Integral correction device for long and thin beam structure and correction method

A chord beam and slender technology, which is applied in the rectification of the slender beam body structure, the post-welding correction of the slender chord beam of the electric locomotive car body, and the overall correction device for the slender chord structure, which can solve the problem of easy deformation and correction Problems such as difficult process, to achieve the effect of centralized correction process, improve correction efficiency, and increase cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

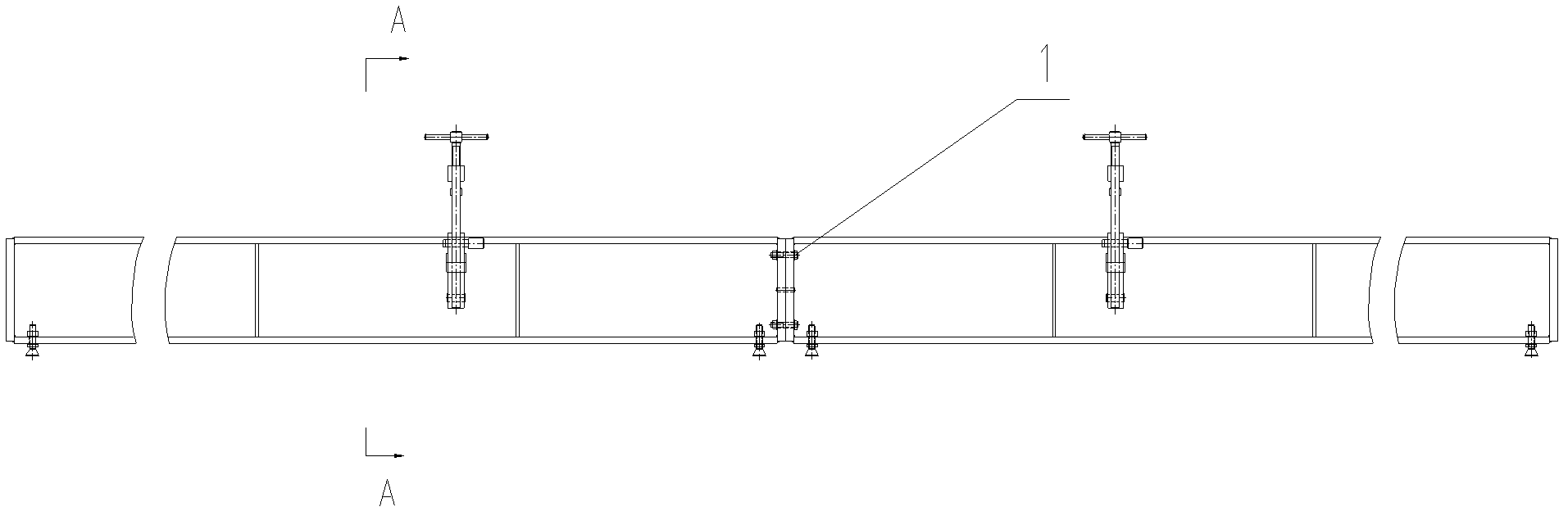

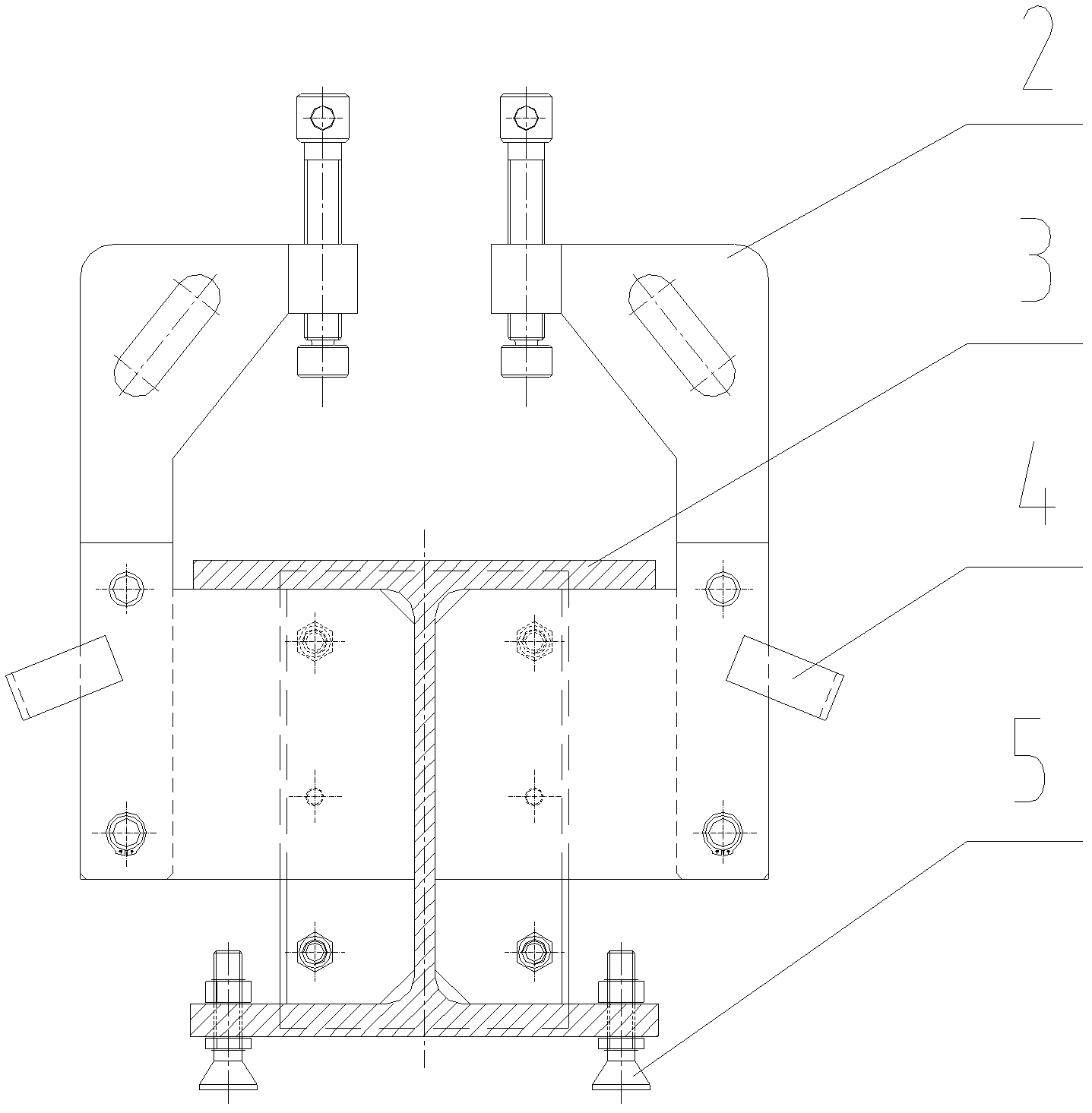

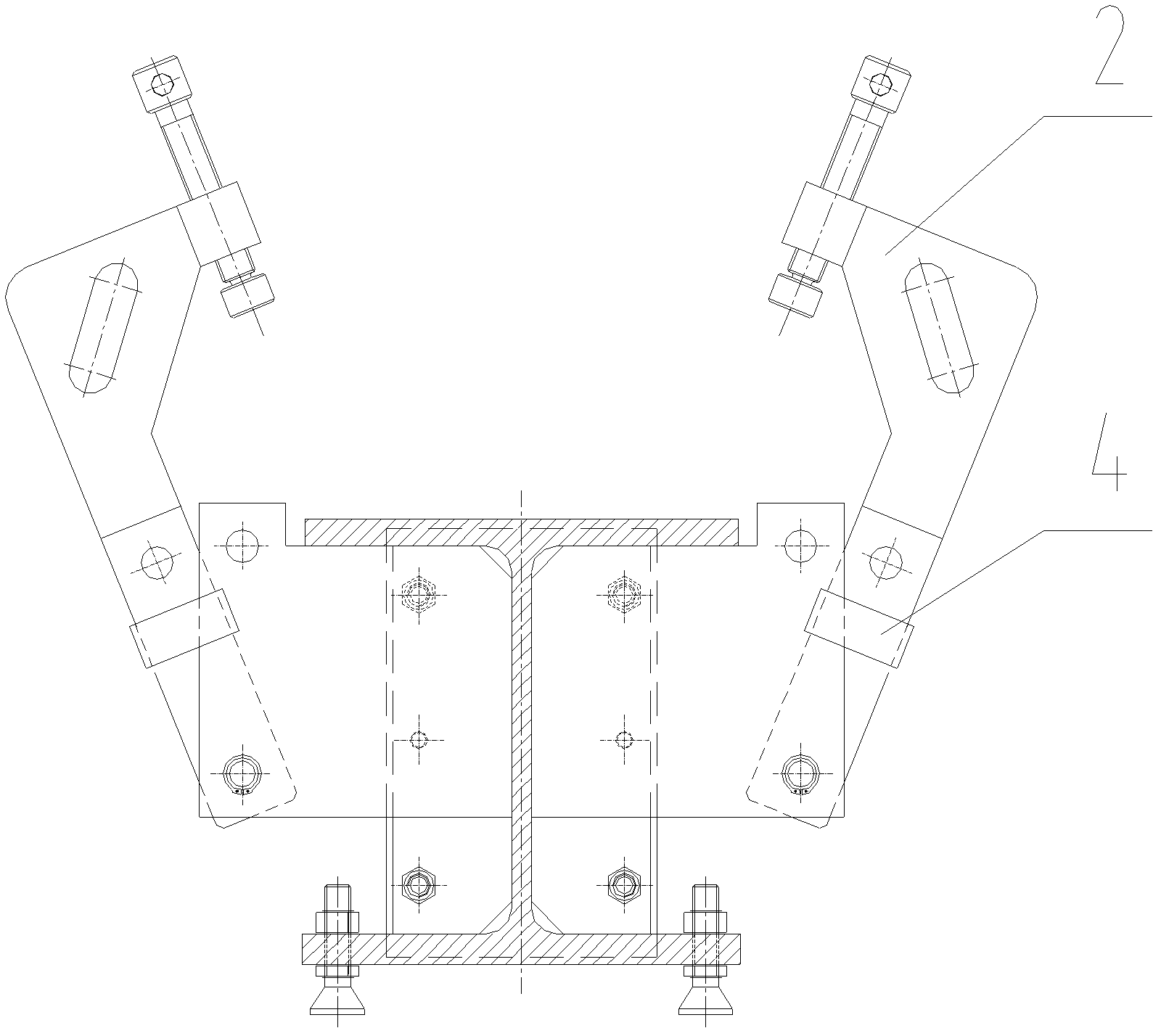

[0034] A whole rectification device with a long and thin string beam structure, such as figure 1 As shown, it is composed of multi-section correction units spliced together, and two adjacent correction units are fixedly connected by a connecting mechanism 1; as figure 2 As shown, the structure of the rectification unit includes an adjustment support 5, a platform 3 for placing string beams mounted on the adjustment support 5, the flatness of the upper plane of the platform 3 is not greater than 0.5mm, and the Both sides of the platform 3 are provided with a pressing mechanism 2 mounted on the platform 3 for pressing the string girder. The pressing mechanism 2 is preferably a reversible threaded pressing mechanism, and a bracket is provided under the side of the pressing mechanism 2. 4. Both sides of the platform 3 are provided with movable C-shaped clamps mounted on the platform 3 for pressing string beams.

[0035] According to the characteristics of the string beam stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com