Method and device for safety treatment on lithium ion battery before recovery and recycling, and lithium ion battery safe recovery method

A lithium-ion battery, safe disposal technology, applied in the field of safe disposal of lithium-ion batteries before recycling, can solve fire, explosion, affect the efficiency and flexibility of battery dismantling, cannot fundamentally eliminate fire operators, etc. problems, to achieve high safety, improve safety and dismantling efficiency, and the effect of appropriate reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

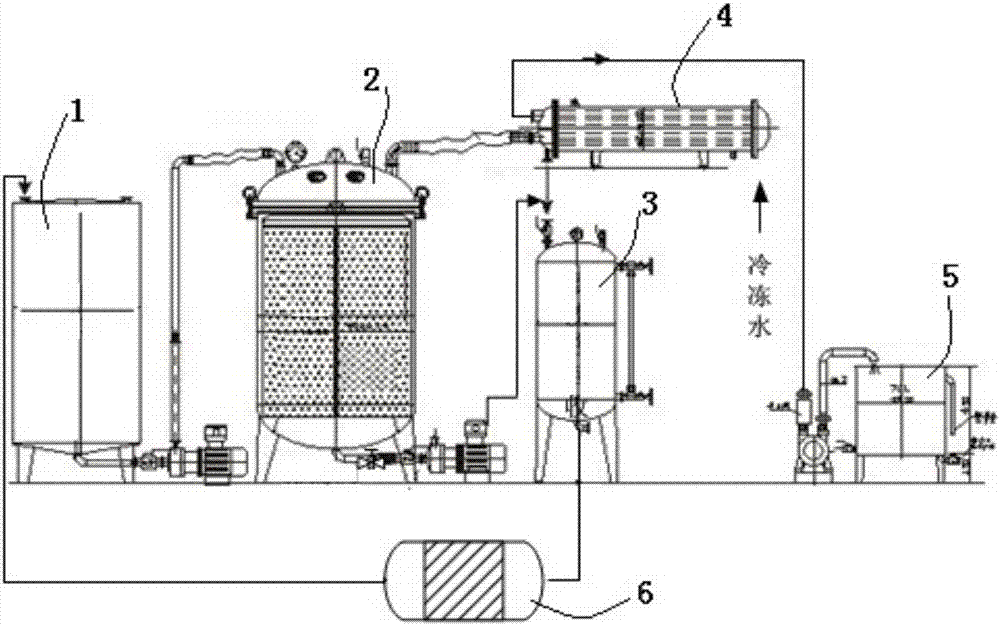

[0044] The safety treatment device before the lithium-ion battery recycling of the present embodiment, such as figure 2 As shown, it includes impregnation liquid storage tank 1, impregnation tank 2, impregnation waste liquid storage tank 3, condenser 4, vacuum equipment 5 and purification system 6, and the outlet of the impregnation liquid storage tank and the entrance of the impregnation tank pass through the first connecting pipe connected to each other, and used to pass the immersion liquid in the immersion liquid storage tank into the immersion tank; the immersion tank has a drain port, and the drain port communicates with the entrance of the immersion waste liquid storage tank through a second connecting pipe, It is used to discharge the impregnation waste liquid produced by impregnation in the impregnation tank into the impregnation waste liquid storage tank; the impregnation tank is also provided with an air outlet, and the air outlet is connected with the inlet of the ...

Embodiment 2

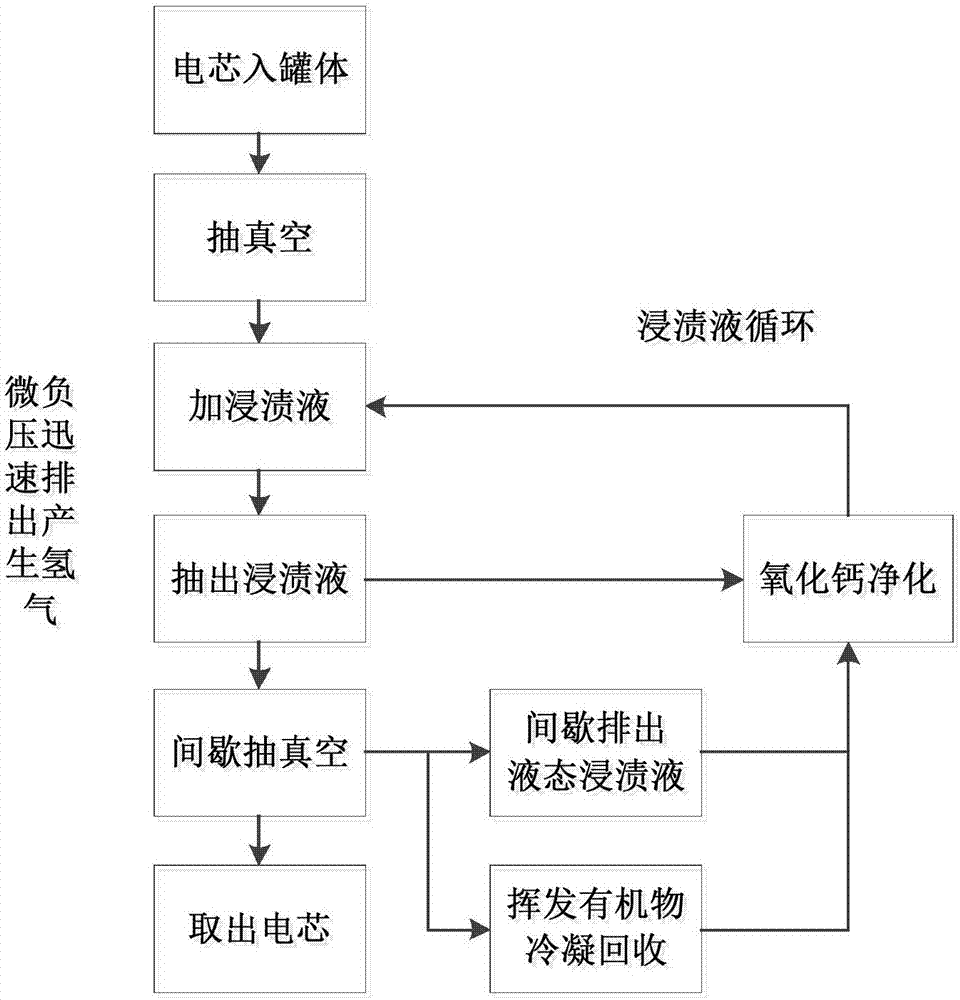

[0046] The safety treatment method before lithium ion battery recycling of the present invention, process flow chart is as follows figure 1 As shown, the safety handling device adopted is as follows figure 2 shown, including the following steps:

[0047] 1) Put the cell with the battery shell removed into the dipping tank, vacuumize the tank to -0.08MPa, and then add a sufficient amount of dipping solution to the dipping tank for dipping treatment, the dipping solution has a mass ratio of 95: 5 mixture of ethanol and water; vacuumize the dipping tank to maintain a vacuum of -0.095MPa, after soaking for 2 hours, open the drain valve of the dipping tank, and discharge the soaking waste liquid after the dipping treatment through the second pumping pump , close the drain valve;

[0048] 2) Vacuum the impregnation tank, and keep the vacuum at -0.05MPa. When the system has flowing impregnation waste liquid, stop vacuuming, open the drain valve of the impregnation tank, and drain ...

Embodiment 3

[0052] The safety treatment method before lithium ion battery recycling of the present embodiment, process flow chart is as follows figure 1 As shown, the safety handling device adopted is as follows figure 2 shown, including the following steps:

[0053] 1) Put the open battery into the impregnation tank, vacuumize the impregnation tank so that the vacuum degree is -0.05MPa, and keep the pressure for 5 minutes;

[0054] 2) adding a sufficient amount of dipping liquid into the dipping tank for dipping treatment, the dipping liquid is a mixture of ethanol and water with a mass ratio of 75:25; vacuumize the dipping tank to keep the vacuum degree not higher than -0.09MPa, After soaking for 0.5h, discharge the soaking waste liquid after soaking treatment;

[0055] 3) Vacuum the impregnation tank and keep the vacuum degree not higher than -0.09MPa. When the system has flowing impregnation waste liquid, stop vacuuming and discharge the impregnation waste liquid; after repeating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com