CCD (charge-coupled device) tool setting and monitoring apparatus for precision machining of complicated microstructural parts

A precision machining and monitoring device technology, applied in the direction of automatic control devices, feeding devices, metal processing, etc., can solve the problems of inconvenient operation, inability to realize fast tool setting, and low tool setting accuracy, so as to save time and energy Easy to move, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

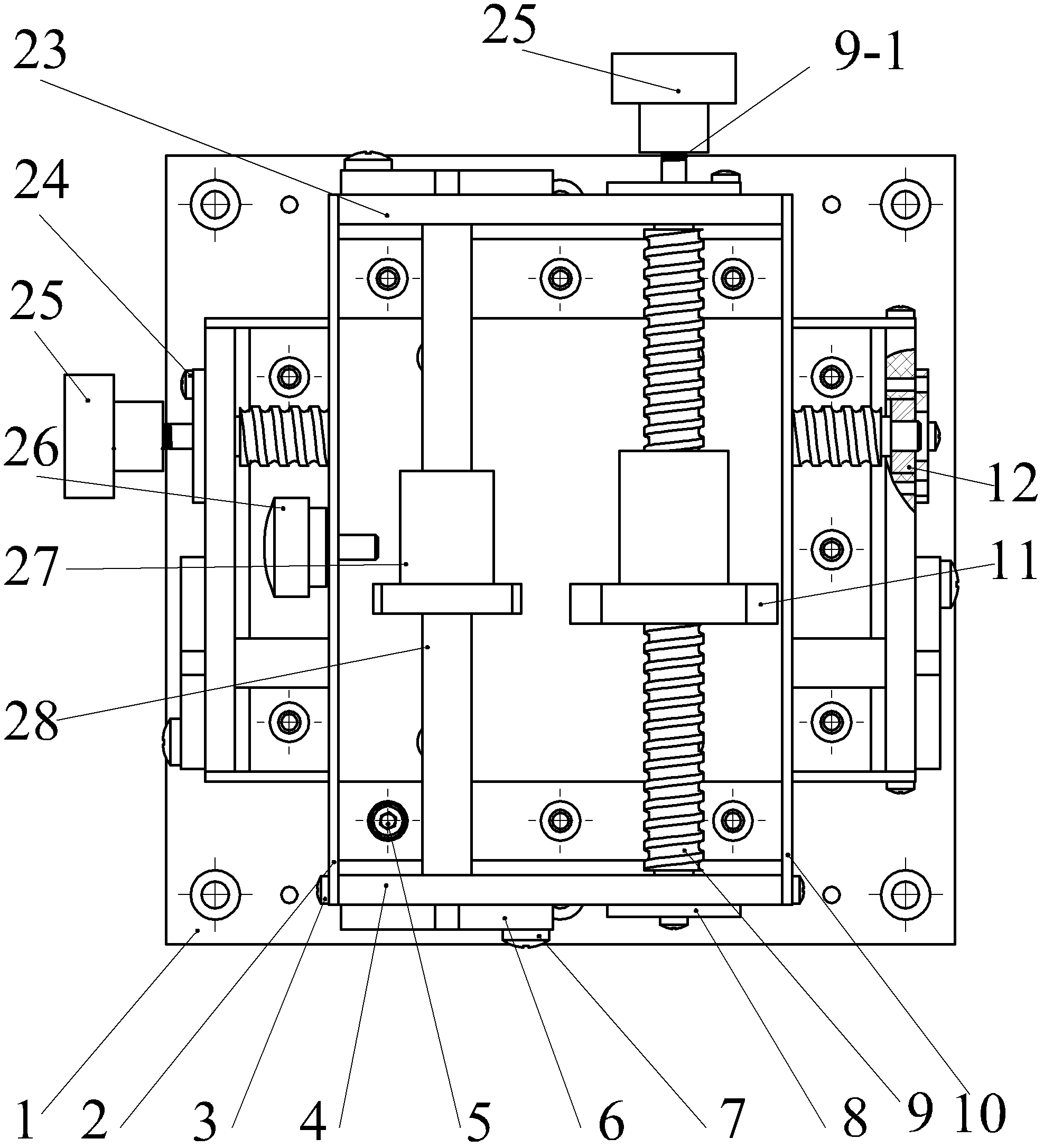

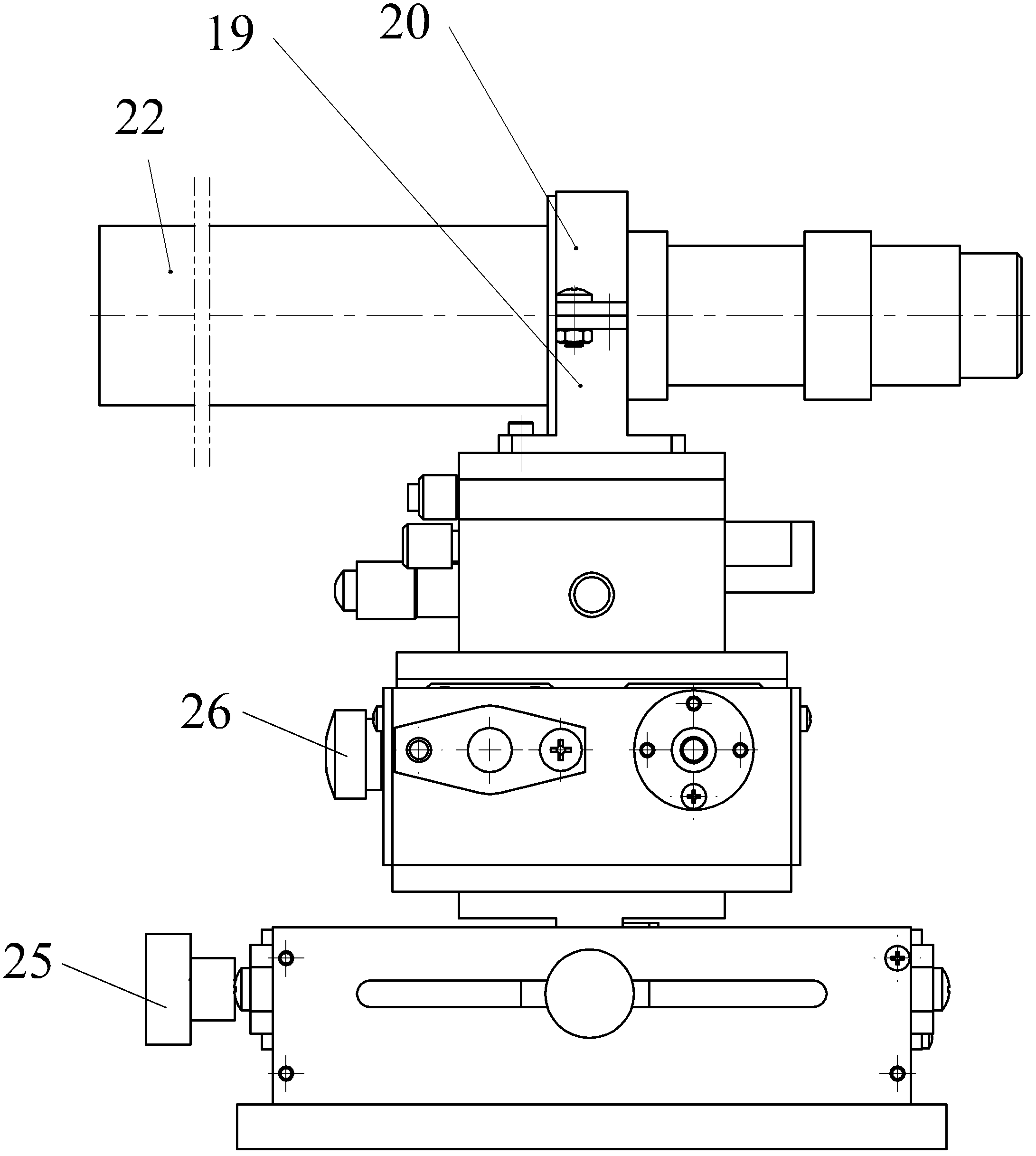

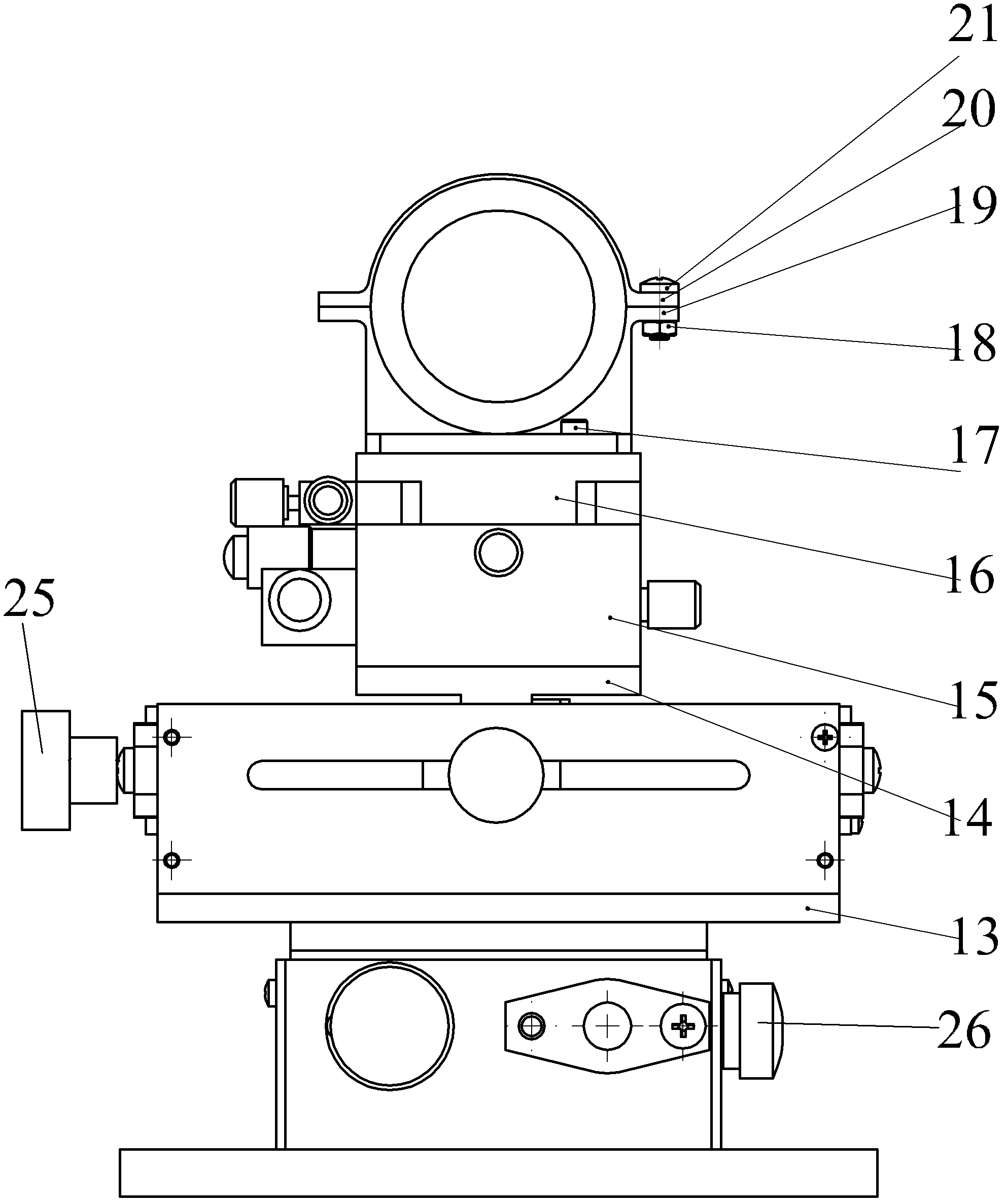

[0018] Specific implementation mode one: as Figure 1-9 As shown, the CCD tool setting and monitoring device platform base 1 of the precision machining of microstructure parts described in this embodiment and the rough adjustment part, fine adjustment part and CCD micromagnifying glass installed on the platform base 1; define the CCD microscopic magnifying glass The axis of the zoom lens 22 is the X-axis, the axis of the electric spindle 29 that controls the rotation of the precision machining tool for the microstructure is the Z-axis, and the Y-axis passes through the intersection of the X-axis and the Z-axis and is perpendicular to the plane defined by the X-axis and the Z-axis The device also includes a coarse adjustment connecting plate 13 and a connecting piece 14; the coarse adjustment part is composed of two X-axis movement adjustment ball screw mechanisms and a Z-axis movement adjustment ball screw mechanism with the same structure, and the fine adjustment It is partia...

specific Embodiment approach 3

[0024] Specific implementation mode three: as Figure 1-9 As shown, the zoom lens 22 of the CCD micromagnifier in this embodiment is installed on the precision turntable 16 through the fixed lower base 19 and the fixed upper base 20 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 4

[0025] Specific implementation mode four: as Figure 1-9 As shown, Bakelite handles 25 are installed on the protruding ends 9 - 1 used for adjustment in the X-axis movement adjustment ball screw mechanism and the Z-axis movement adjustment ball screw mechanism in this embodiment. Other compositions and connections are the same as those in the first, second or third embodiment.

[0026] The specific process description of using the device of the present invention to monitor the tool setting:

[0027] 1. The basic conditions that need to be met when designing the tool setting monitoring device:

[0028] The device uses a high-magnification CCD microscope magnifier (model: MT6350), and its magnification can reach up to 1200 times. Due to its high magnification, its working distance is small, only about 30mm, set as d. Such as figure 1 As shown, let the distance between the end face of the CCD lens and the tip of the tool be L. To carry out the tool setting operation, the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com