, thereby fully removing the graphite. Experimental results show that the content of graphite in graphite-removed explosive powder obtained after treatment through the separation method provided by the invention is extremely low, and the content of graphite is lower than 0.02%.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

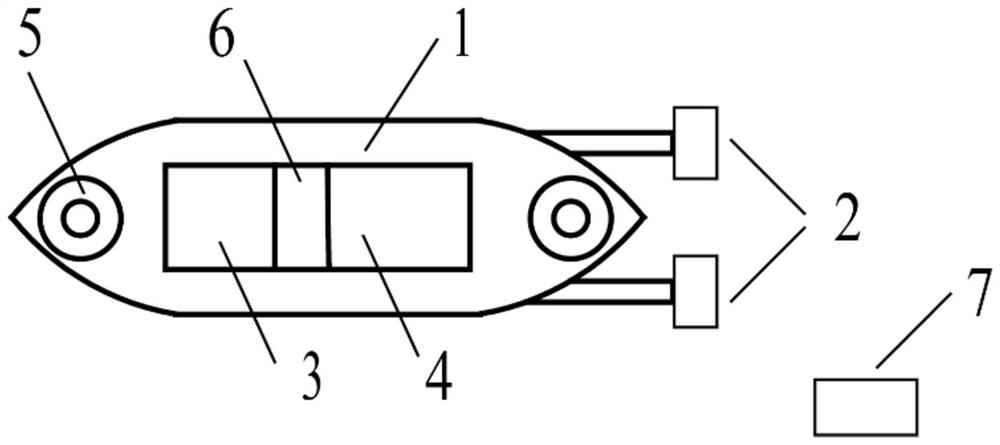

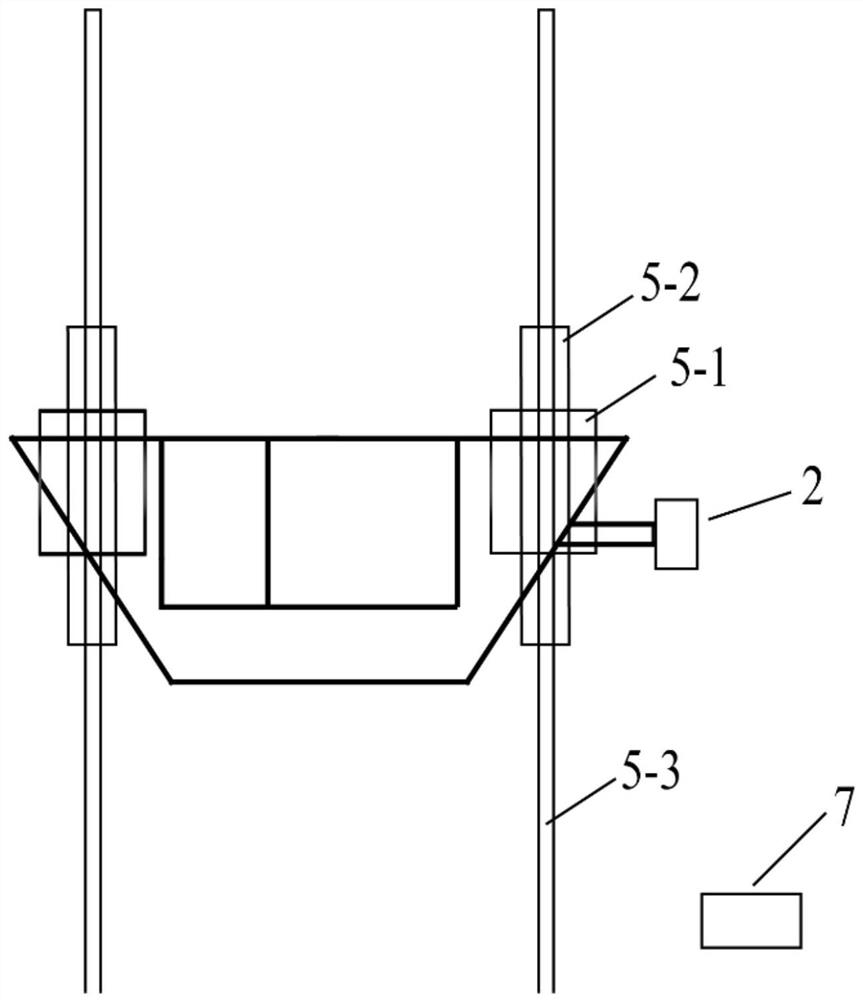

Automatic collecting device suitable for lake deep bottom mud

PendingCN114354241AGuaranteed vertical distributionWon't fall offWithdrawing sample devicesSatellite radio beaconingWireless transmissionBattery cell

The invention relates to an automatic collecting device suitable for lake deep bottom mud, which comprises a ship body, two propellers, a battery, a controller, a GPS position indicator, two mud collecting components and a remote controller, and is characterized in that the two propellers are respectively arranged at the bottom of the ship body, and the battery, the controller and the GPS position indicator are arranged in the ship body; the two mud sampling components are vertically installed at the head end and the tail end of the ship body respectively, the battery supplies power to the controller, the GPS position indicator and the propellers, the controller controls the propellers and mud sampling propellers of the mud sampling components, and the remote controller transmits signals to the controller and the GPS position indicator through wireless transmission. The collecting device is accurate in positioning, can be automatically fixed to a sampling point, can automatically collect deep bottom mud, and is greatly improved compared with a traditional mud collecting device. The method has important significance on lake ecological restoration.

Owner:武汉华德环保工程技术有限公司

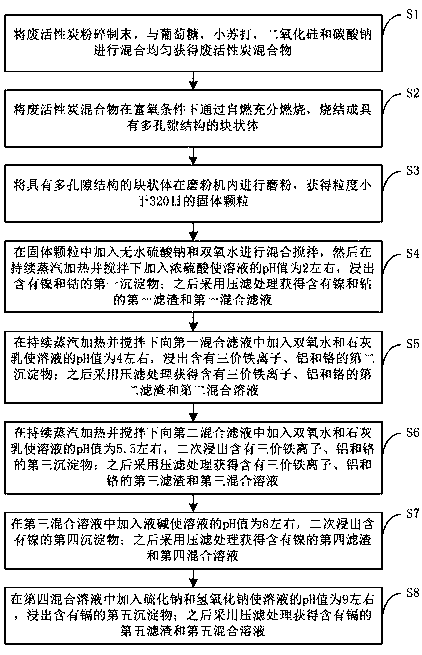

Method for regenerating metal from waste activated carbon

InactiveCN110605105AFully disengagedHigh recovery rateOther chemical processesWater contaminantsActivated carbonCadmium Cation

The invention discloses a method for regenerating metal from waste activated carbon, and relates to the technical field of metal recovery. The method comprises the steps of sintering, powder grinding,secondary nickel leaching, secondary iron leaching, primary cadmium leaching and the like, all useful metals can be extracted from the waste activated carbon through multiple times of filter pressingtreatment, and the recovery rate is improved.

Owner:航天国环技术集团有限公司

Bar Image Inspection Mechanism

Disclosed is a bar image detection mechanism. The mechanism is simple in structure and free of a vacuum system. The mechanism comprises a feeding synchronous belt, synchronous wheels, a storage box, bars, a feeding transferring wheel, eccentric wheels, a detection head, a detection position, a discharging transferring wheel, a discharging plate, a dividing plate, a dividing groove, a rotating synchronous belt, a discharging box, a feeding motor and a rotating motor; each transferring wheel is composed of two half wheels, the feeding synchronous belt passes the middles of the transferring wheels, the gap between the two transferring wheels is adjustable, and due to arrangement of the number of clamping grooves in the transferring wheels, the arc line between two clamping grooves can drive the bars to sufficiently rotate on the detection position; due to the depth of the clamping grooves, the bars are clamped and cannot fall off, and the next bars cannot be disturbed; the eccentric wheels are arranged in the transferring wheels, and deviate from the discharging position, and it is ensured that during feeding, the bars are sufficiently clamped in the clamping grooves, and during discharging, the bars are sufficiently separated from the clamping grooves. The dividing plate and the dividing groove are arranged in the discharging box, due to the dividing plate, the bars pass through or enter the dividing groove, and clamping and separation of the bars can be achieved through the eccentric wheels and the transferring wheels.

Owner:北京凯视佳光电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com