Light harvesting cutter

A cutter and light-collecting technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as increased equipment purchase and use costs, high-priced laser generators, unfavorable operation and maintenance, etc., to improve resistance to heat The ability to deform, ensure the cutting effect, and ensure the effect of cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

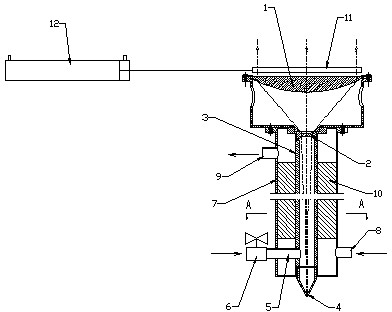

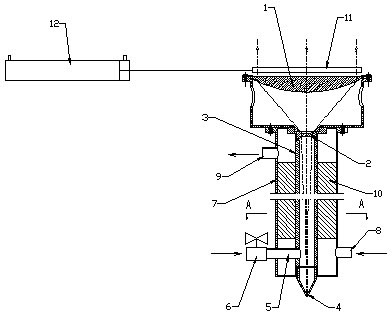

[0014] As shown in the figure, the light-collecting cutter includes a convex lens 1 and a concave lens 2 coaxially arranged from top to bottom, a section of inner tube 3 is connected below the concave lens, and a cutting nozzle 4 with an opening is arranged at the lower end of the inner tube; the convex lens 1. A single-wavelength parallel incident light source is set above. The focus of the parallel light under the convex lens is located under the concave lens. The parallel light is converged by the convex lens and then refocused by the concave lens.

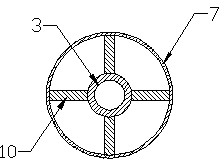

[0015] The upper end of the inner pipe 3 is sealed and connected with the concave lens 2, and the inner cavity of the inner pipe is connected with the compressed air source through the air inlet pipe 5 and the air inlet valve 6. An outer tube 7 is sheathed on the periphery of the inner tube, and the outer tube is provided with a cooling liquid inlet 8 and a cooling liquid outlet 9 connected with the cooling liquid circulation sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com