Solvent separating device for closed isocyanate crystal and preparation method of closed isocyanate crystal

A technology for blocking isocyanate and solvent separation, which is used in crystallization separation, preparation of organic compounds, preparation of carbamate derivatives, etc., can solve the problems of complicated separation process and low solvent separation efficiency, and achieves simplified separation process and simplified solvent separation steps. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

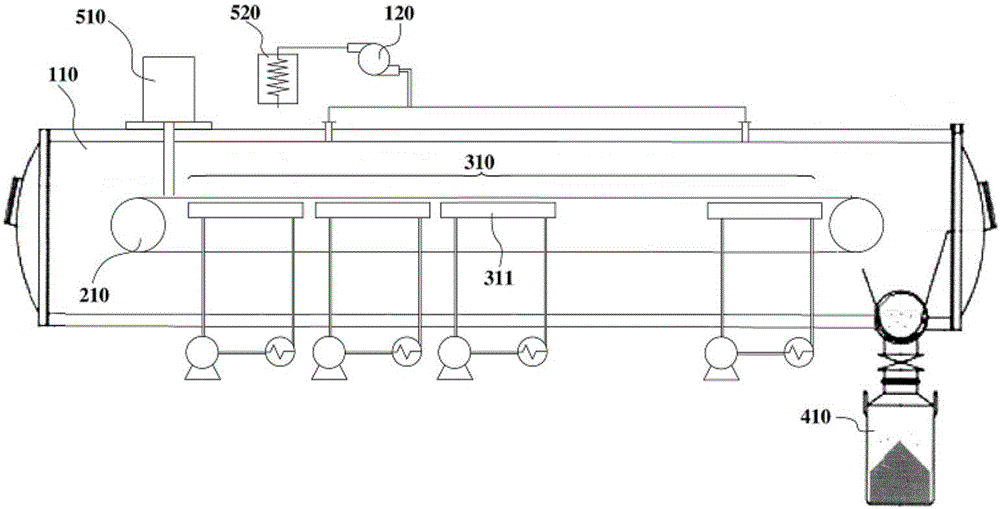

[0055] Such as figure 1 Shown: a solvent separation device for blocking isocyanate crystals of the present invention, including an air isolation unit, a crystal load unit and a heat supply unit. Wherein, the isolated air unit includes an airtight container 110 and an air extraction device 120. The above-mentioned crystallization carrying unit is arranged in the airtight container 110, and the airtight container 110 provides a closed environment for drying the crystallization slurry. The gas is pumped out and a vacuum environment is created; the air isolation unit is used to isolate the influence of air on the process of separating the solvent from the crystal slurry. The crystallization carrying unit is a transfer carrying part 210, and the transfer carrying part 210 is used to keep the crystal grains in a relatively static state for heating and separating the solvent. The heat supply unit is a heating device 310, which is used to provide a heat source for separating the solv...

Embodiment 2

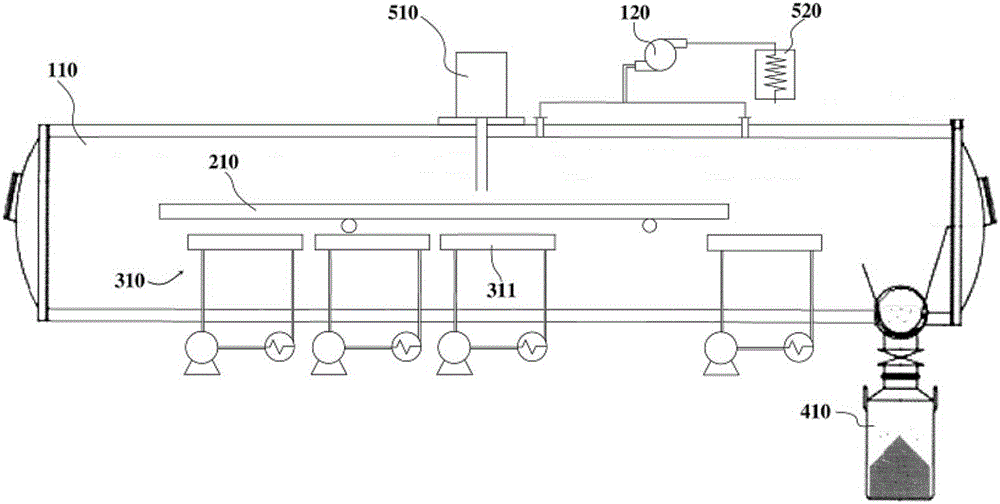

[0081] Such as figure 2 As shown, the basic content of this embodiment is the same as that of Embodiment 1, and the difference is that: the conveying bearing member 210 can also be a carrying plate that moves relative to the slurry adding device 510, and the carrying plate can be moved relative to the slurry adding device 510. Reciprocating movement, during the reciprocating movement of the bearing plate, the crystallization slurry is evenly spread on the surface of the bearing plate, so that the crystallization can be heated and separated from the solvent in a state where the crystal grains are relatively static, and the crystallization slurry is dried and sealed Isocyanate pellets. Of course, the conveying bearing part 210 can also be a fixed plate in a fixed state. At this time, only the feeding port of the slurry adding device 510 needs to reciprocate relative to the fixed plate, and the crystal slurry can also be spread on the surface of the conveying bearing part 210. ...

Embodiment 3

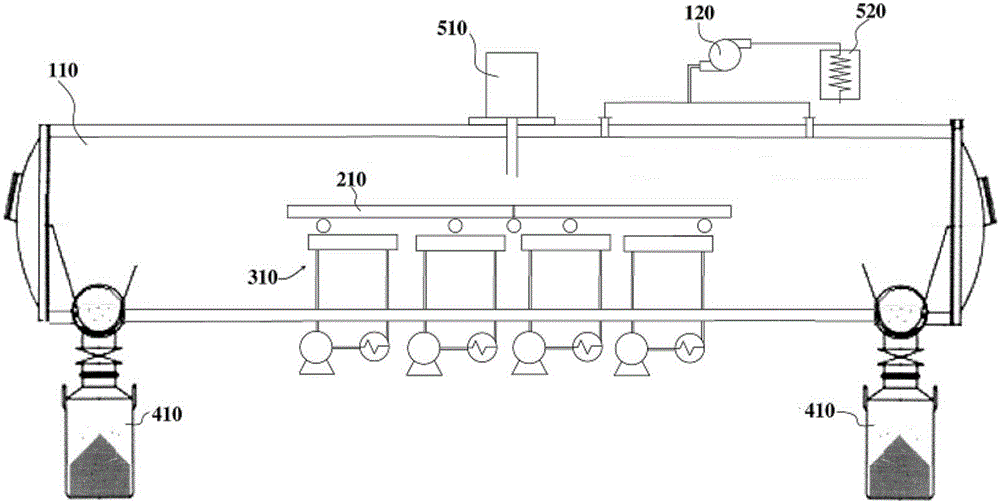

[0084] image 3 and Figure 4 As shown, the basic content of this embodiment is the same as that of Embodiment 1, and the difference is that: the conveying bearing member 210 can also be a bearing plate that moves relative to the slurry adding device 510, wherein the bearing plate is at least divided into two sections (such as image 3 As shown), taking the two-stage bearing plate as an example, the two-stage bearing plates are rotationally connected by hinges or rotating shafts, the bearing plate can reciprocate relative to the slurry adding device 510, and the reciprocating movement of the bearing plate During the process, the crystalline slurry is evenly spread on the surface of the carrier plate, so that the crystalline slurry is heated on the carrier plate to separate the solvent. And the lower part of the transmission carrying part 210 is provided with two particle collection devices 410, and the two particle collection devices 410 are respectively located at the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com