Bean sprout cleaning device for school canteen

A technology for cleaning devices and canteens, applied in applications, household appliances, food processing and other directions, can solve the problems of water cannot be effectively recycled, waste water resources, low cleaning material rate, etc., to save water, improve quality, improve The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

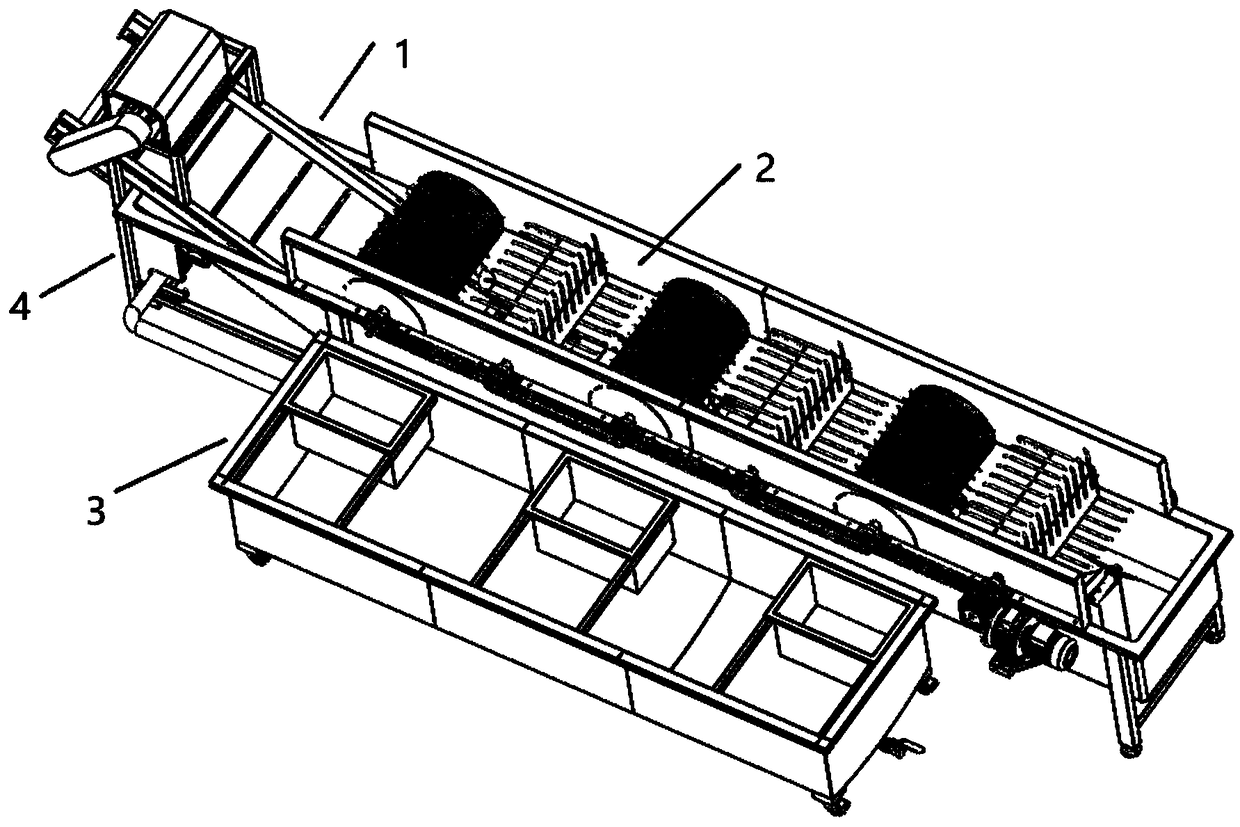

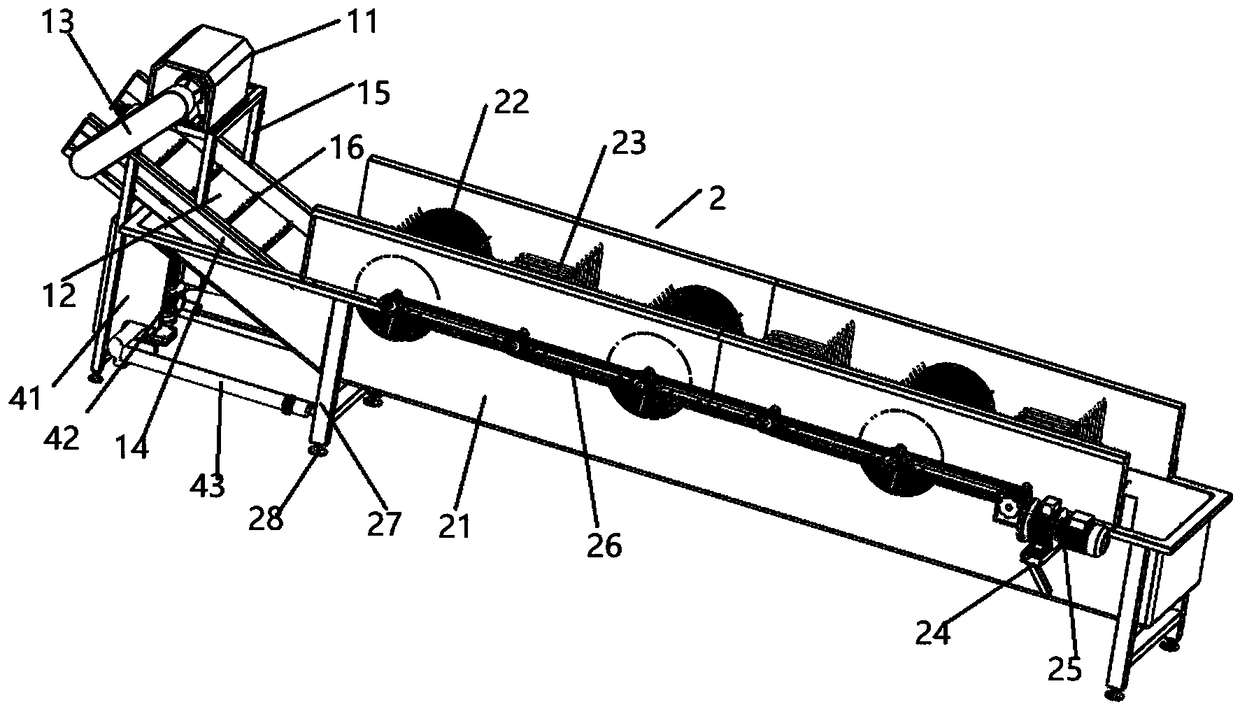

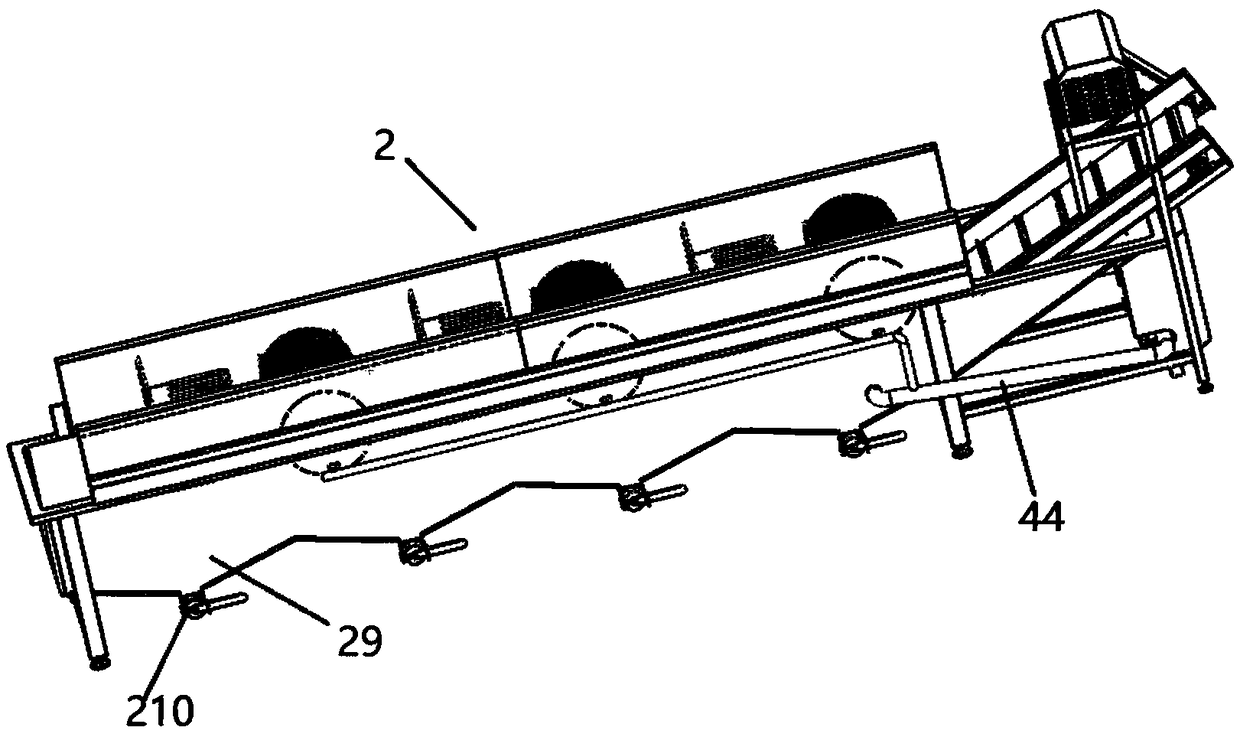

[0025] Such as Figure 1-4 As shown, a kind of bean sprouts cleaning device that the present invention proposes is used for school cafeteria, comprises feeding mechanism 1, cleaning mechanism 2, rinsing mechanism 3 and circulation mechanism 4, and feeding mechanism 1 is used for transporting bean sprouts, and cleaning mechanism 2 carries out bean sprouts Turn over and clean, the rinsing mechanism 3 further rinses the bean sprouts, and the circulation mechanism 4 pumps the water in the rinsing mechanism 3 into the cleaning mechanism 2 for reuse;

[0026] The feeding mechanism 1 includes a transmission motor 11 and a crawler belt 12 that is rotationally connected to the transmission motor 11 through a belt 13. The crawler belt 12 is arranged obliquely, and the front and rear sides of the crawler belt 12 are vertically provided with baffles 14, and the bottom of the transmission motor 11 is fixedly connected by bolts. Support 15, and energize to transmission motor 11 when feeding...

Embodiment 2

[0031] Please continue to refer Figure 1-4 Different from the above embodiments,

[0032] Further, the width of the crawler belt 12 is smaller than the width of the cleaning tank 21, and the surface of the crawler belt 12 is uniformly convex and has several barbs 16,

[0033] By adopting the above technical solution, the barb 16 can be used to contact the bean sprouts. When the barb 16 moves together with the track 12, the barb 16 will hook the bean sprouts so that the bean sprouts can move together with the track 12;

[0034] Further, the left and right ends of the front and rear side walls of the cleaning tank 21 are welded vertically by the legs 27, the legs 27 are in a cylindrical structure, and the bottom ends of the legs 27 are threaded to a gasket 28 in a circular structure,

[0035] By adopting the above-mentioned technical scheme, the cleaning tank 21 can be supported and fixed by the supporting feet 27, and the friction force between the supporting feet 27 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com